Professional Documents

Culture Documents

Ds 30602

Uploaded by

Ridha AbbassiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ds 30602

Uploaded by

Ridha AbbassiCopyright:

Available Formats

Green

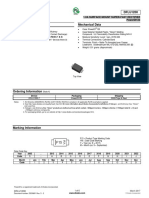

DFLR1200/DFLR1400/DFLR1600

1.0A SURFACE MOUNT GLASS PASSIVATED RECTIFIER

®

POWERDI 123

Product Summary (@ TA = +25°C) Features and Benefits

ADVANCE INFORMATION

VRRM (V) IO (A) VF(MAX) (V) IR(MAX) (µA) Glass Passivated Die Construction

200, 400, 600 1 1.1 3 Ideally Suited for Automated Assembly

Low Forward Voltage Drop

Low Profile Design, Package Height Less than 1.1mm

Lead-Free Finish; RoHS Compliant (Notes 1 & 2)

Halogen and Antimony Free. "Green" Device (Note 3)

Patented Interlocking Clip Design for High Surge Capacity, US

Patent #7,095,113

Description and Applications Mechanical Data

®

This series is packaged in the compact, low profile PowerDI 123 Case: PowerDI®123

package. Providing low forward voltage drop, this device is ideal for Case Material: Molded Plastic, "Green" Molding Compound.

use in general rectification applications such as: UL Flammability Classification Rating 94V-0

Moisture Sensitivity: Level 1 per J-STD-020

Power Supply Applications Terminals: Matte Tin Finish Annealed over Copper Leadframe

DC-DC Converters (Lead-Free Plating).

AC-DC Adaptors/Chargers Solderable per MIL-STD-202, Method 208 e3

Freewheeling Diodes Terminal Connections: Cathode Band

Inverters Weight: 0.01 grams (Approximate)

PowerDI123

Top View

Ordering Information (Note 4)

Part Number Qualification Marking Code Case Packaging

DFLR1200-7 Commercial F12 PowerDI123 3,000/Tape & Reel

DFLR1400-7 Commercial F14 PowerDI123 3,000/Tape & Reel

DFLR1600-7 Commercial F18 PowerDI123 3,000/Tape & Reel

Notes: 1. EU Directive 2002/95/EC (RoHS) & 2011/65/EU (RoHS 2) compliant. All applicable RoHS exemptions applied.

2. See http://www.diodes.com/quality/lead_free.html for more information about Diodes Incorporated’s definitions of Halogen- and Antimony-free, "Green"

and Lead-free.

3. Halogen- and Antimony-free "Green” products are defined as those which contain <900ppm bromine, <900ppm chlorine (<1500ppm total Br + Cl) and

<1000ppm antimony compounds.

4. For packaging details, go to our website at http://www.diodes.com/products/packages.html.

Marking Information

Fxx = Product Type Marking Code

YM

YM = Date Code Marking

Fxx Y = Year (ex: C = 2015)

M = Month (ex: 9 = September)

Date Code Key

Year 2011 … 2015 2016 2017 2018 2019 2020 2021

Code Y … C D E F G H I

Month Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec

Code 1 2 3 4 5 6 7 8 9 O N D

DFLR1200/DFLR1400/DFLR1600 1 of 4 October 2015

Document number: DS30602 Rev. 9 - 2 www.diodes.com © Diodes Incorporated

DFLR1200/DFLR1400/DFLR1600

Maximum Ratings (@TA = +25°C, unless otherwise specified.)

Single phase, half wave, 60Hz, resistive or inductive load.

For capacitive load, derate current by 20%.

