Professional Documents

Culture Documents

Asme Sec. Viii Div-1) : THK - Calc. (

Uploaded by

hardik5818Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Asme Sec. Viii Div-1) : THK - Calc. (

Uploaded by

hardik5818Copyright:

Available Formats

THK.CALC. ( ASME SEC.

VIII DIV-1)

SHELL PLATE( DISK )

PRESSURE 218 Psi ID 3,100.0 mm OD 323 mm

DIAMETER 900 mm THK 10.0 mm THK 40 mm

RADIUS 450 mm L(T/T) 4,200.0 mm QTY 32 Nos.

ALL. STRESS 20,000 Psi L(S/S) 4,200.0 mm W T. 25.73 Kgs.

J.EFFICIENCY 1.00 % OD 3,120.0 mm T WT. 823.33 Kgs.

CORR.ALL 3.0 mm B.D(Dsh+h) 3,870.5 mm PLATE

THK calc-shell 4.97 mm shell circum. 9,770 THK 3 mm

THK CODE 4.97 mm WT. (1-Dsh) 923.6 Kgs. W 1,500 mm

THK corr. allow. 7.97 mm WT. (2-Dsh) 1,847.2 Kgs. L 3,000 mm

THK adapted 8 mm WT.Sh.(S/S) 3,221.3 Kgs. QTY 21 Nos.

THK calc-headsl 4.95 mm TOTAL WT. 5,068.5 Kgs. W T.(Kgs) 105.98 Kgs.

THK CODE 4.95 mm TUBE T W.(Kgs) 2,225.48 Kgs.

THK corr. allow. 7.95 OD 19.05

THK adapted 8 THK 2.11

O.D 916 ID 14.83 RADIOGRAPHY 2 M,LENGTH

O.A LENGTH 233,349 L 6,096 VES. DIA 905 1.4

QTY. 851

VES. LNGTH 4,572 2

S K I R T WT 4,572.88 PL.WIDTH 2000 9.1

ID 1,350 mm PL.LNGTH 8000

THK 8 mm RING SKRT REQ. N

L 4,500 mm OD 22.00 mm CIRCUM. 2,843

OD 1,366 mm THK 12.00 mm RADIOGRAPHY (FULL) 15

WT.SHELL 1,206 Kgs. ID 10 mm RADIOGRAPHY (SPOT) 2

QTY. 3 Nos. SPOT RADIOGRAPHY: AFTER EVERY 15' FOR A

SKIRTS' COMP. RING WT. / RING 0.0 Kgs. LENGTH OF 6"

ID 1,366 mm T. WT. 0.1 CLIPS 0.2

THK 16 mm VESSEL SUR. AREA 0.09 D 1,800 5,655

OD 1,566 mm ID 973 mm L 3,500 3,500

Page 1

WT. 58 Kgs. TH 47 mm DIST: 300

L 4,572 mm IN/OUT/BOTH I NOs.CLIPS

SKIRTS' BASE PLATE B.D 1,354 mm T.WT.(Kg)

ID 1,266 mm QTY.= 2 Nos.

THK 8 mm D.E. AREA = 3 M FOR CONES DATA

OD 1,516 mm SHELL AREA = 16.00 M D (mm) = 1000

WT. 34 Kgs. T.AREA = 19 M d (mm) = 500

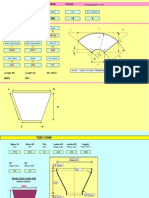

H (mm) = 150

T.WT.SKIRT Wo 2000 T(mm) = 12.7

1,298 Dn 3.6 OUT PUT

DIA 435 Ln 10

THK 10 Th-n 10 Length (mm) = 505

ST. FLNG 50 Do 2.5 Width (mm) = 846

TOT. H. DISH 169 Lo 15 WT (Kgs.) 42.6

Th-o 12

THK.CALC. ( BS-1500 CODE) FAC. 1.152 RING-1

Wn 2,304.00 OD 1,315.00

THK 172

p = 250 lb/in BD FOR TORISPHERICAL DISH ID 951

Di = 5,000 mm ID 2,580 mm QTY. 1

Do = 5080 mm T 13 mm WT./ RING 874.7

f ,STRESS = 17700 lb/in Q 0.46 Radians T. WT. 874.7

j (J. Eff.) = 0.95 % R 2,580 mm HOLES 1,826.00

c (c.a.) = 1.6 mm r 258 mm OD 32

CALC. THK. = 37.45 mm SF 50 mm THK 172

THK.+ C.A = 39.05 mm BD = 3,070 mm QTY 24

THK. ADOPTED = 40 mm W T. 1.07

T WT. 25.66

Page 2

tube hole dia 1.518 38.56

under tolerance 0.007 0.18

over tolerance (96 %) 0.003 0.08

over tolerance (4 %) 0.01 0.25

shell dia 857 mm

33.74 inch

baffle diastance 1220 mm

48.03 inch

baffle hole = tube OD + 0.03125 inch

0.79 mm

tube dia 38.10 mm

baffle hole 38.89 mm

Page 3

Ft 0

Inch 13

Inch 15/16

mm 354.01

PRESS. Conversion

44 PSI 3

45 Kg / cm2 640

15.0 BAR 218

20,000 PSI 1,379.3

8 M,LENGTH

0.57

2 NO. OF PLATES

5.7 NO. OF WELDS

5.7 LENGTH

14.8 T.LENGTH

METERS

METERS

SPOT RADIOGRAPHY: AFTER EVERY 15' FOR A

19

12

Page 4

220

37

Calc. Factors

S1 = 3141.593

S2 = 1570.796

h = 291.548

A = 1.030

R = 583.095

B = 5.388

x = 252.418

r = 291.548

y = -262.814

RING-2

OD 431.80

THK 38.10

ID 951

QTY. 1

WT./ RING (168.6)

T. WT. (168.6)

mm TOTAL WT

mm 680

Nos.

Kgs.

Kgs.

