Professional Documents

Culture Documents

370 373 PDF

370 373 PDF

Uploaded by

SinhrooOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

370 373 PDF

370 373 PDF

Uploaded by

SinhrooCopyright:

Available Formats

Metal Science and Heat Treatment

Vol. 38, Nos. 9 - 1 0 . 1996

UDC 621.78.062.3

PROTECTIVE PROPERTIES OF A N I T R O G E N A T M O S P H E R E

WITH AN A D M I X T U R E OF NATURAL GAS

Yu. M . B r u n z e r t

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 9, pp. 6 - 10, September, 1996.

The present difficulties with energy supply in Russia require strict control of consumption of natural gas and

power and observation of environmental restrictions. This necessitates of the development of economically

and environmentally optimum protective atmospheres. For relatively small heat treatment furnaces the use of

nitrogen as a carrier gas can be of some interest. In this case environmentally inexpedient exo- and endogenerators with the corresponding expensive and complex systems for automatic control of the carbon potential

become unnecessary. Foreign experience shows that nitrogen can be used by means of a rather simple

technology that includes an imported cryostat with liquid nitrogen, a line for feeding natural gas, and the

corresponding mixing and proportioning devices. In the present work the possibility of using nitrogen with an

admixture of natural gas as a protective atmosphere for annealing is considered.

Heat treatment of steel with the use of a protective nitrogen atmosphere containing gaseous hydrocarbons is a common practice in some foreign countries [ 1, 2]. Interest in such

an atmosphere appeared in the U.S. in the energy crisis of the

1970s. Nitrogen used as a carrier gas arrived from oxygen

plants, which made unnecessary the construction of gas generators for the production of exogenous gas or nitrogen-hydrogen mixture ( - 4% H 2 ) and the corresponding investment.

These expenses were especially considerable for metallurgical works, where powerful gas-preparing installations required the construction of large centralized separately located

plants. It was very important that nitrogen cartier gas did not

require natural gas for its production and was a secondary or

side product of the production of oxygen plants.

In the present work 2 we determined the optimum amount

of admixture of natural gas in nitrogen. For this purpose, foils

of different steels were held at different temperatures in an atmosphere of pure nitrogen with various proportions of natural

gas in a laboratory muffle furnace with a precombustion

chamber. Foils 0.1 ram thick were produced from steels further subjected to a heat treatment under experimental industrial conditions, namely, structural steels 25KhGSA (0.25%

C, 1.0% Si, 0.9% Mn, i% Cr) and 30KhSNVFA (0.30% C,

up to 1.5% Cr, Si, Ni, W, V), tool steel U8 (0.8% C), and virtually carbon-free commercial iron with an insignificant content of impurity elements. A foil was placed in a special device in the precombustion chamber, then the chamber and the

communicating functional space were blown with pure nitrogen, and an additive of natural gas was introduced. After this

I

the foil in the device was placed in the functional space

heated to the specified temperature. After a 4-h hold the foil

was placed again in the precombustion chamber, where it was

cooled rapidly in the same atmosphere.

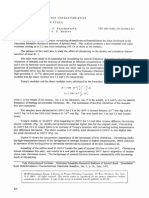

An analysis of the experimental results (see Table 1) has

shown that due to the hold at 800C in the atmosphere of pure

nitrogen (98.98%) all steels were decarburized almost completely. A 8 - 9% addition of natural gas made the atmosphere virtually neutral at 750C for carbon-containing steels

and commercial iron, although the carbon content in them in

the initial state was different (from 0 to 0.8%). A decrease in

the amount of natural gas to 4% at this temperature changed

the picture, namely, carbon-containing steels were decarburized intensely. At 800C the addition of 4% natural gas made

the atmosphere neutral for structural steels (0.3% C), but the

steel with 0.8% C was decarburized markedly. An increase to

8 - 9% natural gas hardly decarburized tool steel but caused

some excess carburization of structural steels. At 850C in

the presence of 8 - 9% natural gas the atmosphere was indifferent for structural steels but exerted some decarburizing action on tool steel.