ADVANCE INFORMATION

Characteristic Symbol DFLR1200 DFLR1400 DFLR1600 Units

Peak Repetitive Reverse Voltage VRRM

Working Peak Reverse Voltage VRWM 200 400 600 V

DC Blocking Voltage VR

RMS Reverse Voltage VR(RMS) 140 280 420 V

Average Rectified Output Current (See Figure 4) IO 1.0 A

Non-Repetitive Peak Forward Surge Current

IFSM 25 A

8.3ms Single Half Sine-Wave Superimposed on Rated Load

Thermal Characteristics

Characteristic Symbol Typ Max Unit

Thermal Resistance, Junction to Ambient Air (Note 5) RJA 134 — °C/W

Thermal Resistance, Junction to Soldering Point (Note 6) RJS — 6 °C/W

Operating and Storage Temperature Range TJ, TSTG — -65 to +150 °C

Electrical Characteristic (@TA = +25°C, unless otherwise specified.)

Characteristic Symbol DFLR1200 DFLR1400 DFLR1600 Unit

Minimum Reverse Breakdown Voltage (Note 7)

V(BR)R 200 400 600 V

@IR=10µA

Maximum Forward Voltage Drop @ IF = 1.0A VF 1.1 V

Peak Reverse Leakage Current @ TA = +25°C 3.0

IR µA

at Rated DC Blocking Voltage @ TA = +125°C 100

Typical Total Capacitance (f = 1MHz, VR= 4.0VDC) CT 10 pF

Notes: 5. Theoretical RJS calculated from the top center of the die straight down to the PCB/cathode tab solder junction.

6. Device mounted on 1in x 1in, FR-4 PCB; 2 oz Cu pad layout as shown on Diodes Incorporated’s suggested pad layout document AP02001.pdf.

7. Short duration pulse test used to minimize self-heating effect.

10000 10

IR, INSTANTANEOUS REVERSE CURRENT (µA)

IF , I NSTANTANEOUS FO RWARD CURRENT (mA)

TA = 150°C

1000

1

TA = 125°C

100 T A = 150°C

0.1

10 TA = 75°C

T A = 25°C

T A = 100°C

1

0.01

TA = 25°C

T A = 0°C

011

0.001

0.01 TA = -65°C

T A = -40°C

0.0001

0.001 0 25 50 75 100

0 200 400 600 800 1000 1200

V F, INSTANTANEOUS FORWARD VOLTAGE (mV) PERCENT OF RATED PEAK REVERSE VOLTAGE (%)

Figure 1 Typical Forward Characteristics Figure 2 Typical Reverse Characteristics

DFLR1200/DFLR1400/DFLR1600 2 of 4 October 2015

Document number: DS30602 Rev. 9 - 2 www.diodes.com © Diodes Incorporated

DFLR1200/DFLR1400/DFLR1600

12 1.2

10 1.0

IF, DC FORWARD CURRENT (A)

ADVANCE INFORMATION

CT, TOTAL CAPACITANCE (pF)

8 0.8

6 0.6

4 0.4

2 0.2

0 0

0 10 20 30 40 0 25 50 75 100 125 150

VR, REVERSE VOLTAGE (V) TA, AMBIENT TEMPERATURE (°C)

Figure 3 Typical Total Capacitance Figure 4 DC Forward Current Derating

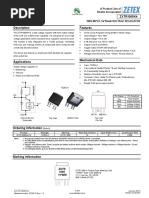

Package Outline Dimensions

Please see AP02002 at http://www.diodes.com/datasheets/ap02002.pdf for the latest version.

D

POWERDI®123

Dim Min Max Typ

A 0.93 1.00 0.98

E1 A3 0.15 0.25 0.20

b 0.85 1.25 1.00

b2 1.025 1.125 1.10

A3 D 1.63 1.93 1.78

A E 3.50 3.90 3.70

E1 2.60 3.00 2.80

L 0.40 0.50 0.45

L1 1.25 1.40 1.35

L(2X) L3 0.125 0.275 0.20

L1

All Dimensions in mm

b b2

L3 L3

DFLR1200/DFLR1400/DFLR1600 3 of 4 October 2015

Document number: DS30602 Rev. 9 - 2 www.diodes.com © Diodes Incorporated

DFLR1200/DFLR1400/DFLR1600

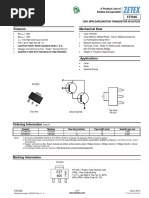

Suggested Pad Layout

Please see AP02001 at http://www.diodes.com/datasheets/ap02001.pdf for the latest version.

