Professional Documents

Culture Documents

2,400 Liters of Transformer Oil Saved in A Year!: Situation & Problems User S Benefits

2,400 Liters of Transformer Oil Saved in A Year!: Situation & Problems User S Benefits

Uploaded by

RAPRATSINOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2,400 Liters of Transformer Oil Saved in A Year!: Situation & Problems User S Benefits

2,400 Liters of Transformer Oil Saved in A Year!: Situation & Problems User S Benefits

Uploaded by

RAPRATSINCopyright:

Available Formats

Transformer

2,400 Liters of Transformer Oil Saved in a Year!

Situation & Problems

Users Benefits

This 110 KV transformer of 220 KV substation was leaking oil right from its

commissioning in 2003. Shut down and completely drainage of oil for repair

was not possible as it was time consuming and the substation was located in

one of the most important areas in N. Delhi. The customer tried online

welding and repairing with local brand putties but to no success.

Loctite Solution

Previous Problems

Oil was getting percolated into earth & contaminating ground water. Heavy leakage

resulted in high operating cost of the transformer.

Loctite Fixmaster Fast Set Steel Putty, Loctite Fixmaster Superior Metal,

and Loctite Pro Strength Degreaser.

Benefits

With Loctite Fixmaster Fast Set Steel Putty, oil leakage was completely

stopped. INR 736,288 (EUR 13,577) is saved by eliminated downtime. 2,400

Liters of transformer oil wastage is avoided for the customer per annum.

Inventory of transformer oil is reduced.

* EUR/INR=54.23

Loctite Solutions

1

Transformer oil drained from the

sump formed at bottom. Foreign

materials are removed with the

help of a chisel. Area of leakage

was throughly cleaned with

Locitte Pro Strength Degreaser,

and inspected. Areas of leakage

were located & marked.

2

Initial Leakage arresting was done

with Loctite Fixmaster Fast Set

Steel Putty after regularly removing

oil from the sump & cleaning with

Locitte Pro Strength Degreaser.

Leakage was arrested from bottom

to top.

3

Leakage was arrested along the

entire welded joint & entire leakage

was brought to one point as seen in

the picture. This leakage was

arrested by preparing fresh batch of

Loctite Fixmaster Fast Set Steel

Putty, and applied with extra

pressure with hands.

4

After arresting the leakage, the

area was further strengthened by

applying Loctite Fixmaster

Superior Metal on top of Loctite

Fixmaster Fast Set Steel Putty.

Power Generation

IN-M-PGN-2005002

You might also like

- New Generation Lubricating Oils For Indian NavyDocument59 pagesNew Generation Lubricating Oils For Indian NavyAkari SoeNo ratings yet

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- Ultra Grease Lithium EP2Document12 pagesUltra Grease Lithium EP2Balaji BalaNo ratings yet

- GLXXMobilgrease XHP 220 SeriesDocument3 pagesGLXXMobilgrease XHP 220 SeriesJavier Cayampi PomallihuaNo ratings yet

- Mobil Mobilgrease XHP222 DatasheetDocument3 pagesMobil Mobilgrease XHP222 Datasheetphankhoa83-1No ratings yet

- Mobil-Iocaengrsmomobilith SHC PMDocument3 pagesMobil-Iocaengrsmomobilith SHC PM황철No ratings yet

- Mobilgrease HTDocument2 pagesMobilgrease HTPedro PerezNo ratings yet

- UNIREX™ N Series UNIREX™ N Series UNIREX™ N Series UNIREX™ N SeriesDocument3 pagesUNIREX™ N Series UNIREX™ N Series UNIREX™ N Series UNIREX™ N Series121212No ratings yet

- GL XX Mobilgrease XHP 220 SeriesDocument4 pagesGL XX Mobilgrease XHP 220 Seriesingperez.07No ratings yet

- Industrial VisitDocument20 pagesIndustrial VisitKanchan kumarNo ratings yet

- GL XX Mobil Velocite Oil No SeriesDocument2 pagesGL XX Mobil Velocite Oil No SeriescruelweyNo ratings yet

- Mobil DTE Oil Named Series EnglishDocument3 pagesMobil DTE Oil Named Series EnglishEduardo Jesus Galeana GonzalezNo ratings yet

- Mobilgrease XHP 222 Pds PDFDocument3 pagesMobilgrease XHP 222 Pds PDFStefan Cel MareNo ratings yet

- Mobilgrease XHP 222 & Special PDSDocument3 pagesMobilgrease XHP 222 & Special PDScatoeraleifNo ratings yet

