Professional Documents

Culture Documents

Munters High Temp Psych Chart

Uploaded by

aniruddhaskCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Munters High Temp Psych Chart

Uploaded by

aniruddhaskCopyright:

Available Formats

90

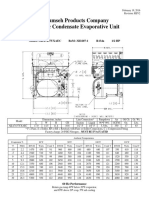

PSYCHROMETRIC CHART

HIGH TEMP

11

ET

LB

14

0

400

RE

19.0

17.0

PE

18.0

75

105

2.2

340

16.0

Y AIR

320

2.0

RATUR

ATION

55

240

90

220

SATUR

50

25%

TEMPE

260

90

200

15.0

180

CIFI

SPE

80

OLU

CV

80%

70%

50

%

40

%

50

40

30

%

20

20

30

10%

40

50

60

4%

40

2%

20

20

5

60

70

Linric Company Psychrometric Chart, www.linric.com

80

80

6%

%

30

13.0

40

30

ATIV

REL

90

IDIT

HUM

100

110

120

90

85

80

1.4

1.2

1.0

75

.8

65

8%

60

%

50

10

AIR

60

15

1.6

100

14.0

60

95

70

DRY

70

20

120

OF

70

25

140

ft/lb

90%

ME

80

30

160

15%

40

1.8

130

140

150

160

170

180

190

200

DRY BULB TEMPERATURE - F

210

220

230

240

250

260

270

280

290

300

.6

60

55

.4

50

45

40

35

30

25

20

10

0

-40

.2

VAPOR PRESSURE - INCHES OF MERCURY

E - F

280

HUMIDITY RATIO - GRAINS OF MOISTURE PER POUND OF D

RY AIR

10

0

60

100

300

65

DEW POINT - F

OF DR

100

45

35

2.4

360

70

POUND

13

5

380

TE

TU

TU PER

13

0

12

5

BU

RA

LPY - B

12

0

11

5

80

ENTHA

11

0

10

5

10

0

95

85

FORMULAS AND CONVERSION FACTORS

WATER VAPOR

7,000 grains = 1 lb. of water

1 gallon water = 8.3 lbs.

FUEL-ENERGY CONVERSION

1 kW electricity = 3,412 BTU/hr

1 Ft3 natural gas = 1,000 BTU

1 gallon #2 fuel oil = 140,000 BTU

1 gallon propane = 91,600 BTU

1 gallon propane = 35.97 ft3 propane

1 therm = 100,000 BTU/hr

1 kCal/hr = 3.968 BTU/hr

FLOW CONVERSION

PAYBACK

SCFM = lb/hr / 4.5

Yearly savings = MMBTU/hr saved* Yearly

hours of operation* Cost of Fuel ($/MMBTU)

SCFM = ACFM * [530/(460 + T)]

ACFM = SCFM * [(460 + T)/530] (sea level)

Altitude Correction Factor:

[(1 - (0.003566*Alt) / 518.69)^5.26]

(Alt = altitude in feet)

ACFM = SCFM*[(460 + T) / 530] / [(1 (0.003566*Alt) / 518.69)^5.26]

Nm3/hr = Normal m3/hr = m3/hr measured

at 0C

SCFM = Nm3/hr * 0.634

HEAT EXCHANGER EFFECTIVENESS

% = T2-T1

T3-T1

T1 = cold gas inlet

T2 = cold gas outlet

T3 = hot gas inlet

T4 = hot gas outlet

Hp (air) = SCFM *P (in. H2O) /

(6,350 * Eff.)

PRESSURES

Hp (water) = GPM *P (ft. H2O) /

(3,960 * Eff.)

27.7 inches W.C. = 1 psi

Valid with equal ows or when cold ow is

the smallest

1 bar = 14.5 psi

STACK FRICTION LOSS

1 inch W.C. = 25.4 mm W.C.