POWERDI®123

ADVANCE INFORMATION

X2 Value

Dimensions

(in mm)

G 0.65

X 1.05

Y Y1

X1 2.40

X2 4.10

Y 1.50

X G X1

Y1 1.50

IMPORTANT NOTICE

DIODES INCORPORATED MAKES NO WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, WITH REGARDS TO THIS DOCUMENT,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE

(AND THEIR EQUIVALENTS UNDER THE LAWS OF ANY JURISDICTION).

Diodes Incorporated and its subsidiaries reserve the right to make modifications, enhancements, improvements, corrections or other changes

without further notice to this document and any product described herein. Diodes Incorporated does not assume any liability arising out of the

application or use of this document or any product described herein; neither does Diodes Incorporated convey any license under its patent or

trademark rights, nor the rights of others. Any Customer or user of this document or products described herein in such applications shall assume

all risks of such use and will agree to hold Diodes Incorporated and all the companies whose products are represented on Diodes Incorporated

website, harmless against all damages.

Diodes Incorporated does not warrant or accept any liability whatsoever in respect of any products purchased through unauthorized sales channel.

Should Customers purchase or use Diodes Incorporated products for any unintended or unauthorized application, Customers shall indemnify and

hold Diodes Incorporated and its representatives harmless against all claims, damages, expenses, and attorney fees arising out of, directly or

indirectly, any claim of personal injury or death associated with such unintended or unauthorized application.

Products described herein may be covered by one or more United States, international or foreign patents pending. Product names and markings

noted herein may also be covered by one or more United States, international or foreign trademarks.

This document is written in English but may be translated into multiple languages for reference. Only the English version of this document is the

final and determinative format released by Diodes Incorporated.

LIFE SUPPORT

Diodes Incorporated products are specifically not authorized for use as critical components in life support devices or systems without the express

written approval of the Chief Executive Officer of Diodes Incorporated. As used herein:

A. Life support devices or systems are devices or systems which:

1. are intended to implant into the body, or

2. support or sustain life and whose failure to perform when properly used in accordance with instructions for use provided in the

labeling can be reasonably expected to result in significant injury to the user.

B. A critical component is any component in a life support device or system whose failure to perform can be reasonably expected to cause the

failure of the life support device or to affect its safety or effectiveness.

Customers represent that they have all necessary expertise in the safety and regulatory ramifications of their life support devices or systems, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products and any

use of Diodes Incorporated products in such safety-critical, life support devices or systems, notwithstanding any devices- or systems-related

information or support that may be provided by Diodes Incorporated. Further, Customers must fully indemnify Diodes Incorporated and its

representatives against any damages arising out of the use of Diodes Incorporated products in such safety-critical, life support devices or systems.

Copyright © 2015, Diodes Incorporated

www.diodes.com

DFLR1200/DFLR1400/DFLR1600 4 of 4 October 2015

Document number: DS30602 Rev. 9 - 2 www.diodes.com © Diodes Incorporated

You might also like

- Dual N-Channel Enhancement Mode Mosfet: DSS DS (ON) D ADocument6 pagesDual N-Channel Enhancement Mode Mosfet: DSS DS (ON) D AErkanNo ratings yet

- Ds 30483Document6 pagesDs 30483yoxan25808No ratings yet

- DMN3350LDW DiodesDocument7 pagesDMN3350LDW DiodesJuan NunesNo ratings yet

- Dflu1200: 1.0A Surface Mount Super-Fast Rectifier Powerdi123Document6 pagesDflu1200: 1.0A Surface Mount Super-Fast Rectifier Powerdi123daniel5morales5castaNo ratings yet

