Professional Documents

Culture Documents

JPSR10135

Uploaded by

rdos14Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JPSR10135

Uploaded by

rdos14Copyright:

Available Formats

www.jpsr.

orgJournalofPetroleumScienceResearch(JPSR)Volume3Issue1,January2014

doi:10.14355/jpsr.2014.0301.04

WaterinOilEmulsions:Formationand

Prediction

MervF.Fingas

SpillScience

1717RutherfordPoint,S.W.,Edmonton,AB,CanadaT6W1J6

*1

fingasmerv@shaw.ca

Abstract

The formation of waterinoil emulsions was described.

Research has shown that asphaltenes are the prime

stabilizers of waterinoil emulsions and that resins are

necessarytosolvatetheasphaltenes.Ithasalsobeenshown

that other factors play a role, including the amount of

saturatesandtheoilviscosityanddensity.Essentially,water

droplets injected into the oil by turbulence or wave action

can be stabilized temporarily by the oil viscosity and on a

longertermbasisbyresinsandthenasphaltenes.Depending

onthestartingoilproperties,fourtypesofwaterinoiltypes

are created: mesostable and stable emulsions, entrained

waterinoil and unstable or thosethatdonotform types.

Each type with unique properties was described. For most

oils, loss of lighter components by evaporation is necessary

beforetheoilsformawaterinoiltype.

Itwasnotedthatvariabilityinemulsionformationis,inpart,

duetothevariationintypesofcompoundsintheasphaltene

and resins groups. Certain types of these compounds form

more stable emulsions than others within the same

asphaltene/resingroupings.

Areviewofnumericalmodellingschemesfortheformation

of waterinoil emulsions was given. A recent model was

based on empirical data and the corresponding physical

knowledge of emulsion formation. The density, viscosity,

asphaltene and resin contents were correlated with a

stabilityindex.

Keywords

Oil Spill Emulsification; Emulsion Formation; Emulsion

Modeling

Introduction

Waterinoil emulsions sometimes form after oil

products are spilled. These emulsions, often called

chocolate mousse ormousse by oil spill workers,

canmakethecleanupofoilspillsverydifficult(NAS

2002).Whenwaterinoilemulsionsform,thephysical

properties of oil change dramatically. As an example,

stable emulsions contain from 60 to 80% water, thus

expanding the spilled material from 2 to 5 times the

originalvolume.Mostimportantly,theviscosityofthe

38

oil typically changes from a few hundred mPa.s to

about 100,000 mPa.s,an increase by afactor of500 to

1000.Aliquidproductischangedintoaheavy,semi

solidmaterial.Theseemulsionsaredifficulttorecover

withordinaryspillrecoveryequipment.

Types of Emulsions

FingasandFieldhousefoundthatfourclearlydefined

waterinoiltypesareformedbycrudeoilwhenmixed

with water (Fingas and Fieldhouse 2009, 2011). This

was shown by water resolution over time, by a

number of rheological measurements, and by the

waterinoil products visual appearance, both on the

dayofformationandoneweeklater.Someemulsions

wereobservedoverayear,withthesameresults.The

types are named stable waterinoil emulsions,

mesostable waterinoil emulsions, entrained water,

and unstable waterinoil types. The differences

amongthefourtypesarequitelargebasedonatleast

twowatercontentmeasurementsandfiverheological

measurements. More than 400 oils or petroleum

productswerestudied.

The four waterinoil types formed by crude oils and

petroleum products are stable, mesostable, entrained

and unstable (Fingas and Fieldhouse 2009, 2011;

Fingas2011).

Stable emulsions are reddishbrown semisolid

substanceswithanaveragewatercontentofabout70

80% on the day of formation andabout the same one

weeklater.Stableemulsionsremainstableforatleast

4weeksunderlaboratoryconditions.Allofthestable

emulsions studied remained at least one year. The

viscosity increase following formation averages 400

times the original viscosity and one week later

averages850timestheoriginalviscosity.

Mesostablewaterinoilemulsionsarereddishbrown

viscous liquids with an average water content of 60

65% on the first day of formation and less than 30%

oneweeklater.Mesostableemulsionsgenerallybreak

JournalofPetroleumScienceResearch(JPSR)Volume3Issue1,January2014www.jpsr.org

down to about 20% water content within one week.

Theviscosityincreasesovertheinitialviscosityonthe

dayofformationaveragesafactorof7andoneweek

lateraverages2.

1. The stability index can be simply calculated from

rheological data and that it can be used, along with

somebasicpropertydatasuchasdensityandviscosity,

toclassifythewaterinoiltypes.

Entrained waterinoil types are black viscous liquids

with an average water content of 4050% on the first

day of formation and less than 28% one week later

(Fingas and Fieldhouse 2009). The viscosity increase

over the day of formation averages a multiple of two

andoneweeklaterstillaveragestwo.Unstablewater

inoilemulsiontypesorthoseoilsthatdonotformany

of the other three types are characterized by the fact

thattheoildoesnotholdsignificantamountsofwater

followingmixingwithwater.

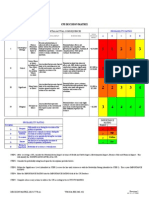

Table1CalculationofaStabilityValue

Stable emulsions, on average, begin at a high level of

water content (about 78%) and lose little water over

one year (Fingas and Fieldhouse 2009). Mesostable

emulsions,ontheotherhand,beginatabout65%and

lose most of this water within a few days. Entrained

waterinoil types pick up only about 40% water and

onlyslowlylosethisoveroneyear.Unstablewaterin

oiltypespickuponlyafewpercentofwaterandthis

does not change much over one year. The apparent

viscosity of stable emulsion increases over the period

of one year and the others generally decline or only

increaseasmallamount.Thus,afterafewmonths,the

stable emulsion will have the greatest viscosity. The

unstabletype of waterinoil products change,

becoming more viscous than elastic. The stable

emulsion has about the same viscous and elastic

componentsovertheyear.Allotherwaterinoiltypes

show a much greater viscous component than the

elasticcomponent.

Calculated Stability

Step

1

2

Carryoutrheologicalstudiesonthewaterinoilproduct

measuringComplexModulusandElasticModulus

Calculatethecrossproduct(Xpr)ofthecomplexmodulusand

elasticmodulusdividedbythestartingoilviscosity

Xpr=

ComplexModulus

StartingOilViscosity

ElasticModulus

StartingOilViscosity

Correctthecrossproduct(Xpr)toyieldStability(sometimes

referredtoasStabilityC)

Stability= ln((Xpr/10000)*(Xpr/10000))

RelationofStabilitiestoWaterinOilType

Calculated

Starting Oil Properties

Minimum

Maximum

Water-in-oil Type

Average Stability

29

Stable

13

10

Mesostable

20

density>0.94or<1.0 Entrained

viscosity>6000

18

density<0.85or>1.0 Unstable

viscosity<100or>800000

AsphaltenesorResins<1.5%

15

20

15

Stability Index

10

Minimum

Average

Maximum

5

0

-5

-10

Stability Indices

-15

Fingas and Fieldhouse (2009) carried out tests of

several indices of stability, a single value that could

provide good discrimination between waterinoil

typesevenonthefirstday.Thiswasnecessaryasthe

water content alone was not entirely discriminating

becausesomeofthewaterlossoccurswithinhoursor

days, especially for mesostable emulsions. It was

found that all of these indices could be used to some

extent to differentiate the four waterinoil types. The

chosenstabilityindexprovedtobetheindexthatbest

differentiatedallfourwaterinoiltypesonthedayof

formation and afterwards. The baseline used was the

water content one week after formation. Figure 1

shows the stability index and the slight overlaps

betweengroups.

-20

Unstable

Meso-stable

Stable

Water-in-oil Type

FIGURE1APLOTOFTHEMINIMUM,AVERAGEAND

MAXIMUMSTABILITYINDEXVALUESFOREACHWATERIN

OILTYPEONTHEDAYOFFORMATION.

Figure 1 shows that the averages are different and

there is little overlap between minimum and

maximumvalues.

Formation of Emulsions

TheRoleofAsphaltenes

Some researchers reported that asphaltenes were a

major factor in waterinoil emulsions more than 40

Thecalculationofthestabilityindex,isshowninTable

Entrained

39

www.jpsr.orgJournalofPetroleumScienceResearch(JPSR)Volume3Issue1,January2014

inorganic solids, waxes and other organic solids, the

main stabilization comes from asphaltenes. Other

workershavenotedthatsolidparticles,suchasclays,

whenpresent,canstabilizeorenhancethestabilityof

emulsions (Sztukowski and Yarranton 2004). This is

trueofemulsionsformedbyclaycontainingbitumens.