Page 5

SIZE

GAL. 5,000 LITERS 2,000.0 PRESS. 1 PASCAL= 0.0001

FACT. 2.64E+02 M3 = 2.000 1 KILO PASCAL= 0.1450

M3 18.928 FT3 = 70.62 100 KILO PASCAL= 15

M3 1 Ft 1 PRESS.

FACT. 2.64E+02 Inch 12 50 PSI 10

GAL. 264 Inch 15/16 20 Kg / cm2 284

mm 633.41 5 BAR 3

50,000 PSI 3,448.3

VESSEL SIZING TEMP.

CAP 2,400.00 TONS 40 C = 104

SP.GR. 0.50 14,471.000 -45 F = -43

FILLING RATIO 1.0 7,235.500 AT IS

RTD.CAP. 4,761.90 M

3

21,706.50 5000 85000

GMT.CAP. 476,190.48 M

3

190.50 50 45000

192.500 20 ?

V = 1.50 M

3

h = 10

ID = 0.90 M d = 6

L (T/T) = 2.058 M h/d = 1.67

L/D (RATIO) ? = 2.29 a = 16.16

THK = 8.00 mm HEATING SURFACE FOR ST. TUBES

OD = 0.916 M TUBE DIA 20.30 mm

O.A LENGTH 2,524 mm THK 2.11 mm

VOL.(Sh-S/S) 1.25

M

3

L 10,000 mm

Vol.(Sh=100mm) 0.06 M

3

QTY. 500 NOs.

VOL. (2-Dsh) 0.19 M

3

H.SURFACE/TUBE 0.638 M

VOL. (TOTAL) 1.50

M

3

TOTAL H. SURFACE 318.9 M

DIA 1.20 TOTAL H. SURFACE 3,430.5 Ft

L 4.00 TOTAL H. SURFACE 493,999.0 in

VOL 4.52 DISH HEAD

VOL 0.200 ID 1,118

Page 6

SIZE

DIA 1.50 DEPTH 280

L 0.113 ST-FLG 46

THK 14

WEIGHT CALCS. % WISE. O/A HEIGHT 340

TONS 1.00 ID 836.0

KGs. 1000.00 L(T/T) 1,000.0

L(S/S) 1,000.0

DETAILS % WTs. CIRCUM 2,626

SHELL 47.0 470

D.END 15.0 150 PL - W 1,500.0

S.PLATES-1 5.0 50 PL - L 6,000.0

NUT BOLTS 5.0 50 1.75 COURSES

FITTINGS 2.0 20 0.44 LENGTHS

SUPPORTS 0 - (0.75)

NOZZLES 10.0 100 - 1.00

FLANGES 16.0 160 - 2.00

100.0 1000 DISH DIA 836.0

0.0 0 QTY 2

VESSEL SIZING

P , DESIGN PRESSURE 385 V = 8.00 M

3

C, CORR. ALLOWANCE 0.1181 D = 1400.00 M

S, STRESS 20000 L (T/T) = (466.667) M

E, J.EFFICIENCY 1 L/D (RATIO) ? = (0.33)

F ? 0.163 TANK SIZING

VOLUME = 3.00 M

3

L/D (RATIO) ? = 2

DIA = 1.24 M

LENGTH = 2.48 M

Page 7

SIZE

Psi

Psi

Psi

Kg / cm2

PSI

PSI

BAR

F

C

INTERPOLATION

44,757.6

VESSEL DIA. 2

VESSEL LENGTH 4

FAB.WEIGHT 2780

12.57

2.09

14.661

14,661

17,441

WEIGHT OF WATER

Page 8

FLANGE SIZE SIZE OF BOLTS # 150 SIZE OF BOLTS # 300 SIZE OF BOLTS # 600

NPS D X L (INCH) WEIGHT (Kgs.) D X L (INCH) WEIGHT (Kgs.) D X L (INCH) WEIGHT (Kgs.)