- B170/B - B1100/B: 1.0A High Voltage Schottky Barrier RectifierDocument6 pagesB170/B - B1100/B: 1.0A High Voltage Schottky Barrier RectifierRandi Eka PutraNo ratings yet

- 1.0A Surface Mount Schottky Barrier Rectifier: RRM O F (MAX) R (MAX)Document5 pages1.0A Surface Mount Schottky Barrier Rectifier: RRM O F (MAX) R (MAX)Сергій ПіхалоNo ratings yet

- DMC3350LDWQ DiodesDocument10 pagesDMC3350LDWQ DiodesJuan NunesNo ratings yet

- UF5JD1: V (V) I (A) V (V) I (μA)Document7 pagesUF5JD1: V (V) I (A) V (V) I (μA)Maz RofulNo ratings yet

- SBR6100CTL: V (V) I (A) V (V) I (Ma)Document5 pagesSBR6100CTL: V (V) I (A) V (V) I (Ma)Richard bermudez sanchezNo ratings yet

- 1N5819HW-7-F-Schottky DiodDocument5 pages1N5819HW-7-F-Schottky DiodMohammad HBNo ratings yet

- DMP4015SK3: P-Channel Enhancement Mode MosfetDocument7 pagesDMP4015SK3: P-Channel Enhancement Mode MosfetpaulpuscasuNo ratings yet

- Diod SDocument8 pagesDiod Scantantesolistalatino duarteNo ratings yet

- DMP2040USSDocument7 pagesDMP2040USSOscarito VázquezNo ratings yet

- Dmn66D0Ldw Product Summary Features and Benefits: Dual N-Channel Enhancement Mode MosfetDocument6 pagesDmn66D0Ldw Product Summary Features and Benefits: Dual N-Channel Enhancement Mode Mosfetzigmund zigmundNo ratings yet

- DMN3730UFB4: A Product Line of Diodes IncorporatedDocument7 pagesDMN3730UFB4: A Product Line of Diodes IncorporatedPușcă MartinNo ratings yet

- DuraClik Crimp Terminal Spec SheetDocument2 pagesDuraClik Crimp Terminal Spec Sheetzhigan chenNo ratings yet

- SBR10100CTB: V (V) I (A) V (V) at +25°C I (Ma) at +25°CDocument5 pagesSBR10100CTB: V (V) I (A) V (V) at +25°C I (Ma) at +25°CTecnico GenioNo ratings yet

- ZVNL110GDocument7 pagesZVNL110GLuis Enrique De los Santos FarfánNo ratings yet

- sl22 108295Document5 pagessl22 108295Mohammad UsmanNo ratings yet

- DMG1029SV N - P Channel FETDocument9 pagesDMG1029SV N - P Channel FETaerNo ratings yet

- Zxmp4a16gq DiodesDocument7 pagesZxmp4a16gq DiodesashwinNo ratings yet

- 2N7002DWK: Dual N-Channel Enhancement Mode MosfetDocument7 pages2N7002DWK: Dual N-Channel Enhancement Mode MosfetErkanNo ratings yet

- Dfls1200: Powerdi 123Document3 pagesDfls1200: Powerdi 123m3y54mNo ratings yet

- Mosfet Dmg3420uDocument6 pagesMosfet Dmg3420uFrancisco MagyarNo ratings yet

- Se80pwtg Se80pwtjDocument5 pagesSe80pwtg Se80pwtjsureshNo ratings yet

- B130L DiodesDocument5 pagesB130L DiodesJuan NunesNo ratings yet

- DMC 2400 UvDocument10 pagesDMC 2400 UvDeniz KarasuNo ratings yet

- 3 0SMCJ5 0ca-3 0smcj170caDocument6 pages3 0SMCJ5 0ca-3 0smcj170caVinicius GiovaneliNo ratings yet

