Professional Documents

Culture Documents

Pages - From - c2TR Ejemplo de Ejercicio Caesar 2

Pages - From - c2TR Ejemplo de Ejercicio Caesar 2

Uploaded by

brujula27Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pages - From - c2TR Ejemplo de Ejercicio Caesar 2

Pages - From - c2TR Ejemplo de Ejercicio Caesar 2

Uploaded by

brujula27Copyright:

Available Formats

Chapter 3 Piping Screen Reference

3-27

Pages from Technical Reference Manual (5.3 Version)

SIFs & Tees

Activate by double-clicking the SIFs and Tees check box on the Pipe Element Spreadsheet. Deactivate by

double-clicking a second time.

There are two basic component types:

Three element intersection components, and

Two element joint components.

A fully defined intersection model requires that three pipes frame into the intersection node, and that two of

them are co-linear. Partial intersection assumptions are made for junctions where the user has coded one or two

pipes into the intersection node, but these models are not recommended. Two element joint components can be

formed equally well with one or two elements framing into the node.

As usual, the intersection or joint type and properties need only be entered on one of the elements going to the

junction. CAESAR II duplicates the intersection characteristics for all other pipes framing into the intersection.

Users are urged to fully review the WARNING messages coming from CAESAR II during error checking. These

messages detail to the user any assumptions made during the assembly and calculation of the intersection SIFs.

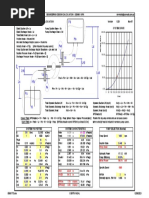

The available intersections and joint types are shown in the table that follows, along with the other parameters

that can affect the stress intensification factors for the respective component.

3-28

Piping Screen Reference

Input Items Optionally Effecting SIF Calculations

1

REINFORCED FABRICATED TEE

PAD THK FTG RO

CROTCH

UNREINFORCED FABRICATED TEE

FTG RO

CROTCH

WELDING TEE

FTG RO

CROTCH

SWEEPOLET

CROTCH

WELDOLET

CROTCH

EXTRUDED WELDING TEE

GIRTH BUTT WELD

WELD D OR ID

SOCKET WELD (NO UNDERCUT)

FILLET

SOCKET WELD (AS WELDED)

FILLET

10

TAPERED TRANSITION

WELD D

11

THREADED JOINT

12

DOUBLE WELDED SLIP-ON

13

LAP JOINT FLANGE (B16.9)

14

BONNEY FORGE SWEEPOLET

15

BONNEY FORGE LATROLET

16

BONNEY FORGE INSERT WELDOLET

17

FULL ENCIRCLEMENT TEE

FTG RO

CROTCH

WELD ID

FTG RO

WELD ID

Node Number

Enter the node number where the Stress Intensification exists. This may be any node in the system, but is most

often at a pipe intersection or joint.

If the node is at an Intersection, stress intensification factors will be automatically

calculated

for all pipes

goingbut i

Mr. Richard

Ay, you defined

this portion

did not mean

this

(Confusion

asentered

per 5.1

to the intersection providing the intersection "TYPE" is specified. The intersection

type

needs

to onlyis,be

thisappropriate

page # is 3-25).

apply the

SIFsMy requirement is

once. CAESAR II will find all other pipes framing into the intersection and manual

on page # 3-32 & 3-33 as per 5.3 manual

accordingly.

please refer it.

If the node is at a two-pipe Joint, i.e. a butt weld, stress intensification factors will be calculated for the two pipes

going to the joint node providing the joint "TYPE" is specified. The joint type needs to only be entered once.

CAESAR II will find the other pipe completing the joint.

If the node is not at an intersection or a joint then the Type field should be left BLANK and the "USER

DEFINED" SIFs entered in the SIF(i) and SIF(o) fields. User entries in the SIF(i) and SIF(o) fields only apply

to the element on which they are defined.

User defined stress intensification factors, must be greater than or equal to one.