In industrial tests in the Krasnyi Oktyabr' Plant we used a

three-chamber continuous furnace for soft annealing of rolled

sheets (Fig. 1). The need for this work was caused by the absence of any atmosphere other than the investigated one in

the plant for this furnace. In the course of annealing, stacks of

sheets were subjected to a cyclic motion over the roller hearth

with stops and holds in each chamber. Metal was heated in

the furnace with radiating tubes. The furnace had three chambers, namely, one for heating and holding (I), one for holding

and regulated cooling (//), and one for jet cooling by a pro-

I. P. Bardin Central Research Institute of Ferrous Metallurgy, Russia.

370

0026-0673/96/0910-0370$15.00 ID 1997 Plenum Publishing Corporation

Protective Properties of a Nitrogen Atmosphere with an Admixture of Natural Gas

TABLE l

Steel

I

Regime of

annealing of foils

lee,s , vol.%

371

C, %

25GSA

30KhSNVFA

U8

8000C, 4 h

0.018

0.017

0.011

25GSA

30KhSNVFA

U8

800C, 4 h

0.26

0,3 I

0.44

25K.hGSA

30KhSNVFA

Commercial iron

U8

800*C, 4 h

8- 9

0.37

0.49

0.48

25KhGSA

30KhSNVFA

U8

750"C, 4 h

0.017

0.108

0.180

25KhGSA

30KhSNVFA

Commercial iron

U8

750C, 4 h

8- 9

0.25

0.35

0.016

25KhGSA

30KhSNVFA

Commercial iron

U8

850C, 4 h

0.71

0.71

8- 9

0.35

0.35

0.09

0.62

N2

N 2 CH 4

tective atmosphere (nitrogen) to the temperature of the shop

(111). The last chamber was equipped with air-cooled tubes.

Thick sheets of alloyed and carbon structural steels hot-rolled

and pickled (in order to remove the scale) were annealed. After rolling (before annealing) the steel was somewhat decarburized, but the decarburization was within the standard

value for annealed steels. In order to cool the metal at a regulated rate the second chamber was equipped, like the third

one, with air-cooled tubes (in addition to the heating ones).

For all heat-treatable steels the standards and specifications

envisage that the permissible depth of deearburization after

annealing should not exceed 0.20 - 0.25% of the thickness of

the sheet on each side. The requisite softening of the steels

was controlled by the hardness, the strength parameters, and

in some cases (additionally) by the elongation. The carrier

gas was nitrogen with a purity of 99.98% that arrived from

the units for separation of air in the oxygen plant. In addition,

natural gas was fed into the functional space. The flow rate of

the gas in the zones, the composition of the gas in the functional space, and its moisture content were controlled (the latter by the dew point).

When testing nitrogen atmosphere with natural gas admixtures we studied various temperature modes of moderating annealing: complete, incomplete, and subcritical.

Results of experiments with underannealing are presented in Fig. 2 and can be used for determining the optimum

amounts of the natural gas admixture to nitrogen. The annealed metal has the form of thick (6-mm) sheets of high-alloyed structural steel with 0.25% C and up to 1.5% Cr, Si, Ni,

Fig. 1. Diagram of a three-chamber continuous furnace with a roller hearth

and of the inlets for the components of the protective atmosphere and the cir

eulating flows: 1 ) charging gate; 2 ) knuckle; 3 ) heat gate; 4 ) rollers; 5 ) discharging gate; L 11,111) numbers of the furnace chambers.

CH4, voi. %

n~ vol. %

4.0

CO vol. %

/0,

1.

3.ol&

,.oi/,V

1.

I.C ~

0f

4

0.4

l/

Notation: Vo.s) volume fraction o f natural gas, C) content of carbon in the

foil a / ~ annealing.

N2

O. ~

o.2

Vu.s, vol.%

005\

o

td.p ,oc

td.p

-20'

-30

-50

Vn.g,VOI.*/Q

Fig.2. Composition of the furnace atmosphere and dependence of the dew

point ta.p and the decarburization depth hd,xaco in steel 25KhSNVFA on the

volume fraction of natural gas added to an atmosphere of pure nitrogen:x) the

process temperature is 720C; O) 750C; O) 780"C.

