Professional Documents

Culture Documents

Samurai

Uploaded by

Nikolat84Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Samurai

Uploaded by

Nikolat84Copyright:

Available Formats

SAMURAI Series

Vol. 2 - 2011

4 Flutes Square

4 Flutes Corner Radius

2 Flutes Ball

51 Models

1 - 12mm

SAMURAI GS - 4 Flutes Square

d2

( 1 10 )

d1

l2

l1

Suitable for the machining of :

Carbon

Steel

Stainless

Steel

Hardness

< 55HRC

Titanium

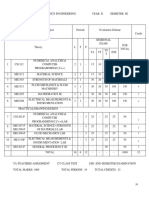

Tool Model

d1

l2

l1

d2

GS 4010

2.5

45

GS 4015

1.5

3.75

45

GS 4020

45

GS 4030

45

GS 4040

11

45

GS 4060

15

60

GS 4080

19

60

GS 4100

10

25

70

10

Copper

Price

()

SAMURAI GS - Milling conditions

WORK MATERIAL

Outside

Model Diameter

Number

(mm)

4010

1

4015

1.5

4020

2

4030

3

4040

4

4060

6

4080

8

4100

10

CARBON STEELS

S45CS50C

(225HB

Speed

(min-1)

20'000

13'500

11'000

7'400

5'900

4'400

3'300

2'600

Velocity

(m/min)

65

70 ~ 85

Feed

(mm/min)

240

245

245

370

435

580

550

525

ALLOY STEELS

SKSCMSUS

(225325HB

Speed

(min-1)

15'000

10'000

8'500

6'400

5'000

3'500

2'600

2'100

Velocity

Feed

(m/min) (mm/min)

215

45

215

215

260

340

55 ~ 65

415

415

405

PREHARDENED

STEELS/HARDENED

STEELS

NAKSKD

(3045HRC

Speed

(min-1)

11'000

8'000

6'400

4'500

3'500

2'450

1'850

1'450

Velocity

Feed

(m/min) (mm/min)

85

35

90

90

105

120

40 ~ 45

130

125

125

HARDENED STEELS

SKD11 61SKT

(4555HRC

Speed

(min-1)

7'100

5'100

4'000

2'800

2'150

1'500

1'200

950

Velocity

Feed

(m/min) (mm/min)

40

20

50

55

65

70

25 ~ 30

70

70

65

For high-speed milling

Outside

Model Diameter

Number

(mm)

4030

3

4040

4

4060

6

4080

8

4100

10

Speed

(min-1)

30'000

23'800

15'900

11'900

9'500

Velocity

(m/min)

300

Milling Amount for Side Milling

ae=0.05D

Less than 45HRC

ap=2.5D

ae=0.02D

More than 45HRC

ap=2D

Feed

(mm/min)

1'500

1'755

2'095

1'985

1'920

ALLOY STEELS

SKSCMSUS

( 25325HB

Speed

(min-1)

26'500

19'800

13'200

9'900

7'900

Velocity

Feed

(m/min) (mm/min)

1'075

1'345

250

1'565

1'580

1'525

ap

WORK MATERIAL

CARBON STEELS

S45CS50C

(225HB

ae

D : Outside Diameter

ap : Axial Depth

ae : Radial Depth

Note

Do not use flammable cutting oils.

Use a machine that has high rigidity and generates a low level of vibration.

Remove chip to prevent heat generation and ignition.

PREHARDENED

STEELS/HARDENED

STEELS

NAKSKD

( 3045HRC

Speed

(min-1)

21'200

15'800

10'600

7'900

6'300

Velocity

Feed

(m/min) (mm/min)

495

540

200

560

535

545

HARDENED STEELS

SKD11 61SKT

( 4555HRC

Speed

(min-1)

15'800

11'900

7'900

5'900

4'700

Velocity

Feed

(m/min) (mm/min)

365

385

150

370

345

320

SAMURAI GCR - 4 Flutes Corner Radius

( 2 12 )

CR

d2

d1

l2

l3

l1

Suitable for the machining of :

Carbon

Steel

Stainless

Steel

Tool Model

Hardness

< 55HRC

Titanium

Inconel

d1

CR

l2

l3

l1

d2

* GCR 4020-05-06

0.5

45

GCR 4030-05-12

0.5

12

60

GCR 4040-03-08

0.3

50

* GCR 4040-05-12

0.5

12

50

GCR 4040-05-16

0.5

16

60

GCR 4060-05-18

0.5

18

60

GCR 4060-05-24L

0.5

24

90

GCR 4060-10-18

18

60

24

90

GCR 4080-05-26

0.5

26

70

GCR 4080-05-32L

0.5

32

100

GCR 4080-10-26

26

70

* GCR 4080-10-32L

32

100

* GCR 4080-15-24

1.5

24

70

* GCR 4060-10-24L

* New models

Price

()