You can get CAESAR II to calculate and display code defined SIFs while in the SIF scratchpad. This scratchpad

is accessed via the K-Aux option on the pipe spreadsheet. Parameters used in the scratchpad may be modified so

Chapter 3 Piping Screen Reference

3-29

that the effects of different geometries and thicknesses can be observed. Most changes made in the scratchpad

may be automatically transferred back into the input, if desired.

If the node is on any part of a bend's curvature then the following applies:

1

User defined SIFs won't override code calculated SIFs for bends, although a SETUP file directive exists to

override this default, i.e. ALLOW_USERS_BEND_SIF=YES. If this parameter appears in the setup file

then users may specify SIFs for bend "to" nodes. The SIFs so specified will apply for the entire bend

curvature.

User defined SIFs will apply to straight pipe going to points on a bend curvature regardless of any parameter

in the setup file. This option is commonly used to intensify injector tie-ins at bends, or dummy legs, or other

bend attachment-type of supports.

PAD THK

Thickness of the reinforcing pad for reinforced fabricated or full encirclement tees, intersection type #1 and #17

respectively. The pad thickness is only valid for these intersection types. Note that in most piping codes the

beneficial effect of the pads thickness is limited to 1.5 times the nominal thickness of the header. This factor

does not apply in BS 806 or Z184, and is 2.5 in the Swedish piping code. If the thickness of a type 1or type 17

intersection is left blank or zero the SIFs for an unreinforced fabricated tee are used.

FTG RO

Fitting outside radius for branch connections. Used for reduced branch connections in the ASME and B31.1

piping codes, Bonney Forge Insert Weldolets, and for WRC 329 intersection SIF calculations. Setup file

directives exist to invoke the WRC 329 calculations, and to limit the application of the reduced branch

connection rules to unreinforced fabricated tees, sweepolets, weldolets, and extruded welding tees. If omitted,

FTG ro defaults to the outside radius of the branch pipe.

CROTCH R

The crotch radius of the formed lip on an extruded welding tee, intersection type 6. This is also the intersection

weld crotch radius for WRC329 calculations. Specifying this value when it is known can result in a 50%

reduction in the stress intensification at the WRC 329 intersection. Basically, if the user makes an attempt to

reduce the stress riser at a fabricated intersection, by guaranteeing that there will be a smooth transition radius

from the header to the branch pipe, then he may reduce the resulting stress intensification by a factor of 2.0.

WELD (D)

Defines the average circumferential weld mismatch measured at the inside diameter of the pipe. Used for Butt

Welds and Tapered transitions. Note that this is the average, and not the maximum mismatch. Users must

themselves verify that any maximum mismatch requirements are satisfied for their particular code.

FILLET

The fillet leg length, and is used only in conjunction with a socket weld component. For an unequal leg fillet

weld, this value is the length of the shorter leg. Note that if a fillet leg is given, both socket weld types result in

the same SIF. See appendix D of the B31 piping codes for further clarification.

3-30

Piping Screen Reference

Weld ID

The following are valid Weld ID values.

Values:

0 or BLANK - As Welded

1 - Finished/Ground Flush

Used for:

BONNEY FORGE SWEEPOLETS

BONNEY FORGE INSERT WELDOLETS

BUTT WELDS IN THE SWEDISH PIPING CODE

If entered as 1 then the weld is considered to be ground flush on the inside and out and the SIF is taken as 1.0.

Refer to the help on Weld Mismatch (Weld d) for more detail on how input parameters are used to compute SIFs

for girth butt welds.

B1; Wc

ASME Class 2 and ASME Class 3

For ASME Class 2 and Class 3, this entry defines the primary stress index to be used for the given node on the

current element.