- Mobil Polyrex EM: Electric Motor Bearing GreaseDocument3 pagesMobil Polyrex EM: Electric Motor Bearing GreaseCarlos MNo ratings yet

- DTE NamedDocument3 pagesDTE NamedDavid LieNo ratings yet

- GulfSea Hyperbar LCM2 PDFDocument2 pagesGulfSea Hyperbar LCM2 PDFObydur RahmanNo ratings yet

- GL XX Mobilux EP SeriesDocument3 pagesGL XX Mobilux EP SeriesMORTEMNo ratings yet

- GL XX Mobilux EP SeriesDocument3 pagesGL XX Mobilux EP SeriesmooninjaNo ratings yet

- PDSDetail PageDocument2 pagesPDSDetail PageDavid ChuNo ratings yet

- Choose Mobil Industrial Greases As Your Lubrication SolutionDocument2 pagesChoose Mobil Industrial Greases As Your Lubrication SolutionGustavo Henrique MachucaNo ratings yet

- Emkarate RL Refrigeration LubricantsDocument6 pagesEmkarate RL Refrigeration LubricantsBrayan MejiaNo ratings yet

- Texamatic 1888: Proven Performance Automatic Transmission OilDocument3 pagesTexamatic 1888: Proven Performance Automatic Transmission Oilhoussem houssemNo ratings yet

- Function: VTC 300A2 With Control Panel, Dual Level Switches, and HandrailsDocument3 pagesFunction: VTC 300A2 With Control Panel, Dual Level Switches, and HandrailsObionochie Onyinye PatrickNo ratings yet

- Petronas Grease Lix Ep 2/380 and Lix Mep: Advanced Industrial Lithium Complex and Heavy Duty GreasesDocument2 pagesPetronas Grease Lix Ep 2/380 and Lix Mep: Advanced Industrial Lithium Complex and Heavy Duty GreasesSolomon Nebiyu100% (1)

- Hydraulic 6105Document8 pagesHydraulic 6105Deltalube TangerangNo ratings yet

- Product Data Sheet: Optimol OptipitDocument2 pagesProduct Data Sheet: Optimol OptipitFBNo ratings yet

- Mobilux EP 3Document3 pagesMobilux EP 3Sachin JawaleNo ratings yet

- EU XX Mobil DTE Oil Named SeriesDocument4 pagesEU XX Mobil DTE Oil Named Seriessantiago celliNo ratings yet

- Mobilith SHC GreaseDocument3 pagesMobilith SHC Greasealexander900616No ratings yet

- Mobilgear 600 XP Series: Product DescriptionDocument4 pagesMobilgear 600 XP Series: Product DescriptionIvan BecerraNo ratings yet

- Mobilgrease HTR, HTM, HTS and HTF: GreaseDocument2 pagesMobilgrease HTR, HTM, HTS and HTF: GreaseCARLOS ALBERTO GalaNo ratings yet

- Ethane 1800 KW Turbo-Expander Reliability Improvement: Vibration & DGS Seal FailuresDocument18 pagesEthane 1800 KW Turbo-Expander Reliability Improvement: Vibration & DGS Seal FailuressanjeevvangeNo ratings yet

- Machinery Coupling Guard Oil Leakage Design Solutions 1595104444Document13 pagesMachinery Coupling Guard Oil Leakage Design Solutions 1595104444Alexander Rodriguez SarmientoNo ratings yet

- Mobilgrease HT Series Mobilgrease HT Series Mobilgrease HT Series Mobilgrease HT SeriesDocument3 pagesMobilgrease HT Series Mobilgrease HT Series Mobilgrease HT Series Mobilgrease HT SeriesAyon HossenNo ratings yet

- Tarby TitanDocument4 pagesTarby TitanAlberto HerreraNo ratings yet

- GL XX Mobil Velocite Oil No SeriesDocument2 pagesGL XX Mobil Velocite Oil No SeriesShailesh BarbateNo ratings yet

- Presentation HYDRO en 2019Document15 pagesPresentation HYDRO en 2019CINTHIANo ratings yet

- Dodge TXT6 Conveyor 19 Gear Reducer SpecsDocument18 pagesDodge TXT6 Conveyor 19 Gear Reducer SpecsEmmanuel DiazNo ratings yet

