Professional Documents

Culture Documents

Goldstar Chassis Nc-5aa Cn-14a30h CN-14 20B30H CN-20H10 PDF

Goldstar Chassis Nc-5aa Cn-14a30h CN-14 20B30H CN-20H10 PDF

Uploaded by

luzmarospiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Goldstar Chassis Nc-5aa Cn-14a30h CN-14 20B30H CN-20H10 PDF

Goldstar Chassis Nc-5aa Cn-14a30h CN-14 20B30H CN-20H10 PDF

Uploaded by

luzmarospiCopyright:

Available Formats

ADJUSTMENT INSTRUCTION

2) Connect H.Scope and Pulse output of Sweamer Generator

to H.Input and Marker input of Alignment Scope,

respectively.

3) Apply AGC Voltage(D.C.) to TP11 of IC201.(7.50.05V)

4) Apply B+ of IC201 to TP12 of R591.(12.00.1V)

5) Set VR526(AGC Adjustment) to mechanical center.

These instructions are applied to only NC-5AA chassis.

Notes

1.So this is a hot chassis, you must be careful, and be caution

not to touch 1st and 2nd concurrently.

2.Adjustment must be done in the correct order.

3.Power supply of a SET which is adjusted is 100~240V

A.C./50~60Hz.

4.The receiver must be operated for about 30 minutes proir to

the adjustment.

1.3. Adjustment

A. VCO

1) Set the vertical range of Alignment Scope to 1V/DIV and

CAL position, and, by applying D.C. 0~9V, do DC

Calibration to place D.C 4.5V point of waveform to center of

Screen.

2) Connect the Input terminal of Alignment Scope to

TP3(Video Detection Output), and set Vertical Variable

Switch to CAL position.

3) Apply AGC Voltage to TP11 of IC201 through 470 to be

7.50.05V

4) Adjust L501 so that BEAT appears on 45.75MHz Marker

like <Fig 2> If not, adjust again after attenuating output 10

~20dBu.

CONTENTS

1) VIF, AFT and SIF Adjustment

2) Sound Multiplex Adjustment

3) FOCUS Adjustment

4) AGC Adjustment

4)-1 Picture AGC Adjustment

5) V-Size and V-Center Adjustment

6) Horizontal Size, Center and Side Pincushion Adjustment

7) Purity and Convergence Adjustment

8) White Balance Adjustment

9) SUB-Bright Adjustment

10) Vertical Center Adjustment

11) Horizontal Center Adjustment

f (MHz)

45.0

42.75

1. VCO and AFT Adjustment

47.25

45.75MHz

(Turn L105 so that the position of Beat

is same with 45.75MHz Marker)

This Adjustment must be applied only to PCB Assy.

1.1. Necessary Instruments

1) Sweamer Generator : can sweep 35MHz~55MHz(over

120dBu)

2) PLUG in Unit : With PIF(45.75MHz), SIF(41.25MHz) Marker

3) Alignment Scope : X-Y mode, 10mV~20V Variable

4) D.C. Power Supply : 0~12V Variable

5) D.C. Power Supply : 13.5V0.2V (over 300mA)

6) Digital Multimeter

<Figure 2>

B. AFT

1) Connect the Input of Alignment Scope to TP4 with keeping

DC voltage of 2pin of IC201.

2) Keep the output of Sweamer Generator 1005dBu.

3) Adjust L506 so that waveform of Alignment Scope to be

that of <Fig 3>.

4) Adjust Vertical Volume of Alignment Scope to place DC

level of waveform to center (4.5V) and 45.75MHz Marker to

7.5V 0.5V.

1.2. Preliminary Steps

1) Connect the output of Sweamer Generator like <Fig 1>.

Here, set the output of Sweamer Gen. to 1005dBu.

45.75 MARKER

POWER SUPPLY

-

470/0.5W

7.5V

TP11

+

L501

9V

VCO COIL

51

8V

50

C508

TP4

47

R507

SAW

FILTER

C122

L506

R520

IC501

AFT COIL

46

45

LA7674

9V

C521

0V

R518

Z502

TP3

14

L502

SWEEMAR

GENERATOR

<Figure 3>

Q503

R517 L503

44

11

12.5V

+

2. SIF Adjustment

2.1. Necessary Instruments

1) Sweamer Generator : can sweep 3~6MHz

2) Plug In Unit : with 4.5MHz Marker

3) Alignment Scope : X-Y mode(can measurable 10mV~

20Vp-p)

4) DC Power Supply : 13.5V, over 300mA

5) DC Power Supply : 0~12V variable

POWER

R591

D502

+

AFT

TP2

VCO

TUNER

IF

TP12

SUPPLY

+B

-ALIGNMENT

SCOPE

<Figure 1>

- 1 -

100% WHITE

2.2. Adjustment

1) Connect Sweamer Generator and Alignment Scope the

same method of VIF adjustment.