1/2" 4 1/2 X 2.25 0.58 4 1/2 X 2.5 0.65 4 1/2 X 3 0.65

3/4" 4 1/2 X 2.5 0.60 4 5/8 X 3 1.16 4 5/8 X 3.5 1.16

1" 4 1/2 X 2.5 0.65 4 5/8 X 3 1.21 4 5/8 X 3.5 1.16

1 1/4" 4 1/2 X 2.75 0.65 4 5/8 X 3.25 1.21 4 5/8 X 3.75 1.26

1 1/2" 4 1/2 X 2.75 0.68 4 3/4 X 3.5 1.54 4 3/4 X 4.25 1.60

2" 4 5/8 X 3.25 1.21 8 5/8 X 3.5 2.62 8 5/8 X 4.25 2.62

2 1/2" 4 5/8 X 3.5 1.31 8 3/4 X 4 3.32 8 3/4 X 4.75 3.55

3" 4 5/8 X 3.5 1.31 8 3/4 X 4.25 3.55 8 3/4 X 5 3.67

3 1/2" 8 5/8 X 3.5 2.62 8 3/4 X 4.25 3.55 8 7/8 X 5.5 6.85

4" 8 5/8 X 3.5 2.62 8 3/4 X 4.5 3.67 8 7/8 X 5.75 7.03

5" 8 3/4 X 3.75 3.32 8 3/4 X 4.75 3.79 8 1 X 6.5 9.81

6" 8 3/4 X 4 3.32 12 3/4 X 4.75 5.87 12 1 X 6.75 14.72

8" 8 3/4 X 4.25 3.56 12 7/8 X 5.5 10.82 12 1-1/8 X 7.5 24.62

10" 12 7/8 X 4.5 9.75 16 1 X 6.25 20.51 16 1-1/4 X 8.5 35.39

12" 12 7/8 X 4.75 10.02 16 1-1/8 X 6.75 31.55 20 1-1/4 X 8.75 45.83

14" 12 1 X 5.25 13.39 20 1-1/8 X 7 41.04 20 1-3/8 X 9.25 52.75

16" 16 1 X 5.25 17.85 20 1-1/4 X 7.5 42.63 20 1-1/2 X 10 70.39

18" 16 1-1/8 X 5.75 28.99 24 1-1/4 X 7.75 51.16 20 1-5/8 X 10.75 104.54

20" 20 1-1/8 X 6.25 37.84 24 1-1/4 X 8 53.08 24 1-5/8 X 11.25 128.86

24" 20 1-1/4 X 6.75 39.44 24 1-1/2 X 9 81.85 24 1-7/8 X 13 146.07

No. OF BOLT No. OF BOLT No. OF BOLT

STANDARD STUD BOLTS WITH TWO NUTS

Prep.By KUH Page 9 Date:6/16/2014

PIPE

THUMB RULES FOR PIPING

DATA

DIA 4 INCHES

THK. 0.25 INCHES

W 16.00 Tons / Km

W 10.01 Lbs / Ft

S 14.00 Feet

PIPE SIZE CALCULATIONS

Q=AV ID - PIPE

18.81

mm

Q(FLOWRATE) 50 M^3/Hr A=Q/V V (VELOCITY) 10 M/sec

V (VELOCITY) 10 M/sec d=Q*4/Pi*V Q(FLOWRATE) 10.0 M^3/Hr

D(DIA) 42.05 mm d = (Q*4/Pi*V)^1/2

D(DIA) 1.66 "

H1 688.7 H1= 90

H2 639.14 H2= 30

DELTA H 49.56 EMTD= 94

ms 20250

Q 1,003,590

AS, Q= mw x (H1- H2)

mw = Q / (H1-H2)

H1-H2 = 60

mw = 16,727 Q 1,003,590

SCHEDULE NO. = 1000 x Ps / Ss OR 2000 x t / Dm

Where,

Ps = internal working pressure 1,500 Psi

Ss = allowable stress 11,000 Psi

t = pipe wall thk. in

Dm = pipe mean diameter in

Page 10

PIPE

Density of water 58.8 lb/ft3

velocity of pipe (V) 6 fps

w = flow rate 50,000 lbs

SCHEDULE NO. (calc.) = 136

SCHEDULE NO. (adp) = 160

As 0.785(Di/12)^2 x V

then Di = 1.77 in

By formula Di

calc

= 2.2*w^0.45*p^-0.31 3.62 in

Page 11

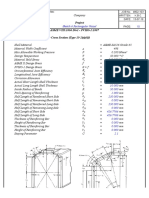

THK.CALC. ( ASME SEC. VIII, Div. 1 ) THK.CALC. ( BS-5500,1976 )

PRESSURE 56 Psi PRESSURE 56

DIAMETER 9,132 mm DIAMETER 9,140

RADIUS 4,566 mm RADIUS 4,570

STRESS 20,000 Psi STRESS 20,000

J.EFFICIENCY 100.00 % J.EFFICIENCY 100.00

CORR.ALL 3.0 mm CORR.ALL 3.0

THK calculated 6.39 THK calculated 6.40

THK corr. allow. 9.39 mm THK corr. allow. 9.40

THK adapted 10 mm THK adapted 10

DIA (MEAN) 9,142 mm DIA (MEAN) 9,150

RADIUS (MEAN) 4,571 mm RADIUS (MEAN) 4,575

WT. OF SPHERE 20,611 Kgs. WT. OF SPHERE 20,647

AREA OF SPHERE 263 M AREA OF SPHERE 264

VOLUME OF SPHERE 400 M

3

VOLUME OF SPHERE 401.1

DEVELOPMENT OF PIECES

CHORD, mm ANGLE, ARC, mm

a = 442.20 5.54 442.37

b = 1283.2 16.14 1287.45

c = 1998.6 25.26 2014.87 g = 2,873.59

d = 2518.4 31.98 2551.39

e = 2791.7 35.56 2837.02 a = 442.37

CL= 2826.5 36.02 2873.59

LENGTHS

g = 2826.5 36.02 2873.59 P. NO. 1

f = 2826.5 36.02 2873.59 P. NO. 2

f = 2826.5 36.02 2873.59 P. NO. 3

f = 2826.5 36.02 2873.59 P. NO. 4

f = 2826.5 36.02 2873.59 P. NO. 5 1,287.45

f = 2826.5 36.02 2873.59 P. NO. 6

b = 1,287.45

RISE b =

RISE

P. NO. 1 CAP 228.96 mm

P. NO. 2 UPPER END 10.35 mm

LOWER END 50.25 mm

P. NO. 3 UPPER END 50.25 2014.87

LOWER END 115.57 c = 2,014.87

P. NO. 4 UPPER END 115.57 c =

LOWER END 181.86 mm

P. NO. 5 UPPER END 181.86 mm

LOWER END 223.34 mm

P. NO. 6 UPPER END 223.34 mm

CENTRE 228.96 mm 2,551.39

LOWER END 223.34 mm 2,551.39

JOINTS d =

NO. OF JOINTS LONGITUDNALLY 20

SPHERICAL TANK CALCULATIONS

Piece No. 5

Piece No. 4

Piece.No. 2

Piece No. 3

NO. OF JOINTS LATITUDINALLY 20

e = 2,837.02

e = 2,837.02

e = 2,837.02

Radiography

Radiography

WELD LINE PIECE ARC NO. OF DEVELOPED MEAN

LENGTH (mm)PIECES LENGTH (mm) DIA(mm)

P.NO.1(line no. 1) 442.4 20 8,847 2,816.2

P.NO.2(line no. 2) 1,287.5 20 25,749 8,196.2

P.NO.3(line no.3) 2,014.9 20 40,297 12,827.1

P.NO.4(line no.4) 2,551.4 20 51,028 16,242.7

P.NO.5(line no,5) 2,837.0 20 56,740 18,061.0

P.NO.5(line no,5) 2,837.0 20 56,740 18,061.0

P.NO.4(line no.4) 2,551.4 20 51,028 16,242.7

P.NO.3(line no.3) 2,014.9 20 40,297 12,827.1

P.NO.2(line no. 2) 1,287.5 20 25,749 8,196.2

P.NO.1(line no. 1) 442.4 20 8,847 2,816.2

365,324

Radiography

NO. OF DEVP. T. DEVP.