W, and V. With increase in the amount of natural gas in the

furnace atmosphere the concentration of active reducing

components (H 2 , CO) increased. For a large content of natural gas it was close to (but still somewhat lower than) the contents of H 2 and CO 2 in an atmosphere of purified and dried

lean exothermic gas. An 8% addition of natural gas had an

almost full effect on decarburization in the process of heat

372

Yu. M. Brunzel'

90o*c

/sh !05,I

900C

b

650C

I

I

I

I

1

4h

H

i l l -~

1_

Fig. 3. Regimes of true annealing: a) annealing with deceleratedcooling;

b) isothermalmmealing;L 11,111)ambers of the furnacechambers.

treatment. With increase in the amount of natural gas the dew

point (tctp ) changed continuously toward decreased moisture

contents. In the presence of more than 8% natural gas carbon

black appeared in the functional space and on the sheets.

We also studied the parameters of a nitrogen atmosphere

with added natural gas in true annealing (Fig. 3), i.e., at temperatures higher than those considered above. We annealed

thick-sheet alloyed structural steel of grade 30KhSNVFA of

martensitic class. The addition of natural gas to the furnace

amounted (on the basis of the previous experiments) to 6 - 8%

of the fed pure nitrogen.

In true annealing by both studied regimes the rolled stock

was not decarburized in the process of heat treatment, and the

hardness and mechanical properties of the metal corresponded to the requirements of the standard.

It should be noted that the temperature of 900C at which

the steel was annealed is a characteristic hardening temperature for many structural steels. The fact that we obtained positive results in preventing decarburization under conditions of

true annealing allows us to conclude that the atmosphere employed can be used successfully for hardening structural

steels.

We conducted a spheroidizing soft annealing of highcarbon steel (0.85% C) in a nitrogen atmosphere with 8%

natural gas by two regimes, namely, (a) a hold at 760 - 740C

and slow cooling (underannealing) and (b) a hold at 720C

(subcriticai isothermal annealing). Both regimes provided the

requisite softening of the steel. It should be noted that the

high-carbon steel with 0.85% C annealed at a low (subcritical)

temperature was characterized by a hardness of 229 - 170 HB

and a decarburization depth within 0 - 0.25% of the thickness

of the sheet, which met the requirements of the specifications.

In addition, the process of spheroidizing annealing was intensified at a low (subcritical) temperature. The duration of the

subcritical annealing was reduced by 50% compared to the

underannealing (10 and 21 h, respectively). Presumably, this

can be explained by the effect of the intensification of the diffusion mobility of carbon discovered in [3, 4] and hence the

intensification of carbide coagulation at a subcritical temperature. It is important that annealing at a lower temperature

increases the service life of the radiating heating tubes.

An analysis of the results obtained has shown that the optimum amount of added natural gas is about 8% of the consumed nitrogen, which imparts protective properties to the atmosphere formed in the furnace in a wide range of annealing

temperatures and carbon concena'ations in the heat-treated

steel. An optimum addition of natural gas creates in the furnace an atmosphere providing a low rate of carbon mass

transfer in the atmosphere-metal system, i.e., creates a viaually indifferent atmosphere. The preparation of such "stabilized" nonequilibrium atmospheres with a low rate of carbon

mass transfer opens up new possibilities in the development

of protective atmospheres.

Such an approach to the preparation of protective atmospheres differs from the conventional methods, for example,

attainment o f an equilibrium carbon potential in the atmosphere. In the case of a kinetically inactive stabilized atmosphere its carbon potential does not have technological value,

because in slow mass transfer of carbon it can be attained

only for hold times exceeding the duration of actual annealing processes.

It can be seen from the data presented that decarburization can be limited only in the case of a low moisture content

in the furnace (t,tp = - 30C or lower). This requires a high

tightness of the furnace space. Since we used a furnace with a

gate opened for charging, the condition of airtightness was

violated periodically.

In the initial "charging" period (Fig. 4) the composition

of the atmosphere in the furnace worsened due to the introduction of oxidizing components together with the charge.

The reccurrence of charging was determined by the duration

of the entire heat treatment. We could trace the kinetics of the

variation of the concentration of the oxidizing components of

the atmosphere (H20, CO 2 ) after charging a stack of metal

sheets with opening up of the gate. It can be seen that td.p

changes from - 40 to - 8C and the concentration of CO 2 increases considerably. Then the protective properties of the atmosphere are recovered due to the arrival of fresh portions of

dry pure nitrogen. In about 2 h the dew point attains the initial

low value; here the regeneration with respect to CO 2 is completed much earlier.