SAMURAI GCR - 4 Flutes Corner Radius

Tool Model

( 2 12 )

d1

CR

l2

l3

l1

d2

* GCR 4080-15-32L

1.5

32

100

* GCR 4080-20-24

24

70

* GCR 4080-20-32L

32

100

GCR 4100-05-30

10

0.5

10

30

80

10

GCR 4100-05-30L

10

0.5

10

30

120

10

GCR 4100-10-30

10

10

30

80

10

10

10

40

120

10

10

1.5

10

30

80

10

10

1.5

10

40

120

10

10

10

30

80

10

* GCR 4100-20-40L

10

10

40

120

10

* GCR 4100-30-30

10

10

30

80

10

* GCR 4100-30-40L

10

10

40

120

10

12

0.5

12

36

100

12

12

0.5

12

48

120

12

12

12

36

100

12

12

12

48

120

12

12

12

36

100

12

12

12

48

120

12

12

12

36

100

12

12

12

48

120

12

* GCR 4100-10-40L

GCR 4100-15-30

* GCR 4100-15-40L

GCR 4100-20-30

GCR 4120-05-36

* GCR 4120-05-48L

GCR 4120-10-36

* GCR 4120-10-48L

GCR 4120-20-36

* GCR 4120-20-48L

GCR 4120-30-36

* GCR 4120-30-48L

* New models

Price

()

SAMURAI GCR - Milling conditions

Roughing Parameters

CARBON STEELS

S45CS55C225HB

WORK MATERIAL

GCR 4020-05-06

GCR 4030-05-12

GCR 4040-03-08

GCR 4040-05-12

GCR 4040-05-16

GCR 4060-05-18

GCR 4060-05-24L

GCR 4060-10-18

GCR 4060-10-24L

GCR 4080-05-26

GCR 4080-05-32L

GCR 4080-10-26

GCR 4080-10-32L

GCR 4080-15-24

GCR 4080-15-32L

GCR 4080-20-24

GCR 4080-20-32L

GCR 4100-05-30

GCR 4100-05-30L

GCS 4100-10-30

GCS 4100-10-40L

GCR 4100-15-30

GCR 4100-15-40L

GCR 4100-20-30

GCR 4100-20-40L

GCR 4100-30-30

GCR 4100-30-40L

GCR 4120-05-36

GCR 4120-05-48L

GCR 4120-10-36

GCR 4120-10-48L

GCR 4120-20-36

GCR 4120-20-48L

GCR 4120-30-36

GCR 4120-30-48L

Outside

Diameter

(mm)

2

3

4

10

12

Corner

Radius

(CR)

R0.5

R0.5

R0.3

R0.5

R0.5

R0.5

R0.5

R1

R1

R0.5

R0.5

R1

R1

R1.5

R1.5

R2

R2

R0.5

R0.5

R1

R1

R1.5

R1.5

R2

R2

R3

R3

R0.5

R0.5

R1

R1

R2

R2

R3

R3

Speed

Feed

(min-1)

30000

20000

15000

15000

15000

10000

10000

10000

10000

7500

7500

7500

7500

7500

7500

7500

7500

6000

6000

6000

6000

6000

6000

6000

6000

6000

6000

5000

5000

5000

5000

5000

5000

5000

5000

(mm/min)

7200

8400

9600

9600

9600

12000

12000

12000

12000

12000

12000

12000

12000

12000

12000

12000

12000

12000

12000

12000

12000

12000

12000

12000

12000

12000

12000

12000

12000

12000

12000

12000

12000

12000

12000

ap

ae

Axial

Depth

(mm)

0.08

0.09

0.09

0.10

0.10

0.14

0.14

0.15

0.15

0.18

0.18

0.20

0.20

0.22

0.22

0.24

0.24

0.22

0.22

0.24

0.24

0.25

0.25

0.26

0.26

0.27

0.27

0.26

0.26

0.26

0.26

0.28

0.28

0.30

0.30

Radial

Depth

(mm)

0.80

1.20

1.60

1.60

1.60

2.40

2.40

2.40

2.40

2.64

2.64

2.72

2.72

2.80

2.80

2.88

2.88

3.04

3.04

3.28

3.28

3.36

3.36

3.44

3.44

3.52

3.52

3.66

3.66

3.70

3.70

3.76

3.76

4.00

4.00

Speed

Feed

(min-1) (mm/min)

30000

7200

20000

7200

15000

7200

15000

7200

15000

7200

10000

7200

10000

7200

10000

7200

10000

7200

7500

7200

7500

7200

7500

7200

7500

7200

7500

7200

7500

7200

7500

7200

7500

7200

5000

5400

5000

5400

5000

5400

5000

5400

5000

5400

5000

5400

5000

5400

5000

5400

5000

5400

5000

5400

3000

4320

3000

4320

3000

4320

3000

4320

3000

4320

3000

4320

3000

4320

3000

4320

ap

ae

Axial

Depth

(mm)

0.04

0.04

0.05

0.05

0.05

0.07

0.07

0.07

0.07

0.08

0.08

0.09

0.09

0.09

0.09

0.10

0.10

0.14

0.14

0.14

0.14

0.14

0.14

0.14

0.14

0.14

0.14

0.18

0.18

0.18

0.18

0.18

0.18

0.18

0.18

Radial

Depth

(mm)