- Voltage RegulatorDocument8 pagesVoltage RegulatorNANo ratings yet

- 2N7002 PDFDocument5 pages2N7002 PDFriyanto_fisika5535No ratings yet

- N-Channel Enhancement Mode Mosfet: (BR) Dss DS (ON) D ADocument6 pagesN-Channel Enhancement Mode Mosfet: (BR) Dss DS (ON) D AAnup BulsaraNo ratings yet

- N-Channel Enhancement Mode Mosfet: (BR) Dss DS (ON) D ADocument5 pagesN-Channel Enhancement Mode Mosfet: (BR) Dss DS (ON) D AVũ Huy Nhật MinhNo ratings yet

- 1SS400T1G, NSV1SS400T1G High-Speed Switching Diode: FeaturesDocument3 pages1SS400T1G, NSV1SS400T1G High-Speed Switching Diode: FeaturesManu MathewNo ratings yet

- N-Channel Enhancement Mode Mosfet: (BR) Dss DS (ON) D ADocument5 pagesN-Channel Enhancement Mode Mosfet: (BR) Dss DS (ON) D AErkanNo ratings yet

- Littelfuse SIDACtor DO 214 Datasheet PDFDocument5 pagesLittelfuse SIDACtor DO 214 Datasheet PDFdvalinaNo ratings yet

- B120/B - B160/BDocument5 pagesB120/B - B160/BJeiki OsNo ratings yet

- SPM4012T 4R7MDocument9 pagesSPM4012T 4R7McesvenegasNo ratings yet

- Pam8403 PDFDocument11 pagesPam8403 PDFDEEPAK MAHTONo ratings yet

- SSB 43 LDocument5 pagesSSB 43 LRomanoNo ratings yet

- Dmc2700udm 73200Document10 pagesDmc2700udm 73200Edgardo Elvio JaugeNo ratings yet

- (SMD) - DatasheetDocument4 pages(SMD) - DatasheetAhmed Sherif CupoNo ratings yet

- Ultra Low V 0.50 V at I 6 A: Vishay General SemiconductorDocument5 pagesUltra Low V 0.50 V at I 6 A: Vishay General Semiconductorjose perezNo ratings yet

- N-Channel Enhancement Mode Field Mosfet: (BR) Dss DS (ON) D ADocument7 pagesN-Channel Enhancement Mode Field Mosfet: (BR) Dss DS (ON) D ABiomed TNo ratings yet

- 2N7002Document5 pages2N7002Frank DiazNo ratings yet

- S3A, S3B, S3D, S3G, S3J, S3K, S3M: Vishay General SemiconductorDocument4 pagesS3A, S3B, S3D, S3G, S3J, S3K, S3M: Vishay General Semiconductormahbub metulNo ratings yet

- Termination Resistor - SAC-5P-M12MS PB TR - 1507803: Key Commercial DataDocument4 pagesTermination Resistor - SAC-5P-M12MS PB TR - 1507803: Key Commercial DataNguyễn Văn ĐịnhNo ratings yet

- DRM New Series RelaysDocument4 pagesDRM New Series RelaysRakesh TondayNo ratings yet

- Datasheet Dioda Miniatur ABS10A-13Document6 pagesDatasheet Dioda Miniatur ABS10A-13Dee JavuNo ratings yet

- 2N7002 Product Summary Features and Benefits: N-Channel Enhancement Mode Field Effect TransistorDocument6 pages2N7002 Product Summary Features and Benefits: N-Channel Enhancement Mode Field Effect TransistorErkanNo ratings yet

- FZT605 58355Document8 pagesFZT605 58355saikumarNo ratings yet

- MBR (F) 20150CTDocument4 pagesMBR (F) 20150CTCassio SousaNo ratings yet

- 3.0A Surface Mount Schottky Barrier Rectifier: RRM O F RDocument6 pages3.0A Surface Mount Schottky Barrier Rectifier: RRM O F RralusanduNo ratings yet

