Professional Documents

Culture Documents

Volvo - N10 &N12 Cab Review

Uploaded by

G-sus Albert Julca Ulloa0 ratings0% found this document useful (0 votes)

40 views6 pagesvolvo

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentvolvo

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

40 views6 pagesVolvo - N10 &N12 Cab Review

Uploaded by

G-sus Albert Julca Ulloavolvo

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 6

VOLvo

N10/12 Cab

(2:441)

APPLICATIONS

N trucks are used primarily for transport operations

where the goods which are being carried have a high

weight per unit volume or when length regulations do

not have a negative effect on the payload. When trucks

are required (0 operate mainly on bad roads, the

simpler design of the N truck contributes to maintain-

ing a high level of operational reliability. If the driver

has to continually get into and out of the vehicle during

his normal working day, the convenient entry/exit

facility on the N truck is a definite advantage. When an

unladen truck is driven on stippery surfaces, an N truck

has better manocuvrability than an F truck. This is due

to the fact that the chassis weight of the N truck is

Aistributed in such a way that more weight is placed on

the driving wheels. N trucks are used primarily for

construction site work, tanker transport, and as tractor

units for semi-trailers, N trucks are often used for

special superstructures ot vehicles of the all-round type.

DESCRIPTION

Exterior: The cab has smooth styling features with

small frontal area that gives low ait drag and lower fuel

consumption. Cab dimensions have been chosen to

maintain an exceptionally good balance between the

demands for a large load area and a spacious cab. At

the same time, the engine must be easily accessible for

servicing. The result is a relatively short cab which,

through its exceptionally well-planned layout, provides

the driver with a comfortable and effective workplace,

‘The distance from the bumper to the rear wall of the

cab (BBC) is 245 cm, which is a good compromise for

this type of truck. This is a relatively short BBC

dimension compared with that of competitors’ trucks,

‘This means that shorter wheelbases can be used or

larger load areas obtained. The bonnet tips forward

Features

© All-steel cab, impact-tested,

Electronic speedometer and tachograph.

© Well-insulated, dense bitumen material.

‘© Unique surface treatment process with 3 coats.

RSP 6956, 947. Eng, Printed in Sweden, Cotes, Kung N57 42368

and makes the entire front end of the vehicle accessi-

ble, thus facilitating servicing. The bonnet also has new

external bonnet locks and rubber-dampened contact

against the cab,

Materials: The cab is made of steel. Its design is similar

to that of earlier Volvo safety cabs. Itis of an all-

welded construction with sheet steel on a frame made

up of steel profiles. The bonnet and mudguards are

made of galvanized sheet steel (on certain markets

these are made of GRP plastic).

Benefits

‘© Robust all-welded steel cab for high level of

operational reliability when operating in difficult

conditions. i

z oe eee

‘¢ Operationally reliable, long service lite. No

ference in

# Low noise level.

Erouiid visi

© High level of quality of resistance to corrosion and

durable finish

N10/12 Cab

Safety cab: The cab complies with the Swedish safety

requitements—which are among the most severe in the

world—by a wide margin. These requirements specify

that the cab roof must withstand a load that is twice the

unladen weight, and that the cab must also withstand

impact against the windscreen pillars and the rear wall

with a force of 29,500 Nm (3,000 kpm). The testis

performed by means of a I-tonne pendulum with a drop

of 3 metres. The demand is that the cab must not be

deformed to such an extent that it encroaches on the

driver's survival space, and that the doors remain

closed. Since the engine, bonnet, wheels and axles ete.

are located in front of the driver, the driver is safer in

an N truck than in an F truck. Inertia reel seat belts

can be fitted for the driver and passenger. All interior

fitting materials used for upholstery, mats, dashboard

and cab trim are fire retardant, and comply with

FMVSS 302, the tough American legislative require-

ments.

‘Cab mountings: The cab has two rubber journalled

‘mountings at the front and two coil springs at the rear.

‘Two shock absorbers are fitted to stabilize the cab.

Lateral movement of the cab is absorbed by a cross stay

fitted between the cab and the chassis frame. This

system means that the cab is well insulated from frame

vibrations and road shock.

Entry: Two wide and robust anti-slip steps formed like

a “staircase” provide access into the cab. This

simplifies exit as well, since you can easily see where to

put your feet. Grab handles, one fitted on the outside

of the cab behind the door and one inside the cab,

facilitate entry and exit even more. Refer to the

dimension sketch for the size of the entry steps.