0.66

1.08

1.32

1.35

1.35

1.98

1.98

2.16

2.16

2.61

2.61

2.70

2.74

2.74

2.74

2.79

2.79

2.88

2.88

2.97

2.97

3.01

3.01

3.06

3.06

3.08

3.08

3.15

3.15

3.15

3.15

3.15

3.15

3.15

3.15

D: Outside Diameter

L: Overhand Length

Speed

Feed

(min-1)

24000

16000

12000

12000

12000

8000

8000

8000

8000

6000

6000

6000

6000

6000

6000

6000

6000

4800

4800

4800

4800

4800

4800

4800

4800

4800

4800

4000

4000

4000

4000

4000

4000

4000

4000

(mm/min)

7000

7000

7000

7000

7000

5250

5250

5250

5250

4100

4100

4100

4100

4100

4100

4100

4100

4100

4100

4100

4100

4100

4100

4100

4100

4100

4100

4100

4100

4100

4100

4100

4100

4100

4100

ap

ae

Axial

Depth

(mm)

0.02

0.04

0.05

0.05

0.05

0.07

0.07

0.08

0.08

0.14

0.14

0.16

0.16

0.17

0.17

0.18

0.18

0.18

0.18

0.19

0.19

0.19

0.19

0.19

0.20

0.20

0.20

0.21

0.21

0.21

0.21

0.21

0.21

0.21

0.21

Radial

Depth

(mm)

0.59

0.88

1.17

1.26

1.26

1.75

1.75

1.75

1.75

1.76

1.76

1.76

1.76

1.84

1.84

1.96

1.96

2.03

2.03

2.10

2.10

2.25

2.25

2.35

2.35

2.45

2.45

2.80

2.80

2.80

2.80

2.80

2.80

2.80

2.80

Roughing Parameter

3.0

4.06.0

ap

Axial

Depth

ae

Radial

Depth

Speed

Feed

(min-1

(mm/min)

(mm)

(mm)

L/D=6

L/D=7

L/D=8

L/D=9

L/D=10

1

0.8

0.7

0.7

0.6

1

0.8

0.7

0.7

0.6

1

0.8

0.7

0.6

0.6

1

0.9

0.9

0.8

0.7

Speed

Feed

(min-1)

1

0.7

0.5

(mm/min)

1

0.6

0.4

ap

Axial

Depth

(mm)

1

0.6

0.5

ae

Radial

Depth

1

0.8

0.7

ap

Axial

Depth

ae

Radial

Depth

(mm/min)

(mm)

(mm)

1

0.8

0.7

0.6

0.4

1

0.9

0.8

0.6

0.6

1

0.9

0.9

0.8

0.7

Speed

Feed

(min-1 )

L/D=4

L/D=5

L/D=6

L/D=7

L/D=8

1

0.9

0.8

0.7

0.5

ap

Model Number

ALLOY STEELS

PREHARDENED STEELS / HARDENED

NAKHPMSKDSKTSTAVAX3055HRC

SKSCMSUS225325HB

Note:Recommend Using Oil Mist

Note:Use a water soluble if milling stainless steel

a p: Axial Depth

a e: Radial Depth

ae

8.012.0

/

L/D=4

L/D=5

L/D=6

Note:

Recommend Using Airblow/Water Soluble/Oil Mist.

Use a water soluble if milling stainless steel.Do not use flammable cutting oils.

This table shows standard milling.Adjust it in accordance with milling type,

purpose and used instruments in actual milling.

In case of spindle rotation does not reach to target,decrease spindle and feed speed in same ratio.

Use a machine that has high rigidity and generates low level of vibration.

Remove chip to prevent heat generation and ignition by milling processing.

Adjust only spindle speed for finishing process based on overhang length.

Please decrease feed rate rate more than 50% from above table for slot milling.

SAMURAI GCR - Milling conditions

Finishing Parameters (Flat / Inclined surface)

CARBON STEELS

S45CS55C225HB

WORK MATERIAL

Model Number

GCR 4020-05-06

GCR 4030-05-12

GCR 4040-03-08

GCR 4040-05-12

GCR 4040-05-16

GCR 4060-05-18

GCR 4060-05-24L

GCR 4060-10-18

GCR 4060-10-24L

GCR 4080-05-26

GCR 4080-05-32L

GCR 4080-10-26

GCR 4080-10-32L

GCR 4080-15-24

GCR 4080-15-32L

GCR 4080-20-24

GCR 4080-20-32L

GCR 4100-05-30

GCR 4100-05-30L

GCS 4100-10-30

GCS 4100-10-40L

GCR 4100-15-30

GCR 4100-15-40L

GCR 4100-20-30

GCR 4100-20-40L

GCR 4100-30-30

GCR 4100-30-40L

GCR 4120-05-36

GCR 4120-05-48L

GCR 4120-10-36

GCR 4120-10-48L

GCR 4120-20-36

GCR 4120-20-48L

GCR 4120-30-36

GCR 4120-30-48L

Outside

Diameter

(mm)

2

3

4

10

12

Corner

Radius

(CR)