2) Connect the output of Sweamer Generator to TP5 like <Fig 4 >.

3) Connect the Input of Alignment Scope to TP6.

4) Apply AGC voltage of IC201 to TP11(7.50.05V).

5) Apply B+ of IC201 to TP12.

6) Adjust L502 S-shaped waveform of Alignment Scope to be

that of <Fig 5>.

Adjust (A=B)

Because 4.5MHz Marker doesnt with horizontal line, apply

(a) marker(4.5MHz) to be the center of (b), (c)Markers.

75% WHITE

<Figure 6>

A

B

DC POWER

SUPPLY

DC 12V

R591

ALIGNMENT

SCOPE

C206

TP6

POWER SUPPLY

-

470/0.5W

VIDEO

7.5V

TP11

+

A/V IN

C509

SWEEMAR

GENERATOR

R210

Q202

IC202

Q206

TP8

3

C204

VR202

DC POWER

SUPPLY

DC 12.5V

ZD201

PATTERN

GENERATOR

TP12

TP13

Q201

VIDEO

C201

L201

TP10

D

SOUND

C508

Q603

C507

SIF COIL

IC601

R609

IC501

SOUND

L502

Q601

C510

6

R618

LA7674

TP5

C515

11

45

C516

COLD

14

HOT

OSCILLOSCOPE

6.0MHz

Z501

<Figure 7>

R591

12.5V

3.3 Adjustment

+

POWER

SUPPLY

+B

Adjust VR202 to get Luminance signal(Color Bar) level like

below. ( Refer to <Fig 6> )

1) White 100% modulated 1.780.1Vp-p

2) White 75% modulated 1.460.1Vp-p

TP12

<Figure 4>

4. Automatic Gain Control(AGC) Adjustment

9V

4.1Turn on a SET and receive Digital Pattern of 65 1dB through

75 Ant. terminal.

4.2 Connect DMM(Digital Multi-Meter) to J27.

4.3 Adjust VR101 to read 5.70.05V of DMM.

(Where, you can set proper AGC voltage according to signal

condition.)

(b)

A

A=B

(a)

B

4.5 MARKER

5. Purity and Convergence Adjustment

(c)

This adjustment should be made when a complete re-alignment

is required or a new picture tube is installed.

0V

<Figure 5>

5.1 Purity Adjustment

3. Composite Video Signal Adjustment

5.1.1 Necessary instruments and Preliminary steps

1) Pattern Generator : 216/1 or Equivalents

2) Degauss CPT and Cabinet with Degaussing coil.

3) Maximize Contrast level.

4) Pre-adjust the DY.

3.1.Necessary Instruments

1) Pattern Generator : PM5518(PHILIPS) or Equivalents

7 Step Color Bar Pattern with 75 out

2) Oscilloscope : VP-5650A or Equivalents

can measure over 1.0Vp-p

Vertical Freq. : over 4MHz

3) DC Power Supply : 12.20.2V/400mA 2EA

5.1.2 Adjustment

3.2. Preliminary Steps

1) Connect the output of Pattern Generator to TP8 like <Fig 7>.

Where, the output of Pattern Generator is 1.0Vp-p.(Point

position A)

2) Connect DC Power Supply to TP12 and TP13.

Where, devide Ground of TP12 and TP13(HOT/COLD).

3) Connect probe to TP10(point D).

- 2 -

1) Receive Raster signal(Red).

2) Push the DY to get Picture like <Fig 8>.

3) Adjust 2-pole magnet to place RED center of screen

orthogonally.

<Figure 8>

4) Pre-fix 2-pole magnet after adjustment with Lock Ring.

5) Pull the DY back slowly to get uniformly RED picture and fix

it.

6. White Balance

6.1 White Balance Adjustment

6.1.1 Necessary Instrument

1) White BAlance Meter

5.2 Convergence Adjustment

6.1.2 Preliminary Steps

5.2.1 Necessary Instruments

1) Do this adjustment after operating the SET more than 30

minutes.

