Professional Documents

Culture Documents

ACCA Example of Duct Sizing

ACCA Example of Duct Sizing

Uploaded by

abianshbaralCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ACCA Example of Duct Sizing

ACCA Example of Duct Sizing

Uploaded by

abianshbaralCopyright:

Available Formats

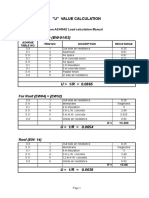

Below is an example of duct sizing

The load calculation indicates a heat gain of 28,000 BTUH, Therefore a 2-1/2 ton A/C unit is

needed. The total system CFM is 1000 (for heating only, use the furnace cfm). The cfm of each

branch is determined using the example shown for room C.

The return trunk must handle 1000 cfm. The first section of the supply trunk must handle 1000 cfm

while the second section will have to handle the remaining 517 cfm

Room C

3000 btuh Heat Gain (obtain from room-by-room load calculation)

3000/28,000 X 1000 = 107 CFM

C

107 cfm

125 cfm

88 cfm

1000 cfm

AHU

1000 cfm

1000 cfm

A

return

517 cfm

68 cfm 110 cfm

110 cfm

External static pressure of air handler @ 100 cfmwet coil

Air filter

registers

Grille

Total Available Static Pressure

50 cfm 123 cfm

84 cfm

Measured length of duct (A to B ) =

Equivalent lengths of turns and fittings between A and B =

Total effective length =

135 cfm

B

65 feet

190 feet

255 feet

.5 w.c

-.10 w.c.

-.15 w.c.

-.03 w.c.

-.03 w.c.

.19 w.c.

Friction Rate= .19 X 100

255

= .075 w.c. (Size all ducts at this friction rate)

Use the Friction Rate (.075) to size all trunks and branches

Return and first section of

supply trunk will be 20

diameter (1000 cfm

@ .075 w.c.

Second section of supply

trunk will be 16 diameter

(517 cfm @.075 w.c.)

Outlet C will be 8

diameter (107 cfm

@ .075 w.c.)

Size the remaining outlets

according to their CFM

@ .075 w.c.

You might also like

- Static Regain Method NEWDocument6 pagesStatic Regain Method NEWMarzookNo ratings yet

- U Value CalculationDocument4 pagesU Value CalculationSatish Kumar Maurya100% (1)

- Back To Basics - Duct DesignDocument17 pagesBack To Basics - Duct DesignAntonio LebrunNo ratings yet

- ESM DUCT CALCULATOR Rev2Document1 pageESM DUCT CALCULATOR Rev2qwerty_conanNo ratings yet

- Offshore Hvac DesignDocument6 pagesOffshore Hvac DesignAndrew AlexNo ratings yet

- Duct Design: ME 425 - Air Distribution & ASHRAE Outlet SelectionDocument9 pagesDuct Design: ME 425 - Air Distribution & ASHRAE Outlet SelectionAbul ShaikhNo ratings yet

- Duct Construction Schedule & References PDFDocument8 pagesDuct Construction Schedule & References PDFEslam ElsayedNo ratings yet

- Ventilation Calculation For Generators RoomDocument3 pagesVentilation Calculation For Generators RoomRashid Ahmed Siddiqui100% (1)

- High Velocity Duct Design Tips by TraneDocument50 pagesHigh Velocity Duct Design Tips by TraneInventor SolidworksNo ratings yet

- Duct DesignDocument18 pagesDuct Designhfguerrac95% (21)

- Basic of HVAC Duct Design PDFDocument3 pagesBasic of HVAC Duct Design PDFHamidullah Asady WardakNo ratings yet

- Duct FittingsDocument31 pagesDuct FittingsSam Jose100% (7)

- CARRIER HVAC Handbook New Edition Part 10 Air SystemsDocument62 pagesCARRIER HVAC Handbook New Edition Part 10 Air SystemsradiopascalgeNo ratings yet

- Air Duct System, DesignDocument9 pagesAir Duct System, DesignkktayNo ratings yet

- Residential Load Calculations SpreadsheetDocument5 pagesResidential Load Calculations SpreadsheetrodrigopeddrosaNo ratings yet

- Kitchen Ventilation ExampleDocument4 pagesKitchen Ventilation ExamplePretty NatyNo ratings yet

- Power Plant CalculationDocument4 pagesPower Plant CalculationSreenbabu100% (1)

- Need For Balancing ValvesDocument12 pagesNeed For Balancing ValvesBubai111No ratings yet

- Basics of Duct DesignDocument2 pagesBasics of Duct DesignApurv Goyal100% (1)

- % Outdoor Air CalculationDocument6 pages% Outdoor Air Calculationamirin_kingNo ratings yet

- HVACDocument27 pagesHVACajuhaseenNo ratings yet

- Holyoake Engineering DataDocument24 pagesHolyoake Engineering DataSantiago J. ramos jr100% (1)

- ASHRAE Commercial Duct CalculationsDocument4 pagesASHRAE Commercial Duct CalculationsNirmal KvNo ratings yet

- Air Distribution SystemDocument21 pagesAir Distribution SystemRohit JainNo ratings yet

- Part 1 - Air in MotionDocument5 pagesPart 1 - Air in Motionrahuldubey1987100% (1)

- Sample Calculations of Boiler Pumps and IDDocument5 pagesSample Calculations of Boiler Pumps and IDMasih BelajarNo ratings yet