A favorable circumstance in the operation of this untight

furnace was that the time of the heat treatment exceeded the

period of the "conditioning" of the atmosphere after charging

and that the period in which the atmosphere was worsened

coincided with the period of heating the stack. In the general

case, under other heat treatment regimes lasting for a time

Protective Properties of a Nitrogen Atmosphere with an Admixture of Natural Gas

comparable with the time of "conditioning," it would be impossible to eliminate decarburization. It should be noted that

the airtightness of the furnace was disrupted additionally due

to a defect of its structure, namely, burnout of the radiative

tubes. This hampered further industrial experiments. H o w ever, when the airtightness was satisfactory, we annealed a

considerable amount of metal in this furnace without decarburization and obtained a product meeting the requirements

of the standard.

We can conclude that a nitrogen atmosphere with added

natural gas can be used with a reliable result only in furnaces

with an appropriate airtightness (for example, a muffle furnace with preliminary blowing of the functional space together with the charge by pure nitrogen). In continuous furnaces the suggested atmosphere can be used under the condition that the charge is sluiced at the inlet into the furnace.

CONCLUSIONS

1. A nitrogen atmosphere with an 8 vol.% addition of

natural gas protects structural and tool steels from decarburization hi soft annealing (true, under, suberitical) conducted at

720 - 900C.

2. The atmosphere formed in the furnace in heat treatmerit is characterized by a low rate of mass exchange of carbon with the metal and is virtually indifferent from the standpoint of decarburization for steel with a carbon concentration

ranging between 0.2 and 0.8%.

3. The aforementioned atmosphere can be used under the

condition that the moisture content in the functional space of

the furnace is maintained at a low level (the dew point is at

most -30C), which should be provided by the design of the

furnace.

4. The use of a nitrogen atmosphere with added natural

gas does not require generators of protective gas (for exam-

373

CO; CO 2 ; CH 4 ; H2, vol.%

1.5

I.

-20

~ , ~

-30 J

-4~

( ~""0.,.~ IL=..

I

10

15

30

45

60

I

75

90

105

x, rain

Fig. 4. Measuredcompositionof the furnace atmosphere(volumefractions

of the components)after cl~rging steel sheets into the furnace. Beforecharg

ing, the furnace temperaturewas 760C.

pie, exothermic gas); herre the nitrogen from oxygen plants is

quite suitable.

REFERENCES

1. Yu. M. Brunzel', "Controllable atmospheres," in: Results in Science and Technology. Metals Science and Heat Treatment [in

Russian], Vol. 12, VINITI, Moscow (1978), pp. 143 - 181.

2. W. Hewitt, "Nitrogen-based atmospheres - a user's view," Metals

Mater TechnoL, No. 7, 344 -348 (1983).

3. B. G. Sazonov, "Experimental diffusion activity of steel ifi the

state of pretransformation," Metalloved. Term. Obrab. Met.,

No. 7, 13 - 15 (1990).

4. A. P. Gulyaev, "The pretransformation state in iron alloys," in:

7th. lnt. Congr. Heat Treat. Mater. (Moscow, Dec. 11 - 14 ), Vol.

1, Moscow (I 990), pp. 15 - 22.

You might also like

- Solubility of Solids in Sub - and Supercritical Fluids A ReviewDocument26 pagesSolubility of Solids in Sub - and Supercritical Fluids A ReviewJonatas LopesNo ratings yet

- Modelling Rotary KilnDocument5 pagesModelling Rotary KilnTC Nazan FıçıcıNo ratings yet

- Enhanced Oxidation of The 9%Cr Steel P91 in Water Vapour Containing EnvironmentsDocument27 pagesEnhanced Oxidation of The 9%Cr Steel P91 in Water Vapour Containing EnvironmentsAleš NagodeNo ratings yet

- 06 Electro-10 AngellDocument9 pages06 Electro-10 AngellPravin KumarNo ratings yet

- Material Selection Distillation Column Initial FindingsDocument7 pagesMaterial Selection Distillation Column Initial FindingsAhmet Samet ÖzdilekNo ratings yet

- The Erosion-Corrosion of Alloys Under Oxidizing-Sulphidizing Conditions at High TemperatureDocument8 pagesThe Erosion-Corrosion of Alloys Under Oxidizing-Sulphidizing Conditions at High Temperaturemoney43No ratings yet