2) Receive Standard White pattern.

3) Adjust under APC ON condition.

4) Turn Screen VR CCW.

5) Set Red driver(VR571) and Blue driver(VR572) to

mechanical center.

6) Set Red Bias(VR574) ,Blue Bias(VR575) and Green

Bias(VR573) to 1/3 point to Clock-wise from full CCW.

7) Set SVC SW to SVC to get Horizontal line.

1) Pattern Generator : 216/1 or Equivalents

2) Degaussing coil

5.2.2 Preliminary Steps

1) Do this adjustment after operating the SET more than 30

minutes.

2) Degauss CPT and Cabinet with Degaussing coil.

3) Receive Cross hatch pattern.

4) Adjust Contrast and Bright properly.

5) Untighten half-fixed Magnet Assy lock ring

6.1.3 Adjustment

5.2.3 Adjustment

A. Center(Static) Convergence Adjustment

1) Unify Red and Blue vertical lines at center of screen by

varying the angle of two tabs of 4-pole magnet.

2) Rotate tab with sustaining the angle of item 1) and unify

Red and Blue vertical lines at center of screen.

3) Unify Red,Blue and Green vertical lines by adjusting two

tab2 of 6-pole magnet.

4) Rotate tab with sustaining the angle of item 3) and unify

Red,Blue and Green vertical lines.

5) To get more detail adjustment repeat 1),2) with

remembering changes of Red,Blue and Green.

6) Fix magnet assy lock ring.

B. Dynamic Convergence Adjustment

1) Prepare bonded rubber wedge.

2) Adhere rubber wedge to A part halfly.

(Dont remove paper of bonding part.)

3) Move the DY every direction to get best convergence in

every corner.

4) Adhere rubber wedge to bottom of CPT.(Refer <Fig 9>).

5) After checking the locatons of 3 wedges and check

Convergence.

6) Paint white lacquer on DY fixing nut and magnet.

1) Turn screen VR slowly to see first horizontal line on screen

2) Make horizontal line white with 2 Bias VRs which arent

displayed in 1).

3) Vary screen VR to get very dim horizontal line.

4) Set SVC SW to Normal position.

5) Receive adjustment signal-White in upper and Black in

Lower.

6) Vary Red driver(VR571) and Blue driver(VR572) to get

White screen in White.

7) Vary Bias and Drivers to get the best screen in White and

Black.

8) Check adjustment condition with White Balance Meter.

9) Refer below for Adjustment

6-POLE

,

,,,,,,,,,,

,,,,,,

,,,,,,,,,,

,,,,,,,,,,

,,,,,,

0.288

1) Receive Digital pattern.

2) Do this adjustment after operating the SET more than 30

minutes.

3) After selecting Sub-mode with SVC Remocon and vary to

distinguish 4 and 5 step of Gray scale.

9. Vertical Size Adjustment

1) Receive Digital pattern and set screen conditon to APC

ON.

2) Vary Vertical Size adjustment VR(VR301) to reach inner

circle of large circle to edge of frame.

TEMPORARY

MOUNTING

10. Vertical Center Adjustment

30

30

0.281

8. Sub-Bright Adjustment

PURITY MAGNET

GLASS CLOTH TAPE

10,000K

1) Receive Digital pattern.

2) Set screen conditon to APC ON.

3) Turn Focus VR to get the best condition in center and

every corner.

,,,,

4-POLE

7. Focus Adjustment

,,,,,,,,,,,,,

,

,,,,,,,,

,,,,,,,

RUBBER

WEDGES

High Light : 40fl

Low Right : 4fl

DEFLECTION YOKE

PURITY &CONVERGENCE

MAGNET ASSEMBLY

ADHESIVE TAPE

Color Temperature

DEFLECTION YOKE

30

RUBBER WEDGES

LOCATION

1) Receive Digital pattern and set screen condition to APC

ON.

2) Adjust the center of screen with SVC SW(SW301) to place

center.

ADHESIVE

11. Horizontal Center Adjustment

1) Receive Digital pattern and set screen condition to APC

ON.

2) Adjust the center of screen with VR505 to place center.

<Figure 9>

- 3 -

COLD

HOT

AUDIO IN VIDEO IN

IC601

3

IC501

PRE-AMP.

