Professional Documents

Culture Documents

Design Formulae: Reference Card

Uploaded by

charge3Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design Formulae: Reference Card

Uploaded by

charge3Copyright:

Available Formats

Design Formulae

Reference Card

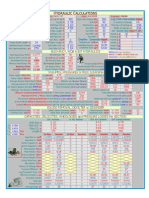

INJECTION MOLDING LBS./HR PER 1 TON MATERIAL 30 HDPE 35 LDPE 35 ACRYLIC 35 PP PPO 40 NYLON 6, 66 40 40 POLYURETHANE PET 40 PS 50 ABS 50 PC 50 CELCON 50 ACETAL 50 PVC 75 BLOW MOLDING LBS./HR MATERIAL PER 1 TON HDPE 40 PET 40 PVC 70

EXTRUSION PIPE PROFILE LBS./HR PER 1 TON MATERIAL 50 HDPE 50 LDPE 50 PP 50 PET 60 ABS 65 PVC 75 PS EXTRUSION TROUGH, BATH, CHILL ROLL 60 POLYSTYRENE ABS 60

VACUUM FORMING LBS./HR MATERIAL PER 1 TON HDPE 70 LDPE 70 PP 70 PS 200 PVC 250

1.14 TONS 1.05 TONS 0.85 TONS INCOMING AIR

BLOWN FILM 100 CFM @ 40 F AIR 33 F GLYCOL 100 CFM @ 45 F AIR 35 F GLYCOL 100 CFM @ 50 F AIR 40 F WATER 90 F D.B./78 F W.B. INCLUDES FAN MOTOR HEAT

COOLING TOWER LOAD FACTORS 1 TON PER INCH OF SCREW DIA. 2 TONS (NOMINAL) 1 TON FOR SCREWS UP TO 3 DIA. 2 TONS FOR SCREWS FROM 4 6 DIA. GEAR DRIVE 0.1 TON PER HP HYDRAULICS 0.1 TON PER HP (< 5 SEC CYCLE TIME) 0.15 TONS PER HP (> 5 SEC CYCLE TIME) SPOT WELDERS 15,000 BTUH PER 100 KVA VACUUM PUMP 0.1 TON PER HP AIR COMP. (NO DRYER) 0.15 TONS PER HP 0.2 TONS PER HP AIR COMP. (WITH DRYER) BARREL SCREW THROAT GENERAL FORMULAE (GPM X DELTA WATER TEMP) / 24 CFM X 1.085 X (DRY BULB 1 DRY BULB 2) CFM X 0.68 X (GRAINS 1 GRAINS 2) CFM X 4.5 X (ENTHALPY 1 ENTHALPY 2) 80 SQ FT PER TON (US GPM X FT HD) / (3960 X PUMP EFFICIENCY) (CFM X INCHES S.P.) / (6356 X STATIC EFFICIENCY) LOAD + (0.5 TONS PER 3/4 HP ZONE) AMPS X VOLTS X 3.414 = BTUH WEB WIDTH () X (0.0000252 X WEB SPEED (FPM) X STOCK WEIGHT (LBS.) X DELTA WEB TEMP (DEG F) X SPEC HEAT (0.342) X 60 MINUTES = BTUH 1 TON PER 125 CFM 1 TO 12 TONS PER PRINTING UNIT

TONS: AIR-SENSIBLE HEAT (BTUH) AIR-LATENT HEAT (BTUH) AIR-TOTAL HEAT (BTUH) AIR-MOLD ROOM HVAC HP- PUMP MOTORS HP FAN MOTOR TCUs RECTIFIERS PRINTING WEB COOLING

PRINTING FOLDER AIR PRINTING VIBRATORS

60 HERTZ GPM HEAD B.H.P. 3,500 RPM 1,750 RPM

PUMP OPERATION AT 50 HZ 50 HERTZ OPERATION X 0.829 (17%) X 0.687 (31%) X 0.569 (43%) 2,900 RPM 1,450 RPM ENERGY & TEMPERATURE 12,000 BTUH (TRUE CONVERSION) 15,000 BTUH (NOMINAL TOWER TON) 0.293 WATTS 252 CALORIES 0.252 KG-CAL (DEG F -32) / 1.8 = DEG C (DEG C X 1.8) + 32 = DEG F POWER