PIECES LENGTH LENGTH

20 45,977.38 919,548

mm

FULL (100 %)

SPOT (10 %) 128

1,285

RADIOGRAPHY (Meters)

Piece No. 5

Piece No. 6 (Center / Common Piece)

Psi

mm

mm

Psi

%

mm

mm

mm

mm

mm

mm

Kgs.

M

M

3

Piece No. 1

f = 2,873.59

f = 2,873.59

f = 2,873.59

= d

f = 2,873.59

CL = 2873.59

DIA= 18,294 2,873.59 = f

Piece No. 6 (Center / Common Piece)

945-V31

N-MARK SIZE pipe-thk y g tc te

A 2.0 8.74 6.12 8.65 6.12 6.00

B 150.0 6.00 4.20 5.94 4.20

C 3.0 11.13 7.79 11.02 7.79 6.00

D 1~3 2.0 8.74 6.12 8.65 6.12 6.00

E 2.0 8.74 6.12 8.65 6.12 6.00

945-V32 AB

N-MARK SIZE pipe-thk y g tc te

A 2.0 8.74 6.12 8.65 6.12 6.00

B 150.0 6.00 4.20 5.94 4.20

C 1.5 7.14 5.00 7.07 5.00

D1~3 2.0 8.74 6.12 8.65 6.12 6.00

E 1.5 7.14 5.00 7.07 5.00

F 2.0 8.74 6.12 8.65 6.12 6.00

945-V40 AB

N-MARK SIZE pipe-thk y g tc te

A 2.0 8.74 6.12 8.65 6.12 6.00

C 1.5 7.14 5.00 7.07 5.00

D 2.0 8.74 6.12 8.65 6.12 6.00

E 1.5 7.14 5.00 7.07 5.00

F 2.0 8.74 6.12 8.65 6.12 6.00

G 1.5 5.08 3.56 5.03 3.56

0.5 lpg

N-MARK SIZE pipe-thk y g tc te

N1 3.0 11.10 7.78 11.00 7.77

N2,N3,N5 2.0 8.70 6.09 8.61 6.09 10.00

N4 6.0 11.00 7.70 10.89 7.70 10.00

N6 0.75 5.60 3.92 5.54 3.92 10.00

N7,N8 0.5 7.50 5.25 7.42 5.25 10.00

M1 16.0 9.50 6.65 9.40 6.65 10.00

td

CAP. DIA LENGTH

(M3) (M) (M)

SHELL ROOF BTM W.GRD MISC.

3.00 1 40,000 60.0 14.2 275.2 188.0 137.4 25.9 14.5

- 2 10,000 30.0 14.2 117.0 59.0 34.5 10.5 10.0

3.00 3 4,000 20.0 13.0 60.0 24.0 15.0 4.6 5.4

3.00 4 29,000 51.0 14.2 207.0 153.0 104.0 11.0 8.0

3.00 5 1,000 12.0 9.0 17.0 10.5 7.0 2.0 3.0

SUMMARY

WT. (TONS)

NO.

6 4,000 25.0 9.0 65.0 26.0 16.0 5.0 5.8

7 75,000 70.0 18.2 550.0 353.0 258.0 48.0 30.0

td

3.00

-

-

3.00

-

3.00

CAP. DIA LENGTH

(M3) (M) (M)

SHELL ROOF BTM W.GRD MISC.

td 1 40,000 60.0 14.2 275.2 188.0 137.4 25.9 14.5

3.00 2 10,000 30.0 14.2 117.0 59.0 34.5 10.5 10.0

SUMMARY

NO.

WT. (TONS)

- 3 4,000 20.0 13.0 60.0 24.0 15.0 4.6 5.4

3.00 4 29,000 51.0 14.2 207.0 153.0 104.0 11.0 8.0

- 5 1,000 12.0 9.0 17.0 10.5 7.0 2.0 3.0

3.00 6 4,000 25.0 9.0 65.0 26.0 16.0 5.0 5.8

- 7 75,000 70.0 18.2 550.0 353.0 258.0 48.0 30.0

td

-

5.00

5.00

5.00

5.00

5.00

MAT. COST FAB. COST T. COST

TOTAL @ 30 Rs/Kg @ 40 Rs/Kg (Rs.) EXT. INT. EXT. (Rs.) INT. (Rs.)

641.0 19,230,000 25,640,000 44,870,000 7,200 8,200 3,016,800 3,608,000

231.0 6,930,000 9,240,000 16,170,000 3,000 3,750 1,257,000 1,650,000

109.0 3,270,000 4,360,000 7,630,000 1,585 1,800 664,115 792,000

483.0 14,490,000 19,320,000 33,810,000 5,300 6,000 2,220,700 2,640,000

39.5 1,185,000 1,580,000 2,765,000 1,200 900 502,800 396,000

SUMMARY

MAT. + FAB. COST PAINTING

WT. (TONS) PAINTING (M2) PAINTING COST

117.8 3,534,000 4,712,000 8,246,000 1,585 1,800 664,115 792,000

1,239.0 37,170,000 49,560,000 86,730,000 9,850 1,300 4,127,150 572,000

MAT. COST FAB. COST T. COST

TOTAL (Rs/Kg) (Rs/Kg) (Rs.) EXT. INT. EXT. (Rs.) INT. (Rs.)

641.0 7,200 8,200

231.0 3,000 3,750

SUMMARY

MAT. + FAB. COST PAINTING

WT. (TONS) PAINTING (M2) PAINTING COST

109.0 1,585 1,800

483.0 5,300 6,000

39.5 1,200 900

117.8 1,585 1,800

1,239.0 9,850 1,300

T. COST G.T. COST

(Rs.) (Rs.)

6,624,800 51,494,800

2,907,000 19,077,000

1,456,115 9,086,115

4,860,700 38,670,700

898,800 3,663,800

SUMMARY

PAINTING

1,456,115 9,702,115

4,699,150 91,429,150

T. COST G.T. COST

(Rs.) (Rs.)