Z101

VIF

TU100

44

5V 12V 33V

SHARP

51

BRI

45

COLOR

AFT

TINT

46

CONT

34

IC1

13

SFE4.5

6

21

H

DET-OUT

IC602

TPS4.5

-Y

SP

CPT PCB

- 1 -

IC2

SDA/SCL

H.Vcc of

IC501

D/G

26

FBP

FROM FBT

39 41

IC301

2

PWR

12

Q10

Q11

Q402

5V

RL801

CPT

R-Y, B-Y, G-Y

R, G, B, Ys

Q401

12V

D/G

COIL

TDA

2006

35

EEPROM

Q208

40

23 28

TMP67CC31

PRE-AMP

IC202

SIF-IN

H. D. T

1877

Q806

T402

FBT

Q805

D801

IC801

STR50092K

3

2

5

SMPS TRANS

3

5

8

B+

CPT 180V

24V

TO IC1

TO CPT

TO T403

1 COL

3

2

HT

24V

12V

FBP

10

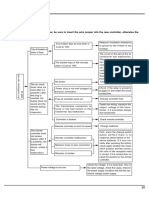

BLOCK DIAGRM

50

VCO

PA1

48

JA001

AFT

TUNER

TX

LA7674

SIF 9

Q102

LOCK

CLOCK

DATA

CS

Q603

T403

You might also like

- Manual de Servicio Mitsubishi Montero 6g74Document38 pagesManual de Servicio Mitsubishi Montero 6g74david2013777100% (4)

- Cross Section F8M F8Q Engine Repair (Motor Diesel F8M F8Q Dacia Papuc Solenza 1307)Document107 pagesCross Section F8M F8Q Engine Repair (Motor Diesel F8M F8Q Dacia Papuc Solenza 1307)bogdanxp2000100% (4)

- 06 - Reactor DesignDocument28 pages06 - Reactor DesignNoman AslamNo ratings yet

- From The Steam Table: Table 3 PT 1@ 540 C & 8mpa H 3496.7 KJ/KG & S 6.8481 PT 2 at 0.0035 Mpa & S S 6.8481 by InterpolationDocument5 pagesFrom The Steam Table: Table 3 PT 1@ 540 C & 8mpa H 3496.7 KJ/KG & S 6.8481 PT 2 at 0.0035 Mpa & S S 6.8481 by InterpolationMark AgusNo ratings yet

- TV LG 21fu1rDocument16 pagesTV LG 21fu1rpurwants100% (1)

- Instrumentation and P&ID - QuestionDocument6 pagesInstrumentation and P&ID - QuestionSharath Kota100% (1)

- Deutz 914 Control BoxDocument6 pagesDeutz 914 Control BoxCarlos GustavoNo ratings yet

- CN 14B80HDocument5 pagesCN 14B80HDavid Argote BellidoNo ratings yet

- Cn-20a30 LG TVDocument10 pagesCn-20a30 LG TVlogin_nameNo ratings yet

- MC 64A ChassisDocument8 pagesMC 64A ChassisPetr PavlíčekNo ratings yet

- Memorex Mt1130c TV Service ManualDocument13 pagesMemorex Mt1130c TV Service Manualricardo_MassisNo ratings yet

- Alignment Instruction (3Y01) : General Set-UpDocument8 pagesAlignment Instruction (3Y01) : General Set-Upprocrastinate1969No ratings yet

- LG Cn-14d99 Cn14a30h Cn20b30h Cn20h10 Adjustment-InstructionDocument15 pagesLG Cn-14d99 Cn14a30h Cn20b30h Cn20h10 Adjustment-InstructionfredyariasdNo ratings yet

- LG Mz40pa10 Plasma TV SMDocument22 pagesLG Mz40pa10 Plasma TV SMLuis MorenoNo ratings yet

- TS2750J - Similar A Chasis PX20084-2CDocument34 pagesTS2750J - Similar A Chasis PX20084-2CAleksander AlexanderNo ratings yet

- LG TV - Mod Ce29q12ip - Chasis Mc993aDocument30 pagesLG TV - Mod Ce29q12ip - Chasis Mc993aAntonio DalioNo ratings yet

- TV KVP2425C05Document62 pagesTV KVP2425C05Tecnico GenioNo ratings yet

- China TS2416 - Tda8377, La78045, Ka5q1265 - TV SMDocument31 pagesChina TS2416 - Tda8377, La78045, Ka5q1265 - TV SMFlorian LeordeanuNo ratings yet