R0.5

R0.5

R0.3

R0.5

R0.5

R0.5

R0.5

R1

R1

R0.5

R0.5

R1

R1

R1.5

R1.5

R2

R2

R0.5

R0.5

R1

R1

R1.5

R1.5

R2

R2

R3

R3

R0.5

R0.5

R1

R1

R2

R2

R3

R3

Speed

Feed

(min-1)

30000

20000

15000

15000

15000

10000

10000

10000

10000

7500

7500

7500

7500

7500

7500

7500

7500

6000

6000

6000

6000

6000

6000

6000

6000

6000

6000

5000

5000

5000

5000

5000

5000

5000

5000

(mm/min)

1720

1890

1050

1360

1360

1150

1150

1630

1630

990

990

1410

1410

1650

1650

1990

1990

940

940

1330

1330

1580

1580

1890

1890

2050

2050

1200

1200

1580

1580

1760

1760

1950

1950

ALLOY STEELS

PREHARDENED STEELS / HARDENED

NAKHPMSKDSKTSTAVAX3055HRC

SKSCMSUS225325HB

Note:Recommend Using Oil Mist

Note:Use a water soluble if milling stainless steel

ap

ae

Axial

Depth

(mm)

0.10

0.10

0.10

0.10

0.10

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

Radial

Depth

(mm)

0.06

0.09

0.07

0.09

0.09

0.12

0.12

0.16

0.16

0.13

0.13

0.19

0.19

0.23

0.23

0.27

0.27

0.16

0.16

0.22

0.22

0.26

0.26

0.32

0.32

0.35

0.35

0.32

0.32

0.33

0.33

0.35

0.35

0.37

0.37

Speed

Feed

(min-1) (mm/min)

30000

1510

20000

1660

15000

910

15000

1180

15000

1180

10000

990

10000

990

10000

1400

10000

1400

7500

860

7500

860

7500

1210

7500

1210

7500

1530

7500

1530

7500

1720

7500

1720

5000

660

5000

660

5000

940

5000

940

5000

1050

5000

1050

5000

1340

5000

1340

5000

1560

5000

1560

3000

660

3000

660

3000

720

3000

720

3000

870

3000

870

3000

1030

3000

1030

ap

ae

Axial

Depth

(mm)

0.05

0.05

0.05

0.05

0.05

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

Radial

Depth

(mm)

0.05

0.08

0.06

0.08

0.08

0.10

1.00

0.14

0.14

0.11

0.11

0.16

0.16

0.20

0.20

0.23

0.23

0.13

0.13

0.19

0.19

0.24

0.24

0.27

0.27

0.30

0.30

0.24

0.24

0.27

0.27

0.29

0.29

0.33

0.33

D: Outside Diameter

L: Overhand Length

Speed

Feed

(min-1)

24000

16000

12000

12000

12000

8000

8000

8000

8000

6000

6000

6000

6000

6000

6000

6000

6000

4800

4800

4800

4800

4800

4800

4800

4800

4800

4800

4000

4000

4000

4000

4000

4000

4000

4000

(mm/min)

1070

1160

620

810

810

670

670

950

950

580

580

830

830

1040

1040

1170

1170

520

520

740

740

960

960

1050

1050

1180

1180

690

690

820

820

960

960

1080

1080

ae

Radial

Depth

(mm)

0.04

0.07

0.05

0.07

0.07

0.08

0.08

0.12

0.12

0.10

0.10

0.14

0.14

0.17

0.17

0.20

0.20

0.11

0.11

0.15

0.15

0.18

0.18

0.22

0.22

0.25

0.25

0.18

0.18

0.21

0.21

0.24

0.24

0.27

0.27

Finishing Parameter ( Flat / Inclined surface )

4.06.0

3.0

ap

Axial

Depth

ae

Radial

Depth

Speed

Feed

ap

Axial

Depth

ae

Radial

Depth

Speed

Feed

(min-1

(mm/min)

(mm)

(mm)

(min )

(mm/min)

(mm)

(mm)

L/D=6

L/D=7

L/D=8

L/D=9

L/D=10

1

0.8

0.7

0.7

0.6

1

0.8

0.7

0.7

0.6

1

0.8

0.7

0.6

0.6

1

0.9

0.9

0.8

0.7

L/D=4

L/D=5

L/D=6

L/D=7

L/D=8

1

0.9

0.8

0.7

0.5

1

0.8

0.7

0.6

0.4

1

0.9

0.8

0.6

0.6

1

0.9

0.9

0.8

0.7

Speed

Feed

ap

Axial

Depth

(mm)

1

0.6

0.5

ae

Radial

Depth

1

0.8

0.7

-1

ap

ae

a p: Axial Depth

a e: Radial Depth

ap

8.012.0

/

L/D=4

L/D=5

L/D=6

ap

Axial

Depth

(mm)

0.05

0.05

0.05

0.05

0.05

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

-1

(min )

1

0.7

0.5

(mm/min)

1

0.6

0.4

Note:

Recommend Using Airblow/Water Soluble/Oil Mist.