1 TON 1 BTU TEMPERATURE

1 HP PRESSURE 1 PSI

2,545 BTUH 746 WATTS

2.31 FT HD 0.068947 BAR 6.8947 KILOPASCALS 2.036 INCHES OF MERCURY FLOW 3.785 LITRES / MINUTE 227.1 LITRES / HOUR 0.2271 CU METRES / HOUR VOLUME 7.481 U.S. GALLONS 0.0283 CU METRES 35.314 CU FEET 264.2 U.S. GALLONS 8.34 POUNDS OF WATER 3.785 LITRES 0.833 IMPERIAL GALLONS AREA / MISC. 0.0929 SQ METRES (DIA X DIA) X 0.7854 DIA X 3.142 (DIA X DIA) X 0.7854 X LENGTH DISTANCE

1 US GPM

1 CU FT 1 CU METRE 1 U.S. GALLON

1 SQ FT AREA OF A CIRCLE CIRCUM OF A CYLINDER VOLUME OF A CYLINDER

1 INCH 1 FOOT 1 YARD 1 MILE

2.54 CM 30.48 CM 0.9144 METRES 1.609 KILOMETRES PRESSURE DROP ACROSS CONTROL VALVES PSI PRESS DROP = (DESIGN GPM / VALVE CV)2

ELEVATION ABOVE SEA LEVEL 2,000 FT 4,000 FT 6,000 FT 8,000 FT

DERATE CONDENSER BY 0.95 0.90 0.87 0.83

PIPE SIZING GUIDE PROCESS PIPING LOSSES PIPE PER WATER FLOW 100FT VELOCITY SIZE 2 GPM 4.8 FT HD 2.2 FPS 1/2 3/4 4 GPM 4.2 FT HD 2.4 FPS 1 7 GPM 3.6 FT HD 2.6 FPS 15 GPM 3.8 FT HD 3.3 FPS 1 1/4 23 GPM 3.9 FT HD 3.2 FPS 1 1/2 45 GPM 3.9 FT HD 4.3 FPS 2 2 1/2 73 GPM 3.9 FT HD 4.9 FPS 3 131 GPM 3.9 FT HD 5.7 FPS 4 270 GPM 4.0 FT HD 6.8 FPS 796 GPM 4.0 FT HD 8.9 FPS 6 1,530 GPM 3.6 FT HD 10.0 FPS 8 10 2,450 GPM 2.8 FT HD 10.0 FPS 12 3,500 GPM 2.3 FT HD 10.0 FPS 4,200 GPM 2.0 FT HD 10.0 FPS 14 5,500 GPM 1.7 FT HD 10.0 FPS 16

TOWER RETURNS FLOW WATER VELOCITY

90 GPM 155 GPM 360 GPM 620 GPM 975 GPM 1,400 GPM 1,680 GPM 2,200 GPM

<4 <4 <4 <4 <4 <4 <4 <4

FPS FPS FPS FPS FPS FPS FPS FPS

FITTINGS ADD FRICTIONAL LOSS IN EQUIVALENT LENGTH OF PIPE BALL VALVE TEE PIPE STRAIGHT CHECK REDUCED GATE ELBOW THRU VALVE PORT VALVE SIZE 1/2 3.6 2.4 8.0 3.5 0.7 3/4 4.4 3.2 8.8 4.5 0.9 1 5.2 4.6 11.0 3.0 1.0 1 1/4 6.6 5.6 13.0 6.5 1.5 1 1/2 7.4 7.7 15.0 4.5 1.8 2 8.5 9.3 19.0 9.0 2.3 2 1/2 9.3 2.2 22.0 3.5 2.8 3 4.4 2.8 27.0 5.0 3.2 4 5.9 3.3 38.0 19.0 4.5 6 8.9 3.8 50.0 7.0 8 12.0 4.7 63.0 9.0 10 14.0 5.2 90.0 12.0 12 17.0 6.0 120.0 13.0 14 18.0 6.4 140.0 15.0 16 21.0 7.2 150.0 17.0 ETHYLENE GLYCOL PERCENT FREEZE SPECIFIC VOLUME POINT HEAT 10% 25 F 0.938 20% 17 F 0.894 30% 5F 0.847 40% -12 F 0.792 50% -35 F 0.732 PROPYLENE GLYCOL PERCENT FREEZE SPECIFIC VOLUME POINT HEAT 10% 26 F 0.958 20% 18 F 0.935 30% 8F 0.897 40% -7 F 0.852 50% -28 F 0.796