For ASME Class 2 and Class 3 piping. Unless otherwise over-ridden by the user the following values are

applied as:

Straight Pipe:

B1 = 0.5 B2 = 1.0

Curved Pipe:

B1 = -0.1 + 0.4h; but not <0 or >0.5

B2 = 1.30/h**2/3 but not <1.0; h = tR/ rm**2

Intersections:

B1 = 0.5

Butt Welded Tees: B2b = 0.4(R/T)**2/3 but not < 1.0

B2r = 0.5(R/T)**2/3 but not < 1.0

Branch Connections:

(r < 0.5R)

B2b = 0.50 C2b but not < 1.0

B2r = 0.75 C2r but not < 1.0

C2b = 3(R/T)**2/3 (r/R)**1/2 (t/T)(r/FTG ro) but not < 1.5

C2r = 1.15(r/t)**1/4 but not < 1.5

B31.1 / B31.3

For B31.1 and B31.3, this field is used to specify the weld strength reduction factor (W c ), used to reduce the

allowable stress for the Sustained load case.

Chapter 3 Piping Screen Reference

3-31

BS-7159 and UKOOA

For BS 7159 and UKOOA codes, B1 is used to enter the pressure stress multiplier (m), if other than as per the

code requirements. For straight pipe, m = 1.0; for bends and tees, m is defined in Figures 7.1 and 7.12 of the BS

7159 Code.

IGE/TD/12

For IGE/TD/12 this field is used to override the cyclic pressure Stress Intensification Factor Ip(Cyc), if other

than as per the code calculations (calculated as per Table 9, Figure 5, and Figure 7 of the code).

B2

This entry defines the primary stress index to be used for the given node on the current element. This entry is

only applicable for ASME Class 2 and 3 piping.

If omitted, B1 and B2 are defaulted as shown as follows:

Straight Pipe:

B1=0.5 B2=1.0

Curved Pipe:

B1=-0.1+0.4h; but not <0 or >0.5

2/3

2

B2=1.30/h ; but not <1.0; h=tR/rm

Intersections:

B1=0.5

Butt-Welded Tees: B2b=0.4(R/T)2/3 but not <1.0

B2r=0.5(R/T)2/3 but not <1.0

Branch Connections:

(r<0.5R)

B2b=0.50 C2b but not <1.0

B2r=0.75 C2r but not <1.0

C2b=3(R/T)2/3 (r/R)1/2 (t/T)(r/FTG ro) but not <1.5

C2r=1.15(r/t)1/4 but not <1.5

The SIF(IN) and SIF(OUT) fields may be used to override the CAESAR II calculated values for any intersection.

Override values only apply for the single element they are defined on. SIFs may be calculated for partial

intersections and dummy legs.

Note: When IGE/TD/12 is active, the SIF/TEE spreadsheet changes its appearance to accommodate specialized

SIF parameters. Refer to supplementary IGE/TD/12 documentation for further information.

Code Options (B31.1 & B31.8)

B31.1:

Enabling this check box indicates that the tee meets the dimensional criteria of Figure D1 as well as Notes 6a,

6c, 6d, 6e, and 6f. This allows the use of the "branch equation" when determining the SIF value for the tee.

Note that this option relies on the setting of the Configuration Directives Reduced Intersection and No RFT /

WLT in Reduced Fitting SIFs.

3-32

Piping Screen Reference

B31.8:

Enabling this check box indicates that B31.8 Notes 6, 9, or 10 (as applicable) should be used when determining

the SIF value for the tee.

ASME NC and ND:

Enabling this check box indicates that the tee meets the dimensional criteria of Figure 3673.2(b)-2 as well as

Notes 10 and 11. This allows the use of the "branch equation" when determining the SIF value for the tee. Note

that this option relies on the setting of the Configuration Directives Reduced Intersection and No RFT / WLT

in Reduced Fitting SIFs.

ASME NC/ND 3673.2(b)-1 Note 3

Checking this check box indicates that the material for this tee is ferrous, which enables the "Y" value to be

computed based on the highest temperature value specified.

Input Items Optionally Effecting SIF Calculations For ISO 14692

1 TEES

2 JOINTS

User-Defined SIFs Anywhere in the Piping System

Unless the piping element is a bend, SIFs for non-intersection points are normally taken to be 1.0. If for some

reason the SIF should be greater than (1.0) the user may enter the non-unity SIF in the Intersection Auxiliary

field without specifying the intersection type. Note that a user defined SIF only acts at the node on the current

element.