- RF 01065Document3 pagesRF 01065Vasile GurezNo ratings yet

- ZXMN10A07Z: 100V N-Channel Enhancement Mode Mosfet in Sot89 PackageDocument8 pagesZXMN10A07Z: 100V N-Channel Enhancement Mode Mosfet in Sot89 PackageneftalicastroNo ratings yet

- MB10S 1112788Document6 pagesMB10S 1112788Luis Enrique Villacorta CalleNo ratings yet

- SD103A, SD103B, SD103C: Vishay SemiconductorsDocument4 pagesSD103A, SD103B, SD103C: Vishay SemiconductorsPablo AllosiaNo ratings yet

- SBR20A45D1 (d101)Document5 pagesSBR20A45D1 (d101)diegoNo ratings yet

- 7-16 DIN Male Connector For 1-15/8" Coaxial Cable, OMNI FIT™ Premium, Straight, O-Ring and Compression SealingDocument2 pages7-16 DIN Male Connector For 1-15/8" Coaxial Cable, OMNI FIT™ Premium, Straight, O-Ring and Compression SealingLuciano Silvério LeiteNo ratings yet

- Zxmp6A17Gq: BV R I T +25°CDocument9 pagesZxmp6A17Gq: BV R I T +25°CKarim KarimmNo ratings yet

- External Gear Motors: RE 14 026/01.05 Replaces: 1 987 760 101/01.99Document40 pagesExternal Gear Motors: RE 14 026/01.05 Replaces: 1 987 760 101/01.99Ridha AbbassiNo ratings yet

- Radial Piston Motor Technical ManualDocument48 pagesRadial Piston Motor Technical ManualElias80No ratings yet

- DoosanM300 HYDDocument1 pageDoosanM300 HYDRidha AbbassiNo ratings yet

- MT 16Document2 pagesMT 16Ridha AbbassiNo ratings yet

- Sauerdanfoss Series Osp Catalogue en 11007611Document80 pagesSauerdanfoss Series Osp Catalogue en 11007611Ridha AbbassiNo ratings yet

- Catalogue Vickers PumpiDocument35 pagesCatalogue Vickers PumpiRn SrtnNo ratings yet

- Service Manual: S/N 233311001 & Above S/N 233211001 & Above (D Series)Document6 pagesService Manual: S/N 233311001 & Above S/N 233211001 & Above (D Series)Ridha AbbassiNo ratings yet

- MVP 07 T A Edition: 07/03.2022 Replaces: MVP 06 T ADocument72 pagesMVP 07 T A Edition: 07/03.2022 Replaces: MVP 06 T ARidha AbbassiNo ratings yet

- Variable-Displacement Piston Pump: PP VB2V F8A3 EE B GDocument4 pagesVariable-Displacement Piston Pump: PP VB2V F8A3 EE B GRidha AbbassiNo ratings yet

- Specifications: Ackhoe OaderDocument4 pagesSpecifications: Ackhoe OaderRidha AbbassiNo ratings yet

- Industrial Training Template BasicsDocument65 pagesIndustrial Training Template BasicsFaiz IbrahimNo ratings yet

- Hydraulic Training Smiley PDFDocument100 pagesHydraulic Training Smiley PDFliu zhao liu zhaoNo ratings yet

- Vane Pump PDFDocument76 pagesVane Pump PDFHidroil Neuquen SrlNo ratings yet

- Eaton Vickers 20V 25V 35V 45VDocument35 pagesEaton Vickers 20V 25V 35V 45VRidha Abbassi100% (1)

- Bomba Sauer Partes m40-m46Document132 pagesBomba Sauer Partes m40-m46fercsl100% (3)

- PDF V10 V20 V2010 V2020 - Vickers PDFDocument27 pagesPDF V10 V20 V2010 V2020 - Vickers PDFAyoub RouissiNo ratings yet