Friction Loss (in W.C.)/100 ft. of stack =

[(0.109136* q1.9)] / [D5.02]

SENSIBLE HEATING/COOLING

BTU/hr = lb/hr * Cp * T

BTU/hr = SCFM * 1.08 * T

(Assumes Cp = .24 and density = .075 lb/ft3)

BTU/hr = 500 * GPM * T

BTU/hr = 4.5 * SCFM * h (Total Energy)

BTU/hr = 4,840 * SCFM * HR

(Latent Energy)

BR0009-00

Simple payback = equipment cost /

yearly savings

THERMAL MATERIAL PROPERTIES

Material

Density

(lb / in3)

1100

Aluminum

0.1

Thermal

Coeff of Thermal

Conductivity

Expansion

(BTU / hr - in (in / in-F)

Ft2 - F)

13 x 10-6

-6

D = stack diameter in inches

q = Air ow rate in CFM (cubic feet

per minute)

1536

Carbon Steel

0.29

7.7 x 10

456

304

Stainless Steel

0.29

10 x 10-6

105.6

12,000 BTUs = 1 ton

AMBIENT PRESSURE AT ALTITUDE

Tons = 24 * GPM * T (water)

P (psia) = 14.696* [1 - (6.8754* 10-6 *

Alt)]5.2559

Note: These formulae are for reference and estimation

purposes only. Assumptions have been made to

simplify formulae and conversions.

You might also like

- Design Formulae: Reference CardDocument4 pagesDesign Formulae: Reference Cardcharge3No ratings yet

- "Solutions For The Plastics Industry": Co. IncDocument4 pages"Solutions For The Plastics Industry": Co. IncminiongskyNo ratings yet

- Thermal Tech EquipmentcoDocument5 pagesThermal Tech EquipmentcoSaleem UddinNo ratings yet

- Tecumseh evaporative unit specsDocument2 pagesTecumseh evaporative unit specsAlexisNo ratings yet

- Access Denied Your Page Is Blocked Due To A Security Policy That Prohibits Access To Category DefaultDocument87 pagesAccess Denied Your Page Is Blocked Due To A Security Policy That Prohibits Access To Category DefaultSahil PalNo ratings yet

- Engineering Formulas: Nominal Design ParametersDocument4 pagesEngineering Formulas: Nominal Design Parametersbashist1969No ratings yet

- HVAC Formulas by AEMEPDocument9 pagesHVAC Formulas by AEMEPZen LohNo ratings yet

- Book 1Document6 pagesBook 1Punthep PunnotokNo ratings yet

- 2008 Refrigerated Dryers Binder NewDocument17 pages2008 Refrigerated Dryers Binder NewGeorge CharitouNo ratings yet

- R407C Air-Cooled Split SystemsDocument30 pagesR407C Air-Cooled Split SystemsTerry GunawanNo ratings yet

- Thumb Rules Xls For Chemical EngineerDocument44 pagesThumb Rules Xls For Chemical EngineershashibagewadiNo ratings yet

- Thumb Rules For Chemical EngineerDocument44 pagesThumb Rules For Chemical EngineerNallathambiNo ratings yet

- Design DataDocument29 pagesDesign DatakalyanikishoreNo ratings yet

- Psych Chart TraneDocument1 pagePsych Chart Tranebhargavacharya0% (1)

- Compresor 104G 7550 DanfossDocument2 pagesCompresor 104G 7550 DanfossAdán Castro GallegosNo ratings yet

- Split Type Air Conditioner Engineering DataDocument114 pagesSplit Type Air Conditioner Engineering DataHenry Colmenares0% (1)

- DC Inverter Multi-Split Air Conditioner Service ManualDocument62 pagesDC Inverter Multi-Split Air Conditioner Service ManualFrancis RiveroNo ratings yet

- Performance Data: 345 1 BB, BCDocument2 pagesPerformance Data: 345 1 BB, BCtexwan_No ratings yet