Stress Intensification Factors Details

Stress intensification factors are calculated automatically for bends and defined intersections as specified by the

applicable piping code. You may enter specific stress intensification factor for any point in the piping system by

clicking the SIFs and Tees check box on the pipe spreadsheet. The node number where the stress is to be

intensified is entered in the first available Node field, and the in-plane and out-plane stress intensification factors

are entered in the SIF(i) and the SIF(o) fields, respectively. The only exception is that you cannot specify SIFs

for bend elements unless the Allow User's Bend SIF directive is activated in the configuration file. Code

defined SIFs always apply. CAESAR II will not allow user-defined stress intensification factors to be less than

1.0. The node to be intensified must be the TO or the FROM node on the current element.

Stresses are only intensified at the element end going to the specified node. For example, if two pipes frameare

going into node 10, one going from 5 to 10, and the other from 10 to 15; and a stress intensification factor of 2.0

for node 10 is defined on the element from 5 to 10, then the 10 end of the element from 5 to 10 will have a stress

intensification of 2.0, and the 10 end of the element from 10 to 15 will have a stress intensification of 1.0.

User defined stress intensification factors can be used to override code calculated values for nodes at

intersections. For example, if node 40 is an intersection defined by an unreinforced fabricated tee. The header

pipes framing into the intersection go from 35 to 40 and from 40 to 45. The branch pipe framing going into the

intersection goes from 175 to 40. The code-calculated values for the stress intensification factors in the header

pipes are:

Chapter 3 Piping Screen Reference

SIF(i)

3-33

First Query,

In which code or case, the SIF for header and branch are different?

= 4.50

SIF(o) = 3.75

and in the branch pipe are

SIF(i)

= 6.70

SIF(o) = 5.58

Also assume that finite element analysis of the intersection showed the header stress intensification factors to be

2.3 and 1.87, respectively, and the branch stress intensification factors to be equal to the code recommended

values, i.e. 6.70 and 5.58. To properly override the code-calculated stress intensification factors for the header

pipes, two pipe elements will have to be modified:

35 to 40

NODE 40

Type:

As per the clouded sentence, the "Type" field is left blank.

SIF(i): 2.3

SIF(o): 1.87

40 to 15

NODE 40

Type:

In my case, the intersection is a 45 deg lateral tee which is

not available in the Caesar-II SIF/Tee option or ASME code,

then how i can define the intersection type.

SIF(i): 2.3

SIF(o): 1.87

The stress intensification for the branch pipes can be calculated according to the code; so part of the branch pipe

spreadsheet might appear:

175 to 40

NODE 40

Type: 2 - Unreinforced

This sentence is not clear, please clarify.

SIF(i):

SIF(o):

If either of the SIF fields for the header elements going to 40 were left blank, the code-calculated value would be

used in its place. This is only true where code-calculated values exist along with user-specified values.

If the element from 110 to 115 needs the stress intensification factors for each of its ends is 2.0, then a part of

that element's spreadsheet might appear:

110 to 115

NODE 110

Type:

SIF(i):

2.0

SIF(o):

Node:

115

Type:

SIF(i):

SIF(o):

2.0

3-34

Piping Screen Reference

Leaving the out-of-plane stress intensification factor blank implies that it is equal to the in-plane stress

intensification factor. There are no code-calculated values to override these user-input values.

The user is not permitted to override code-calculated stress intensification factors for bend elements (unless the

Allow User's Bend SIF directive is activated in the configuration file). Additionally, bend stress intensification

factors will supersede any code-calculated intersection stress intensification factors for the same node. This

characteristic allows the user to apply code-calculated intersection stress intensification factors to dummy legs

without disturbing the normal bend stress intensification factors. The node on the dummy leg, which is also on

the bend curvature, is defined as an intersection on the Intersection SIF Scratchpad. The intersection stress

intensification factors will be calculated and can be applied to the dummy leg end that connects to the bend.

Bend stress intensification factors are unchanged.