- Panasonic TC-21FX20,21 Service ManualDocument29 pagesPanasonic TC-21FX20,21 Service ManualPratik Gandhi83% (12)

- Elite 21es63Document29 pagesElite 21es63dann222No ratings yet

- SHARP 37DM-23H: General InformationDocument3 pagesSHARP 37DM-23H: General InformationsoyvatzogloyNo ratings yet

- China TK2026 - Tda8377, Ka5q0765, Stv9302a - TV SMDocument56 pagesChina TK2026 - Tda8377, Ka5q0765, Stv9302a - TV SMFlorian LeordeanuNo ratings yet

- Samsung Ks1b Chassis Cs21k9mldc TV SMDocument22 pagesSamsung Ks1b Chassis Cs21k9mldc TV SMangga_scribdNo ratings yet

- Advent Dv1418a Tda9377ps-N2 Tda8357Document30 pagesAdvent Dv1418a Tda9377ps-N2 Tda8357Gerardo ReyesNo ratings yet

- Power Electronics Lab ManualDocument51 pagesPower Electronics Lab ManualAnand ShankarNo ratings yet

- Durabrand Bh2004d One ChipDocument27 pagesDurabrand Bh2004d One ChipAlejo Alex CondeNo ratings yet

- Haier Htar14Document16 pagesHaier Htar14elsubber100% (1)

- Panasonic Tc-21pm30rDocument29 pagesPanasonic Tc-21pm30rKasun Chamara Prathapasingha0% (1)

- Cl-21k5mq6 Ks9 Disc2Document23 pagesCl-21k5mq6 Ks9 Disc2Alberto SanchezNo ratings yet

- Metronic Installation Guide For The Motor Horizon Ref 450907Document24 pagesMetronic Installation Guide For The Motor Horizon Ref 450907box987No ratings yet

- Premium 3000 ManualDocument16 pagesPremium 3000 ManualIks PagaNo ratings yet

- Daewoo Dsj-5510cra-4710Document97 pagesDaewoo Dsj-5510cra-4710Diego Javier SantillanNo ratings yet

- Site Master™: Maintenance Manual Model S251C Antenna and Cable AnalyzerDocument16 pagesSite Master™: Maintenance Manual Model S251C Antenna and Cable AnalyzerBert En Sonya PauwelsNo ratings yet

- Panasonic Tc-21gx30p Chassis Gl1 SMDocument29 pagesPanasonic Tc-21gx30p Chassis Gl1 SMsontuyet82No ratings yet

- TC 21gx20m MalaysiaDocument29 pagesTC 21gx20m MalaysiaChandan Tripathi100% (4)

- Acer V551 (New) CRT Monitor Service Guide Chapter 3 Alignment ProcedureDocument118 pagesAcer V551 (New) CRT Monitor Service Guide Chapter 3 Alignment ProcedureCarlos Diaz Zavala0% (1)

- LG cn-14d99 Cn14a30h cn20b30h cn20h10 Adjustment-Instruction PDFDocument15 pagesLG cn-14d99 Cn14a30h cn20b30h cn20h10 Adjustment-Instruction PDFjrozo87No ratings yet

- Sony Ta Fb920rDocument26 pagesSony Ta Fb920rGeorge Ion ȘușalăNo ratings yet

- Samsung v18b Chassis Tc29j6mnxDocument67 pagesSamsung v18b Chassis Tc29j6mnxPony_37No ratings yet

- Practicas Digiac 1750 1Document18 pagesPracticas Digiac 1750 1Saga Adolfo GonzalezNo ratings yet

- Daewoo 14C4T - 20C4Tch - CP005 PDFDocument7 pagesDaewoo 14C4T - 20C4Tch - CP005 PDFHelder MartinsNo ratings yet

- Panasonic KX-TC1468LBB - 900 MHZ Cordless Phone Service ManualDocument64 pagesPanasonic KX-TC1468LBB - 900 MHZ Cordless Phone Service Manualrik206No ratings yet

- Service Manual 3Y11 Chassis: Design and Specifications Are Subject To Change Without Prior Notice. (Only Referrence)Document5 pagesService Manual 3Y11 Chassis: Design and Specifications Are Subject To Change Without Prior Notice. (Only Referrence)Александар МазињанинNo ratings yet