COMMONLY USED TOWER CITY-WATER MAKE-UP CALCULATIONS EVAP. RATE = 2 GPM PER 1,000,000 BTUH EVAP. RATE = 3 GPM PER 100 TOWER TONS {(TOTAL BTUH) / 960 BTU PER LB. / 8.33 LBS. PER GAL / 60 MINUTES PER HOUR} X 2 ( = BLEED-OFF RATE FACTOR) = GPM MAKE-UP

CIMCO REFRIGERA TION 65 Villiers Street, Toronto, Ontario M5A 3S1 Tel: (416) 465-3987 Fax: (416) 465-8815 St. Johns Dartmouth Moncton Alma Quebec City Montreal Gasp Ottawa Toronto London Windsor Winnipeg Regina Saskatoon Calgary Edmonton Vancouver Kelowna Victoria Hartford Salt Lake City Houston Dallas/Ft. Worth Phoenix Syracuse London, UK Beijing, PR. China Visit our website at www.cimcorefrigeration.com

You might also like

- Southern Marine Engineering Desk Reference: Second Edition Volume IFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INo ratings yet

- Munters High Temp Psych ChartDocument2 pagesMunters High Temp Psych ChartaniruddhaskNo ratings yet

- "Solutions For The Plastics Industry": Co. IncDocument4 pages"Solutions For The Plastics Industry": Co. IncminiongskyNo ratings yet

- Gas Sweetening and Processing Field ManualFrom EverandGas Sweetening and Processing Field ManualRating: 4 out of 5 stars4/5 (7)

- Thermal Tech EquipmentcoDocument5 pagesThermal Tech EquipmentcoSaleem UddinNo ratings yet

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- Engineering Formulas: Nominal Design ParametersDocument4 pagesEngineering Formulas: Nominal Design Parametersbashist1969No ratings yet

- PBL Hole CleaningDocument2 pagesPBL Hole CleaningOlgaLuciaNo ratings yet

- FORMULASDocument5 pagesFORMULASsrinivas1973No ratings yet

- Satuan New (Unit)Document29 pagesSatuan New (Unit)Avininda FitriaNo ratings yet

- Engineering Formulas: Nominal Design ParametersDocument4 pagesEngineering Formulas: Nominal Design Parametersehtesham314No ratings yet

- Fluid Power FormulasDocument5 pagesFluid Power FormulasSamad A BakarNo ratings yet

- Thumb Rules Xls For Chemical EngineerDocument44 pagesThumb Rules Xls For Chemical EngineershashibagewadiNo ratings yet

- Thumb Rules For Chemical EngineerDocument44 pagesThumb Rules For Chemical EngineerNallathambiNo ratings yet

- Hoja de Calculo FP Borrador - 2Document14 pagesHoja de Calculo FP Borrador - 22artNo ratings yet

- Process Flow DiagramDocument1 pageProcess Flow DiagramRobie RoqueNo ratings yet

- Conversion Factors - Gas IndustryDocument2 pagesConversion Factors - Gas IndustryKailas Nimbalkar100% (3)

- Hydraulics, PsiDocument1 pageHydraulics, Psiscrbdgharavi100% (1)

- Hydraulic Calculations MudpumpDocument1 pageHydraulic Calculations MudpumpSudish BhatNo ratings yet

- Formulas: Nominal Design ParametersDocument4 pagesFormulas: Nominal Design Parametersehtesham314No ratings yet

- Kill Sheet HHHHHDocument5 pagesKill Sheet HHHHHRyan Llaneta67% (3)

- Engineering FormulaeDocument49 pagesEngineering FormulaedestresscallNo ratings yet

- Perhitungan CT, Hydrant, Dan BlowerDocument13 pagesPerhitungan CT, Hydrant, Dan BlowerNicholas GeorgeNo ratings yet

- Salamat-1 Mud Report 54-28092012Document4 pagesSalamat-1 Mud Report 54-28092012mega87_2000No ratings yet

- Drilling FormulasDocument87 pagesDrilling FormulasVeCoMo100% (1)

- Pipe Calculations For Velocity and GPMDocument1 pagePipe Calculations For Velocity and GPMAhmed El GebalyNo ratings yet

- Air Compressors, Screw Type, Altitude Corrections - 01 PDFDocument28 pagesAir Compressors, Screw Type, Altitude Corrections - 01 PDFluisbitron1527No ratings yet

- Bottomholemodaloil PCDocument6 pagesBottomholemodaloil PCKimiko ShopNo ratings yet

- Asme Sec. Viii Div-1) : THK - Calc. (Document35 pagesAsme Sec. Viii Div-1) : THK - Calc. (hardik5818No ratings yet