Use a water soluble if milling stainless steel.Do not use flammable cutting oils.

This table shows standard milling.Adjust it in accordance with milling type,

purpose and used instruments in actual milling.

In case of spindle rotation does not reach to target,decrease spindle and feed speed in same ratio.

Use a machine that has high rigidity and generates low level of vibration.

Remove chip to prevent heat generation and ignition by milling processing.

Adjust only spindle speed for finishing process based on overhang length.

Please decrease feed rate rate more than 50% from above table for slot milling.

ae

SAMURAI GB - 2 Flutes Ball

( 1 10 )

d2

d1

l2

l1

Suitable for the machining of :

Carbon

Steel

Stainless

Steel

Hardness

< 55HRC

Titanium

Tool Model

d1

l2

l1

d2

GB 2010

2.5

50

GB 2015

1.5

50

GB 2020

50

GB 2030

70

GB 2040

70

GB 2060

12

70

GB 2080

14

80

GB 2100

10

18

90

10

Copper

Price

()

SAMURAI GB - Milling conditions

CARBON STEELS

ALLOY STEELS

PREHARDENED STEELS

/ HARDENED STEELS

S45CS50C

SKSCMSUS

NAKSKD

SKD1161SKT

225HB

225325HB

3045HRC

4555HRC

WORK MATERIAL

Model

Number

2010

2020

2030

2040

2060

2080

2100

Radius of Outside

Ball Nose Diameter

(mm)

(mm)

R0.5

R1

R1.5

R2

R3

R4

R5

1

2

3

4

6

8

10

HARDENED STEELS

Speed

(min-1)

Velocity

(m/min)

Feed

(mm/min)

Speed

(min-1)

Velocity

(m/min)

Feed

(mm/min)

Speed

(min-1)

Velocity

(m/min)

Feed

(mm/min)

Speed

(min-1)

Velocity

(m/min)

Feed

(mm/min)

20700

17500

11700

8750

5800

4400

3500

65

970

1570

1460

1140

750

580

440

19100

15100

10100

7550

5000

3800

3000

60

830

1260

1170

900

600

440

340

17500

9550

6400

4780

3200

2400

1900

55

630

660

620

480

320

230

190

9550

5600

3700

2800

1850

1400

1100

30

310

310

280

230

150

120

90

110

95

60

a p 0.05D

For

Roughing

a p 0.04D

a e 0.5D

Milling Amount (mm)

35

a e 0.4D

a p 0.04D (MAX 0.1)

For

Finishing

a e F/n

For high-speed milling

CARBON STEELS

WORK MATERIAL

Model

Number

2020

2030

2040

2060

2080

2100

Radius of Outside

Ball Nose Diameter

(mm)

(mm)

R1

R1.5

R2

R3

R4

R5

2

3

4

6

8

10

Speed

(min-1)

22750

15210

11380

7540

5720

4550

ALLOY STEELS

S45CS50C

SKSCMSUS

PREHARDENED STEELS/

HARDENED STEELS

NAKSKD

225HB

225325HB

3045HRC

Velocity

(m/min)

143

142

144

143

Feed

(mm/min)

Speed

(min-1)

Velocity

(m/min)

Feed

(mm/min)

Speed

(min-1)

2700

2500

2000

1300

1000

700

19630

13130

3820

6500

4940

3900

123

124

123

122

124

122

2100

2000

1500

1000

700

600

12420

8320

6210

4160

3120

2470

a p 0.05D

For

Roughing

Note

Recommend Airblow or Oil Mist.

Do not use flammable cutting oils.

Use a machine that has high rigidity and generates low level of vibration.

Please decrease feed when cutting load changes such as when cutting corner.

Remove chip to prevent heat generation and ignition.

a e F/n

ap

apAxial Depth (mm)

aeRadial Depth (mm)

D Outside Diameter (mm)

n : Speed (min-1)

V f : Feed (mm/min)

SKD1161SKT

Velocity

(m/min)

Feed

(mm/min)

Speed

(min-1)

Velocity

(m/min)

Feed

(mm/min)

78

1100

1100

800

500

400

300

7280

4810

3640

2410

1820

1430

46

45

46

45

46

45

500

500

400

300

200

200

a e 0.4D

a p 0.04D (MAX 0.1)

For

Finishing

4555HRC

a p 0.04D

a e 0.5D

Milling Amount (mm)

HARDENED STEELS

ae

You might also like

- Material Reference ListDocument7 pagesMaterial Reference ListionijhonnieNo ratings yet

- Sds Eng PDFDocument8 pagesSds Eng PDFdaviko313No ratings yet

- CW Hydro Pump PDFDocument56 pagesCW Hydro Pump PDFashim_scribdNo ratings yet

- Produse Laminate La Cald Din Oteluri de Constructii NealiateDocument1 pageProduse Laminate La Cald Din Oteluri de Constructii Nealiatecaty29No ratings yet

- Ductile Iron Pipes FittingsDocument44 pagesDuctile Iron Pipes FittingsSaifur RahmanNo ratings yet