- Rca Tv-D52w20yx1 Chassis Atc221 (ET)Document48 pagesRca Tv-D52w20yx1 Chassis Atc221 (ET)IoanDomutaNo ratings yet

- Akira ct-21px9cp 3y11 PDFDocument41 pagesAkira ct-21px9cp 3y11 PDFAdam LiviuNo ratings yet

- 110 Waveform Generator Projects for the Home ConstructorFrom Everand110 Waveform Generator Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysFrom EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysNo ratings yet

- Digital Power Electronics and ApplicationsFrom EverandDigital Power Electronics and ApplicationsRating: 3.5 out of 5 stars3.5/5 (3)

- Power Systems-On-Chip: Practical Aspects of DesignFrom EverandPower Systems-On-Chip: Practical Aspects of DesignBruno AllardNo ratings yet

- Operational Amplifier Circuits: Analysis and DesignFrom EverandOperational Amplifier Circuits: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (2)

- Audio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsFrom EverandAudio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsNo ratings yet

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to LSIFrom EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to LSINo ratings yet

- Radio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142From EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142No ratings yet

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsFrom EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsRating: 3 out of 5 stars3/5 (2)

- TroubleshootingDocument24 pagesTroubleshootingMohammed Aldaffaie100% (1)

- Helmholtz CoilDocument6 pagesHelmholtz CoilFieraru Ionut RaduNo ratings yet

- 10H 11HDocument4 pages10H 11HJuan Jose Bonilla RNo ratings yet

- 2013 JC1 H2 Promo Sect ADocument8 pages2013 JC1 H2 Promo Sect AVarshLokNo ratings yet

- Improvements in Pipeline Modeling in HYSYS V7.3Document10 pagesImprovements in Pipeline Modeling in HYSYS V7.3Gabrielito PachacamaNo ratings yet

- Voltage Sag Analysis Case StudiesDocument7 pagesVoltage Sag Analysis Case Studiesmonirul_ahmedNo ratings yet

- UntitledDocument29 pagesUntitledThiago MansillaNo ratings yet

- Specification Sheet: Specifications TV2000, TV4000, TV7000DCDocument6 pagesSpecification Sheet: Specifications TV2000, TV4000, TV7000DCAatir AhmedNo ratings yet

- Climate Conscious Design-Abhilasha FoglaDocument32 pagesClimate Conscious Design-Abhilasha FoglapallaviNo ratings yet

- MM 761-781Document1,148 pagesMM 761-781Melvin MejiaNo ratings yet

- Submersible Pump Type & PriceDocument1 pageSubmersible Pump Type & PriceBudi MWNo ratings yet

- NSF61Document12 pagesNSF61Congson Jeff100% (1)

- SP70Document58 pagesSP70Pritesh Ramesh BareNo ratings yet

- Ds 30602Document4 pagesDs 30602Ridha AbbassiNo ratings yet

- MTE HPHT Cement ConsistometerDocument2 pagesMTE HPHT Cement ConsistometerWahid MiaNo ratings yet

- (English) The Nervous System, Part 2 - Action! Potential! - Crash Course A&P #9 (DownSub - Com)Document9 pages(English) The Nervous System, Part 2 - Action! Potential! - Crash Course A&P #9 (DownSub - Com)bank townNo ratings yet

- Photomultiplier Tubes: Photon Is Our BusinessDocument323 pagesPhotomultiplier Tubes: Photon Is Our Businessico haydNo ratings yet

- Esd 75-160Document6 pagesEsd 75-160proma13No ratings yet

- Model Elbow EngineDocument5 pagesModel Elbow EngineJim100% (3)

- Distribution Business Unit Cummins Field Service Report Pal EngineersDocument1 pageDistribution Business Unit Cummins Field Service Report Pal EngineersPrabhu VijayakumaranNo ratings yet

- Samsung RL42HDocument29 pagesSamsung RL42HMarcus MillerNo ratings yet

- Photodiode Investigatory ProjectDocument25 pagesPhotodiode Investigatory ProjectNishant KumarNo ratings yet

- HVAC Apr 2020 - CBTDocument2 pagesHVAC Apr 2020 - CBTArtur MkrtchyanNo ratings yet

- Curva Bomba Fristam Tipo FPX1732Document1 pageCurva Bomba Fristam Tipo FPX1732Fernando Pulgar BarillasNo ratings yet