- Chiller Refrigeration TonsDocument6 pagesChiller Refrigeration Tonsrogel_ganaNo ratings yet

- Design DataDocument29 pagesDesign DatakalyanikishoreNo ratings yet

- New Microsoft Office Excel WorksheetDocument16 pagesNew Microsoft Office Excel WorksheetAaron Horton100% (1)

- PSV Seabulk AngraDocument2 pagesPSV Seabulk AngraCriss MadNo ratings yet

- Hydraulic Calc by VassDocument1 pageHydraulic Calc by VassKyzak K. KeorkNo ratings yet

- Steam Drum LevelsDocument11 pagesSteam Drum LevelsAnith kumar Reddy100% (1)

- Brown Field Pipe Rack Design ForcesDocument7 pagesBrown Field Pipe Rack Design ForcesjnmanivannanNo ratings yet

- Hydraulic Calculations & MudpumpDocument1 pageHydraulic Calculations & MudpumpUok Ritchie100% (1)

- Pilot Hole Hole OpenerDocument2 pagesPilot Hole Hole OpenerscrbdgharaviNo ratings yet

- PROPANE TANK SPECIFICATIONS AND PROPERTIESDocument25 pagesPROPANE TANK SPECIFICATIONS AND PROPERTIESNicandroGonzalesNo ratings yet

- Vertical Wells, WT & WT MethodDocument2 pagesVertical Wells, WT & WT MethodSudish BhatNo ratings yet

- Mud FormulasDocument10 pagesMud FormulasWilmer PalenciaNo ratings yet

- Horizontal SeparatorDocument16 pagesHorizontal SeparatorMaryJane Ayisha Sado-Obah100% (1)

- SVS Well hydraulic calculations and drilling parametersDocument1 pageSVS Well hydraulic calculations and drilling parametershuangjlNo ratings yet

- HYD01Document6 pagesHYD01scrbdgharaviNo ratings yet

- Design CalculationsDocument43 pagesDesign CalculationsPravin Nair90% (10)

- Cement PlannerDocument6 pagesCement PlannerscrbdgharaviNo ratings yet

- ConversionFactors PDFDocument1 pageConversionFactors PDFBboubrahim BbnnNo ratings yet

- Sprinkler SystemDocument16 pagesSprinkler SystemNethaji100% (1)

- EIND 3184 15 Liquid Flash Vessel SizingDocument20 pagesEIND 3184 15 Liquid Flash Vessel SizingzamijakaNo ratings yet

- Diámetros Tubería ConvertidorDocument1 pageDiámetros Tubería ConvertidorROBERTO OCTAVIO PEREZ LOPEZNo ratings yet

- Mud Tool KitDocument52 pagesMud Tool KitChris RoarkNo ratings yet

- Project: El Madaen Duct Pressure LossesDocument40 pagesProject: El Madaen Duct Pressure LossesKarthy GanesanNo ratings yet

- Qaverage Phase-1 Phase-2 Qpeak Phase-1 Phase-2 m3/d m3/d m3/hr m3/hr M3/sec M3/secDocument7 pagesQaverage Phase-1 Phase-2 Qpeak Phase-1 Phase-2 m3/d m3/d m3/hr m3/hr M3/sec M3/secHemantk8731100% (1)

- Daikin - RXYQ-PBTJ VRVIII 208-230 Heat Pump PDFDocument64 pagesDaikin - RXYQ-PBTJ VRVIII 208-230 Heat Pump PDFLuis DomdNo ratings yet

- B1. Fan Laws and Fan Control - RobinsonDocument74 pagesB1. Fan Laws and Fan Control - RobinsonNelly Isabel Narvaez PachecoNo ratings yet

- Filament Yarn Quench AirDocument2 pagesFilament Yarn Quench AirClarence AG YueNo ratings yet

- CE 432 Wastewater treatment plant design optimizationDocument19 pagesCE 432 Wastewater treatment plant design optimizationjnmanivannanNo ratings yet

- Column sizing input dataDocument29 pagesColumn sizing input datasyamsudin2006100% (1)

- IVECO NEF SeriesDocument36 pagesIVECO NEF SeriesOlivier ORMANNo ratings yet

- Execution and Documentation Requirements For Life Cycle Cost AnalysesDocument20 pagesExecution and Documentation Requirements For Life Cycle Cost AnalysessmetNo ratings yet

- Design For Six Sigma Za PrevodDocument21 pagesDesign For Six Sigma Za PrevodSrdjan TomicNo ratings yet