These claystabilized emulsions may have differences

from the crude oil and petroleum product emulsions

notedinthispaper.

years ago (Fingas 2011). The specific roles of

asphaltenes in emulsions were not defined until

recently. Currently, the basics of waterinoil

emulsification are now understood to a much better

degree (Sjblom et al. 2003, Czarnecki 2009). The

fundamentalprocessisthatwaterinoilemulsionsare

stabilized by the formation of highstrength visco

elastic asphaltene films around water droplets in oil.

Resins could also form emulsions, but resins do not

form stable emulsions, and actually aid in asphaltene

emulsionstabilitybyactingasasphaltenesolventsand

by providing temporary stability during the time of

the slow asphaltene migration. Overall, a wide

spectrumofscientistshasfoundthatoilcompositionis

the key factor in waterinoil emulsion formation

includingtheamountsandtypesofasphaltene,resin,

andsaturatecontents.

Asphaltenesareaclassofsubstancesdefinedonlyby

their precipitation from oil in pentane, hexane, or

heptane. The specific structure of asphaltenes is

unknown, however, the molecular weight averages

about 750 Daltons or more and there is a planar

aromatic structure surrounded by alkane groups,

some with heteroatoms, S, N and O (Groenzin and

Mullins2007).Studiesofthetimedependencyoffilm

strength by viscosity measurements showed that the

complexmodulusincreasedbyabout2foldbetween2

to 4 hours. This indicated an increased film strength,

probably due to asphaltene aggregation and cross

linking. The mechanism by which emulsions form

begins when asphaltenes migrate to the oilwater

interface,aprocessthatisregulatedbythediffusionof

the soluble asphaltenes. At the interface, the

asphaltenesselfassembletoproduceanelastic,rigid,

stablefilm(Lobatoetal.2007,Zhangetal.2005).This

isthesourceofstabilityforwaterinoilemulsions.

Asphaltenes represent a very broad category of

substances. Graham et al. (2008) separated resins and

asphaltenes into two classes of binding and non

binding, and found that the binding component

formed emulsions, whereas the nonbinding did not.

Czarnecki(2009)analysedseveralfractionsandfound

thatthereweredifferencesintheoxygenandsulphur

contentsofthedifferentfractionsstudied.Further,he

noted that the composition of rag, a persistent

emulsionoftenleftbehindafteranemulsionisbroken,

consisted of multiple emulsion droplets, a number of

water droplets unable to break through the interface

andflocculatedfinesolids.VaradarajandBrons(2012)

found that rag, the residual of a broken emulsion,

contains high proportions of asphaltenes; then noted

that waterinoil emulsions, solidsinoil dispersions,

oilinoil dispersions and oilinwaterinoil multiple

emulsionscoexistintherag.

Recentworkonasphalteneshasshownthatseparation

of asphaltenes into fractions results in more

informationonthefractionthatformsemulsions.Arla

andcoworkers(2007)notedthattheacidfractionsof

the asphaltenes formed more stable waterinoil

emulsionsthansomeothercompounds.

The adsorption of asphaltenes at the wateroil

interface proceeds for a long time and may still

proceedafterayear(FingasandFieldhouse2006).This

impliesthattheadsorptionattheinterfacelowersthe

net energy of the system and is thus favoured

thermodynamically. The bulk concentration of

asphaltenesisimportantanddrivestheamountthatis

adsorbed at the interface. Asphaltenes have their

greatest tendency to adsorb and make the strongest

interfacial film at their limit of solubility, otherwise

they would stay in solution (Fingas and Fieldhouse

2006). Several workers noted that there were

differencesinthestabilityofemulsions,dependingon

the fractions of asphaltenes taken and also by the

amountofasphalteneaggregationpresent(Spieckeret

al.2003,Yangetal.2004).Asphalteneaggregationmay

be an important topic in emulsion stability.

Several scientists reviewed emulsions and concluded

that the asphaltene content is the most important

factor in the formation of emulsions (Gu et al. 2002,

Yarranton et al. 2000, Kilpatrick and Spiecker 2001).

Even in the absence of any other possiblysynergistic

compoundssuchasresins,asphalteneswerefoundto

becapableofformingrigid,elasticfilmswhicharethe

primary agents in stabilizing waterincrude oil

emulsions. The exact conformations by which

asphaltenes organize at oilwater interfaces and the

corresponding intermolecular interactions have not

been elucidated. Workers studying only crude oil

emulsions concluded that waterinoil emulsions are

exclusively stabilized by asphaltenes, although the

specific stability was not measured (Kilpatrick and

Spiecker 2001). Even though the emulsions contain

40

JournalofPetroleumScienceResearch(JPSR)Volume3Issue1,January2014www.jpsr.org

2009).

Asphaltenes may selfassociate in a manner that is

oligimerization rather than simple stacking, implying

thatsomeformofbondingtakesplace.

MethodstoStudyEmulsions

The availability of methodologies to study emulsions

is very important. In the past 15 years, dielectric

methods and rheological methods and many other

methods have been used to study formation

mechanisms and stability of emulsions (Nordi et al.

1991). Standard chemical techniques, including

Nuclear Magnetic Resonance (NMR), chemical

analysistechniques,Nearinfraredspectroscopy(NIR),

microscopy, interfacial pressure, and interfacial

tension, are also being applied to emulsions. These

techniques have largely confirmed findings noted in

thedielectricandrheologicalmechanisms.

TheRoleofResinsandOtherComponents

Severalresearchersstudiedtheroleofresinsinwater

inoil formation (Fingas and Fieldhouse 2009). They

notedthatthemainroleappearstobesolvationofthe

asphaltenes in the oil solution. Research was

conductedwhichshowedthattheadditionofresinsat

ratios of 2:1 (resins:asphaltenes) could increase the

stability of the waterinoil emulsions by as much as

twice as that without the resins (Kilpatrick and

Spiecker 2001). Others have noted that resins and

asphaltenes are somehow correlated in emulsion

stability. Some researchers note that with increasing

asphaltene:resin ratio, the emulsions in well heads

weremorestable(AliandAlqam2000).Theinterfacial

properties of asphaltenes in several Norwegian

offshore crude oils were studied (Nordli et al. 1991).

Asphaltenes were shown to be the agent responsible

forstabilizingthecrudeoilstested,howevertheresins

werealsonotedasbeingimportant.Pereiraetal.(2007)

noted that resins can determine whether asphaltenes

stabilize or destabilize emulsions depending on the

type of resins and asphaltenes. Resin adsorption

experiments were carried out on different substrates

including silica substrates and asphaltenes. Some

resins were found to adsorb much more on the same

surface areas. The experiments showed a high self

interactionandweresuggestedasbeingthekeyfactor

in determining whether the resins would stabilize

asphaltenesagainstaggregationornot.

Mostresearchersstudiedthestabilityofemulsionsby

measuring the amount of water resolved with time

(Fingas and Fieldhouse 2009, Aguilera et al. 2010,

Rondon et al. 2010, Borges et al. 2009). This method

certainlyisthebaselinemethod.Someresearchersalso

subjected the emulsions to centrifugation removing

water,toassessstability.

The use of high pressure NIR has been used by one

group to study asphaltene aggregation of live crude

oils (Kallevik et al. 2000). NIR information on the

amount of asphaltenes and resins was tied to the

emulsionstability.Araujoetal.(2008)studiedtheuse

of NIR and found that NIR was both sensitive to the

water content and droplet size, and models were

proposed to estimate both water content and droplet

size from NIR data. Many of the measurements can

now be intercorrelated. NMR provides the best

methodofmeasuringwaterdropletsizeinemulsions

(Araujoetal.2008).Standardopticaltechniquessuffer

from the fact that the continuous medium, oil, is not

transparent. Therefore, only the surface droplets are

measuredusingopticaltechniques.

Silset and coworkers (2003) noted that many of the

stability differences in emulsions can be explained by

the interactions between asphaltenes and resins. The

authors noted that asphaltenes are believed to be

suspended as colloids in the oil with stabilization by

resins. Each particle is believed to consist of one or

more sheets of asphaltene monomers and absorbed

resins to stabilize the suspension. Under certain

conditions,theresinscandesorbfromtheasphaltenes

leading to increased asphaltene aggregation and

precipitation of the larger asphaltene aggregates.

Severalworkersnotethatthereissignificantinterplay

betweenasphaltenesandresinsandthatresinssolvate

theasphaltenes(Spieckeretal.2003).

The NMR method is known as pulse field gradient

with diffusion editing (PFGDE) NMR (Aichele et al.

2008). Results from recent measurements of a water

inoil emulsion shows a change in droplet size from

the revolution rate of the mixing vessel. The average

water droplet size in one experiment varied with

mixingenergyfromabout12to30micrometers.