- Conversion Factors - Gas IndustryDocument2 pagesConversion Factors - Gas IndustryKailas Nimbalkar100% (3)

- Fujitsu RLS2HDocument2 pagesFujitsu RLS2HEric HalsteadNo ratings yet

- Location of X Ray Viwers, Storage, Graphics, Mgps Sockets and Power PanelDocument17 pagesLocation of X Ray Viwers, Storage, Graphics, Mgps Sockets and Power PanelNazir Uddin SodawalaNo ratings yet

- Performance Data: Curve 14.00 1BB065, 2BB065Document2 pagesPerformance Data: Curve 14.00 1BB065, 2BB065texwan_No ratings yet

- Webasto-Blue Line Premium A-C SystemDocument12 pagesWebasto-Blue Line Premium A-C Systemhayrierenli100% (1)

- Air Compressors, Screw Type, Altitude Corrections - 01 PDFDocument28 pagesAir Compressors, Screw Type, Altitude Corrections - 01 PDFluisbitron1527No ratings yet

- PROPANE TANK SPECIFICATIONS AND PROPERTIESDocument25 pagesPROPANE TANK SPECIFICATIONS AND PROPERTIESNicandroGonzalesNo ratings yet

- Engineering Formulas: Nominal Design ParametersDocument4 pagesEngineering Formulas: Nominal Design Parametersehtesham314No ratings yet

- Barometric pressure and psychrometric chart dataDocument1 pageBarometric pressure and psychrometric chart dataJavier MendozaNo ratings yet

- Psychrometric Chart: Enthalpy - Btu Per Pound of Dry AirDocument1 pagePsychrometric Chart: Enthalpy - Btu Per Pound of Dry AirFa Ch100% (1)

- Psych Ro Metric ChartDocument1 pagePsych Ro Metric ChartGuilherme RezendeNo ratings yet

- Psikometric ChartDocument1 pagePsikometric Chartjohn_kadier651No ratings yet

- Psychrometric Sist. INGLESDocument1 pagePsychrometric Sist. INGLESguzmanitaNo ratings yet

- Psychrometric Chart: Enthalpy - Btu Per Pound of Dry AirDocument1 pagePsychrometric Chart: Enthalpy - Btu Per Pound of Dry AirElvis HuvNo ratings yet

- Skenario Poly AbDocument4 pagesSkenario Poly AbRahadyan AkbarNo ratings yet

- Gas Turbine PerformancexlsDocument15 pagesGas Turbine PerformancexlsMahmood ElnagarNo ratings yet

- HSPCDocument2 pagesHSPCAhmed AzadNo ratings yet

- SPW Immersion Fired - Specification Data Sheet (7000)Document9 pagesSPW Immersion Fired - Specification Data Sheet (7000)daemonohNo ratings yet

- Unit-4 TG Desk Engineer'S Log BookDocument6 pagesUnit-4 TG Desk Engineer'S Log BookJai GuptaNo ratings yet

- Acson Catalogue Ceiling Cassette ECOCool Inverter CAT-ACKE ACKC-1301Document7 pagesAcson Catalogue Ceiling Cassette ECOCool Inverter CAT-ACKE ACKC-1301PH LimNo ratings yet

- Danfoss-Maneurop Refrigeration Hermetic Condensing UnitsDocument25 pagesDanfoss-Maneurop Refrigeration Hermetic Condensing Unitsegon73_gmail_comNo ratings yet

- Surface Production Operations 7Document108 pagesSurface Production Operations 7Сергей Вельдяксов100% (1)

- CALCULATION Characteristic Pump2Document16 pagesCALCULATION Characteristic Pump2Ahlan Haryo PambudiNo ratings yet

- 4ZS01350 Data Sheet DM8605 G3606 A3Document5 pages4ZS01350 Data Sheet DM8605 G3606 A3MitulNo ratings yet

- Technical specifications and features of high wall air conditioning unitsDocument2 pagesTechnical specifications and features of high wall air conditioning unitsAhmed ElsayedNo ratings yet