- Carbonitriding of Low-And Medium-Carbon Steels in Fluidized BedDocument4 pagesCarbonitriding of Low-And Medium-Carbon Steels in Fluidized BedSinhro018No ratings yet

- Effect of Metallurgy On Pygas Fouling PDFDocument6 pagesEffect of Metallurgy On Pygas Fouling PDFstreamtNo ratings yet

- Fireside Corrosion of Alloys For Combustion Power PlantsDocument11 pagesFireside Corrosion of Alloys For Combustion Power Plantsdealer82No ratings yet

- AC Catalst PTDocument5 pagesAC Catalst PTJarretNo ratings yet

- Article Coal-FiredDocument3 pagesArticle Coal-FiredClaudia MmsNo ratings yet

- Sciencedirect: of MM CoDocument5 pagesSciencedirect: of MM CoSutan PauloNo ratings yet

- DownloadfileDocument8 pagesDownloadfileyo makNo ratings yet

- Table C-2. Energy Efficiency Technologies and Measures Applied To EAF Steel Production in The U.S. (Worrell 1999, 2009 AISI, 2011)Document12 pagesTable C-2. Energy Efficiency Technologies and Measures Applied To EAF Steel Production in The U.S. (Worrell 1999, 2009 AISI, 2011)janfarsa9623No ratings yet

- Combined Steam and CO Reforming of Methane Using Catalytic Nickel Membrane For Gas To Liquid (GTL) ProcessDocument8 pagesCombined Steam and CO Reforming of Methane Using Catalytic Nickel Membrane For Gas To Liquid (GTL) ProcessKeysler PonceNo ratings yet

- Decarburization Kinetics During Annealingil.44.618Document5 pagesDecarburization Kinetics During Annealingil.44.618Suvro ChakrabortyNo ratings yet

- Survey of Worldwide Experience With Metal DustingDocument12 pagesSurvey of Worldwide Experience With Metal Dustingsoubhadra nag100% (1)

- Production of Synthesis Gas: Caalysis Today, 18 (1993) 305-324Document20 pagesProduction of Synthesis Gas: Caalysis Today, 18 (1993) 305-324ainmnrhNo ratings yet

- 10.1016@S0921 34490200010 1Document12 pages10.1016@S0921 34490200010 1Daniel ParraNo ratings yet

- BF01087562Document4 pagesBF01087562Ehab MassoudNo ratings yet

- 1981 Catalytic Combustion Hydrogen1 MaterialsSelection PDFDocument8 pages1981 Catalytic Combustion Hydrogen1 MaterialsSelection PDFAlex CoțNo ratings yet

- The Influences of Alloy Elements On The Carburized Layer in Steels Using Vacuum Carburization in An Acetylene AtmosphereDocument7 pagesThe Influences of Alloy Elements On The Carburized Layer in Steels Using Vacuum Carburization in An Acetylene AtmosphereSumit KumarNo ratings yet

- For English Editing (Done)Document23 pagesFor English Editing (Done)api-3728640No ratings yet

- High Temperature Corrosion Resistance of Metallic Materials in Harsh ConditionsDocument11 pagesHigh Temperature Corrosion Resistance of Metallic Materials in Harsh Conditionsreza chamanfarNo ratings yet

- Homogeneous vs. Catalytic Combustion of Lean Methane-Air Mixtures in Reverse - Ow ReactorsDocument10 pagesHomogeneous vs. Catalytic Combustion of Lean Methane-Air Mixtures in Reverse - Ow ReactorsRohitKumarDiwakarNo ratings yet

- Carbothermic Reduction of Alumina at 1 823 K in The Presence of Molten Steel: A Sessile Drop InvestigationDocument8 pagesCarbothermic Reduction of Alumina at 1 823 K in The Presence of Molten Steel: A Sessile Drop InvestigationNajwa Nurrasyidah Muhd NazriNo ratings yet

- Production of Synthesis GasDocument18 pagesProduction of Synthesis GasGonzalo TitoNo ratings yet

- Temperature-Programmed Oxidation of Coked Noble Metal Catalysts After Autothermal Reforming of N-HexadecaneDocument9 pagesTemperature-Programmed Oxidation of Coked Noble Metal Catalysts After Autothermal Reforming of N-HexadecaneImran KhanNo ratings yet

