Professional Documents

Culture Documents

Slip Test DME

Uploaded by

Ryan GomezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Slip Test DME

Uploaded by

Ryan GomezCopyright:

Available Formats

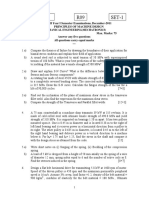

Department of Mechanical Engineering

Subject Code/Name: ME 6503 DESIGN OF MACHNIE ELEMENTS

Year/Sem: III/V/B Sec

Slip Test-1

Marks-20

1. The load on a bolt consists of an axial pull of 10kN together with a transverse shear force

of 5kN. Find the diameter of bolt required according to

(i). Maximum principal stress theory (ii). Maximum shear stress theory

(iii). Maximum principal strain theory

2. A simply supported beam has a concentrated load at the centre which fluctuates from a

value of P to 4P. The span of the beam is 500 mm and its cross section is circular with a

diameter of 60 mm. Taking for the beam material an ultimate stress of 700 MPa, a yield

stress of 500 MPa, endurance limit of 330 MPa for reversed bending, and a factor of

safety of 1.3, calculate the maximum value of P. Take size factor of 0.85 and a surface

finish factor of 0.9.

Department of Mechanical Engineering

Subject Code/Name: ME 6503 DESIGN OF MACHINE ELEMENTS

Year/Sem: III/V/B Sec

Slip Test-2

Marks-20

1. A shaft made of mild steel is required to transmit 100 kW at 300 r.p.m. The supported

length of the shaft is 3 metres. It carries two pulleys each weighing 1500 N supported

at a distance of 1 metre from the ends respectively. Assuming the safe value of stress,

determine the diameter of the shaft.

2. Design a cast iron protective type flange coupling to transmit 15 kW at 900 r.p.m

from an electric motor to a compressor. The service factor may be assumed as 1.35.

The following permissible stresses may be used:

Shear stress for shaft, bolt and key material = 40 MPa

Crushing stress for bolt and key = 80 MPa

Shear stress for cast iron = 8 MPa

Draw a neat sketch of the coupling.

Department of Mechanical Engineering

Subject Code/Name: ME 6503 DESIGN OF MACHINE ELEMENTS

Year/Sem: III/V/B Sec

Slip Test-3

Marks-20

1. A 200 x 150 x 10 mm angle is to be welded to a steel plate by fillet weld as shown in fig. If

the angle is subjected to a static load of 200 kN, find the length of weld at the top and

bottom. The allowable shear stress for static loading may be taken as 75 MPa.

2. An otto cycle engine develops 50 kW at 150 rpm with 75 explosions per minute. The change

of speed from the commencement to the end of power stroke must not exceed 0.5 % of mean

on either side. Design a suitable rim section having width four times the depth so that the

hoop stress does not exceed 4 MPa. Assume that the flywheel stores 15/15 times the energy

stored by the rim and that the work done during power stroke is 1.4 times the work done

during the cycle. Density of rim material is 7200 kg /m3.

You might also like

- DME Model QuesDocument3 pagesDME Model QuesSiva RamanNo ratings yet

- Dme Home Assignment 2019-20Document4 pagesDme Home Assignment 2019-20VenkateshNo ratings yet

- DME QB All UnitsDocument11 pagesDME QB All UnitsPrakash ThangavelNo ratings yet

- DMM - I Question Bank For StudentsDocument11 pagesDMM - I Question Bank For StudentsDushyanthkumar DasariNo ratings yet

- DMM - I Question Bank For StudentsDocument11 pagesDMM - I Question Bank For StudentsDushyanthkumar DasariNo ratings yet

- Dme Model Key 2019Document25 pagesDme Model Key 2019Siva RamanNo ratings yet

- Dme Lab Sheets Ii Iii IvDocument4 pagesDme Lab Sheets Ii Iii IvA58Vikas UbovejaNo ratings yet

- ME-6503 Design of Machine Elements - 16 MarksDocument12 pagesME-6503 Design of Machine Elements - 16 MarksMadhu MithaNo ratings yet

- Me8593 Iq R17Document4 pagesMe8593 Iq R17Vaideesh LJNo ratings yet

- Docs MEDMMIAssignments2013 PDFDocument13 pagesDocs MEDMMIAssignments2013 PDFHafiz Mahar28No ratings yet

- Kings: Department of Mechanical EngineeringDocument14 pagesKings: Department of Mechanical EngineeringAdam AhmadNo ratings yet

- Design of Machine ElementDocument11 pagesDesign of Machine ElementVenkat RajaNo ratings yet

- Mech-V-Design of Machine Elements I (10me52) - AssignmentDocument10 pagesMech-V-Design of Machine Elements I (10me52) - AssignmentArunNo ratings yet

- Machine Design & Industrial Drafting SUBJECT CODE:-2141907 Tutorial - 01Document10 pagesMachine Design & Industrial Drafting SUBJECT CODE:-2141907 Tutorial - 01The AIRS CreationsNo ratings yet

- 9A14503 Principles of Machine DesignDocument8 pages9A14503 Principles of Machine DesignsivabharathamurthyNo ratings yet