Stress intensification factors can be calculated for intersections having one, two, or three pipes framing into it.

Where two pipes form a partial intersection, CAESAR II assumes that the larger pipe is the header and the smaller

the branch.

Where one pipe forms a partial intersection, CAESAR II assumes that the intersection is full sized.

CAESAR II will not calculate stress intensification factors for intersections having more than three pipes framing

into it.

SIF Scratchpad

The stress intensification factors calculated by CAESAR II can be viewed interactively from the pipe spreadsheet

by selecting either the ENVIRONMENT - REVIEW SIFS AT INTERSECTION NODES menu item or the KAUX - REVIEW SIFS AT

BEND NODES menu item. One of the following SIF scratchpads will appear after typing in the node number to

review when prompted. Note that the Node must be a valid Bend node when Reviewing SIFs at Bends.

At this point the user may interactively change any of the spreadsheet data and recalculate the SIFs. This feature

allows the user to see the effect that changing geometries and properties have on code stress intensification

Chapter 3 Piping Screen Reference

3-35

factors.

Note: CAESAR II gives the user the opportunity to transfer back to the actual model any data, which might be

changed in the scratchpad.

IGE\TD\12 Requirements

IGE\TD\12 requires different information than the other codes used in CAESAR II. When IGE/TD/12 is active,

the SIFs/Tees spreadsheet changes its appearance to accommodate specialized SIF parameters. For more

information regarding the specialized parameters refer to the text and figures at the end of this section.

Node Number

Enter the node number where the Stress Intensification exists. This may be any node in the system, but is most

often at a pipe intersection or joint.

If the node is at an Intersection, stress intensification factors will be automatically calculated for all pipes going

to the intersection providing the intersection "TYPE" is specified. The intersection type needs to only be entered

once. CAESAR II will find all other pipes framing into the intersection and apply the appropriate SIFs

accordingly.

If the node is at a two-pipe Joint, i.e. a butt weld, stress intensification factors will be calculated for the two pipes

3-36

Piping Screen Reference

going to the joint node providing the joint "TYPE" is specified. The joint type needs to only be entered once.

CAESAR II will find the other pipe completing the joint.

If the node is not at an intersection or a joint then the Type field should be left BLANK and the "USER

DEFINED" SIFs entered in the SIF(i) and SIF(o) fields. User entries in the SIF(i) and SIF(o) fields only apply

to the element on which they are defined.

User defined stress intensification factors, must be greater than or equal to one.

The user can get CAESAR II to calculate and display code defined SIFs while in the SIF scratchpad. This

scratchpad is accessed via the K-Aux option on the pipe spreadsheet. Parameters used in the scratchpad may be

modified so that the effects of different geometries and thicknesses can be observed. Most changes made in the

scratchpad may be automatically transferred back into the input, if desired.

If the node is on any part of a bend's curvature then the following applies:

1

User defined SIFs won't override code calculated SIFs for bends, although a SETUP file directive exists to

override this default, i.e. ALLOW_USERS_BEND_SIF=YES. If this parameter appears in the setup file

then users may specify SIFs for bend "to" nodes. The SIFs so specified will apply for the entire bend

curvature.

User defined SIFs will apply to straight pipe going to points on a bend curvature regardless of any parameter

in the setup file. This option is commonly used to intensify injector tie-ins at bends, or dummy legs, or other

bend attachment-type of supports.

Do/r3

This field corresponds to the following terms for each component type:

For more information on Do refer to the figures (on page 3-39) at the end of this section.

Forged Tee to BS 1640:

Weldolet:

For more information on r3 refer to the figures (on page 3-39) at the end of this section.

Drawn/Extruded Tee:

Weldoflange:

For more information on Do refer to the figures (on page 3-39) at the end of this section.

For more information on r3 refer to the figures (on page 3-39) at the end of this section.

T/Th/T'b

This field corresponds to the following terms for each component type:

For more information on T refer to the figures (on page 3-39) at the end of this section.