Dielectric spectroscopy has been used to study

emulsions. The electrical permittivity of the emulsion

can be used to characterize an emulsion and assign a

stability (Midttun 2000). The Sjblom group has

measuredthedielectricspectrausingthetimedomain

spectroscopy (TDS) technique (Midttun 2000). A

Waxeshavenotbeenfoundtostabilizeoilwaterinoil

emulsionsbuthavebeenfoundtoplayaroleinother

types of emulsions, such as food formulations, but

onlyiftheyaremoltenordeformed(BinksandRocher

41

www.jpsr.orgJournalofPetroleumScienceResearch(JPSR)Volume3Issue1,January2014

willnotformanywaterinoiltypeandwillretainless

than about 6% water. Oils of very high viscosity

(typically > 10,000 mPa.s) will also not form any of

these waterinoil types and thus are classified as

unstable.Thisisprobablyduetotheinabilityofwater

dropletstopenetratetheoilmass.

sampleisplacedattheendofacoaxiallinetomeasure

total reflection. Reflected pulses are observed in time

windows of 20 ns and Fourier transformed in the

frequencyrangefrom50MHzto2Ghz.

Manystudiesontherheologyofemulsionshavebeen

performed (Johnsen and Rnningsen 2003, Spiecker

and Kilpatrick 2004). Emulsions stabilized by

surfactant films (such as resins and asphaltenes)

behave like hard sphere dispersions and display

viscoelastic behaviour. Relaxation time can be

determined for the system, which increases with the

volume fraction of the discontinuous phase. It has

been noted that the emulsion stability is highly

dependent on the rheological properties of the

water/oil interface and that a high elasticity will

increasethelevelofstability.

The discussion in 4.1 and 4.2 above certainly shows

thatasphaltenesandresinscombinetostabilizewater

droplets in emulsions. This can be seen in Figure 2.

Figure 2 shows a simplified plot of oil composition

and viscosity and the types of emulsions that result

from this combination. This figure shows that even a

very simplified presentation can highlight the

importance of the starting oil viscosity and resin and

asphaltenecontents.

The information given in section 4 highlights the

formation process. The start of the process is the

injection of water droplets into the oil mass. This

would typically occur as the result of turbulence or

wave action. This also could occur as the result of oil

injection into water, such as from an underwater

blowout.Onceintheoilmass,thewaterdropletsmay

coalesce and sink to the bottom unless these water

droplets are somehow stabilized. Asphaltenes

probablyresideintheoilintheformofresinsolvated

agglomerates.Theyarenotlikelytostabilizethewater

droplets immediately as the large asphalteneresin

agglomerates migrate too slowly. If, however, the oil

has a viscosity between about 50 to 5000 mPa.s, the

water droplets will move slowly, allowing time for

some chemical stabilization. It is thought that resins,

weaklystabilizethewaterdropletsinitially.Resinsare

alsopolarcompoundsandcanbecomeassociatedwith

polar water. Once stabilized by resins, the large

asphalteneswill move toward the water dropletsand

willformelasticfilmsaroundthewaterdroplets.The

ratio of asphaltene to resins can affect this process. If

thequantityofresinsistoohigh,theywillsolvatethe

asphaltenes to the extent that their migration is

affected and will also create a barrier between the

asphaltenesandthewaterdroplets.Thusinthecaseof

too high resin content, destabilization will also occur.

It is thought that this destabilization is the origin of

mesostableemulsions.

Many researchers studied emulsification by using

model oils or modified crude oils. Other researchers

studiedemulsionsasthinlayersorbydroplets(Ridiet

al.2009).Hemmingsenetal.(2005)studiedthewater

inoilemulsionsformedfrom27crudeoilsofdifferent

origins. They found that there is an increase in

stability as viscosity increases. Viscosity also

correlatedwiththeSARA(Saturates,AromaticsResins

andAsphaltenes)datatakenonthecrudeoil.Askeet

al.(2002)studied16crudesfromtheNorthSeaand5

from North Africa. Stability was measured using the

results from an electric field cell. A voltage was

appliedtothecelluntilcoalesencewasobservedusing

a microscope. The value of the voltage at the critical

point was taken as a measure of stability. Fingas and

Fieldhouse (2011) studied more than 400 oils at

various weathering stages using rheological

measurements.

TheOverallTheoryofEmulsionFormation

The data indicate that the waterinoil types are

stabilized by both asphaltenes and resins, but for

greater stability, resin content should exceed the

asphaltene content slightly (Fingas and Fieldhouse

2009).However,excessresincontent(A/R>about0.6)

apparently destabilizes the emulsion. This does not

considerthequestionofdifferenttypesofasphaltenes

or resins.Ahighasphaltene content (typically > 10%)

increases the viscosity of the oil such that a stable

emulsion will not form. Viscous oils will only uptake

waterasentrainedwaterandwillslowlylosemuchof

this water over a period of about one week. Viscous

oils (typically >1000 mPa.s) will not form stable or

mesostable emulsions. Oils of low viscosity or

withoutsignificantamountsofasphaltenesandresins

42

If the viscosity of the oil is too high, water droplets

cannot penetrate the oil mass to a great extent and

thus emulsions are not formed. At moderate oil

viscosities, about 1000 to 10,000 mPa.s, the water

droplets may be retained by viscosity alone. This is

possibly theoriginoftheentrainedwaterinoiltype.

JournalofPetroleumScienceResearch(JPSR)Volume3Issue1,January2014www.jpsr.org

the form of rag in broken mesostable emulsions.

Thisragformationappearstoprohibittheformation

ofothertypesofemulsions.

Unstable light fuels

Modeling the Formation of Water-in-oil

Emulsions

Ln Viscosity (ln mPas.s)

Stable

2

OlderModels

Stable

Theemulsificationprocessesdescribedabovewerenot

apparentuntilabout15yearsagoandhavesincebeen

translatedintomodellingequations(Fingas2011).The

different waterinoil states dictate that one simple

equation is not adequate to predict formation.

Information on the kinetics of formation at sea and

other modeling data waslessabundant in the past.It

is now known that emulsion formation is a result of

surfactantlikeactionofthepolarasphalteneandresin

compounds. While these are similar compounds that

both behave like surfactants when they are not in

solution, asphaltenes form much more stable

emulsions. Emulsions begin to form when the

required chemical and viscosity conditions are met

and when there is sufficient sea energy. Further, as

pointed out above, three different waterinoil types

are formed, depending on the oil type and its

composition. Some oils do not form any waterinoil

typesandthisfactisstatedtobeafourthtype.

Mesostable

4

Entrained

5

Unstable

Unstable - heavy products

7

50

100

150

200

250

300

400

Resin times Asphaltene Content (%)

FIGURE2APLOTOFTHESTARTINGOILVISCOSITYVERSUS

THEASPHALTENETIMESTHERESINCONTENTOFTHE

STARTINGOIL.THESHADEDREGIONSSHOWALLAREAS

WHERETHEPARTICULARWATERINOILTYPEEXISTS.THIS

SIMPLECOMPARISONSHOWSTHATTHEREARE

APPROXIMATEREGIONSOFSTABILITYWITHONLYTHESE

THREEFACTORS.ANOTHERIMPORTANTFACTORISTHE

ASPHALTENE/RESINRATIOANDTHISFACTORHELPS

SEPARATEANYOVERLAPS.THISPLOTUSESDATAONTHE

DAYOFFORMATION.

Inthedistantpast,therateofemulsionformationwas

assumed to be firstorder with time. This was

approximated with a logarithmic (or exponential)

curve. The physical assumption was that all oils

uptake water on a firstorder basis. Although not

consistentwiththeknowledgeofhowemulsionsform,

this assumption was used extensively in oil spill

models. As was shown in comparisons, this does not

yieldcorrectresults(FingasandFieldhouse2011).The

old models and comparison with newer models are

described in the literature (Fingas 2011). This

comparison shows that most of the older approaches

arenotreliableandcanresultininaccuratepredictions.

TheRoleofWeathering

Most crude oils and petroleum products require

weathering (evaporation) before they will form

emulsions (Fingas and Fieldhouse 2011). Some heavy

oilswillmaketransitionsfromstabletoentrainedand

further on to being unable to form a waterinoil

mixture (unstable heavy oil type) upon weathering.

Mosttypicalcrudeoilsrequireweatheringtomakethe

transition from the basic crude to a mesostable or

stable emulsion. The weathering is necessary to

increasetheviscosityandtheasphaltene/resincontent

to the point where the next waterinoil type is

possible.

In summary, there are two basic ingredients to the

formation of waterinoil types: sea energy, and the

correctchemicalconditionsinanoil.Oftenanoilmust

lose certain components by evaporation before it can

formanemulsionorentrainedwatertype.

NewModels

It should be noted that once a waterinoil type is

formed, it cannot make a transition to another type

even if extensive weathering or mixing takes place.

