Professional Documents

Culture Documents

Information For The Application of Boiler Design Approval

Uploaded by

Bukhory Tajudin0 ratings0% found this document useful (0 votes)

42 views2 pagesGuideline for Application of Boiler Design Approval

Original Title

Information for the Application of Boiler Design Approval

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentGuideline for Application of Boiler Design Approval

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

42 views2 pagesInformation For The Application of Boiler Design Approval

Uploaded by

Bukhory TajudinGuideline for Application of Boiler Design Approval

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 2

Gly: relebnt 5 3_ B5R€ 500 6

E APPLI ILER DI

(LOCAL / IMPORTED)

1. The application letter must be from manufacture or owner.

2. Three copies of design drawings showing the principal dimensions of the

steam boiler with views of the front, side and end elevations. ‘The drawings

must be furnished with the following information’s and to be certified by any

recognized Inspecting Authority [ according to Forth Schedule of

Factories and Machinery ( Steam Boiler and Unfired Pressure Vessel )

Regulations 1970 of Factories and Machinery Act. 1967]:

Main dimensions

Welding details

Service, orientation and dimension of each nozzles

Details of flange specifications

Details of material specifications

Design pressure, design temperature, working pressurc,

working temperature, test pressure, design code, Non

Destructive Testing (NDT) details and ete

g Detail drawings of any components and welding including

reference and configuration must be noted on the drawing

h. Full assembly drawing of the boiler showing the essential

fittings

i. Each design drawing must be furnished with the

information's as per Appendix 1 (Local)

j. other useful information (if any)

3. A fully filled form of Boiler Appendix,

4. A set of particulars concerning the formula and design pressure calculations

using the recognized latest edition of design code.

meaoge

5. Every document submitted must be in the Malay or English language.

6. Further information with regards to the above matters and so forth can be

obtained from the Factories and Machinery ( Steam Boiler and Unfired

Pressure Vessel) Regulations 1970 of Factories and Machinery Act. 1967

(Act. 139) and Regulations and Rules.

Notes: Design, fabrication, inspection and testing of the boiler must be followed as

per required by recognized latest edition of design code.

BOILER APPENDIX

INFORMATI

1 | Reference Letter

2 | Date of Receive

3 | Processing Status

| Applicant Name and Address

5 | Type of Boiler

© | Model (if any)

T | Heating Surface (m)

@ | Design Drawing No.

Boiler

Economizer

Thermal Oi

Heater,

9 | Safe Working Pressure (kPa)

70 | Test Pressure (kPa)

11 | Design Temperature (Celcius)

72 | Design Code

13 | Capacity (kg/hr)

74 | Owner

18 | DOSH State

76 | Manufacturer

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Sprinkler Calculation - Training Room No 3 - 4Document15 pagesSprinkler Calculation - Training Room No 3 - 4Bukhory Tajudin100% (1)

- Line Sizing - Training Room No 3 - 4Document10 pagesLine Sizing - Training Room No 3 - 4Bukhory Tajudin0% (1)

- Lean EngineeringDocument4 pagesLean EngineeringBukhory TajudinNo ratings yet

- Chapter 1 - PsychrometricsDocument31 pagesChapter 1 - PsychrometricsBukhory TajudinNo ratings yet

- Engineering Specification For Piping DesignDocument24 pagesEngineering Specification For Piping DesignBukhory TajudinNo ratings yet

- Requisition For Carbon Steel VesselDocument28 pagesRequisition For Carbon Steel VesselBukhory TajudinNo ratings yet

- Petronas/Ucc JV Malaysia Project: Pressure-Temperature Ratings Pipe MaterialDocument5 pagesPetronas/Ucc JV Malaysia Project: Pressure-Temperature Ratings Pipe MaterialBukhory TajudinNo ratings yet

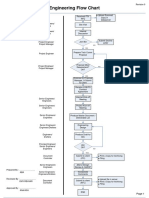

- Engineering Flowchart - Rev0Document1 pageEngineering Flowchart - Rev0Bukhory TajudinNo ratings yet

- Guideline For CEMS (Continous Emission Monitoring System)Document27 pagesGuideline For CEMS (Continous Emission Monitoring System)Anonymous exJEEJBNo ratings yet

- Eng Spec For Acoustic InsulationDocument48 pagesEng Spec For Acoustic InsulationBukhory TajudinNo ratings yet

- CNH-B 80-200/11: Charact. CurvesDocument1 pageCNH-B 80-200/11: Charact. CurvesBukhory TajudinNo ratings yet

- Malaysian Sewerage Industry Guideline (Volume III) 1st EditionDocument165 pagesMalaysian Sewerage Industry Guideline (Volume III) 1st EditionBukhory Tajudin100% (2)

- Environmental Quality - Clean Air - Regulations 1978Document33 pagesEnvironmental Quality - Clean Air - Regulations 1978Ahmad AzuwanNo ratings yet

- Ms-1228-1991 Design & Installation of Sewerage...Document49 pagesMs-1228-1991 Design & Installation of Sewerage...Bukhory Tajudin100% (1)

- 05 Jadual3 PDFDocument24 pages05 Jadual3 PDFBukhory TajudinNo ratings yet

- Sample of Piping Vibration StudyDocument12 pagesSample of Piping Vibration StudyBukhory Tajudin100% (1)

- Load CasesDocument8 pagesLoad Casestebodin_319100% (1)

- P11218 SPE ME 00 - 005 RevB Spec For Pressure VesselDocument17 pagesP11218 SPE ME 00 - 005 RevB Spec For Pressure VesselBukhory TajudinNo ratings yet

- Al-Mawa'ithat Ul-Hasana ENGDocument29 pagesAl-Mawa'ithat Ul-Hasana ENGThe Arrivalists - Al QadimoenNo ratings yet

- (Page Chapter 5 - ACGIH) : Velocity Pressure Method Calculation SheetDocument2 pages(Page Chapter 5 - ACGIH) : Velocity Pressure Method Calculation SheetBukhory Tajudin0% (1)

- Price List: Jadual Kadar Sewa Loji 2003Document9 pagesPrice List: Jadual Kadar Sewa Loji 2003nik arif100% (3)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)