- Ductile Iron ValvesDocument44 pagesDuctile Iron ValvesCattleya MalaikaNo ratings yet

- Specification Sheet: Customer Name PO Number Vendor Name Vendor Reference Document Title Revision NoDocument13 pagesSpecification Sheet: Customer Name PO Number Vendor Name Vendor Reference Document Title Revision NoAmit SurtiNo ratings yet

- Turbine Blade MachiningDocument36 pagesTurbine Blade Machiningyh1.yuNo ratings yet

- Material Equivalents Table: Werkstoffnr. DIN Aisi/Astm/Sae BS Afnor Cast IronDocument3 pagesMaterial Equivalents Table: Werkstoffnr. DIN Aisi/Astm/Sae BS Afnor Cast IronGohilakrishnan ThiagarajanNo ratings yet

- Structural Steel Standard SANS 50025 / EN 10025:2004: Macsteel Trading Macsteel VRN Tel: 011-871-4600 Tel: 011-861-5200Document11 pagesStructural Steel Standard SANS 50025 / EN 10025:2004: Macsteel Trading Macsteel VRN Tel: 011-871-4600 Tel: 011-861-5200JakesNo ratings yet

- En 10025 - 2004Document11 pagesEn 10025 - 2004Abhishek GoelNo ratings yet

- Steel Grades Specifications: Grades, Properties, and Nearest EquivalentsDocument5 pagesSteel Grades Specifications: Grades, Properties, and Nearest EquivalentsBelal AhmedNo ratings yet

- ASTM / JIS /DIN之儀控常用材質對照表: A126 Class BDocument2 pagesASTM / JIS /DIN之儀控常用材質對照表: A126 Class BKetan DesaiNo ratings yet

- Tsa 2Document6 pagesTsa 2Amit SurtiNo ratings yet

- JYS Casting Replacement Parts For TrioDocument8 pagesJYS Casting Replacement Parts For TrioborchecNo ratings yet

- AMRI ISORIA 16 Type Series Booklet DataDocument20 pagesAMRI ISORIA 16 Type Series Booklet Datarudiskw456No ratings yet

- Steel Grade Equivalency TableDocument8 pagesSteel Grade Equivalency TableplanningNo ratings yet

- EN10025 - Steel Grades SpecificationsDocument6 pagesEN10025 - Steel Grades SpecificationsFYNo ratings yet

- Kyocera Catalog CeramicDocument36 pagesKyocera Catalog CeramicJoel Alexandre Santiago AlmeidaNo ratings yet

- Trim Number Chart API ValveDocument2 pagesTrim Number Chart API ValveJuliusMaximus12No ratings yet

- Especificacion API 5lDocument44 pagesEspecificacion API 5ljpcc1986100% (1)

- CAST STEEL GATE VALVES UNDER 40 CHARACTERSDocument4 pagesCAST STEEL GATE VALVES UNDER 40 CHARACTERSsghinausNo ratings yet

- Steel (TSL) Specification Chemical-Physical270109Document55 pagesSteel (TSL) Specification Chemical-Physical270109dyutimanhazra88% (8)

- W.-Nr. DIN UNI Afnor B.S. UNE Aisi/Sae/Astm JIS SS Gost EN: Italy France England Spain U.S.A. Japan Sweden RussiaDocument1 pageW.-Nr. DIN UNI Afnor B.S. UNE Aisi/Sae/Astm JIS SS Gost EN: Italy France England Spain U.S.A. Japan Sweden RussiaDouglas CortezziNo ratings yet

- Ingersoll CAT-009 HoleM TechDocument30 pagesIngersoll CAT-009 HoleM TechLLNo ratings yet

- Пазовые фрезы PDFDocument72 pagesПазовые фрезы PDFstctoolNo ratings yet

- Valve Material EquivalentsDocument3 pagesValve Material EquivalentsAndre Villegas Romero100% (1)

- Cross Reference of STANDARDS For Equivalent Grades of Steel: 1. Bearing Quality Steel: BS DIN IS EN Sae/AisiDocument4 pagesCross Reference of STANDARDS For Equivalent Grades of Steel: 1. Bearing Quality Steel: BS DIN IS EN Sae/AisiManjunath MNo ratings yet

- Piping Equipment SpecificationsDocument4 pagesPiping Equipment Specificationsmabrouk2013No ratings yet

- Work Order Trans. NBR Work Center User ID Item NumberDocument4 pagesWork Order Trans. NBR Work Center User ID Item NumberDian ShofiyullohNo ratings yet

- Alloy Steel Astm Asme A 335 GR p911 Seamless PipeDocument15 pagesAlloy Steel Astm Asme A 335 GR p911 Seamless Pipemanuelq9No ratings yet

- Alloy Steel Astm Asme A 335 GR p2 Seamless PipeDocument15 pagesAlloy Steel Astm Asme A 335 GR p2 Seamless PipeApurva GuptaNo ratings yet

- Material ComparisionDocument1 pageMaterial Comparisionvalli rajuNo ratings yet

- Wire RoadDocument16 pagesWire Road02081987No ratings yet

- Tabel Plat BajaDocument6 pagesTabel Plat BajaAlexander Ignatius100% (2)