Forged Tee to BS 1640:

Weldolet:

For more information on theta refer to the figures (on page 3-39) at the end of this section.

Drawn/Extruded Tee:

Weldoflange:

For more information on T refer to the figures (on page 3-39) at the end of this section.

For more information on theta refer to the figures (on page 3-39) at the end of this section.

Te/Tb

This field corresponds to the following terms for each component type:

Fabricated Tee with Pad:

Forged Tee to BS 1640:

For more information on Te refer to the figures (on page 3-39) at the end of this section.

For more information on Tb refer to the figures (on page 3-39) at the end of this section.

Chapter 3 Piping Screen Reference

Weldolet:

3-37

For more information on Tb refer to the figures (on page 3-39) at the end of this section.

Drawn/Extruded Tee:

For more information on Tb refer to the figures (on page 3-39) at the end of this section.

For more information on Te refer to the figures (on page 3-39) at the end of this section.

Full Encirclement Tee:

Long Weldneck Flange:

Weldoflange:

For more information on Tb refer to the figures (on page 3-39) at the end of this section.

For more information on Tb refer to the figures (on page 3-39) at the end of this section.

rp/do

This field corresponds to the following terms for each component type:

Fabricated Tee:

For more information on rp refer to the figures (on page 3-39) at the end of this section.

For more information on do refer to the figures (on page 3-39) at the end of this section.

Forged Tee to BS 1640:

Weldolet:

For more information on rp refer to the figures (on page 3-39) at the end of this section.

Drawn/Extruded Tee:

For more information on do refer to the figures (on page 3-39) at the end of this section.

Long Weldneck Flange:

Weldoflange:

For more information on rp refer to the figures (on page 3-39) at the end of this section.

For more information on rp refer to the figures (on page 3-39) at the end of this section.

r2/rc

This field corresponds to the following terms for each component type:

Fabricated Tee:

For more information on r2 refer to the figures (on page 3-39) at the end of this section.

For more information on rc refer to the figures (on page 3-39) at the end of this section.

Forged Tee to BS 1640:

Sweepolet:

For more information on rc refer to the figures (on page 3-39) at the end of this section.

Weldolet:

For more information on r2 refer to the figures (on page 3-39) at the end of this section.

Drawn/Extruded Tee:

For more information on rc refer to the figures (on page 3-39) at the end of this section.

Long Weldneck Flange:

Weldoflange:

For more information on r2 refer to the figures (on page 3-39) at the end of this section.

For more information on r2 refer to the figures (on page 3-39) at the end of this section

r1/Tc/Lh

This field corresponds to the following terms for each component type:

Fabricated Tee:

For more information on r1 refer to the figures (on page 3-39) at the end of this section

Forged Tee to BS 1640:

Sweepolet:

For more information on Tc refer to the figures (on page 3-39) at the end of this section

For more information on r1 refer to the figures (on page 3-39) at the end of this section

3-38

Weldolet:

Piping Screen Reference

For more information on r1 refer to the figures (on page 3-39) at the end of this section

Drawn/Extruded Tee:

For more information on Lh refer to the figures (on page 3-39) at the end of this section

Long Weldneck Flange:

Weldoflange:

For more information on r1 refer to the figures (on page 3-39) at the end of this section

For more information on r1 refer to the figures (on page 3-39) at the end of this section

L1/Lb

This field corresponds to the following terms for each component type:

Fabricated Tee:

Weldolet:

For more information on L1 refer to the figures (on page 3-39) at the end of this section

For more information on L1 refer to the figures (on page 3-39) at the end of this section

Drawn/Extruded Tee:

For more information on Lb refer to the figures (on page 3-39) at the end of this section

Long Weldneck Flange:

Weldoflange:

For more information on L1 refer to the figures (on page 3-39) at the end of this section

For more information on L1 refer to the figures (on page 3-39) at the end of this section

Use the figures below to identify the specialized parameters.