- Applications Steel: Plexicoke in The VmezuelanDocument8 pagesApplications Steel: Plexicoke in The VmezuelanJose Marval RodriguezNo ratings yet

- 386 389 PDFDocument4 pages386 389 PDFSinhrooNo ratings yet

- Metal Dusting in A Laboratory Environment - Alloying Addition EffectsDocument15 pagesMetal Dusting in A Laboratory Environment - Alloying Addition EffectsClaudia MmsNo ratings yet

- Autothermal Reforming of Simulated Gasoline and Diesel FuelsDocument8 pagesAutothermal Reforming of Simulated Gasoline and Diesel FuelsMOHAMMAD HASHIM KHANNo ratings yet

- 49 2 Philadelphia 10-04 1148Document3 pages49 2 Philadelphia 10-04 1148Niraj_Singh_988No ratings yet

- Fluidized Bed Gasification As A Means of Converting Waste To EnergyDocument28 pagesFluidized Bed Gasification As A Means of Converting Waste To Energyoscop2009No ratings yet

- Addition of Renewable Carbon To Liquid Steel: Plant Trials at Onesteel Sydney Steel MillDocument13 pagesAddition of Renewable Carbon To Liquid Steel: Plant Trials at Onesteel Sydney Steel MillRidwand KartikaNo ratings yet

- Heat Bal CalcDocument39 pagesHeat Bal Calcsklux100% (1)

- Mechanism of NO Formation From Nitrogen in The Combustion of The Coals Used in Sintering ProcessDocument11 pagesMechanism of NO Formation From Nitrogen in The Combustion of The Coals Used in Sintering ProcessRachman KurniaNo ratings yet

- Control of Decarburization of Steel PDFDocument5 pagesControl of Decarburization of Steel PDFBhushan VermaNo ratings yet

- MET 51 1 25 27 OleksiakDocument3 pagesMET 51 1 25 27 OleksiaknemezisnyxNo ratings yet

- EAF Energy OptimizationDocument7 pagesEAF Energy OptimizationAron LopezNo ratings yet

- Chapter 5Document20 pagesChapter 5Oscar Espinosa BonillaNo ratings yet

- Effect of Iron Ore-Coal Pellets During Reduction With Hydrogen and Carbon MonoxideDocument18 pagesEffect of Iron Ore-Coal Pellets During Reduction With Hydrogen and Carbon MonoxideAdrian Cruz EspinozaNo ratings yet

- Fundamentals of Gas Welding and CuttingDocument73 pagesFundamentals of Gas Welding and CuttingDilipNo ratings yet

- Feasibility of In-Situ Combustion of Tar From A Tarmat ReservoirDocument16 pagesFeasibility of In-Situ Combustion of Tar From A Tarmat ReservoirReservorio UagrmNo ratings yet

- Alloy Solutions To Metal Dusting Problems in The Petrochemical Industry PDFDocument8 pagesAlloy Solutions To Metal Dusting Problems in The Petrochemical Industry PDFZeeshan SajidNo ratings yet

- 09 Combustion (Burners, Combustion Systems)Document1 page09 Combustion (Burners, Combustion Systems)ahmed1581973No ratings yet

- Contro Corrosion FactorsDocument10 pagesContro Corrosion Factorsramadoss_alwar7307No ratings yet

- Shot Peening SSDocument23 pagesShot Peening SSnitbabhishekNo ratings yet

- Analysis of Sootblowing Experiments and Research oDocument7 pagesAnalysis of Sootblowing Experiments and Research ouser_nitsNo ratings yet

- RevisionDocument22 pagesRevisionapi-3728640No ratings yet

- 08 Steam Raising: Boiler Operation/designDocument1 page08 Steam Raising: Boiler Operation/designNorman IskandarNo ratings yet

- Coddet2015 PDFDocument8 pagesCoddet2015 PDFjohn paulNo ratings yet

- Lowtemp Didari2009Document8 pagesLowtemp Didari2009Zia Ru'ya HilalNo ratings yet

- Welding of Ni Based Alloys For Energy Applications, J. DuPont WJDocument15 pagesWelding of Ni Based Alloys For Energy Applications, J. DuPont WJdeweyj1No ratings yet