-

-

SUMMARY

PAINTING

-

-

-

-

-

Capacity 300.00 Tons shell 191946.79

Sp. Gravity 0.50 Dishends 370.05

Filling ratio 0.90 Manhole ring 100

Geomatric capacity. 661.38 M3 Flanges & pads 1350

Diameter 1200.00 mm Nozzle pipes. 30

Volume in dished ends 0.45 M3 lifting lugs& cleats 70

Cylindrical volume 660.92 M3 cradles. 516 Gr. 70 370

Cylindrical length 584385 mm A283 1480

Straight portion of dish ends 50.00 mm Plateform ladder 1000

Shell length 584285 mm Fasteners 100

Overall length. 585006

Corrosion allownce 3.00 mm 196816.84

Design pressure 250.00 psig

Design temperature -50.00 C

Material A 516-70

Allowable stress 20000 psi

radio graphy 100 %

Required thickness 10.557

Adopted thickness 11.000 mm

TUBE SHEET THICKNESS FOR DRG. NO. E-51

DATA

1

DESIGN PRESSURE 90.0 PSI

GASKET MEAN DIA 12.75 INCHES

TUBE OD 1.25 INCHES

TUBE PITCH 1.57 INCHES

T = F x G x SQRT ( P )

3 n x S

where,

T = EFFECTIVE TUBE SHEET THICKNESS ?

F = FACTOR = 0.9 (ASSUMED FOR FIXED TUBE SHEET

DESIGN, REFER TABLE RCB-7.132) 0.9

G = GASKET MEAN DIA 12.75

P = DESIGN PRESSURE 90.0

S = ALLOWABLE STRESS 20,000

n = FACTOR = 1 - ( 0.907)

(FOR TRIANGULAR (TUBE PITCH / TUBE OD)2 0.43

PITCH)

T = 0.39

9.96

DATA FOR DRG. NO. TPP-M-958

2

DESIGN PRESSURE 116.0 PSI

GASKET MEAN DIA 33.86 INCHES

TUBE OD 0.75 INCHES

TUBE PITCH 0.85 INCHES

T = F x G x SQRT ( P )

3 n x S

where,

T = EFFECTIVE TUBE SHEET THICKNESS ?

F = FACTOR = 0.9 (ASSUMED FOR FIXED TUBE SHEET

DESIGN, REFER TABLE RCB-7.132) 0.9

G = GASKET MEAN DIA 33.86

P = DESIGN PRESSURE 116.0

S = ALLOWABLE STRESS 20,000

n = FACTOR = 1 - ( 0.907)

(FOR TRIANGULAR (TUBE PITCH / TUBE OD)2 0.29

PITCH)