Thisisfelttobearesultoftheexactingconditionsfor

eachtype.Further,asphaltenesappeartobetiedupin

Several new models for the prediction of waterinoil

emulsions were recently developed by the present

author (Fingas 2011, Fingas and Fieldhouse 2004),

Yetilmezsoyetal.2011).Thesemodelsusedempirical

43

www.jpsr.orgJournalofPetroleumScienceResearch(JPSR)Volume3Issue1,January2014

function. This peak function fit is available from

TableCurvesoftware.

data to predict the formation of emulsions using a

continuous function and employing the physical and

chemical properties of oil. The emulsification

properties of more oils were measured and the

properties of some of the oils in the existing oil set

havebeenremeasured.Thisenablesthemodelstobe

recalculated with sound data on over 400 discreet oil

samples.

The arithmetic to perform the transformation is: 1. if

the initial value is less than the peak value, then the

adjustedvalueisthepeakvaluelesstheinitialvalue;2.

andiftheinitialvalueismorethanthepeakvalue,the

adjusted value is theinitial value less the peak value.

Itshouldbenotedthattheexponentialofdensitywas

used and the natural log of the viscosity. Previous

modeling work had shown that these mathematical

changesarenecessarytoachievehighercorrelations.

The basis of these models is the result of the

knowledge demonstrated abovenamely, that models

arestabilizedbyasphaltenes,withtheparticipationof

resins. Findings of thisgroup and other groups show

thattheentireSARA(Saturates,Aromatic,Resins,and

Asphaltene) distribution effects the formation of

emulsions. The prime stabilizers, asphaltenes and

secondarily resins, are only available for emulsion

formationwhentheconcentrationofthesaturatesand

aromatics are at a certain level and when the density

andviscosityarecorrect.

Having the transformed values, the new model

development proceeds by fitting a multiple linear

equation to the data. The functionalities of square,

logarithmic or exponential curves are achieved by

correlating the straight value of the input properties

plus their expanded values, taken here as the

exponential of the starting value; and their

companded values, the natural log (ln). Each

parameteriscorrelatedwiththestabilityindexinfive

sets of mathematicalstatements. This is similar to the

standard Gaussian expansion regression technique

(Kozachenkoetal.2011).Inthismethod,theregression

isexpanded to functionalities aboveand below linear

until the entire entity is optimized. For example, a

linearfunctionwouldbeincluded,thenasquareanda

square root and so on until tests of the complete

regression show that there are no more gains in

increased expansions. Using this technique, six input

parameters: exponential of density, ln of viscosity,

saturatecontent,resincontent,asphaltenecontentand

the asphaltene/resin ratio (A/R) were found to be

optimal. Thus with 4 transformation and the original

values of these input parameters, there are six times

fiveor30inputcombinations.

The approaches to model development were

implementedandaredetailedintheliterature(Fingas

2011, Fingas and Fieldhouse 2004, Yetilmezsoy et al.

2011). The empirical data including oil content data,

viscosity, density and the resulting waterinoil type

stability were used to develop mathematical

correlation. The value for each parameter was

correlatedinaseriesofmodelsusingDataFit(Oakdale

Engineering), which calculates linear models. A two

step process is necessary as DataFit is not able to

calculatethespecificmathematicalfunctionwithmore

than 2 variables, due to the large number of

possibilities.Thestepstoproducethefirstmodelsare

summarizedinearlierpapers(Fingas2011).Firstofall,

theparametersavailablewerecorrelatedoneatatime.

The latest model used the new stability index as the

target of the correlation. This new approach used a

multiregression program directly, using various

multifunctional transformations of the input oil

propertydata.

Using Datafit, a multiple regression software, a

maximumof20ofthesecouldbetakenatatimetotest

thegoodnessoffit.ValuesthatyieldProb(t)factorsof

greater than 0.9 were dropped until all remaining

factors could be calculated at once. The Prob(t) is the

probability that input can be dropped without

affecting the regression or goodnessoffit. Over

twentyregressionswerecarriedoutuntiltheresulting

model was optimal. The r2, the regression coefficient,

was 0.82, which is high considering many potential

sourcesoferror,etc.

A transformation is needed to adjust the data to a

singularincreasingordecreasingfunction.Regression

methods will not respond correctly to a function that

varies both directly and inversely with the target

parameter. Most parameters have an optimal value

with respect to class, that is, the values have a peak

function with respect to stability or class. After this

correction is made to the values, the regression

coefficientincreases.Thearithmeticconvertsvaluesin

front of the peak to values behind the peak, thus

yielding a simple declining function. The optimal

value of this manipulation is found by using a peak

44

Thepresentmodelwasdevelopedbyaddingmultiple

datasetstoforcetheparameterstolowervalues.The

similarities and differences between older models

include:

JournalofPetroleumScienceResearch(JPSR)Volume3Issue1,January2014www.jpsr.org

1.TheGaussianexpansionissimplifiedfurthertoone

termexpansionandonetermcompression,

Viscistheuntransformednaturallogarithm(ln)ofthe

viscosity,

2. Three terms are also not rationalized in the same

manner as above, this includes density, viscosity and

asphaltene/resin ratio. These are felt to be continuous

functionsastheyareandthuscanbeusedassuch,

Rst is the transformed resin content as calculated in

equation(2),

Ast is the transformed asphaltene content as

calculatedinequation(3),

3.Theinputvaluesarealsouseddirectlyaswellasthe

Gaussianexpansion,

A/Risthe(untransformed)asphaltene/resinratio,

4.Therearetwolessterms,and

Exponential den is the exponential of the exponential

ofdensity,

5. The resulting equation terms are mostly of values

lessthan100,leadingtoagreaterstability.

Exponential (A/R) is the exponential of the

asphaltene/resinratio,

The first step is to transform the input data so that it

formsacontinuousdecliningorincreasingfunction.It

shouldbenotedthatthegreaterthancanalsoberead

asgreaterorequalto.

Ln (natural logarithm) of the natural logarithm of

viscosity,

Density: in g/mL, not transformedjust take the

exponential,abbreviatedDen,

Ln(naturallogarithm)ofthetransformedsaturatesas

calculatedinequation(1),

Viscosity: in mPa.s, nottransformedjusttakethenatural

log,abbreviatedVisc,

Ln (natural logarithm) of the transformed resins as

calculatedinequation(2),

Saturate Content: (%) If the saturate content is lessthan

45, then the saturate content parameter is 45 less the

saturatecontentandifitisgreaterthan45,itbecomesthe

saturate content less 45. The value used in the equation is

thistransformedvalue. (1)

Ln(naturallogarithm)ofthetransformedasphaltenes

ascalculatedinequation(3)

Ln(naturallogarithm)oftheexponentialofdensity,

Ln (natural logarithm) of the (untransformed) (A/R)

ratio.

TABLE2VISCOSITYINCREASESFROMSTARTINGOILANDTYPICALWATER

Resin Content: (%) If the resin content is less than 10,

thentheresincontentparameteris10lesstheresincontent

andifitisgreaterthan10,itbecomestheresincontentless

10.Thevalueusedintheequationisthistransformedvalue.

Ifthevalueoftheresinsiszero,thenthisvalueissettobe

20.(2)

CONTENT

Entrained

Mesostable

Stable

Unstable

Entrained

Mesostable

Stable

Unstable

Asphaltene Content: (5) If the asphaltene content is less

than 4, then the asphaltene content parameter is 4 less the

asphaltenecontentandifitisgreaterthan4,itbecomesthe

asphaltenecontentless4.Thevalueusedintheequationis

thistransformedvalue.Ifthevalueoftheasphaltenecontent

iszero,thenthevalueissettobe20.(3)

Year

2.1

32

991

1.0

Year

6

6

70

5

Thevaluesofstabilitywhichareassignedtoeachclass

aregiveninTable1.Theviscositiesandwatercontents

of the resulting products can be taken as the average

of the types at a given time as shown in Table2. The

regression table is given in Table 3. The calculations

for this model are summarized in Table 4. The new

procedure is that the density and viscosity data are

first applied to remove the unstable and entrained

types.Thecalculationinequation4isusedtoseparate

thestableandmesostabletypes.

