Professional Documents

Culture Documents

Head Joints As Per UL142

Uploaded by

muhdqasim0 ratings0% found this document useful (0 votes)

57 views2 pagesHead Joint types as per UL 142 for above ground storage tanks

Original Title

Head Joints as Per UL142

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentHead Joint types as per UL 142 for above ground storage tanks

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

57 views2 pagesHead Joints As Per UL142

Uploaded by

muhdqasimHead Joint types as per UL 142 for above ground storage tanks

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 2

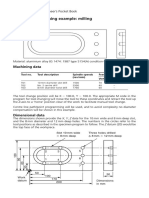

STANDAND OF UNDERWRITERS’ LARORATORIES

Heads and Head Joints

18, A head of a horizontal tank shall be fabricated of not more than

‘three pieces for diameters of from 48 to 96 inches, and four pieces for

ters of from 97 to 144 inches. When two or more pieces are used,

seams shall be one of the forms shown by Pigure 1, except joint No. 5

shal not be used.

19, A head of a horizontal tank shall be attached to the shell by one

of the joints shown by Figure 2.

ELLIRIIZZS «cre UM a ot

fare eis ay fa Sear

ne Ein Se ome fan

Double-welded full Sllet lap joint,

or single-welded full filet lap joint

on outside with 1-inch intermittent

‘weld spaced not over 12 inches’ on

inside; minimum overlap, “A”

inch for tank diameters 48 inches

‘or less, % inch for tank diameters

bt over 4 inches.

Groove weld equivalent in thick-

ness to “t”; full penetration and

7 :

Fall fillet weld on outside; "0" is

Yetnch minimum diameter lock

‘weld spaced not over 12 inches.

ke Single welded full filet lap joint;

minimum overlap, “A”—¥% inch

for tank diameters 48 inches or

Jess, % inch for tank diameters

over 48 inches. This joint only for

nee ‘tanks of 65-inch diameter or less.

FIGURE 1

STEEL ABOVEGROUND TANKS FOR FLAMMADLE Ad

‘COMBUSTIBLE LIQUIDS. '

HEAD JOINTS FOR HORIZONTAL TANKS

TZZETESSy _Douhlowelded vv, bevel or

square groove butt juint; fall

Nott penetration and eouplete fa

. NOW sion.

Bale FASE Ssingtewelded fom set tap

joint, single-welded full sllet

i p lap joint on outside with 1-

eae nos F~F—N inch intermittent weld spaced

noe spaced not over 12 inches on

inside, or double-welded full

let “lap joint; minimum

aR

Sk overlay, "AY, inch; “F”

i ts St thn

Ss BSSQQ Ge greater, but not ine tan

¥, inch,

n0.14 10.15

Groove weld equivalent in

Agim idem tess

Sree atts

" SHEER TET ate

i br ‘head thickness or greater, but

we wor No MBSR ES

at st

ven! wo Ea wat

‘than thickness of shell; “FP”

is ivo times head thickness

for greater, but not Jess than

ie si inc,

. FIGURE 2

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Cleanout FittingDocument1 pageCleanout FittingmuhdqasimNo ratings yet

- Shell Nozzle FlangesDocument1 pageShell Nozzle FlangesmuhdqasimNo ratings yet

- Problem 1Document1 pageProblem 1muhdqasimNo ratings yet

- Column Foundation DesignDocument1 pageColumn Foundation DesignmuhdqasimNo ratings yet

- Problem 5Document1 pageProblem 5muhdqasimNo ratings yet

- Column 2 Foundation DesignDocument1 pageColumn 2 Foundation DesignmuhdqasimNo ratings yet

- Problem 3Document1 pageProblem 3muhdqasimNo ratings yet

- 1.5 MM (/ In.) + 6 MM (/ In.) Max + 6 MM (/ In.) Max Min Min 1.4Document1 page1.5 MM (/ In.) + 6 MM (/ In.) Max + 6 MM (/ In.) Max Min Min 1.4muhdqasimNo ratings yet

- Problem 4Document1 pageProblem 4muhdqasimNo ratings yet

- Problem 2Document1 pageProblem 2muhdqasimNo ratings yet

- Column 3 FoundationDocument1 pageColumn 3 FoundationmuhdqasimNo ratings yet

- Isolated Footing Design (ACI 318-05) : Footing No. Group ID Foundation Geometry - Length Width ThicknessDocument1 pageIsolated Footing Design (ACI 318-05) : Footing No. Group ID Foundation Geometry - Length Width ThicknessmuhdqasimNo ratings yet

- Structure LoadsDocument1 pageStructure LoadsmuhdqasimNo ratings yet

- Column Dimensions: Design ParametersDocument1 pageColumn Dimensions: Design ParametersmuhdqasimNo ratings yet

- Thriving On Riff 4Document1 pageThriving On Riff 4muhdqasimNo ratings yet

- Vessel LoadsDocument1 pageVessel LoadsmuhdqasimNo ratings yet

- Thriving on a Riff: How Ornette Coleman's Harmolodics Revolutionized Jazz ImprovisationDocument1 pageThriving on a Riff: How Ornette Coleman's Harmolodics Revolutionized Jazz ImprovisationmuhdqasimNo ratings yet

- Piping LoadsDocument1 pagePiping LoadsmuhdqasimNo ratings yet

- Thriving On A Riff: During The Summers, IDocument1 pageThriving On A Riff: During The Summers, ImuhdqasimNo ratings yet

- Thriving On Riff 2Document1 pageThriving On Riff 2muhdqasimNo ratings yet

- Typical Belt Tensioning DevicesDocument1 pageTypical Belt Tensioning DevicesmuhdqasimNo ratings yet

- Thriving On Riff 3Document1 pageThriving On Riff 3muhdqasimNo ratings yet

- 8.1.12 Programming Example: Milling: ComponentDocument1 page8.1.12 Programming Example: Milling: ComponentmuhdqasimNo ratings yet

- Worm and Worm Wheel NomenclatureDocument1 pageWorm and Worm Wheel NomenclaturemuhdqasimNo ratings yet

- Power Transmission: Simple and Crossed Belt DrivesDocument1 pagePower Transmission: Simple and Crossed Belt DrivesmuhdqasimNo ratings yet

- Design BasisDocument1 pageDesign BasismuhdqasimNo ratings yet

- Typical V-Belt and Synchronous-Belt Drive ApplicationsDocument1 pageTypical V-Belt and Synchronous-Belt Drive ApplicationsmuhdqasimNo ratings yet

- Mechanical Engineer's Pocket Book Pulley CalculationsDocument1 pageMechanical Engineer's Pocket Book Pulley CalculationsmuhdqasimNo ratings yet

- CNC Commands and DescriptionDocument1 pageCNC Commands and DescriptionmuhdqasimNo ratings yet

- 8.1.11 Programming Techniques: Milling and Drilling: Canned CyclesDocument1 page8.1.11 Programming Techniques: Milling and Drilling: Canned CyclesmuhdqasimNo ratings yet