- ME2303Document5 pagesME2303balameckNo ratings yet

- Unit - 1Document8 pagesUnit - 1Dhileepan KumarasamyNo ratings yet

- Dmm1 Mar2006Document8 pagesDmm1 Mar2006prk74No ratings yet

- Question Bank Disign of MachineDocument11 pagesQuestion Bank Disign of Machinedipzbarma5No ratings yet

- PMD ModelDocument8 pagesPMD ModelDamodara SatyaDeva MadhukarNo ratings yet

- 9A03504 Design of Machine Elements 21Document8 pages9A03504 Design of Machine Elements 21slv_prasaadNo ratings yet

- UNIT-1: Department of Mechanical EngineeringDocument14 pagesUNIT-1: Department of Mechanical EngineeringManivannan JeevaNo ratings yet

- Design of Machine Elements IDocument8 pagesDesign of Machine Elements Imesab100No ratings yet

- Assignment 1Document3 pagesAssignment 1Anand DevNo ratings yet

- Iat 1 DmeDocument3 pagesIat 1 DmesathishskymechNo ratings yet

- Design of Machine Element ProblemsDocument2 pagesDesign of Machine Element Problemsmaxpayne5550% (1)

- Question For IcDocument4 pagesQuestion For IcPrem MNo ratings yet

- Assignment 01Document3 pagesAssignment 01RamNocturnalNo ratings yet

- Draw The Stress - Strain Diagram For Mild Steel. Explain.: Unit - IDocument9 pagesDraw The Stress - Strain Diagram For Mild Steel. Explain.: Unit - IKomma Hema100% (1)

- Design of Machine Elements 2 Jan 2014Document2 pagesDesign of Machine Elements 2 Jan 2014Prasad C M100% (1)

- Assignment No-01 MEPC-301Document6 pagesAssignment No-01 MEPC-301SANDEEP BUDANIANo ratings yet

- Internal Test 1Document3 pagesInternal Test 1Sathish KumarNo ratings yet

- Machine Design I - ME501 - Sup 011Document2 pagesMachine Design I - ME501 - Sup 011Saurav JainNo ratings yet

- M.D-I Final Tutorial and AssignmentDocument16 pagesM.D-I Final Tutorial and AssignmentnageshNo ratings yet

- dmm1 PDFDocument9 pagesdmm1 PDFmohan_rapaka6095No ratings yet

- Me 331Document5 pagesMe 331arumugam_rNo ratings yet

- ME6503-Design of Machine Elements PDFDocument15 pagesME6503-Design of Machine Elements PDFkarthikNo ratings yet

- Assignment - 2Document4 pagesAssignment - 2vaijanath patilNo ratings yet

- Dme Quest Ut-2Document9 pagesDme Quest Ut-2aadhithyarajasekaranNo ratings yet

- Me1302 Dme 2Document4 pagesMe1302 Dme 2sumikannu100% (1)

- Machine Design Answer KeyDocument16 pagesMachine Design Answer KeyK.KESAVARAJ HICET STAFF MCTSNo ratings yet

- Set No: 1: Code No: V3203/R07Document50 pagesSet No: 1: Code No: V3203/R07Polireddi Gopala KrishnaNo ratings yet

- DomeDocument3 pagesDomevikaskumar1986No ratings yet

- 13 ME AssignmentDocument2 pages13 ME AssignmentMuhammad Sharif JamaliNo ratings yet

- DME - Assignment - IDocument3 pagesDME - Assignment - ISathis KumarNo ratings yet

- EMM7241-Advanced Machine Design Examination June 2016Document8 pagesEMM7241-Advanced Machine Design Examination June 2016Charles OndiekiNo ratings yet

- Me 6503 Design of Machine Elements QBDocument3 pagesMe 6503 Design of Machine Elements QBDeepak SNo ratings yet

- Previous Exam QuestionsDocument8 pagesPrevious Exam QuestionssallyreffatNo ratings yet

- DMM-1 MID-2 Assignment QuestionsDocument3 pagesDMM-1 MID-2 Assignment Questionsuppada AnilNo ratings yet

- Assignment 2 Fluctuating LoadDocument3 pagesAssignment 2 Fluctuating Loadabhishek chaurasiyaNo ratings yet

- Me2303 - Design of Machine ElementsDocument14 pagesMe2303 - Design of Machine ElementsGowtham RajNo ratings yet

- Design of Machine Elements - IIDocument8 pagesDesign of Machine Elements - IIprasaad26No ratings yet

- QuestionsDocument11 pagesQuestionsSundara MoorthyNo ratings yet

- Deisgn of Machine Elements (MTE2202 - 2)Document3 pagesDeisgn of Machine Elements (MTE2202 - 2)MeghaNo ratings yet

- ME 352 - All Problem Class - 14-18 BatchDocument125 pagesME 352 - All Problem Class - 14-18 BatchEntertainment GamingNo ratings yet

- Dynamics of Machinery r10 May-2016Document20 pagesDynamics of Machinery r10 May-2016Srimanthula SrikanthNo ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)