A/RorAsphaltene/ResinRatio:nottransformed

The class of the resulting emulsion is then calculated

asfollows:

Stability = 15.3 +1010*Den 3.66*Visc +0.174*Rst

0.579*Ast +34.4*A/R +1.02*exp(Den) 7.91*exp(A/R)

2740*ln(Den) +12.2*ln(Visc) 0.334*ln(Sst) 3.17*ln(Rst)

+0.99*ln(Ast)2.29*ln(A/R)

(4)

Where:Stabilityisthestabilityoftheresultingwater

inoiltypeonthedayofformation,

A comparison of data is given in Table 5. The

comparison of calculated stability compared to actual

Denistheuntransformedexponentialofthedensity,

Viscosityincreaseon

FirstDay

Week

1.9

1.9

7.2

11

405

1054

0.99

1.0

Typicalwatercontent

FirstDay

Week

44.5

27.5

64.3

30

81

78

6.1

6

45

www.jpsr.orgJournalofPetroleumScienceResearch(JPSR)Volume3Issue1,January2014

stability (measured by rheology) shows good

correlation. This shows how the new model can

predictthewateruptake.

Visc

takenaturallogarithmofviscosity

Divideasphaltenecontentbyresin

content

Rst

Asphaltenecontent

Ast

FourthStepCalculateGaussianExpansionSteps

Exponentialofresincontent

ExponentialofA/Rratio

exp(Rst)

exp(A/R) exponentialofA/Rratio

naturallogarithmofdensity

naturallogarithmofviscosity

naturallogarithmofsaturates

naturallogarithmofresins

naturallogarithmofasphaltenes

naturallogarithmofA/Rratio

ln(Den)

ln(Visc)

ln(Sst)

ln(Rst)

ln(Ast)

ln(A/R)

*zerosmustbepurgedfromnumbersastheycauseproblemsin

divisionandwithlogarithmicexpressions

46

stable

stable

stable

stable

stable

stable

stable

stable

stable

stable

stable

stable

stable

stable

stable

stable

stable

stable

meso

stable

stable

stable

stable

stable

stable

stable

stable

stable

stable

stable

0

Neptune Spar (Viosca Knoll 826) 22.6 stable

0

Platform Gail (Sockeye)

stable

0

Point Arguello Comingled

stable

9.05 stable

Point Arguello Comingled

0

Point Arguello Heavy

stable

0

Point Arguello Light

stable

10.2 stable

Point Arguello Light

19 stable

Point Arguello Light

28.3 stable

Point Arguello Light

9.32 stable

Prudhoe Bay (1995)

0

Sockeye

stable

12.5 stable

Sockeye

22.1 stable

Sockeye

0

Sockeye Comingled

stable

0

Sockeye Sour

stable

26.9 stable

Sockeye Sweet

0

Takula

stable

Takula

11 stable

Takula

18 stable

24 stable

Viosca Knoll 826

35.2 Stable

Viosca Knoll 990

stable

Oil

stable

stable

stable

meso

stable

stable

stable

stable

stable

stable

stable

stable

stable

stable

stable

stable

stable

stable

stable

stable

stable

GreenCanyon200

Green Canyon 65

Green Canyon 65

Green Canyon 65

Gulfaks

Hibernia[2000]

Hibernia[2000]

exponentialoftheexponentialof

density

exponentialofrationalizedresin

content

exp(Den)

stable

Carpenteria

Carpenteria

Dos Cuadras

Dos Cuadras

Gail E019

Garden Banks 387

Genesis

Green Canyon 184

replacezero'satrationalizationstage

with'20.1'

replacezero'satrationalizationstage

with'20.1'

Exponentialofdensity

stable

Vis

co

sit

y

Sa

tur

ate

s

Ar

om

ati

cs

Re

sin

s

As

ph

alt

en

es

Ac

tua

lS

tab

ilit

y

Mo

de

l P

%

156

14

29

46

103

254

1350

152

1410

4530

136

676

1442

735

9583

272

43

6118

6359

195

402

187

406

533

4988

3250

22

76

183

671

55

45

163

628

550

821

321

110

844

3148

325

91

41

51

54

60

57

56

51

56

44

40

56

46

40

33

27

38

67

62

60

52

58

61

39

36

31

32

57

54

48

45

51

48

44

39

34

38

48

65

62

60

59

62

27

39

32

24

25

25

28

29

40

39

32

32

35

31

33

38

22

26

28

34

13

29

28

25

33

32

27

30

31

32

35

31

32

34

32

29

33

22

24

25

29

28

26

6

7

8

8

8

10

7

8

8

10

9

12

24

29

14

8

9

10

11

19

8

21

23

19

17

9

9

12

12

10

13

15

15

21

20

14

8

10

11

8

8

6

3

6

8

9

10

11

7

8

13

3

13

14

12

12

11

4

4

3

3

10

2

12

16

17

19

7

8

9

11

3

8

9

11

13

13

6

2

4

4

3

2

19.0

23.3

21.0

27.2

19.9

15.1

9.9

14.8

10.2

7.0

6.7

4.0

5.2

10.1

0.9

11.4

20.9

3.6

0.6

9.5

4.0

15.6

3.6

10.6

2.0

1.4

22.7

24.3

20.9

10.7

19.0

29.1

17.3

12.3

2.0

0.5

11.0

17.8

10.5

5.1

9.3

9.5

4.9

24.1

25.0

23.8

20.0

16.5

7.4

16.0

5.2

1.5

7.2

8.9

5.1

2.8

-6.2

9.1

26.4

7.1

0.7

6.0

6.2

7.9

5.5

5.8

-1.3

1.2

23.5

17.5

11.7

9.0

7.0

15.6

10.3

6.8

4.2

3.1

6.4

18.4

9.9

5.8

7.9

10.7

Table 5 (Ctd.) Comparison of Model Predictions with Actual Values

Asphaltene/Resinratio

A/R

SecondStepRationalization(convertsunitstosimpledecliningorincreasingfunctions)

Saturatecontent

Sst

if(S<45,45S,S45)

Resincontent

Rst

if(R<10,10R,R10)

Asphaltenecontent

Ast

if(A<4,4A,A4)

ThirdStepParsingZerosfromSARAnumbers*

Resincontent

stable

stable

mPa.s

Lucula

MARS - TLP

MARS - TLP

MARS - TLP

Mississippi Canyon 72

Mississippi Canyon 807

Mississippi Canyon 807

naturallogarithm(ln)ofthe

exponentialofdensity

naturallogarithm(ln)ofthenatural

logarithmofviscosity

naturallogarithm(ln)ofthe

rationalizedsaturatecontent

MississippiCanyonBlock807

MississippiCanyonBlock807

MississippiCanyonBlock807

MorpethEW921

MorpethEW921

North Slope (Middle Pipeline)

North Slope (Northern Pipeline)

North Slope (Southern Pipeline)

Prudhoe Bay (1995)

Prudhoe Bay (1995)

naturallogarithm(ln)ofthe

rationalizedresincontent

Sakhalin

Santa Clara

Santa Clara

Santa Clara

Sockeye (2000)

Sockeye (2000)

Sockeye Sweet

Waxy Light Heavy Blend

Waxy Light Heavy Blend

West Texas (2000)

West Texas (2000)

naturallogarithm(ln)ofthe

rationalizedasphaltenecontent

naturallogarithm(ln)oftheA/Rratio

10.3

14.9

11.2

20.3

24.4

23.3

23.1

38.2

30.7

7.7

13.1

22.9

29.8

22.8

33.5

10.7

8.42

17.2

26.2

18

0

8.67

11.8

22.4

35.9

15.2

24.0

30.5

31.1

29.6

0

27.3

42.0

0

11.4

21.6

meso

0

7

meso

17.5

12

19.6

21

31

meso

meso

meso

meso

meso

meso

meso

meso

meso

meso

meso

meso

meso

meso

meso

meso

meso

meso

meso

meso

meso

meso

meso

meso

meso

meso

meso

meso

meso

meso

meso

meso

meso

meso

meso

meso

meso

meso

meso

meso

meso

As

ph

alt

en

es

Ac

tua

lS

tab

ilit

y

Mo

de

l P

takeexponentialofdensity

stable

stable

Neptune[2009]

Units

g/mL

mPa.s

%

%

%

Description

Den

stable

(@15C)

0.9372

0.8658

0.8783

0.8817

0.8961

0.9077

0.9200

0.9143

0.9883

1.0032

0.8993

0.9344

0.9423

0.9356

0.9674

0.9230

0.8574

0.8904

0.8970

0.9095

0.9244

0.8986

0.9297

0.9248

0.9528

0.9447

0.8739

0.8979

0.9132

0.9289

0.9048

0.8965

0.9166

0.9264

0.9350

0.9409

0.9229

0.8637

0.8860

0.8961

0.9067

0.8905

Re

sin

s

Viscosity

Symbol

D

V

S

R

A

stable

Cook Inlet - Swanson River

Fuel Oil #5 (2000)

Fuel Oil #5 (2000)