- Peeled Round Steel BarsDocument9 pagesPeeled Round Steel BarsaxgasaNo ratings yet

- ASTM MATERIAL COMPARISON TABLEDocument10 pagesASTM MATERIAL COMPARISON TABLEMardeOpamenNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- Metal Tanks (Heavy Gauge) World Summary: Market Values & Financials by CountryFrom EverandMetal Tanks (Heavy Gauge) World Summary: Market Values & Financials by CountryNo ratings yet

- Machine Tools, Metal Cutting Types World Summary: Market Values & Financials by CountryFrom EverandMachine Tools, Metal Cutting Types World Summary: Market Values & Financials by CountryNo ratings yet

- Power Boilers & Heat Exchangers World Summary: Market Values & Financials by CountryFrom EverandPower Boilers & Heat Exchangers World Summary: Market Values & Financials by CountryNo ratings yet

- Cutting Tool & Machine Tool Accessories World Summary: Market Values & Financials by CountryFrom EverandCutting Tool & Machine Tool Accessories World Summary: Market Values & Financials by CountryRating: 2 out of 5 stars2/5 (1)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- High-Performance GM LS-Series Cylinder Head GuideFrom EverandHigh-Performance GM LS-Series Cylinder Head GuideRating: 4.5 out of 5 stars4.5/5 (2)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Jeep, Dana & Chrysler Differentials: How to Rebuild the 8-1/4, 8-3/4, Dana 44 & 60 & AMC 20From EverandJeep, Dana & Chrysler Differentials: How to Rebuild the 8-1/4, 8-3/4, Dana 44 & 60 & AMC 20No ratings yet

- Drilling Fluids Processing HandbookFrom EverandDrilling Fluids Processing HandbookRating: 4.5 out of 5 stars4.5/5 (4)

- Speed Changers, Drives & Gears World Summary: Market Values & Financials by CountryFrom EverandSpeed Changers, Drives & Gears World Summary: Market Values & Financials by CountryNo ratings yet

- Metal Material Identification GuideDocument1 pageMetal Material Identification GuideNikolat84No ratings yet

- The Aero Engine Experts: Intelligence and CreativityDocument12 pagesThe Aero Engine Experts: Intelligence and CreativityNikolat84No ratings yet

- LANCANIK Z 7 KORAK P 150mmDocument2 pagesLANCANIK Z 7 KORAK P 150mmNikolat84No ratings yet

- The Aero Engine Experts: Intelligence and CreativityDocument12 pagesThe Aero Engine Experts: Intelligence and CreativityNikolat84No ratings yet

- What Is My IP and My SpeedDocument1 pageWhat Is My IP and My SpeedNikolat84No ratings yet

- LANCANIK Z 7 KORAK P 150mmDocument2 pagesLANCANIK Z 7 KORAK P 150mmNikolat84No ratings yet

- SiteDocument1 pageSiteNikolat84No ratings yet

- Site For Internet Ip and SpeedDocument1 pageSite For Internet Ip and SpeedNikolat84No ratings yet

- SiteDocument1 pageSiteNikolat84No ratings yet

- LANCANIK Z 7 KORAK P 150mmDocument2 pagesLANCANIK Z 7 KORAK P 150mmNikolat84No ratings yet

- Solid - Program KursevaDocument5 pagesSolid - Program KursevaNikolat84No ratings yet

- Zglobne GlaveDocument4 pagesZglobne GlaveNikolat84No ratings yet

- N9380 (Podloska Lamele Pogona - Hema CB2)Document1 pageN9380 (Podloska Lamele Pogona - Hema CB2)Nikolat84No ratings yet

- 0634 (Poz 2)Document1 page0634 (Poz 2)Nikolat84No ratings yet

- N9988Document1 pageN9988Nikolat84No ratings yet

- N9333Document1 pageN9333Nikolat84No ratings yet

- Konstante Maho 600E2Document6 pagesKonstante Maho 600E2Nikolat84No ratings yet

- Push-In Fittings and Connectors QS, Quick StarDocument93 pagesPush-In Fittings and Connectors QS, Quick StarNikolat84No ratings yet

- Fittings and Accessories 1-0103-En TCM 12-30929 NEWDocument48 pagesFittings and Accessories 1-0103-En TCM 12-30929 NEWNikolat84100% (1)

- O RingDocument89 pagesO RingNikolat84No ratings yet

- DIN3771sizes PDFDocument10 pagesDIN3771sizes PDFVisan GheorgheNo ratings yet

- Intehna NC Mill Promo 2015Document2 pagesIntehna NC Mill Promo 2015Nikolat84No ratings yet

- Chain Catalog UKDocument125 pagesChain Catalog UKÖzkan ÇakırNo ratings yet

- 20160323010627-C45E (Ck45) - C45R (Cm45) PDFDocument2 pages20160323010627-C45E (Ck45) - C45R (Cm45) PDFNikolat84No ratings yet