- Universal Compressor Data Sheet R134a 115V 60HzDocument2 pagesUniversal Compressor Data Sheet R134a 115V 60HzWalther Joshue CanelNo ratings yet

- Fcu 2Document1 pageFcu 2Iban GranadosNo ratings yet

- Formulas: Nominal Design ParametersDocument4 pagesFormulas: Nominal Design Parametersehtesham314No ratings yet

- Pump SpecificationsDocument2 pagesPump Specificationsstranger252LavaNo ratings yet

- Lp-Gas Serviceman'S Manual: Now Available in The Rego App!Document56 pagesLp-Gas Serviceman'S Manual: Now Available in The Rego App!Shehab Abu AhmadNo ratings yet

- Midea 2005 Split Service ManualDocument359 pagesMidea 2005 Split Service ManualSotiris Ioannou60% (5)

- Design Data BaseDocument17 pagesDesign Data BaseparthivNo ratings yet

- 07 Ac 85-225 - Rev 01-2001Document43 pages07 Ac 85-225 - Rev 01-2001Jon LercheNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Southern Marine Engineering Desk Reference: Second Edition Volume IFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INo ratings yet

- Warm Air Heating: International Series of Monographs in Heating, Ventilation and RefrigerationFrom EverandWarm Air Heating: International Series of Monographs in Heating, Ventilation and RefrigerationNo ratings yet

- Gas Sweetening and Processing Field ManualFrom EverandGas Sweetening and Processing Field ManualRating: 4 out of 5 stars4/5 (7)

- Total Energy: International Series in Heating, Ventilation and RefrigerationFrom EverandTotal Energy: International Series in Heating, Ventilation and RefrigerationNo ratings yet

- Handbook of Heating, Ventilating and Air ConditioningFrom EverandHandbook of Heating, Ventilating and Air ConditioningRating: 4 out of 5 stars4/5 (6)

- Cooling TowersDocument4 pagesCooling TowersAjay SastryNo ratings yet

- Cooling Tower IITDDocument32 pagesCooling Tower IITDsnehangshu06No ratings yet

- As Built But For Schedule Delay AnalysisDocument25 pagesAs Built But For Schedule Delay AnalysisaniruddhaskNo ratings yet

- Viking Johnson Dismantling Joint+brochureDocument13 pagesViking Johnson Dismantling Joint+brochureaniruddhaskNo ratings yet

- Chapter-Cooling TowersDocument17 pagesChapter-Cooling TowersSAGIS ETIENNENo ratings yet

- Cooling TowersDocument4 pagesCooling TowersAjay SastryNo ratings yet

- Anchor Panasonic RangeDocument147 pagesAnchor Panasonic RangeaniruddhaskNo ratings yet

- Cooling Tower FundamentalsDocument117 pagesCooling Tower FundamentalspadzicNo ratings yet

- Ashtavakra Gita - Bart MarshallDocument60 pagesAshtavakra Gita - Bart Marshallமோகன் புதுவைNo ratings yet

- Six Glorious Epochs of Indian History - Veer SavarkarDocument401 pagesSix Glorious Epochs of Indian History - Veer SavarkarsatyabhashnamNo ratings yet

- Arthashastra of Chanakya - EnglishDocument614 pagesArthashastra of Chanakya - EnglishHari Chandana K83% (6)

- Understanding Exposure in DSLR CamerasDocument91 pagesUnderstanding Exposure in DSLR CamerasaniruddhaskNo ratings yet

- Fire DuctDocument6 pagesFire DuctaniruddhaskNo ratings yet

- Understanding Exposure in DSLR CamerasDocument91 pagesUnderstanding Exposure in DSLR CamerasaniruddhaskNo ratings yet

- Arthashastra of Chanakya - EnglishDocument614 pagesArthashastra of Chanakya - EnglishHari Chandana K83% (6)