- To Be Used For Pars Service Option Only in Bond: ExpressDocument4 pagesTo Be Used For Pars Service Option Only in Bond: ExpressRidha AbbassiNo ratings yet

- Variable Displacements Axial Piston Pumps: Edition: 06/06.2020 Replaces: MVP 05 T ADocument72 pagesVariable Displacements Axial Piston Pumps: Edition: 06/06.2020 Replaces: MVP 05 T ARidha AbbassiNo ratings yet

- To Be Used For Pars Service Option Only in Bond: ExpressDocument4 pagesTo Be Used For Pars Service Option Only in Bond: ExpressRidha AbbassiNo ratings yet

- Bomba Sauer Partes m40-m46Document132 pagesBomba Sauer Partes m40-m46fercsl100% (3)

- Series 20 Axial Piston Pumps Service ManualDocument36 pagesSeries 20 Axial Piston Pumps Service Manualvrosalio100% (1)

- Catalogue: Guns For GenerationsDocument38 pagesCatalogue: Guns For GenerationsRidha AbbassiNo ratings yet

- Service Training for 325D/320D Hydraulic Excavators Pump and Pump ControlsDocument13 pagesService Training for 325D/320D Hydraulic Excavators Pump and Pump Controlsمحمد يونس100% (1)

- PVC-CPVC-80 - PVC Plastic Pipe and Fittings 80Document12 pagesPVC-CPVC-80 - PVC Plastic Pipe and Fittings 80Ridha AbbassiNo ratings yet

- To Be Used For Pars Service Option Only in Bond: ExpressDocument4 pagesTo Be Used For Pars Service Option Only in Bond: ExpressRidha AbbassiNo ratings yet

- Variable Displacements Axial Piston Pumps: Edition: 06/06.2020 Replaces: MVP 05 T ADocument72 pagesVariable Displacements Axial Piston Pumps: Edition: 06/06.2020 Replaces: MVP 05 T ARidha AbbassiNo ratings yet

- Nexbraid Clear PVC Hose: Series 125 (Standard Wall) / Series 126 (Heavy Duty)Document2 pagesNexbraid Clear PVC Hose: Series 125 (Standard Wall) / Series 126 (Heavy Duty)Ridha AbbassiNo ratings yet

- Vane Motors High Performance Hydraulic Series M5B - M5BS - M5BFDocument11 pagesVane Motors High Performance Hydraulic Series M5B - M5BS - M5BFRidha AbbassiNo ratings yet

- Parts Information: Char-LynnDocument5 pagesParts Information: Char-LynnRidha AbbassiNo ratings yet

- Toshiba Main Pump Solar-V PDFDocument12 pagesToshiba Main Pump Solar-V PDFRonald AuquiNo ratings yet

- MCB CatalogueDocument52 pagesMCB CatalogueECATOnlineNo ratings yet

- Product Manual 26727 (Revision Y, 11/2022) : Varistroke-I (Vs-I) Electro-Hydraulic ActuatorDocument141 pagesProduct Manual 26727 (Revision Y, 11/2022) : Varistroke-I (Vs-I) Electro-Hydraulic ActuatorFathima ReginNo ratings yet

- Murata Products PTC Thermistors R90eDocument105 pagesMurata Products PTC Thermistors R90ealltheloveintheworldNo ratings yet

- Toshiba Rd-xv48dtkb SMDocument124 pagesToshiba Rd-xv48dtkb SMmarshall tmNo ratings yet

- Powervalue 11 RT G2: User ManualDocument40 pagesPowervalue 11 RT G2: User ManualElisvan Jordan Guzman EspinozaNo ratings yet

- Sharp Lc-60-70le650u 70le657u 70757u C6500u Le755u Le857u C7500uDocument136 pagesSharp Lc-60-70le650u 70le657u 70757u C6500u Le755u Le857u C7500uJuan Carlos Srafan100% (1)