- Navoji - PodatciDocument88 pagesNavoji - PodatciNikolat84No ratings yet

- Cam Rollers 305701 C 2ZDocument1 pageCam Rollers 305701 C 2ZNikolat84No ratings yet

- Cam Rollers 305701 C 2ZDocument1 pageCam Rollers 305701 C 2ZNikolat84No ratings yet

- 20160323010627-C45E (Ck45) - C45R (Cm45) PDFDocument2 pages20160323010627-C45E (Ck45) - C45R (Cm45) PDFNikolat84No ratings yet

- 10 Probojac 400gDocument1 page10 Probojac 400gNikolat84No ratings yet

- Transformer Fault Detection Using Zigbee and GSMDocument46 pagesTransformer Fault Detection Using Zigbee and GSMIrfan Baig100% (1)

- 3rd-grading-physics-2022-summative-quizDocument2 pages3rd-grading-physics-2022-summative-quizOdessa SantosNo ratings yet

- OnTarget ARA Software InstructionsDocument7 pagesOnTarget ARA Software InstructionsMpmendoNo ratings yet

- SK Product HandbookDocument110 pagesSK Product Handbooksupriyo110No ratings yet

- Field Installation HandbookDocument88 pagesField Installation HandbookRamiro RamirezNo ratings yet

- A Detailed Lesson PlanDocument7 pagesA Detailed Lesson PlanNorol-in SabacanNo ratings yet

- Tower Crane Raft Design ReportDocument22 pagesTower Crane Raft Design ReportFranklyn Genove100% (4)

- Electrical & Electronics Engineering Syllabus-Sem III To Sem VIIIDocument64 pagesElectrical & Electronics Engineering Syllabus-Sem III To Sem VIIISaroj Kumar RajakNo ratings yet

- Final Report - HVACDocument10 pagesFinal Report - HVACBenny BennyNo ratings yet

- Yoke Calibration Test Bar Parker Research Corporation Mpi Magnetic Particle Inspection Probe ElectromagnetDocument2 pagesYoke Calibration Test Bar Parker Research Corporation Mpi Magnetic Particle Inspection Probe Electromagnetnewton5805No ratings yet

- Vensim-Tutorial Stepbystep v.2Document52 pagesVensim-Tutorial Stepbystep v.2Mark DelaNo ratings yet

- Lab3b NewDocument12 pagesLab3b NewChidiebere KaluNo ratings yet

- AB 14 para Tranzystorow DarlingtonaDocument23 pagesAB 14 para Tranzystorow DarlingtonavengalamahenderNo ratings yet

- Constellations 2010 Silicon Valley - Complete Slide SetDocument227 pagesConstellations 2010 Silicon Valley - Complete Slide SetWarren SavageNo ratings yet

- 01 - 04 - Measurement of Skid Resistance PDFDocument2 pages01 - 04 - Measurement of Skid Resistance PDFFlavioMuhaleNo ratings yet

- Compilation of Random Problems From Various OlympiadsDocument4 pagesCompilation of Random Problems From Various OlympiadsaayamNo ratings yet

- Guia Contador de Palabras ClouderaDocument23 pagesGuia Contador de Palabras ClouderaHarrison QUINTERO CAICEDONo ratings yet

- Oracle Fusion Middle Ware Installation Guide For Oracle WebLogic Server 11g Release 1Document86 pagesOracle Fusion Middle Ware Installation Guide For Oracle WebLogic Server 11g Release 1EttoreNo ratings yet

- Proselect Psts21np and Psts11np Installation ManualDocument1 pageProselect Psts21np and Psts11np Installation ManualRyan Murray33% (6)

- NEF Tier 3 Electronic EngineDocument120 pagesNEF Tier 3 Electronic EngineJuan Guzmán100% (12)

- Injection Pump Test SpecificationsDocument2 pagesInjection Pump Test SpecificationsKevin TtitoNo ratings yet

- Chilled Water Fittings - CoDocument209 pagesChilled Water Fittings - CoHarish MenonNo ratings yet

- Electric Towing Tractors: NTT/NTF SeriesDocument5 pagesElectric Towing Tractors: NTT/NTF SeriesВася100% (1)

- The ancient Mayan mathematics systemDocument5 pagesThe ancient Mayan mathematics systemDebby Wura AbiodunNo ratings yet

- CS134 Web Site Design QuizDocument6 pagesCS134 Web Site Design QuizMoulinaDasNo ratings yet

- Database Administration AssessmentDocument10 pagesDatabase Administration AssessmentEsubalewNo ratings yet

- MQSeries Architecture - GeneraliDocument13 pagesMQSeries Architecture - GeneralirajsundarsNo ratings yet

- LETHALITY TABLEDocument44 pagesLETHALITY TABLEdiagnoz7auto7carsvanNo ratings yet

- Calculus and Analytical GeometryDocument8 pagesCalculus and Analytical Geometrynep llNo ratings yet

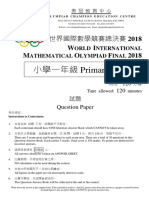

- WIMO Final 2018 Mock P1fDocument8 pagesWIMO Final 2018 Mock P1fDo Yun100% (1)