- Annealing of Wire TechDocument4 pagesAnnealing of Wire TechJayabharath KrishnanNo ratings yet

- Effects of Gas Composition and Temperature On The Fluidization Characteristics of Carbon Coated Iron Ore 2016 Powder TechnologyDocument11 pagesEffects of Gas Composition and Temperature On The Fluidization Characteristics of Carbon Coated Iron Ore 2016 Powder TechnologyMuhammad FathurrahmanNo ratings yet

- CT 02 - Salbidegoitia Et AlDocument3 pagesCT 02 - Salbidegoitia Et AlJon Bisu DebnathNo ratings yet

- Coatings Against High Temperature Corrosion Deposited by Metal-Organic Low Pressure Chemical Vapour DepositionDocument6 pagesCoatings Against High Temperature Corrosion Deposited by Metal-Organic Low Pressure Chemical Vapour DepositionmileivandaNo ratings yet

- Alloy Solutions To Metal Dusting Problems in The Chemical Processing IndustryDocument8 pagesAlloy Solutions To Metal Dusting Problems in The Chemical Processing IndustryGiuseppe Di RuoccoNo ratings yet

- Heating IN AN Electrically Conducting Layer Carbon-Containing Particles OFDocument4 pagesHeating IN AN Electrically Conducting Layer Carbon-Containing Particles OFSinhrooNo ratings yet

- Foreign TechnologyDocument1 pageForeign TechnologySinhrooNo ratings yet

- 1006 1009Document4 pages1006 1009SinhrooNo ratings yet

- Effect of Various Kinds of Thermomechanical Treatment On The Structure and Properties of Steels Studied Using Acoustomicroscopic MethodsDocument5 pagesEffect of Various Kinds of Thermomechanical Treatment On The Structure and Properties of Steels Studied Using Acoustomicroscopic MethodsSinhrooNo ratings yet

- Hydrostatic Extrusion at 100°C and Its Effect On The Grain Size and Mechanical Properties of Magnesium AlloysDocument5 pagesHydrostatic Extrusion at 100°C and Its Effect On The Grain Size and Mechanical Properties of Magnesium AlloysSinhrooNo ratings yet

- Phase Composition of Scale of Hot-Rolled Automobile Sheet Steel 08yuDocument2 pagesPhase Composition of Scale of Hot-Rolled Automobile Sheet Steel 08yuSinhrooNo ratings yet

- Hardness OF: CementiteDocument2 pagesHardness OF: CementiteSinhrooNo ratings yet

- 382 385 PDFDocument4 pages382 385 PDFSinhrooNo ratings yet

- 386 389 PDFDocument4 pages386 389 PDFSinhrooNo ratings yet

- 390 394 PDFDocument5 pages390 394 PDFSinhrooNo ratings yet

- 374 376 PDFDocument3 pages374 376 PDFSinhrooNo ratings yet

- Effect of Alloying, Heat Treatment, and Deformation On The Structure and Properties of Damping Z N - A I AlloysDocument4 pagesEffect of Alloying, Heat Treatment, and Deformation On The Structure and Properties of Damping Z N - A I AlloysSinhrooNo ratings yet

- Technology of Heat Treatment: Volume-Surface Hardening of by A High-Speed Water Stream Railroad Transport PartsDocument5 pagesTechnology of Heat Treatment: Volume-Surface Hardening of by A High-Speed Water Stream Railroad Transport PartsSinhrooNo ratings yet

- Hardening From The Liquid StateDocument5 pagesHardening From The Liquid StateSinhrooNo ratings yet

- E 1 - 6 3 8 8 - L o - / Y) - 7 - Zi : Corporation, StreetDocument1 pageE 1 - 6 3 8 8 - L o - / Y) - 7 - Zi : Corporation, StreetSinhrooNo ratings yet

- 9 (I,, TillDocument4 pages9 (I,, TillSinhrooNo ratings yet

- Chemistry CH # 1Document14 pagesChemistry CH # 1Ibrahim IshfaqNo ratings yet

- Feedback The Correct Answer Is: All of The ChoicesDocument20 pagesFeedback The Correct Answer Is: All of The ChoicesEdrian A. MañalongNo ratings yet