RAW WATER HEATER

T = 1.44

36.62

INCHES

INCHES

PSI

PSI

INCHES

MM

INCHES

INCHES

PSI

PSI

RAW WATER HEATER

INCHES

MM

g

tc

y

t

NOZZLE WELDING DATA

S.NO. NOZZLE SIZE

(Inches) t y g tc t y g tc t y g tc t y g tc t y g tc

1 1/2 2.77 2 3 2 2.77 2 3 2 3.70 3 4 3 - - - - 4.70 3 5 3

2 3/4 2.87 2 3 2 2.87 2 3 2 3.90 3 4 3 - - - - 5.60 4 6 4

3 1 3.38 2 3 2 3.40 2 3 2 4.50 3 4 3 - - - - 6.30 4 6 4

4 1 1/4 3.50 2 3 2 3.50 2 3 2 4.80 3 5 3 - - - - 6.30 4 6 4

5 1 1/2 3.70 3 4 3 3.70 3 4 3 5.00 4 5 4 - - - - 7.10 5 7 5

6 2 3.90 3 4 3 3.90 3 4 3 5.50 4 5 4 - - - - 8.70 6 9 6

7 2 1/2 5.10 4 5 4 5.10 4 5 4 7.00 5 7 5 - - - - 9.50 7 9 7

8 3 5.50 4 5 4 5.50 4 5 4 7.60 5 8 5 - - - - 11.10 8 11 8

8 3 1/2 5.70 4 6 4 5.70 4 6 4 8.00 6 8 6 - - - - - - - -

9 4 6.00 4 6 4 6.00 4 6 4 8.60 6 9 6 11.10 8 11 8 13.50 9 13 9

10 5 6.50 5 6 5 6.50 5 6 5 9.50 7 9 7 12.70 9 13 9 15.90 11 16 11

11 6 7.10 5 7 5 7.10 5 7 5 11.00 8 11 8 14.20 10 14 10 18.20 13 18 13

12 8 8.20 6 8 6 8.20 6 8 6 12.70 9 13 9 18.20 13 18 13 23.00 16 23 16

13 10 9.20 6 9 6 9.20 6 9 6 15.00 11 15 11 21.40 15 21 15 28.60 20 28 20

14 12 9.50 7 9 7 10.30 7 10 7 17.40 12 17 12 25.40 18 25 18 33.30 23 33 23

15 14 9.50 7 9 7 11.10 8 11 8 19.00 13 19 13 27.70 19 27 19 35.70 25 35 25

16 16 9.50 7 9 7 12.70 9 13 9 21.40 15 21 15 30.90 22 31 22 40.50 28 40 28

17 18 9.50 7 9 7 14.20 10 14 10 23.80 17 24 17 34.90 24 35 24 45.20 32 45 32

18 20 9.50 7 9 7 15.00 11 15 11 26.10 18 26 18 38.10 27 38 27 49.90 35 49 35

19 24 9.50 7 9 7 17.40 12 17 12 31.00 22 31 22 46.00 32 46 32 59.50 42 59 42

PIPE - Sch. 160 PIPE - Sch. STD PIPE - Sch. 40 PIPE - Sch. 80 PIPE - Sch. 120

INCHES mm INCHES mm INCHES mm INCHES mm INCHES mm

1/4 6.4 0.259 6.6 0.004 0.10 0.002 0.05 0.007 0.18

3/8 9.5 0.384 9.8 0.004 0.10 0.002 0.05 0.007 0.18

1/2 12.7 0.51 13.0 0.004 0.10 0.002 0.05 0.008 0.20

5/8 15.9 0.635 16.1 0.004 0.10 0.002 0.05 0.010 0.25

3/4 19.1 0.76 19.3 0.004 0.10 0.002 0.05 0.010 0.25

7/8 22.2 0.885 22.5 0.004 0.10 0.002 0.05 0.010 0.25

1 25.4 1.012 25.7 0.004 0.10 0.002 0.05 0.010 0.25

1 1/4 31.8 1.264 32.1 0.006 0.15 0.003 0.08 0.010 0.25

1 1/2 38.1 1.518 38.6 0.007 0.18 0.003 0.08 0.010 0.25

2 50.8 2.022 51.4 0.007 0.18 0.003 0.08 0.010 0.25

TUBE HOLE DIAMETERS AND TOLERANCES - TABLE RCB-7.41

STANDARD FIT OVER TOLERANCE

TUBE OD

NOM. DIA UNDER TOLERANCE FOR 96 % FOR 4 %

DESCRIPTION

tube hole dia 1.518 38.56

under tolerance 0.007 0.18

over tolerance (96 %) 0.003 0.08

over tolerance (4 %) 0.01 0.25

shell dia 33.74 857.00

baffle diastance 48.03 1,220.00

baffle hole = tube OD + 0.03125 0.79

tube dia 38.10

baffle hole 38.89

You might also like

- Asme Sec. Viii Div-1) : Shell Plate (Disk) ConversionDocument33 pagesAsme Sec. Viii Div-1) : Shell Plate (Disk) ConversionuzairmetallurgistNo ratings yet

- THK Pressure Calculations For Internal DimensionsDocument2 pagesTHK Pressure Calculations For Internal DimensionsConstrsupervisNo ratings yet

- Imperial Piping Weight Load Calculation WorkbookDocument13 pagesImperial Piping Weight Load Calculation WorkbookKakoDa100% (1)

- Option-2-Piping Support Structural BOQDocument12 pagesOption-2-Piping Support Structural BOQMaqsood Ibn Shaikhul ArfeenNo ratings yet

- Storage Tank Design Calculations for Hydrogen PeroxideDocument12 pagesStorage Tank Design Calculations for Hydrogen Peroxidechompink6900No ratings yet

- Tailing Lug Design FormulaDocument2 pagesTailing Lug Design FormulaRajeshNo ratings yet

- IIT Hyderabad Faculty Housing Design CalculationsDocument33 pagesIIT Hyderabad Faculty Housing Design CalculationssmijusNo ratings yet

- 07 Piping BOQDocument54 pages07 Piping BOQHRK65No ratings yet

- A11Document1 pageA11liviu_dovaNo ratings yet

- Power Calculation For AgitatorDocument12 pagesPower Calculation For AgitatorDeepikaNo ratings yet

- Digester Design2Document16 pagesDigester Design2Pragathees WaranNo ratings yet

- Output Summary: SI UnitsDocument42 pagesOutput Summary: SI UnitsAkhil JoseNo ratings yet

- Cpp-Tank DSGN Calc-Rev CDocument42 pagesCpp-Tank DSGN Calc-Rev CnamasralNo ratings yet

- API 650 Baseplate DesignDocument3 pagesAPI 650 Baseplate DesignmjlazoNo ratings yet

- New Storage Tanks Design GuidelinesDocument6 pagesNew Storage Tanks Design GuidelineschrisevabNo ratings yet

- Sectional WeightsDocument1 pageSectional WeightsradhakrishnangNo ratings yet

- FRP RF CalcDocument1 pageFRP RF CalcmukeshNo ratings yet

- Memoria ASME-Pressure-Vessel-DesignDocument143 pagesMemoria ASME-Pressure-Vessel-DesignJuan MendozaNo ratings yet

- Tank DesignDocument2 pagesTank DesignkamleshyadavmoneyNo ratings yet

- Shell: Working Pressure of Shell (As Per Ibr 270 & 271 New Amendment)Document1 pageShell: Working Pressure of Shell (As Per Ibr 270 & 271 New Amendment)Karthic KeyanNo ratings yet

- Pressure Drop AND HEADDocument2 pagesPressure Drop AND HEADHoney TiwariNo ratings yet

- em-TEK PVT LTD engineering data sheets for LPG pressure vessels and tanksDocument6 pagesem-TEK PVT LTD engineering data sheets for LPG pressure vessels and tanksAli BaigNo ratings yet

- Pipe Weight Formulas & TablesDocument12 pagesPipe Weight Formulas & TablesuzairmetallurgistNo ratings yet

- Cone DevlpmentDocument8 pagesCone DevlpmentNasir RamzanNo ratings yet

- Load Calculation: Self-Weight of Materials SL No Material Density (KN/M)Document6 pagesLoad Calculation: Self-Weight of Materials SL No Material Density (KN/M)ajith chandranNo ratings yet

- And Dipstick Chart: Scroll Down For InstructionsDocument2 pagesAnd Dipstick Chart: Scroll Down For Instructionspowder18No ratings yet

- Mechanical Design SpreadsheetDocument1 pageMechanical Design SpreadsheetHoney TiwariNo ratings yet

- DishDocument1 pageDishmishtinilNo ratings yet

- Pumpstation Input Data: Zone M1Document95 pagesPumpstation Input Data: Zone M1TahirJabbar50% (2)

- Preva: Pressure Vessels and Heat ExchangersDocument6 pagesPreva: Pressure Vessels and Heat ExchangersTrishul Nath PallayNo ratings yet

- BuoyancyDocument1 pageBuoyancyLcm TnlNo ratings yet

- 8KL FERMENTER DESIGN CALCULATIONSDocument3 pages8KL FERMENTER DESIGN CALCULATIONSkirandas_mullasseryNo ratings yet

- Reff: A Text Book of Machine Design - Chapter 10, RS. KHURMIDocument5 pagesReff: A Text Book of Machine Design - Chapter 10, RS. KHURMIAsep MulyadiNo ratings yet