Interior: The cab interior is very well planned and

spacious, and provides exceptionally good driving

comfort, particulary with regard to the fact that the cab

is relatively short.

Seats: The driver's seat is fully sprung and has a long

dished backrest for lateral support. The seat cushion is

also dished for good support even when the truck rolls

and sways. The seat is provided with a wide range of

adjustments, This means that the driver has every

chance of adapting the seat to suit his own particular

requirements, The adjustment range fore-aft is 150 mm.

‘The seat springs can be adjusted to suit the weight of

the driver. Adjustment range 40—130 kg. Backrest

inclination can also be adjusted, as well as the height

and inclination of the seat cushion. Adjustment range

65 mm through 7 positions for both the front and the

reat edge of the seat, All controls are fitted on the side

of the seat nearest to the door.

An air suspension seat is available when even better

sitting comfort is required. This seat has an ait

suspension system that automatically adjusts to the

river's weight to give the smoothest possible ride. ‘The

seat takes about 10—15 seconds to adjust itself, When

there is no weight or load on the seat, the seat is about

4 cm lower than when loaded. This gives more space

between the seat and steering Wheel for easier access

into the cab. This ergonomilcally-designed seat also

incorporates an adjustable fumbar support consisting of

‘wo ait-illed pads in the lower region. With the help of

the lumbar support the driver can adjust the seat to suit

his own personal requirements.

N10/12 Cab

Controls and instruments: The steering wheel can be

set to various positions and moved fore-aft (range 20°)

and up-down (40 mm). The instrument panel is divided

into three units that can be removed separately. The

control lamps and instruments are grouped and located

in the centre in front of the driver. To the left are the

heater controls, and to the right the switches. The

panel is prepared for the installation of extra switches,

and a radio.

‘There are three stalks on the steering column, To the

left is the stalk for the windscreen wipers and washers,

and a stalk for turn indicators, light switch, and

headlight flasher. The stalk on the right regulates the

trailer brakes,

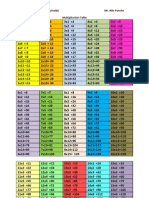

The following controls and functions are grouped

between the driver's seat and passenger bench seat. See

figure. ‘The engine is started by means of a key.

Key to symbols

1, Warning, standard alternator charge

Warning, extra alternator charge

Spare

Warning for lov oil pressure in engine

‘Warning for high coolant temperature or low

coolant level

Warning for low air pressure in service brake

system

7. Warning, parking brake applied or low air pressure

in parking brake circuit

8. Control, splitter (overdrive)

9. Control, turn indicators

10. Control, turn indicators, trailer

11, Control, bogie lift in end position (or Robson drive

engaged)

12, Control, main beam on

13. Control, electric starting heater on, pre- or post-

heating on

14. Control, engine air cleaner clogged

15. Control, differential lock between driven wheels

engaged

16. Control, differential lock between axles engaged

(6x4 models)

‘Checking bulbs: Control lamps &—oil temperature

MR62 and 4—engine air cleaner normally never light

up. For this reason you should check the function of

the bulbs themselves by switching on the master key

without starting the engine, and then these bulbs

should also light up.

Buzzer: The following Warning lamps and control lamps

are combined with a buzzétt 4, 5, 6, 15 and 16.

&

1

U

@

@

Si

©

4. Pasking brake

2. Blocking valve for parking

siceait

3. Stop contro!

44. Hand throttle

5. Tyeintlion vale

Control lamps and warning lamps:

5)

1-2 3

©) (|& en

6 7 8 9-10

3° iG-| [mim

a B iu

ke Ef

bb 16

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Audi 0b6 AutomaticDocument181 pagesAudi 0b6 Automaticchoco84100% (1)

- Daihatsu Terios User ManualDocument146 pagesDaihatsu Terios User Manualluimg33% (3)

- Involuntary Repossession PALADIN PRESSDocument34 pagesInvoluntary Repossession PALADIN PRESSJason Noneyabiz100% (12)