Garden Banks 426

Hebron M-04

Hebron M-04

Hondo

Hondo

Lago Treco

Lucula

Lucula

Malongo

Mississippi Canyon 72

Table4SummaryofCalculationsforModel

BasicInputs

Density

Viscosity

Saturatecontent

Resincontent

Asphaltenecontent

FirstCalculation

Density

stable

Canolimon

Canolimon

Canolimon

Canolimon

exp

ln

Viscosity (ln)

adjusted

Resins

Asphaltenes adjusted

A/R

expDensity exp

expA/R

ln

lnDensity

lnViscosity

lnSaturates

lnResins

lnAsphaltenes

lnA/R

Constant

stable

Arabian Light

Arabian Medium

Math

Applied

Density

stable

Vis

co

sit

y

Sa

tur

ate

s

Ar

om

ati

cs

0.0

0.00002

0.079

0.00005

0.00035

0.0089

0.011

0.0

0.0155

0.0687

0.182

0.00594

0.212

0.713

Input

Variable

0

0

0

0

6.97

13.5

21.0

39.7

0

7.25

37.7

8.8

16.4

0

16.7

0

0

15.4

11.8

26.2

ctu

al

St

ab

ilit

y

Mo

de

lP

red

ict

ion

De

ns

ity

Prob(t)

AlbianHeavySynthetic

Oi

lE

va

po

rat

ion

A

Regression Variable Results

Standard

Variable Value

t-ratio

Error

a

1006

210

4.79

b

3.66

0.839

4.36

c

0.175

0.100

1.76

d

0.579

0.142

4.08

e

34.4

9.56

3.60

f

1.02

0.389

2.63

g

7.91

3.10

2.55

h

2740

535

5.12

i

12.2

5.01

2.43

j

0.334

0.183

1.82

k

0.317

0.237

1.34

l

0.990

0.358

2.76

m

2.29

1.83

1.25

n

15.3

41.6

0.37

Oi

lE

va

po

rat

ion

A

Oil

Table 3 Regression Results for the Emulsification Model

ctu

al

St

ab

ilit

Mo

y

de

lP

red

ict

ion

De

ns

ity

Table 5 Comparison of Model Predictions with Actual Values

(@15C)

mPa.s

0.9299

0.9482

meso 0.9270

entrain 0.9359

meso 0.9346

meso 0.9287

meso 0.9364

meso 0.9043

meso 0.9071

meso 0.9509

meso 0.9559

meso 0.9716

meso 0.9129

stable 0.8893

meso 0.9075

stable 0.8821

stable 0.9122

meso 0.9331

stable 0.9520

stable 0.8966

stable 0.8894

stable 0.9187

stable 0.9202

meso 0.9562

meso 0.9693

meso 0.9426

meso 0.9619

meso 0.9418

meso 0.9402

meso 0.9431

stable 0.8837

meso 0.9352

meso 0.9201

meso 0.9202

meso 0.9479

meso 0.9672

meso 0.9354

meso 0.9537

stable 0.9089

meso 0.9582

meso 0.9749

stable 0.8827

meso 0.8973

755

3426

187

741

1357

579

543

117

121

457

800

4250

202

99

773

5214

93

404

2237

76

41

127

165

396

1472

551

3697

900

748

961

22

623

52

304

1859

22760

761

2720

103

2002

17280

38

112

40

31

42

41

59

46

48

54

77

38

36

32

46

61

56

64

55

50

49

58

47

39

70

66

63

66

60

42

44

42

53

43

56

36

32

28

50

47

50

32

30

76

75

30

36

31

31

21

40

28

34

13

42

44

45

42

29

29

23

28

30

29

32

35

41

16

17

16

18

19

38

37

39

34

38

32

22

28

32

18

17

32

38

35

15

14

19

22

20

19

12

13

21

11

9

15

15

16

12

8

11

8

11

13

13

9

12

13

8

10

11

10

13

12

12

13

10

15

10

29

27

23

18

19

13

24

28

8

10

11

11

7

9

8

2

3

1

1

5

4

8

1

2

4

4

6

7

10

2

6

7

6

7

10

6

8

7

7

7

4

5

2

13

13

17

15

16

5

6

6

1

2

meso

meso

-1.0

-4.8

-9.1

-4.2

6.8

-9.3

-5.2

1.5

3.9

3.3

0.0

-5.6

2.1

10.4

9.4

-0.8

-0.4

-4.4

-5.2

-0.8

3.1

-0.8

1.5

-0.6

-2.8

-0.3

-3.2

0.7

1.2

2.5

4.5

3.6

8.4

-7.7

5.3

-8.5

2.9

-1.3

4.3

-9.9

-10.2

6.3

7.9

4.7

-1.7

6.2

3.3

2.9

0.3

2.0

4.6

3.5

0.9

-1.1

-3.7

3.3

11.0

6.1

11.2

10.3

5.3

1.6

8.5

16.4

9.1

11.5

1.7

1.5

1.6

-2.0

3.0

3.9

2.4

14.6

2.8

1.7

6.6

-0.7

-7.2

5.1

0.5

9.8

-2.3

-7.8

11.3

4.9

JournalofPetroleumScienceResearch(JPSR)Volume3Issue1,January2014www.jpsr.org

whichinturnpredictseitheranunstableorentrained

waterinoilstateoramesostableorstableemulsion.

ModelCertainty

Itisnotedthatthereislittleerrorformorestabletypes,

butmoreerrorfortheunstabletypesorthosethatdo

not form any of the otherthree types.This was noted

in previous modeling as well (Fingas 2011). It is

suspectedthatthereasonsforthisare:

The new model can provide accurate prediction of

class about 90% of the time. This can be compared

withtheoldermodelswherethefitvariedfromabout

60 to 80% ofcases(Fingas andFieldhouse,2011). The

new procedure is that the density and viscosity data

arefirstappliedtoremovetheunstableandentrained

types.Thecalculationinequation4isusedtoseparate

thestableandmesostabletypes.Themajorinaccuracy

lies with the unstable types because of the fact that

there are three distinct types of oils or fuels in this

class, each very different, as well as the possible

presence of emulsion breakers or asphaltene

suspendersintheoils.

a)Unstabletypesorthoseoilsthatdonotformanyof

theotherthreetypes,generallyconsistofthreewidely

separateclassesofoilsorfuels,verylightoilssuchas

thefuelswhichhavelittleornoresinsorasphaltenes;

those very heavy oils which are so viscous that they

will not uptake water; and those oils that have the

incorrectratiooramountsofresinsorasphaltenes.Itis

difficult to mathematically incorporate all three of

thesevariancesintoonegrouping.Thenewprocedure

is that the density and viscosity dataare first applied

to remove the unstable and entrained types. The

calculationinequation4isusedtoseparatethestable

andmesostabletypes.

REFERENCES

Aguilera,B.M.,J.G.Delgado,andA.L.Cardenas,Waterin

Oil Emulsions Stabilized by Asphaltenes Obtained from

b) Some of the oils may be able to form different

waterinoil types, but emulsion inhibitors or

asphaltene suspenders have been added to the

products. These types of oils make prediction very

difficult,and

Venezuelan Crude Oils,JournalofDispersionScienceand

Technology,pp.359363,2010.

Aichele, C.P., W.G. Chapman, L.D. Rhyne, H.J. Subramani

andW.V.House,AnalysisoftheFormationofWaterin

OilEmulsion,Energy&Fuels,pp.36743680,2009.

c)Therearemanydifferentasphaltenessomeofwhich

makemuchmorestableemulsionsthanothers.Recent

workhasshownthattherearehundredsofasphaltene

subcomponents varying very much in composition

and molecular size (Fingas 2011). Thus the percent of

asphaltenes(orresins)certainlydoesnottellthewhole

storyabouttheemulsionstabilizers.

Ali,M.F.andM.H.Alqam,TheRoleofAsphaltenes,Resins

and Other Solids in the Stabilization of Water in Oil

EmulsionsanditsEffectsonOilProductioninSaudiOil

Fields,Fuel,Vol.79,pp.13091316,2000.

Araujo,A.M.,L.M.Santos,M.Fortuny,R.L.F.V.Melo,R.C.C.

Coutinho,andA.F.Santos,EvaluationofWaterContent

TheregressiontableisgiveninTable3.

and Average Droplet Size in WaterinCrude Oil

Conclusions

Emulsions by Means of NearInfrared Spectroscopy,

Energy&Fuels,pp.34503458,2008.

Waterinoil emulsions are formed as a result of

asphalteneandresinsurfactantcharacteristicsinoilof

moderate viscosity (50 to 2000 mPa.s). Four types of

waterinoil products are formed: stable and meso

stable emulsions, entrained water in oil and unstable

(orthosethatdonotformanyoftheotherthreetypes)

types. Each of these types has unique characteristics

and is thought to be nonconvertible to other types

onceformed.