- Cambridge International General Certificate of Secondary EducationDocument16 pagesCambridge International General Certificate of Secondary EducationNewton JohnNo ratings yet

- 4 Carbon Residue TestDocument5 pages4 Carbon Residue Testsoran najebNo ratings yet

- Pine Tar C260 Â - TDS (04-12)Document1 pagePine Tar C260 Â - TDS (04-12)Abhinav BansalNo ratings yet

- Group 14 ElementsDocument10 pagesGroup 14 ElementsWorld of ScienceNo ratings yet

- Jaglerod Mono-Di OksidDocument10 pagesJaglerod Mono-Di OksidLiljana DimeskaNo ratings yet

- Alkanes, Alkenes and AlkynesDocument85 pagesAlkanes, Alkenes and AlkynesYoichi Kho100% (1)

- Multiple Choice Questions (MCQ) With Answers On Ecosystems - Page 3 of 5 - ScholarexpressDocument4 pagesMultiple Choice Questions (MCQ) With Answers On Ecosystems - Page 3 of 5 - ScholarexpressIsmatNo ratings yet

- Organic ChemistryDocument128 pagesOrganic ChemistryJoshua lopezNo ratings yet

- Carbon & Halogens Group: Amelia N. Muallil & Angel ChavezDocument9 pagesCarbon & Halogens Group: Amelia N. Muallil & Angel ChavezAngel Rose ChavezNo ratings yet

- Study The Self Rescuer Respirator W-65Document5 pagesStudy The Self Rescuer Respirator W-65Usman Umar TabassumNo ratings yet

- Petcoke CertificateDocument24 pagesPetcoke CertificateakloioNo ratings yet

- @@@ Q and A Fire@@@ (Repaired)Document100 pages@@@ Q and A Fire@@@ (Repaired)Harrison sajorNo ratings yet

- Physical Properties of Group IIIB ElementsDocument18 pagesPhysical Properties of Group IIIB Elementssundus1993No ratings yet

- Cambridge International General Certificate of Secondary EducationDocument16 pagesCambridge International General Certificate of Secondary EducationTshegofatso SaliNo ratings yet

- IGCSE Petroleum Chemistry WS PDFDocument3 pagesIGCSE Petroleum Chemistry WS PDFNazarNo ratings yet

- Chem Unit 1 2019 Sdad IALDocument24 pagesChem Unit 1 2019 Sdad IALHamza Tahir Iqbal100% (1)

- Compiled Equipment & Spell ServicesDocument37 pagesCompiled Equipment & Spell Services1d8100% (4)

- 2016 Test Paper Homi Bhabha (Neev Foundation)Document12 pages2016 Test Paper Homi Bhabha (Neev Foundation)Kunal SonwaneNo ratings yet

- Carbon Film ResistorDocument2 pagesCarbon Film ResistorMarkee ChoiNo ratings yet

- Graco e Xp2 For SaleDocument3 pagesGraco e Xp2 For SaleBoscoNo ratings yet

- Ideal-Gas Properties of Various Substances (Si Units), Entropies at 0.1-Mpa (1-Bar) Pressure, Mole BasisDocument7 pagesIdeal-Gas Properties of Various Substances (Si Units), Entropies at 0.1-Mpa (1-Bar) Pressure, Mole BasisVivek SuryavanshiNo ratings yet

- Carboflam eDocument8 pagesCarboflam eVan SotNo ratings yet

- Science Form 4 Chapter 5 5.4Document19 pagesScience Form 4 Chapter 5 5.4KSSM TSENo ratings yet

- Application of Cold Plasma in Nanofillers Surface Modification For Enhancement of Insulation Characteristics of Polymer Nanocomposites: A ReviewDocument27 pagesApplication of Cold Plasma in Nanofillers Surface Modification For Enhancement of Insulation Characteristics of Polymer Nanocomposites: A ReviewHafiziAhmadNo ratings yet

- Gold Chemistry Leaching Processes CHEMISTRY of The CIP PROCESS CyanideDocument38 pagesGold Chemistry Leaching Processes CHEMISTRY of The CIP PROCESS CyanideAFLAC ............89% (9)

- Manufacturing Process and Material Properties of Carbon and Graphite MaterialsDocument12 pagesManufacturing Process and Material Properties of Carbon and Graphite Materialsdtkraeut100% (1)