- Pipe Steel BookDocument449 pagesPipe Steel BookAlonzo MedinaNo ratings yet

- Flange Loading CheckDocument48 pagesFlange Loading CheckrefuzerNo ratings yet

- Demo Weld Cost Calc XLDocument10 pagesDemo Weld Cost Calc XLKhalid Ahmod ShibleeNo ratings yet

- Project: Date Jobno: Designed ACTIVITY: Utility Pipe/ Valve Workshop Checked SheetDocument36 pagesProject: Date Jobno: Designed ACTIVITY: Utility Pipe/ Valve Workshop Checked SheetGeorge Georgian100% (1)

- Pipes. Maximum Span Between Pipe Supports For A Given Maximum Bending StressDocument62 pagesPipes. Maximum Span Between Pipe Supports For A Given Maximum Bending StressArunkumar RackanNo ratings yet

- LPG STORAGE TANK DESIGN CALCULATIONSDocument2 pagesLPG STORAGE TANK DESIGN CALCULATIONSRamesh GanapathyNo ratings yet

- Calculation BS 31.3Document1 pageCalculation BS 31.3prabhjot123No ratings yet

- Bisep Hot Tapping Plugging 1Document7 pagesBisep Hot Tapping Plugging 1mospt100% (1)

- Weight CalculatorDocument2 pagesWeight CalculatorenjoygurujiNo ratings yet

- Cone Design Tool: Pressure Vessel Engineering LTDDocument1 pageCone Design Tool: Pressure Vessel Engineering LTDrina2393No ratings yet

- Pipe ScheduleDocument6 pagesPipe ScheduleQuyen VuNo ratings yet

- 1.5D Bend Calculation Per B31.1-2018Document84 pages1.5D Bend Calculation Per B31.1-2018Amit SharmaNo ratings yet

- Rectangular Cooling Water Tank Design CalculationsDocument43 pagesRectangular Cooling Water Tank Design CalculationsNguyễn Quốc PhượngNo ratings yet

- Calculate Surface Area for Cylindrical TankDocument10 pagesCalculate Surface Area for Cylindrical TanksudjonoNo ratings yet

- ASTM A53 Vs A500 EquivalenceDocument6 pagesASTM A53 Vs A500 Equivalenceemmanuilmoulos6339No ratings yet

- Sa-516 70 TDCDocument2 pagesSa-516 70 TDCshazan100% (1)

- Fresh HDO Storage TankDocument42 pagesFresh HDO Storage TankHgagselim SelimNo ratings yet

- THK CALC FOR PRESSURE VESSEL AND PIPING DATADocument37 pagesTHK CALC FOR PRESSURE VESSEL AND PIPING DATAalexnomitaNo ratings yet

- Estimation Software For Presure VesselDocument36 pagesEstimation Software For Presure VesselKarthikeyan Shanmugavel0% (1)

- Estimation Software For Presure VesselDocument36 pagesEstimation Software For Presure Vesselfqadir0% (1)

- Tank DesignDocument89 pagesTank DesignDietrich von BismarckNo ratings yet

- Tank DesignDocument89 pagesTank DesignRafael ReyesNo ratings yet

- Tank Design PDFDocument89 pagesTank Design PDFcecgootyNo ratings yet

- DS-RJY Tally BookDocument44 pagesDS-RJY Tally BookCamron Gomes100% (2)

- Thermal ExpansionDocument12 pagesThermal ExpansionAdipati Syahidullah Ulini'amNo ratings yet

- Storage Tank Design Calculations and SummaryDocument75 pagesStorage Tank Design Calculations and Summaryace1205No ratings yet

- PH - Acidity H2S Level Temperature Duration of Exposure Nature of The MaterialDocument9 pagesPH - Acidity H2S Level Temperature Duration of Exposure Nature of The Materialhardik5818No ratings yet

- Tema ReqDocument21 pagesTema Reqhardik5818No ratings yet

- EIL Nozzle LoadsDocument5 pagesEIL Nozzle LoadsAniket GaikwadNo ratings yet

- Baffle Cut Diagrams and ExplanationsDocument2 pagesBaffle Cut Diagrams and ExplanationsPravin KhilariNo ratings yet

- Ngineers India Limited: Allowable Nozzle Loads Standard NoDocument4 pagesNgineers India Limited: Allowable Nozzle Loads Standard Nohardik5818No ratings yet

- Collar Type BoltDocument1 pageCollar Type Bolthardik5818No ratings yet

- PH - Acidity H2S Level Temperature Duration of Exposure Nature of The MaterialDocument9 pagesPH - Acidity H2S Level Temperature Duration of Exposure Nature of The Materialhardik5818No ratings yet

- ASME VIII A13 - Vessels of Noncircular Cross Section (Type 13-2 (A) (6) )Document14 pagesASME VIII A13 - Vessels of Noncircular Cross Section (Type 13-2 (A) (6) )hardik5818100% (2)

- Mechanical Design Basics of Tall ColumnsDocument45 pagesMechanical Design Basics of Tall Columnshardik5818No ratings yet

- Torque-Tension Chart For B7Document1 pageTorque-Tension Chart For B7Ramón C. Silva H.No ratings yet

- Stainless Steel Pressure RatingsDocument7 pagesStainless Steel Pressure RatingsNauman KhanNo ratings yet

- Bending Moment and Shear Force Diagrams ExplainedDocument11 pagesBending Moment and Shear Force Diagrams Explainedhardik5818100% (1)

- Asme - PVP2005-71728Document11 pagesAsme - PVP2005-71728ash1968No ratings yet

- Base Ring AnalysisDocument9 pagesBase Ring Analysisasirul_meNo ratings yet

- Section Properties03Document20 pagesSection Properties03xavierlthNo ratings yet

- PV Elite Heat Exchanger CalculationsDocument99 pagesPV Elite Heat Exchanger CalculationscbousmuNo ratings yet

- 2 - Pipe Schedule & Inner Dia DimensionsDocument1 page2 - Pipe Schedule & Inner Dia DimensionsHazairin As-Shiddiq RahmanNo ratings yet

- Wood Thermal ConductivityDocument8 pagesWood Thermal Conductivityhardik5818No ratings yet