- The 4 PsDocument7 pagesThe 4 PsJuan Camilo Giorgi MartinezNo ratings yet

- Industry Standard: What Are The Benefits For You?Document4 pagesIndustry Standard: What Are The Benefits For You?Zarnimyomyint MyintNo ratings yet

- Law On Sales: Perfection Stage Forms of Sale When Sale Is SimulatedDocument21 pagesLaw On Sales: Perfection Stage Forms of Sale When Sale Is SimulatedRalph ManuelNo ratings yet

- Design of Grounding System For GIS Indoor SubstationDocument4 pagesDesign of Grounding System For GIS Indoor Substationzerferuz67% (3)

- AMD DEL: Popat / Hitul MR AI0817Document1 pageAMD DEL: Popat / Hitul MR AI0817Mahan YadavNo ratings yet

- Petition For ReviewDocument18 pagesPetition For ReviewJay ArNo ratings yet

- Social and cultural geographies of Southeast Asia exploredDocument18 pagesSocial and cultural geographies of Southeast Asia exploredJohn Lemuel MagnayeNo ratings yet

- Janachaitanya SouthDocument1 pageJanachaitanya SouthbharatchhayaNo ratings yet

- Veritas d1.6.1 FinalDocument28 pagesVeritas d1.6.1 FinalgkoutNo ratings yet

- Minhaj University Lahore: Paper: ICT BSCS Smester-1 Section C Instructor: Kainat Ilyas Exam: Mid-Term Total Marks: 25Document4 pagesMinhaj University Lahore: Paper: ICT BSCS Smester-1 Section C Instructor: Kainat Ilyas Exam: Mid-Term Total Marks: 25Ahmed AliNo ratings yet

- No or Islamic Bank OurStory EnglishDocument45 pagesNo or Islamic Bank OurStory EnglishTalib ZaidiNo ratings yet

- Strengthening RC Structures with Steel Plate Bonding MethodsDocument29 pagesStrengthening RC Structures with Steel Plate Bonding MethodsSiti Rohani Isdris100% (1)

- Cameron VBR-II (Variable Bore Ram) PackerDocument2 pagesCameron VBR-II (Variable Bore Ram) Packerjuan olarteNo ratings yet

- VespaDocument5 pagesVespaAmirul AimanNo ratings yet

- 18th Century Political Formation. CL 7Document22 pages18th Century Political Formation. CL 7Gamer AditKills100% (1)

- Collective Fleet Agreement TermsDocument25 pagesCollective Fleet Agreement TermskjdckncknsNo ratings yet

- OCS Study Analyzes Instrument Performance for NC Oceanography ProgramDocument127 pagesOCS Study Analyzes Instrument Performance for NC Oceanography ProgramAniruddhNo ratings yet

- HOUSEKEEPING SESSION PLANDocument2 pagesHOUSEKEEPING SESSION PLANScarlette Beauty Enriquez100% (1)

- Carpenter Company MarketingDocument14 pagesCarpenter Company Marketingsladex17No ratings yet

- Kami Export - Exercise Lab - Mini-2Document3 pagesKami Export - Exercise Lab - Mini-2Ryan FungNo ratings yet

- CIMA Introduction To NLPDocument4 pagesCIMA Introduction To NLPsambrefoNo ratings yet

- Robotic Surgery History and SystemsDocument28 pagesRobotic Surgery History and SystemsLidhi DileepNo ratings yet

- Pangilinan, Zobel de Ayala, Sy Sr., Dangote, Rupert, Jameel - Power and influence of business leaders in Asia and AfricaDocument20 pagesPangilinan, Zobel de Ayala, Sy Sr., Dangote, Rupert, Jameel - Power and influence of business leaders in Asia and AfricaGwenNo ratings yet

- As 3566.1-2002 Self-Drilling Screws For The Building and Construction Industries General Requirements and MecDocument7 pagesAs 3566.1-2002 Self-Drilling Screws For The Building and Construction Industries General Requirements and MecSAI Global - APAC0% (2)

- The Effect of Multicollinearity in Nonlinear Regression ModelsDocument4 pagesThe Effect of Multicollinearity in Nonlinear Regression ModelsKeshav PoolaNo ratings yet

- Pulse of Fintech h2 2020Document72 pagesPulse of Fintech h2 2020OleksandraNo ratings yet

- DENR CC 2022 1st - Edition FIN 25 - March - 2022Document234 pagesDENR CC 2022 1st - Edition FIN 25 - March - 2022CENRO BANGUED PLANNINGNo ratings yet