For ged Tee

Weldolet

Chapter 3 Piping Screen Reference

Dr awn/Extr uded Tee

Weldoflange

Full Encir clement Tee

3-39

3-40

Long Weldneck Flange

Sweepolet

Fabr icated Tee

Piping Screen Reference

Chapter 3 Piping Screen Reference

3-41

Fabr icated Tee with Pad

Weld ID

The following are valid Weld ID values.

Values:

0 or BLANK - As Welded

1 - Finished/Ground Flush

Used for:

BONNEY FORGE SWEEPOLETS

BONNEY FORGE INSERT WELDOLETS

BUTT WELDS IN THE SWEDISH PIPING CODE

If entered as 1 then the weld is considered to be ground flush on the inside and out and the SIF is taken as 1.0.

Refer to the help on Weld Mismatch (Weld d) for more detail on how input parameters are used to compute SIFs

for girth butt welds.

Stress Concentration Factors

Entering Stress Concentration Factors here overrides those calculated according to the IGE/TD/12 Code

equations. Note that any values entered here will apply only to the element on which they have been entered

(except when entered on a bend node, they will apply throughout the bend).

Note that for branches of tees, any bending SCFs entered here must include the w term.

Fatigue Class

Selecting a fatigue class here overrides those calculated according to the IGE/TD/12 Code equations. Note that

any values selected here will apply only to the element on which they have been entered (except when entered

on a bend node, they will apply throughout the bend).

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Productlistingcaterpillar 2010-14-1Document67 pagesProductlistingcaterpillar 2010-14-1Edgar Rojas EspejoNo ratings yet

- On API 650Document52 pagesOn API 650ferdad79% (19)

- Understanding IBR 1950Document7 pagesUnderstanding IBR 1950sammar_10No ratings yet

- P&ID-Presentation (GOOD)Document104 pagesP&ID-Presentation (GOOD)alejandro inostroza100% (3)

- Broad Crested WeirDocument7 pagesBroad Crested Weirrancid100% (1)

- Pressure Vessel Design ASME Section VIII Divison1 and Division 2Document3 pagesPressure Vessel Design ASME Section VIII Divison1 and Division 2sammar_10No ratings yet

- BOSFluids Dynaflow HammerDocument18 pagesBOSFluids Dynaflow Hammersammar_10No ratings yet

- EJMA Bellows CalculatorDocument6 pagesEJMA Bellows Calculatorsammar_10No ratings yet

- Basic Aerodynamics Module 4Document86 pagesBasic Aerodynamics Module 4Gadadhar DeyNo ratings yet

- Bucher Hydraulics hds11 - 200-P-991210-EnDocument39 pagesBucher Hydraulics hds11 - 200-P-991210-EnJustin100% (1)

- ESP CentriliftDocument102 pagesESP CentriliftJB BalcacerNo ratings yet

- Engineering Design Calculation - Dennis Kirk Single Stage Centrifugal Pump Calculation (Clean Water Use) System CurveDocument1 pageEngineering Design Calculation - Dennis Kirk Single Stage Centrifugal Pump Calculation (Clean Water Use) System Curvebuntimehta007No ratings yet

- New SANDVIK Basic HydraulicDocument106 pagesNew SANDVIK Basic HydraulicSamuel Ernesto Matsinhe100% (1)

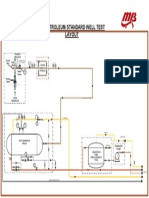

- MB Petroleum Standard Well Test Layout: Production Wing ValveDocument1 pageMB Petroleum Standard Well Test Layout: Production Wing ValveabdounouNo ratings yet

- Tank - Design and AnalysisDocument4 pagesTank - Design and Analysissammar_10No ratings yet

- Jacketed Piping Tutorial in CAEPIPEDocument8 pagesJacketed Piping Tutorial in CAEPIPEsammar_10No ratings yet

- The Fiberbond® Engineering Guide: Engineered Composite Piping SystemsDocument41 pagesThe Fiberbond® Engineering Guide: Engineered Composite Piping Systemssammar_10No ratings yet