- EJMA Bellows - CalculatorDocument5 pagesEJMA Bellows - Calculatorhardik5818No ratings yet

- Strengthening Mechanism3 PDFDocument78 pagesStrengthening Mechanism3 PDFAmber WilliamsNo ratings yet

- Nozzle Table 27.9.2017Document1 pageNozzle Table 27.9.2017hardik5818No ratings yet

- Asme - PVP2005-71728Document11 pagesAsme - PVP2005-71728ash1968No ratings yet

- Strain Hardening, Cold Working, and Annealing EffectsDocument7 pagesStrain Hardening, Cold Working, and Annealing EffectsPawan Kumar SapraNo ratings yet

- Stainless Steel Pressure RatingsDocument7 pagesStainless Steel Pressure RatingsNauman KhanNo ratings yet

- 2 - Pipe Schedule & Inner Dia DimensionsDocument1 page2 - Pipe Schedule & Inner Dia DimensionsHazairin As-Shiddiq RahmanNo ratings yet

- Appendix 2) : Optional Type Flange (Fig. 2-4 (8) )Document18 pagesAppendix 2) : Optional Type Flange (Fig. 2-4 (8) )hardik5818No ratings yet

- Pressure Vessel Design CalculationsDocument127 pagesPressure Vessel Design Calculationsajayghosh314086% (22)

- Pressure Drop Calc - STDDocument25 pagesPressure Drop Calc - STDhardik5818No ratings yet

- PV Elite Heat Exchanger CalculationsDocument99 pagesPV Elite Heat Exchanger CalculationscbousmuNo ratings yet

- 2 - Pipe Schedule & Inner Dia DimensionsDocument1 page2 - Pipe Schedule & Inner Dia DimensionsHazairin As-Shiddiq RahmanNo ratings yet

- Stone Fox BookletDocument19 pagesStone Fox Bookletapi-220567377100% (3)

- 18 MN216 Fluid Mechanics IDocument2 pages18 MN216 Fluid Mechanics Ijorge luisNo ratings yet

- All About The Hathras Case - IpleadersDocument1 pageAll About The Hathras Case - IpleadersBadhon Chandra SarkarNo ratings yet

- Current Openings: The Sirpur Paper Mills LTDDocument3 pagesCurrent Openings: The Sirpur Paper Mills LTDMano VardhanNo ratings yet

- Cat Behavior - Facts and MythsDocument3 pagesCat Behavior - Facts and MythsCharlie CajigalNo ratings yet

- Advanced Accounting PDFDocument14 pagesAdvanced Accounting PDFYvette Pauline JovenNo ratings yet

- BSNL Cda RulesDocument3 pagesBSNL Cda RulesAlexander MccormickNo ratings yet

- Wealth Management Asia: ParsimonyDocument3 pagesWealth Management Asia: ParsimonyJohn RockefellerNo ratings yet

- Below Is A List of Offices For India - PWCDocument10 pagesBelow Is A List of Offices For India - PWCAnonymous xMYE0TiNBcNo ratings yet

- Inelastic Response SpectrumDocument10 pagesInelastic Response Spectrummathewsujith31No ratings yet

- EN Sample Paper 19 UnsolvedDocument12 pagesEN Sample Paper 19 UnsolvedRashvandhNo ratings yet

- Everyman A Structural Analysis Thomas F. Van LaanDocument12 pagesEveryman A Structural Analysis Thomas F. Van LaanRodrigoCarrilloLopezNo ratings yet

- 5 Integumentary SystemDocument67 pages5 Integumentary SystemchelsealivesforeverNo ratings yet

- Railways MedicalDocument73 pagesRailways MedicalGaurav KapoorNo ratings yet

- Estimation and Costing - LigDocument30 pagesEstimation and Costing - LigR SumithraNo ratings yet

- 100 transaction cycle in VisionPLUS banking systemDocument7 pages100 transaction cycle in VisionPLUS banking systemGoushik Balakrishnan100% (1)

- MEM05 Header R8.1Document388 pagesMEM05 Header R8.1andysupaNo ratings yet

- 9 Measures of Variability DisperseDocument14 pages9 Measures of Variability DisperseSourabh ChavanNo ratings yet

- ICT4D - Richard Heeks (2305843009216382716)Document307 pagesICT4D - Richard Heeks (2305843009216382716)Jeff GeoffNo ratings yet

- The Nonlinear Dynamics of Ships in Broaching Kostas J. SpyrouDocument7 pagesThe Nonlinear Dynamics of Ships in Broaching Kostas J. SpyrouFelipe IlhaNo ratings yet

- Hangnails and HomoeopathyDocument7 pagesHangnails and HomoeopathyDr. Rajneesh Kumar Sharma MD HomNo ratings yet

- 1 The Importance of Business ProcessesDocument17 pages1 The Importance of Business ProcessesFanny- Fan.nyNo ratings yet

- Laws On Banks-A4Document16 pagesLaws On Banks-A4Steven OrtizNo ratings yet

- KCIS 2nd Semester Science Fair ProjectsDocument2 pagesKCIS 2nd Semester Science Fair ProjectsCaT BlAcKNo ratings yet

- GJ ScriptDocument83 pagesGJ ScriptKim LawrenceNo ratings yet

- Asian Studies Vol 49 No 2 - 2013Document218 pagesAsian Studies Vol 49 No 2 - 2013Ari Dodol100% (1)

- Theory of Machines Kinematics FundamentalsDocument31 pagesTheory of Machines Kinematics FundamentalsmungutiNo ratings yet

- 3gpp Cdrs Specs AlcatelDocument337 pages3gpp Cdrs Specs AlcatelPatrick AdinaNo ratings yet

- NIMS University Jaipur - Ph.D. Economics Selection Process, Course Fee, PlacementDocument6 pagesNIMS University Jaipur - Ph.D. Economics Selection Process, Course Fee, PlacementstepincollegeNo ratings yet

- Sam's Melancholic MorningDocument4 pagesSam's Melancholic Morningali moizNo ratings yet