- Fan Fundamentals - Greenheck (May2005)Document24 pagesFan Fundamentals - Greenheck (May2005)jagdishgharoteNo ratings yet

- Technical Handbook Air CurtainsDocument13 pagesTechnical Handbook Air Curtainsaca111111No ratings yet

- How Do You Calculate Airflow Required For Maintaining The Building at 50 PA Positive Pressure - Bayt - Com SpecialtiesDocument3 pagesHow Do You Calculate Airflow Required For Maintaining The Building at 50 PA Positive Pressure - Bayt - Com Specialtieshadi jamshidiNo ratings yet

- Ashrae Duct FittingsDocument117 pagesAshrae Duct Fittingssachinsaklani23100% (2)

- Duct Design Rev2Document18 pagesDuct Design Rev2AshokNo ratings yet

- Ashrae Duct PDFDocument3 pagesAshrae Duct PDFAnonymous XhkjXCxxsTNo ratings yet

- Pan Humidifier CalculaitonDocument1 pagePan Humidifier CalculaitonAshok KrishnamurthyNo ratings yet

- Duct Presentation MaineDocument22 pagesDuct Presentation MaineCharmaine ManliguezNo ratings yet

- DUCT - DESIGN Class Material PDFDocument59 pagesDUCT - DESIGN Class Material PDFmasoodae100% (1)

- EIMDocument3 pagesEIMjuanlukaNo ratings yet

- Part 10. All-Air Systems - Chapter 4. Dual-Duct System: Table 1 Summarizes The Cooling Load Requirements of 2)Document1 pagePart 10. All-Air Systems - Chapter 4. Dual-Duct System: Table 1 Summarizes The Cooling Load Requirements of 2)Karthikeyan SankarrajanNo ratings yet

- MECH4880-Assignment1 S2 2017 v1 - 01Document25 pagesMECH4880-Assignment1 S2 2017 v1 - 01charitha RanwalaNo ratings yet

- Ultrasonic Humidifiers: Course No: M02-006 Credit: 2 PDHDocument21 pagesUltrasonic Humidifiers: Course No: M02-006 Credit: 2 PDHnitin guptaNo ratings yet

- ADC Flexible Duct Performance & Installation Standards. Installation Guidelines. 4th Ed.Document8 pagesADC Flexible Duct Performance & Installation Standards. Installation Guidelines. 4th Ed.John EvansNo ratings yet

- ASPE PSD - Building Storm Water SystemsDocument1 pageASPE PSD - Building Storm Water SystemsNiong DavidNo ratings yet

- Duct DesignDocument49 pagesDuct DesignabianshbaralNo ratings yet

- Design Phase Commissioning HandbookDocument1 pageDesign Phase Commissioning HandbookHerberth SilitongaNo ratings yet

- Cooling Coil Design (SI Units)Document3 pagesCooling Coil Design (SI Units)Christopher PersaudNo ratings yet

- Kitchen HoodDocument10 pagesKitchen HoodkumarNo ratings yet

- AC Duct Design PDFDocument6 pagesAC Duct Design PDFkumar123rajuNo ratings yet

- Duct Pressure Loss CalculationDocument24 pagesDuct Pressure Loss CalculationbernardsilvanoNo ratings yet

- T Ces Series PDFDocument12 pagesT Ces Series PDFDaniel InostrozaNo ratings yet

- Air Duct CalculatorDocument1 pageAir Duct CalculatorEngFaisal AlraiNo ratings yet

- Hap Free CoolingDocument2 pagesHap Free CoolingHnin PwintNo ratings yet

- Elite Software - RhvacDocument12 pagesElite Software - Rhvacsyedkaleem55No ratings yet

- DuctSox DesignManualDocument20 pagesDuctSox DesignManualPanduNo ratings yet

- Ashrae 15-34-Rev 3 MitsubishiDocument7 pagesAshrae 15-34-Rev 3 MitsubishiJosho SandovalNo ratings yet

- Engineering Guidelines (Diffuser)Document34 pagesEngineering Guidelines (Diffuser)Kyaw ZawNo ratings yet

- CHW Pump - HotelDocument7 pagesCHW Pump - HotelTiffany CombsNo ratings yet

- PVC Duct DesignDocument10 pagesPVC Duct DesigncitramuaraNo ratings yet

- Duct DesignDocument13 pagesDuct DesignamitNo ratings yet

- 40LX Ceiling Concealed CCAC InstallationDocument17 pages40LX Ceiling Concealed CCAC Installationjeferson binayNo ratings yet

- Tube Size and Component Selection PDFDocument20 pagesTube Size and Component Selection PDFLinh TruongNo ratings yet

- Air Distribution and BalanceDocument11 pagesAir Distribution and BalanceradusettNo ratings yet

- 7.5 Appendix 7.5.1 The Number of Tubes in CondenserDocument5 pages7.5 Appendix 7.5.1 The Number of Tubes in CondenserAhmad Najie ZulkifliNo ratings yet

- Microcontroilador ArduinoDocument21 pagesMicrocontroilador ArduinohfguerracNo ratings yet

- Air Conditioning Duct Design-Lecture 38Document20 pagesAir Conditioning Duct Design-Lecture 38Mrityunjay TiwariNo ratings yet

- Fallas StartDocument1 pageFallas StarthfguerracNo ratings yet

- Donalsson PDFDocument193 pagesDonalsson PDFhfguerracNo ratings yet

- Donalsson PDFDocument193 pagesDonalsson PDFhfguerracNo ratings yet