- Kd674 ManualDocument426 pagesKd674 ManualRichard RosalesNo ratings yet

- Uc2825 PDFDocument20 pagesUc2825 PDFCk MontillaNo ratings yet

- Uaf 42Document8 pagesUaf 42ensvNo ratings yet

- Product Data Sheet: Easergy BAT24Ah 12V 24ah 10 Years Life High Rate Industrial VRLA BatteryDocument2 pagesProduct Data Sheet: Easergy BAT24Ah 12V 24ah 10 Years Life High Rate Industrial VRLA BatteryPreditec PeruNo ratings yet

- Telemecanique Inductive Proximity Sensor (XSA-V11373L10) ManualDocument7 pagesTelemecanique Inductive Proximity Sensor (XSA-V11373L10) Manual빠끄No ratings yet

- Operating Instructions and Specifications: Deutsch FrançaisDocument40 pagesOperating Instructions and Specifications: Deutsch FrançaisMedoBoudyNo ratings yet

- Philips FWD186 Service Manual, Repair Schematics, Online DownloadDocument69 pagesPhilips FWD186 Service Manual, Repair Schematics, Online DownloadSatrio Ongis NadeNo ratings yet

- Service Manual: LC-32D41U LC-32M41U LC-40C32UDocument148 pagesService Manual: LC-32D41U LC-32M41U LC-40C32UkalentoneschatNo ratings yet

- AIS Service Manual JHS183 PDFDocument106 pagesAIS Service Manual JHS183 PDFDamian Majewski100% (1)

- ATV930D30N4 Product Data SheetDocument13 pagesATV930D30N4 Product Data Sheetsofcrow1No ratings yet

- Alinco DX-SR8 InstructionDocument97 pagesAlinco DX-SR8 InstructionprotobooksNo ratings yet

- Fault Protected, Extended Common Mode Range, RS-485/RS-422 Transceivers With 16.5kV ESDDocument19 pagesFault Protected, Extended Common Mode Range, RS-485/RS-422 Transceivers With 16.5kV ESDWelleyNo ratings yet

- Pioneer Deh-2350ub PDFDocument62 pagesPioneer Deh-2350ub PDFChristian Yair Macxon OliverNo ratings yet

- RSP 1570 OmDocument50 pagesRSP 1570 OmnwescoNo ratings yet

- Dcon5114853 PDFDocument91 pagesDcon5114853 PDFAmrit KumarNo ratings yet

- Nepcon 08Document13 pagesNepcon 08Amlan ChakrabartiNo ratings yet

- Manual Usuario Hiki User-Manual-5392612Document174 pagesManual Usuario Hiki User-Manual-5392612Rafael MunueraNo ratings yet

- High Voltage Shunt RegulatorsDocument1 pageHigh Voltage Shunt RegulatorsOil lessNo ratings yet

- 1SDA072876R1 E2 2n 800 Ekip Touch Lsig 4p WMPDocument4 pages1SDA072876R1 E2 2n 800 Ekip Touch Lsig 4p WMPSushant RathiNo ratings yet

- Rukovodstvo Po Podklyucheniyu Magelis GTO Eng PDFDocument142 pagesRukovodstvo Po Podklyucheniyu Magelis GTO Eng PDFaswinraveendranNo ratings yet

- GA1A2S100Document10 pagesGA1A2S100Cedric BodinNo ratings yet

- 21PT9457.55 Chasis SK4 (1) .0L CADocument56 pages21PT9457.55 Chasis SK4 (1) .0L CAequus43No ratings yet

- Sharp xl-mp50h SMDocument72 pagesSharp xl-mp50h SMJohnNo ratings yet

- Zelio Control Relays - RM22TR33Document7 pagesZelio Control Relays - RM22TR33SIVARAMANJAGANATHANNo ratings yet