Arla, D., A. Singuin, T. Palermo, C. Hurtevent, A. Graciaa,

andC.Dicharry,InfluenceofpHandWaterContenton

the Type and Stability of Acidic Crude Oil Emulsions,

Energy&Fuels,pp.13321342,2007.

Aske, N., H. Kallevik and J. Sjblom, WaterinCrude Oil

Emulsion Stability Studied by Critical Electric Field

Measurement:

to

PhysicoChemical

Parameters and NearInfrared Spectroscopy, Journal of

Theknowledgethatwaterinoiltypesexistandthata

new scheme to classify their stability, herein called

stability, enables the development of new and much

more accurate emulsion formation models. The

density, viscosity, asphaltene and resin contents are

used to develop a regression equation to stability,

Correlation

PetroleumScienceandEngineering,Vol.36,pp.117,2002.

Binks,B.P.andA.Rocher,EffectsofTemperatureonWater

inoilEmulsionsStabilizedSolelybyWaxMicroparticles,

ColloidsandInterfaceScience,94,2009.

Borges,B.M.Rondon,O.Sereno,andJ.Asuaje,Breakingof

47

www.jpsr.orgJournalofPetroleumScienceResearch(JPSR)Volume3Issue1,January2014

WaterinCrudeOilEmulsions:InfluenceofSalinityand

DeterminationofAsphaltenesandResinsinSolutionby

WaterOil Ratio on Demulsifier Action, Energy&Fuels,

Means of NearInfrared Spectroscopy: Correlations to

pp.15681574,2009.

EmulsionStability,JournalofColloidandInterfaceScience,

Czarnecki,J.,StabilizationofWaterinCrudeOilEmulsions.

Vol.225,pp.494504,2000.

Part2,Energy&Fuels,pp.12531257,2009.

Kilpatrick,P.E.,andP.M.Spiecker,AsphalteneEmulsions,

Fingas, M. and B. Fieldhouse, Formation of Waterinoil

in Encyclopedic Handbook of Emulsion Technology, Ed. J.

Emulsions and Application to Oil Spill Modelling,

Sjoblom, Marcel Dekker, Inc., New York, pp. 707730,

JournalofHazardousMaterials,Vol.107,pp.3750,2004a.

2001.

Fingas, M. and B. Fieldhouse, Studies on Crude Oil and

Kozachenko,Y.,A.Olenko,A.,andO.Polosmak,Uniform

Petroleum Product Emulsions: Water Resolution and

Convergence of Wavelet Expansions of Gaussian

Rheology, Colloids and Surfaces A: Physicochemical and

Random Processes, Stochastic Analysis and Applications,

EngineeringAspects,Vol.333,pp.6781,2009.

29(2),pp.169184,2011.

Fingas, M., Models for WaterinOil Emulsion Formation,

Lobato,M.D.,J.M.Pedrosa,A.R.Hortal,B.MartinezHaya,R.

Chapter10,inOilSpillScienceandTechnology,M.Fingas,

LebronAguilar, and S. Lago, Characterization and

Editor,ElsevierPublishers,NY,NY,pp.243273,2011.

LangmuirFilmPropertiesofAsphaltenesExtractedfrom

Fingas,M.,B.Fieldhouse,StudiesonWaterinoilProducts

ArabianLightCrudeOil,ColloidsandSurfaces,A,pp.72

79,2007.

from Crude Oils and Petroleum Products, Mar.Pollut.

Midttun, O., H. Kallevik, J. Sjoblom and O.M. Kvalheim,

Bull.,Vol:64,pp.272283,2011.

Multivariate Screening Analysis of WaterinOil

Fingas,M.F.andB.Fieldhouse,AReviewofKnowledgeon

EmulsionsinHighExternalElectricFieldsasStudiedby

WaterinoilEmulsions,AMOP,pp.126,2006

MeansofDielectricTimeDomainSpectroscopy,Journal

Graham, B.F., E.F. May and R.D. Trengove, Emulsion

ofColloidandInterfaceScience,Vol.227,pp.262271,2000.

InhibitingComponentsinCrudeOil,Energy&Fuels,pp.

NAS, Oil in the Sea III, Inputs, Fates and Effects, National

10931099,2008.

Research

Groenzin,H.andO.C.Mullins,AsphalteneMolecularSize

and

Weight

by

TimeResolved

Council,

National

Academies

Press,

Washington,D.C.,2002

Fluorescence

Asphaltenes, Heavy Oils and

Nordli,K.G.,J.Sjblom,andP.Stenius,WaterinCrudeOil

Petroleomics,O.C.Mullins,E.Y.Sheu,A.Hammami,and

Emulsions from the Norwegian Continental Shelf: 4.

A.G.Marshall,Editors,SpringerPublications,pp.1740,

Monolayer Properties of the Interfacially Active Crude

2007.

Oil Fraction, Colloids and Surfaces, Vol. 57, pp. 8398,

Depolarization,

in

1991.

Gu,G.,Z.Xu,K.NandakumarandJ.H.Masliyah,Influence

of WaterSoluble and WaterInsoluble Natural Surface

Pereira, J.C., I. Lopez, R. Salas, F. Silva, C. Fernandez, C.

ActiveComponentsontheStabilityofWaterinToluene

Urbina, and J.C. Lopez, Resins, The Molecules

DilutedBitumenEmulsion,Fuel,Vol.81,pp.18591869,

Responsible for the Stability/Instability Phenomena of

2002.

Asphaltenes,Energy&Fuels,pp.13171321,2007.

Hemmingston, P.V., A. Silset, A. Hannisdal and J. Sjblom,

Ridi, F., N. Verdal, P. Balioni and E.Y. Sheu, Phase

Emulsions of Heavy Crude Oils. I: Influence of

Separation Kinetics of Maya Asphaltene Emulsion and

Viscosity, Temperature and Dilution, Journal of

FreetoboundWaterTransformation,Fuel,319,2009.

Dispersion Science and Technology, Vol. 26, pp. 615627,

Rondon, M., J.C. Pereira, P. Bouriat, A. Graciaa, J. Lachaise

and JL. Salagar, Breaking of WaterinCrudeOil

2005.

Johnsen, E.E. and H.P. Rnningsen, Viscosity of Live

Emulsions.2.InfluenceofAsphalteneConcentrationand

WaterinCrudeOil Emulsions: Experimental Work and

Diluent Nature on Demulsifier Action, Energy & Fuels,

Validation of Correlations, Journal of Petroleum Science

pp.702707,2008.

Silset, A., A. Hannisdal, P. Hemmingsen, and J. Sjblom,

andEngineering,Vol.38,pp.2336,2003.

Emulsions of Heavy Crude Oils. II. Viscous Responses

Kallevik, H., O.M. Kvalheim and J. Sjblom, Qualitative

48

JournalofPetroleumScienceResearch(JPSR)Volume3Issue1,January2014www.jpsr.org

and

Their

Influence

Measurements,

Journal

on

of

Emulsion

Dispersion

Stability

Yang, X., H. Hamza and J. Czarnecki, Investigation of

Science

SubfractionsofAthabascaAsphaltenesandTheirRolein

andTechnology,1432,2010.

EmulsionStability,EnergyFuels,pp.770779,2004.

Sjblom,J.,N.Aske,I.H.Auflem,O.Brandal,T.E.Havre,O.

Yarranton, H.W., H. Hussein and J.H. Masliyah, Waterin

Saether, A. Westvik, E.E. Jonsen and H. Kallevik, Our

Hydrocarbon Emulsions Stabilized by Asphaltenes at

CurrentUnderstandingofWaterinCrudeOilEmulsions:

Low Concentrations, Journal of Colloid and Interface

Recent Characterization Techniques and High Pressure

Science,Vol.228,pp.5263,2000.

Yetilmezsoy, K, M. Fingas, and B. Fieldhouse, Modeling

Performance, Advances in Colloid and Interface Science,

WaterinOil Emulsion Formation Using Fuzzy Logic,

Vol.100102,pp.399473,2003.

Journal of MultipleValued Logic Soft Computing, pp. 125,

Spiecker, P.M. and P.K. Kilpatrick, Interfacial Rheology of

2011,2011.

Petroleum Asphaltenes at the OilWater Interface,

Zhang, L.Y., R. Lopetinsky, Z. Xu and J.H. Masliyah,

Langmuir,Vol.20,pp.40224032,2004.

Spiecker, P.M., K.L. Gawrys, C.B. Trail and P.K. Kilpatrick,

Asphaltene Monolayers at a Toluene/Water Interface,

EffectsofPetroleumResinsonAsphalteneAggregation

EnergyFuels,1330,2005

Merv F. Fingas scientist living in Edmonton, Alberta,

Canada, Dr. Fingas has a PhD in environmental physics

fromMcGillUniversity(1996),threemastersdegrees;thatis,

chemistry (1984), business and mathematics (1978), all from

University of Ottawa. He also has a bachelor of science in

Chemistry from Alberta (1974) and a bachelor of arts from

Indiana(1968).

and WaterinOil Emulsion Formation, Colloids and

Surfaces,Vol.220A,pp.927,2003.