- Dge TXT ReducersDocument18 pagesDge TXT ReducersDênis DáyolNo ratings yet

- زيت موبيل PDFDocument3 pagesزيت موبيل PDFSami KahtaniNo ratings yet

- The Ultimate Way To Dehydrate Oils Used in The Hydrocarbon Processing IndustryDocument2 pagesThe Ultimate Way To Dehydrate Oils Used in The Hydrocarbon Processing IndustryDelio Rafael Sánchez FernandezNo ratings yet

- Ball Bearing Case Studies enDocument8 pagesBall Bearing Case Studies ensubodh ranjanNo ratings yet

- Mobil Vactra Oil Numbered Seiries BroshureDocument2 pagesMobil Vactra Oil Numbered Seiries BroshureAnibal RiosNo ratings yet

- CC 46 - Premium Quality Industrial Gas, Steam &combined Cycle Turbine OilDocument2 pagesCC 46 - Premium Quality Industrial Gas, Steam &combined Cycle Turbine OilRaden ArdyNo ratings yet

- GLXXMobil DTE Named SeriesDocument3 pagesGLXXMobil DTE Named Seriesjesusjj01No ratings yet

- Mobilith SHC 100 & 220 Pds PDFDocument2 pagesMobilith SHC 100 & 220 Pds PDFEmerson 2140100% (1)

- Multifak EP: Specialty Industrial GreaseDocument2 pagesMultifak EP: Specialty Industrial GreaseMahmoud TaroutiNo ratings yet

- PDSDetail PageDocument4 pagesPDSDetail Pagemgamal1080No ratings yet

- Molykote Lubrication Petro IndustriesDocument6 pagesMolykote Lubrication Petro IndustriesDicky PratamaNo ratings yet

- Pump Efficiency Improvement Program (Cost Saving & Energy Saving)Document42 pagesPump Efficiency Improvement Program (Cost Saving & Energy Saving)Ns KimNo ratings yet

- Petronas Grease LiX 2-380 and MEPDocument2 pagesPetronas Grease LiX 2-380 and MEPChristianEspinal100% (1)

- GL XX Mobil SHC Grease 460 WTDocument3 pagesGL XX Mobil SHC Grease 460 WTRakka HardiyantaNo ratings yet

- Copper Sail 220Document1 pageCopper Sail 220Fzl2No ratings yet

- Mobilux™ EP 0, 1, 2, 3, 004 and 023: GreaseDocument2 pagesMobilux™ EP 0, 1, 2, 3, 004 and 023: GreaseyierbNo ratings yet

- Molykote High Temperature GreasesDocument1 pageMolykote High Temperature GreasesProject Sales Corp100% (1)

- Mobilux Ep SeriesDocument3 pagesMobilux Ep Seriesyurik119281No ratings yet

- High-Performance GM LS-Series Cylinder Head GuideFrom EverandHigh-Performance GM LS-Series Cylinder Head GuideRating: 4.5 out of 5 stars4.5/5 (2)

- To, The Principle, Hem Sheela Model School, Durgapur, West Bengal, Pin-713214Document1 pageTo, The Principle, Hem Sheela Model School, Durgapur, West Bengal, Pin-713214RAPRATSINNo ratings yet

- Press Release PageDocument2 pagesPress Release PageRAPRATSINNo ratings yet

- Ee256 Power System Protection andDocument1 pageEe256 Power System Protection andRAPRATSINNo ratings yet

- PS7203-Advanced Power System ProtectionDocument6 pagesPS7203-Advanced Power System ProtectionRAPRATSINNo ratings yet

- 6.arteche CVT HVDocument8 pages6.arteche CVT HVRAPRATSINNo ratings yet

- Measurement Based Voltage Stability Monitoring of Power SystemDocument6 pagesMeasurement Based Voltage Stability Monitoring of Power SystemRAPRATSINNo ratings yet

- Industrial Electrical Power System ProtectionDocument5 pagesIndustrial Electrical Power System ProtectionRAPRATSINNo ratings yet

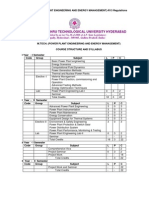

- Power Plant Engineering and Energy Management 2Document22 pagesPower Plant Engineering and Energy Management 2RAPRATSINNo ratings yet

- Relay Protection Coordination Study The Electricity ForumDocument6 pagesRelay Protection Coordination Study The Electricity ForumRAPRATSINNo ratings yet

- Instruction Manual: 5COW423700 - REV02Document16 pagesInstruction Manual: 5COW423700 - REV02RAPRATSINNo ratings yet

- Intelligent Protection: Prospect / RetrospectDocument4 pagesIntelligent Protection: Prospect / RetrospectRAPRATSINNo ratings yet