- Mannol Atf Ag60 PDFDocument2 pagesMannol Atf Ag60 PDFUiTM MERBOKNo ratings yet

- Global Fundamentals: Curriculum Training - TF1010013S Manual Transmission and DrivetrainDocument114 pagesGlobal Fundamentals: Curriculum Training - TF1010013S Manual Transmission and DrivetrainShahrizan Abdul RahmanNo ratings yet

- Minor Project 1Document20 pagesMinor Project 1Yasmeen BanuNo ratings yet

- TOGETHER Eco-Driving 5 Handout 01 PDFDocument2 pagesTOGETHER Eco-Driving 5 Handout 01 PDFGaffar KNo ratings yet

- Ultimate Diesel Builders Guide - September 2015 USADocument132 pagesUltimate Diesel Builders Guide - September 2015 USAdapsiduNo ratings yet

- Workung CapitalDocument96 pagesWorkung CapitalSanju ReddyNo ratings yet

- Evan John Barnuevo V-Aguinaldo Mr. Nilo Pancito Multiplication TableDocument1 pageEvan John Barnuevo V-Aguinaldo Mr. Nilo Pancito Multiplication TableJill BarnuevoNo ratings yet

- Nippon Piston Ring Co.,Ltd.: Gasoline-engine Automobiles ガソリン車Document4 pagesNippon Piston Ring Co.,Ltd.: Gasoline-engine Automobiles ガソリン車Edixo ReyesNo ratings yet

- 1sz Fe Workshop ManualDocument2 pages1sz Fe Workshop ManualA-t Hector41% (17)

- Spare Parts For Engine Management: Extended Product Range KS Camshafts and AccessoriesDocument12 pagesSpare Parts For Engine Management: Extended Product Range KS Camshafts and Accessoriesartsarajevo100% (1)

- Tata Nano: A Report On Decline in Tata Nano Car SalesDocument6 pagesTata Nano: A Report On Decline in Tata Nano Car SalesishwaryaNo ratings yet

- MF 385 Spec SheetDocument2 pagesMF 385 Spec SheetLAli100% (2)

- Kia LEDPuddlelights Doorprojector Overview ForMPFDocument2 pagesKia LEDPuddlelights Doorprojector Overview ForMPFwalterquiqueNo ratings yet

- Judging Procedures Manual Model A Ford Club of America 59207 PDFDocument30 pagesJudging Procedures Manual Model A Ford Club of America 59207 PDFDaniel AlvaradoNo ratings yet

- Poster: A New Car Every D AY, Start Collecting Now!Document1 pagePoster: A New Car Every D AY, Start Collecting Now!Richy Ottero MontanezNo ratings yet

- 001-Tc-17021-000 (Turbocharger Datasheet 001 TC 17021 000 (English) )Document1 page001-Tc-17021-000 (Turbocharger Datasheet 001 TC 17021 000 (English) )dromakiNo ratings yet

- Brochure Maserati - Int Granturismo - 2014Document44 pagesBrochure Maserati - Int Granturismo - 2014aleNo ratings yet

- Digital: Name: Bhavay AroraDocument7 pagesDigital: Name: Bhavay AroraSaji JosephNo ratings yet

- FSAE EV - Virtual SDPS PresentationDocument23 pagesFSAE EV - Virtual SDPS PresentationStewart PrinceNo ratings yet

- Cikkszám THU 754002+THU 712200+THU KIT1057 PDFDocument8 pagesCikkszám THU 754002+THU 712200+THU KIT1057 PDFSuto BandNo ratings yet

- Aerodynamics of Road Vehicle PDFDocument84 pagesAerodynamics of Road Vehicle PDFShashankBhosale100% (1)

- Read Online: Hilti DD 150 Parts ManualDocument4 pagesRead Online: Hilti DD 150 Parts ManualblinkeskuNo ratings yet

- Sudhir MBA Research Report Final DFTDocument109 pagesSudhir MBA Research Report Final DFTSúdhír YãdávNo ratings yet

- Nissan & Renault DR Web N WikiDocument30 pagesNissan & Renault DR Web N Wikividya_simarmataNo ratings yet

- Vision & MissionDocument26 pagesVision & MissionA K Azad Suman50% (2)

- 19 - Engine - Cooling SystemDocument48 pages19 - Engine - Cooling Systemakmal15No ratings yet

- Denso FIRAD Catalogue PDFDocument20 pagesDenso FIRAD Catalogue PDFdchosgo2639No ratings yet