Spiecker, P.M., K.L. Gawrys, C.B. Trail and P.K. Kilpatrick,

EffectsofPetroleumResinsonAsphalteneAggregation

and WaterinOil Emulsion Formation, Colloids and

Surfaces,Vol.220A,pp.927,2003.

He was Chief of the Emergencies Science Division of

Environment Canada for over 30 years in Ottawa, Ontario

andiscurrentlyworkingonresearchinEdmonton,Western

Canada as an independent researcher. He has published

more than 840 papers. Merv has prepared 7 books on spill

topicsandisworkingon2others.

Sztukowski, D.M. and H.W. Yarranton, Characterization

andInterfacialBehaviourofOilSandsSolidsImplicated

in Emulsion Stability, Journal of Dispersion Science and

Technology,Vol.25,pp.299310,2004.

Varadaraj,R.andBrons,C.MolecularOriginsofCrudeOil

Dr. Fingas is a member of the American Chemical Society

and the American Association for the Advancement of

Science. He has been active in the American Society for

TestingandMaterials.

Interfacial Activity. Part 4: Oilwater Interface Elasticity

and Crude Oil Asphaltene Films, Energy and Fuels, 26

(12),pp.71647169,2012.

49

You might also like

- Pendiente Buscar Standares PDFDocument4 pagesPendiente Buscar Standares PDFrdos14No ratings yet

- Documento 1Document15 pagesDocumento 1rdos14No ratings yet

- PP010000734 02Document2 pagesPP010000734 02rdos140% (1)

- Documento de Prueba para Ver Que TalDocument4 pagesDocumento de Prueba para Ver Que Talrdos14No ratings yet

- 9 Words That Woman UseDocument1 page9 Words That Woman Userdos14No ratings yet

- Sustainability 11 06083 PDFDocument14 pagesSustainability 11 06083 PDFrdos14No ratings yet

- Calculate Buoyancy Factor Using Mud WeightDocument2 pagesCalculate Buoyancy Factor Using Mud Weightrdos14No ratings yet

- 4.0 S-135 Drill Pipe W Xt39Document1 page4.0 S-135 Drill Pipe W Xt39rdos14No ratings yet

- Web Interface User's Guide: ADSL Ethernet & USB Combo RouterDocument64 pagesWeb Interface User's Guide: ADSL Ethernet & USB Combo Routerrdos14No ratings yet

- 5614 Creating A Portable Windows 10 Environment External WSGDocument8 pages5614 Creating A Portable Windows 10 Environment External WSGrdos14No ratings yet

- Candidate Screening Form: Evaluating Ubd, MPD, Air/Mist/Aerated/Foam Drilling TechniquesDocument2 pagesCandidate Screening Form: Evaluating Ubd, MPD, Air/Mist/Aerated/Foam Drilling Techniquesrdos14No ratings yet

- HG658 V2 Home Gateway: User GuideDocument54 pagesHG658 V2 Home Gateway: User Guiderdos14No ratings yet

- Programa de Densidades Xanab-600 AdendaDocument3 pagesPrograma de Densidades Xanab-600 Adendardos14No ratings yet

- 2011 05 25 Final EFCOGDocument18 pages2011 05 25 Final EFCOGrdos14No ratings yet

- Offshore201607 DLDocument83 pagesOffshore201607 DLrdos14No ratings yet

- MB Manual Ga-h61m-Ds2 v2.x eDocument40 pagesMB Manual Ga-h61m-Ds2 v2.x erdos14No ratings yet

- Costestimatingsystemaace 208aDocument7 pagesCostestimatingsystemaace 208aMarianoNo ratings yet

- Guide To Cost PredictabilityDocument26 pagesGuide To Cost Predictabilityal-gazNo ratings yet

- Guide To Cost PredictabilityDocument26 pagesGuide To Cost Predictabilityal-gazNo ratings yet

- SkilledMigration DevelopmentDocument12 pagesSkilledMigration DevelopmentYoussef AbbyaNo ratings yet

- TT Platform Rig Evaluation Matrix - FINALDocument9 pagesTT Platform Rig Evaluation Matrix - FINALrdos14100% (1)

- Design Index PDC PDFDocument2 pagesDesign Index PDC PDFrdos14No ratings yet

- Jha Basic Risk MatrixDocument1 pageJha Basic Risk Matrixrdos14No ratings yet

- Decision MatrixDocument12 pagesDecision Matrixrdos14No ratings yet

- Deepwater Landing String DesignDocument6 pagesDeepwater Landing String Designrdos14No ratings yet

- Costestimatingsystemaace 208aDocument7 pagesCostestimatingsystemaace 208aMarianoNo ratings yet

- Evaluation of Drilling Rig SelectionDocument39 pagesEvaluation of Drilling Rig Selectionamithakim100% (4)

- Calculation RigDocument9 pagesCalculation Rigrdos14No ratings yet

- The Pressure and Drilling ProductionDocument20 pagesThe Pressure and Drilling Productionrdos14100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- QB 2014 Math SL 5Document119 pagesQB 2014 Math SL 5Nicole PuyoNo ratings yet

- Crazy DerivativesDocument4 pagesCrazy Derivativesapi-249709617No ratings yet

- Solutions to the 82nd William Lowell Putnam Mathematical CompetitionDocument5 pagesSolutions to the 82nd William Lowell Putnam Mathematical CompetitionNrezNat100% (2)

- Algebra HandbookDocument178 pagesAlgebra HandbookDhiman NathNo ratings yet

- Baker (2011) CMS Overview, JSEDocument19 pagesBaker (2011) CMS Overview, JSEmarin_sNo ratings yet

- Permeability From Production Logs - Method and ApplicationDocument16 pagesPermeability From Production Logs - Method and ApplicationTwirX100% (1)

- Convergence Acceleration of Alternating SeriesDocument10 pagesConvergence Acceleration of Alternating SeriesblablityNo ratings yet

- Sequence & Series Practice Sheet 01 Prayas 2 0 2023 VP Star PDFDocument4 pagesSequence & Series Practice Sheet 01 Prayas 2 0 2023 VP Star PDFAditya VermaNo ratings yet

- Analysis of Complex Statistical Variables into Principal ComponentsDocument25 pagesAnalysis of Complex Statistical Variables into Principal ComponentsAhhhhhhhNo ratings yet

- 02 AS Pure Mathematics Practice Paper A Mark SchemeDocument13 pages02 AS Pure Mathematics Practice Paper A Mark Schemeyolanda gaoliNo ratings yet

- Introduction To Probability Solutions To The Odd Numbered Exercises (Charles M. Grinstead & J. Laurie Snell - 0821807498) PDFDocument51 pagesIntroduction To Probability Solutions To The Odd Numbered Exercises (Charles M. Grinstead & J. Laurie Snell - 0821807498) PDFIrina ConstantinescuNo ratings yet

- Derivatives of Exponential Functions 1q591oq PDFDocument5 pagesDerivatives of Exponential Functions 1q591oq PDFMohammedNo ratings yet

- 24 - 1982 AugustDocument76 pages24 - 1982 AugustTheodoros Maragakis100% (1)

- (Methods in Exploration Series 5) George B. Asquith - Handbook of Log Evaluation Techniques For Carbonate Reservoirs-American Association of Petroleum Geologists (1985) PDFDocument53 pages(Methods in Exploration Series 5) George B. Asquith - Handbook of Log Evaluation Techniques For Carbonate Reservoirs-American Association of Petroleum Geologists (1985) PDFNicolas Cardenas AcevedoNo ratings yet

- Module 1 AlgebraDocument33 pagesModule 1 AlgebraJeffrey Joseph MojicaNo ratings yet

- Logarithms 2011 WorksheetDocument5 pagesLogarithms 2011 Worksheetsahil7031100% (1)

- IGCSE Additional Maths-0606Document350 pagesIGCSE Additional Maths-0606Phone Myat Kaung100% (1)

- A Simple Method of Estimating Fifty Per Cent EndpointsDocument5 pagesA Simple Method of Estimating Fifty Per Cent EndpointsPrzemysław MaksymowiczNo ratings yet

- Meggitt 62Document17 pagesMeggitt 62bzkizo_sbbNo ratings yet

- Asymptotic NotationsDocument8 pagesAsymptotic NotationssaiNo ratings yet

- Basic Calculus: Limits of Exponential, Logarithmic, and Trigonometric FunctionsDocument12 pagesBasic Calculus: Limits of Exponential, Logarithmic, and Trigonometric Functionsgarry100% (1)