- Builder Noc FormatDocument1 pageBuilder Noc Formatsammar_10No ratings yet

- Support Friction in Pipe Stress AnalysisDocument6 pagesSupport Friction in Pipe Stress AnalysisArya AryanNo ratings yet

- Allowable Steam Turbine LoadsDocument5 pagesAllowable Steam Turbine LoadsSami SyedNo ratings yet

- Guided Cantilever Formula MethodDocument8 pagesGuided Cantilever Formula Methodsammar_10No ratings yet

- Tailing Lug Calculations 01Document2 pagesTailing Lug Calculations 01sammar_10No ratings yet

- Dynamic Analysis of Water Hammer LoadsDocument11 pagesDynamic Analysis of Water Hammer Loadskummi_scribd100% (1)

- Bernolii EquationDocument5 pagesBernolii EquationEsra BelhajNo ratings yet

- Modeling Low Reynolds Number Incompressible Flows Using SPH PDFDocument13 pagesModeling Low Reynolds Number Incompressible Flows Using SPH PDFAbhiyan PaudelNo ratings yet

- Spray Drying Handbook Third Edition by K Masters 687 Pages George GodwinDocument1 pageSpray Drying Handbook Third Edition by K Masters 687 Pages George Godwinduong nguyen0% (1)

- Power Piping: ASME B31.1-2012Document1 pagePower Piping: ASME B31.1-2012Jonathan GagliardiNo ratings yet

- Filter Oil Comressor BaruDocument1 pageFilter Oil Comressor BaruSyahrul SaputraNo ratings yet

- Internal Force ConvectionDocument43 pagesInternal Force Convectionirvan100% (1)

- Winter - 18 Examination Subject Name: Model Answer Subject CodeDocument15 pagesWinter - 18 Examination Subject Name: Model Answer Subject CodeD06 suraj kumarNo ratings yet

- 5 2018 03 05!01 13 43 PMDocument40 pages5 2018 03 05!01 13 43 PMquike6041-150% (2)

- Chapter - 6 - FUNDAMENTALS OF CONVECTIONDocument56 pagesChapter - 6 - FUNDAMENTALS OF CONVECTIONBT20MEC058AdeshNo ratings yet

- 700htp 2 ManualDocument2 pages700htp 2 ManualLuis Alfredo Lopez SanchezNo ratings yet

- Chapter 13Document23 pagesChapter 138angeldoll8100% (1)

- FLUENT - Bifurcating Artery - SimCafe - DashboardDocument3 pagesFLUENT - Bifurcating Artery - SimCafe - DashboardShri Vignesh KNo ratings yet

- Chee 312 Final Lab 3 ReportDocument25 pagesChee 312 Final Lab 3 ReportTshegofatso GotsilengNo ratings yet

- API 5l Pipe Manufacturer in IndiaDocument3 pagesAPI 5l Pipe Manufacturer in IndiaSTEEL TUBES INDIANo ratings yet

- Assignment IVDocument2 pagesAssignment IVMANOJ MNo ratings yet

- Argohytoslr PDFDocument874 pagesArgohytoslr PDFdonnyNo ratings yet

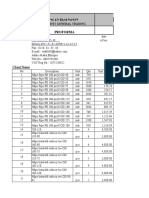

- ProformaDocument10 pagesProformaArse AbiNo ratings yet

- Hy 2nd Exam Spring 2018Document4 pagesHy 2nd Exam Spring 2018FahedNo ratings yet

- Solution: 11-1. Oil Flows With A Free-Stream Velocity of U 3 FT SDocument126 pagesSolution: 11-1. Oil Flows With A Free-Stream Velocity of U 3 FT SSayyadh Rahamath BabaNo ratings yet

- Micro-Lok® Pipe Insulation Dimensions For NPS Pipe SizesDocument1 pageMicro-Lok® Pipe Insulation Dimensions For NPS Pipe SizesNavdeep Singh SidhuNo ratings yet

- Bci - 750gpm@250psi PDFDocument2 pagesBci - 750gpm@250psi PDFSergio ZegarraNo ratings yet