Professional Documents

Culture Documents

Information About Hydrostatic Testing.: Pressure Vessels Pipelines Plumbing Gas Cylinders Boilers

Uploaded by

Adnan Atif0 ratings0% found this document useful (0 votes)

7 views1 pagehydro testing technique

Original Title

Hydro Test

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documenthydro testing technique

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views1 pageInformation About Hydrostatic Testing.: Pressure Vessels Pipelines Plumbing Gas Cylinders Boilers

Uploaded by

Adnan Atifhydro testing technique

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

Information about hydrostatic testing.

A hydrostatic test is a way in which pressure vessels such as pipelines, plumbing,

gas cylinders, boilers and fuel tanks can be tested for strength and leaks. The test

involves filling the vessel or pipe system with a liquid, usually water, which may be

dyed to aid in visual leak detection, and pressurization of the vessel to the specified

test pressure. Pressure tightness can be tested by shutting off the supply valve and

observing whether there is a pressure loss. The location of a leak can be visually

identified more easily if the water contains a colorant. Strength is usually tested by

measuring permanent deformation of the container. Hydrostatic testing is the most

common method employed for testing pipes and pressure vessels. Using this test

helps maintain safety standards and durability of a vessel over time. Newly

manufactured pieces are initially qualified using the hydrostatic test. They are then

re-qualified at regular intervals using the proof pressure test which is also called the

modified hydrostatic tes] Testing of pressure vessels for transport and storage of

gases is very important because such containers can explode if they fail under

pressure.

You might also like

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- TN 46 Guidance Field Hydro Test Hdpe Pressure ConsiderationsDocument17 pagesTN 46 Guidance Field Hydro Test Hdpe Pressure ConsiderationsZohair AftabNo ratings yet

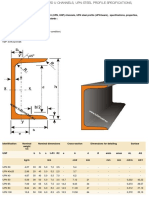

- UPN (UNP) European Standard U Channels, UPN Steel Profile Specifications, DimenDocument2 pagesUPN (UNP) European Standard U Channels, UPN Steel Profile Specifications, DimenAdnan Atif100% (1)

- Ships PipingDocument25 pagesShips Pipinggopaltry100% (1)

- Well TestingDocument22 pagesWell TestingSuleiman BaruniNo ratings yet

- Chapter 3 - Groundwater Flow To WellsDocument92 pagesChapter 3 - Groundwater Flow To WellsCarlos Chévez100% (1)

- Scaling Chemical Processes: Practical Guides in Chemical EngineeringFrom EverandScaling Chemical Processes: Practical Guides in Chemical EngineeringNo ratings yet

- This Document Was Downloaded From The Penspen Integrity Virtual LibraryDocument20 pagesThis Document Was Downloaded From The Penspen Integrity Virtual LibraryGRANRICKYNo ratings yet

- Pipeline Hydro Test Pressure Determination - Pipeline & Gas JournalDocument4 pagesPipeline Hydro Test Pressure Determination - Pipeline & Gas Journallewgne08No ratings yet

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- Hydro Static Universal Field Test ProcedureDocument16 pagesHydro Static Universal Field Test ProcedureHarvey Svetlik100% (1)

- Dynamic Testing of CheckvalveDocument10 pagesDynamic Testing of Checkvalveamirthraj74No ratings yet

- Pressure TestingDocument14 pagesPressure TestingWeld Bro Sandeep100% (2)

- Pressure & Leak TestingDocument18 pagesPressure & Leak TestingBilly KurniawanNo ratings yet

- Design and Implementation of Well TestingDocument33 pagesDesign and Implementation of Well TestingMuhammad Tahir100% (1)

- Advanced Water Injection for Low Permeability Reservoirs: Theory and PracticeFrom EverandAdvanced Water Injection for Low Permeability Reservoirs: Theory and PracticeRating: 4 out of 5 stars4/5 (2)

- Production Logging For Reservoir TestingDocument5 pagesProduction Logging For Reservoir Testingmahimoh18No ratings yet

- Comparing Concrete Durability Testing MethodsDocument3 pagesComparing Concrete Durability Testing MethodsHoang An TranNo ratings yet

- Prevention of Actuator Emissions in the Oil and Gas IndustryFrom EverandPrevention of Actuator Emissions in the Oil and Gas IndustryNo ratings yet

- Well Testing Schlumberger GlossaryDocument18 pagesWell Testing Schlumberger GlossaryDiana La Cruz100% (1)

- Section 5, Introduction To Flow TestsDocument8 pagesSection 5, Introduction To Flow TestshammamiNo ratings yet

- Well Testing ProjectDocument24 pagesWell Testing ProjectLuis Abdul-MelendezNo ratings yet

- Introduction To Well TestingDocument38 pagesIntroduction To Well TestingKhalil HdedehNo ratings yet

- Pressure Transient Formation and Well Testing: Convolution, Deconvolution and Nonlinear EstimationFrom EverandPressure Transient Formation and Well Testing: Convolution, Deconvolution and Nonlinear EstimationRating: 2 out of 5 stars2/5 (1)

- Step Changing in Well Test OperationDocument10 pagesStep Changing in Well Test OperationAnugrah FadhlanNo ratings yet

- Wireline Formation TesterDocument35 pagesWireline Formation TesterRasheed100% (1)

- Magnetic Particle TestingDocument1 pageMagnetic Particle TestingAdnan AtifNo ratings yet

- Hydrostatic Test - Wikipedia, The Free EncyclopediaDocument4 pagesHydrostatic Test - Wikipedia, The Free Encyclopediaramthecharm_46098467No ratings yet

- M2.2.10 Other Test MethodsDocument9 pagesM2.2.10 Other Test MethodsAldy Bagus PratamaNo ratings yet

- Hydrostatic Test: From Wikipedia, The Free EncyclopediaDocument5 pagesHydrostatic Test: From Wikipedia, The Free EncyclopediaLinlin DuanNo ratings yet

- Hydrotest ProcedureDocument2 pagesHydrotest ProcedureVarun MalhotraNo ratings yet

- Pressure Testing in Main PipelineDocument7 pagesPressure Testing in Main PipelineChintamani KuralkarNo ratings yet

- Testing Procedures: Water Oil Red Fluorescent DyesDocument2 pagesTesting Procedures: Water Oil Red Fluorescent DyesMayur MandrekarNo ratings yet

- DKK2462 Chapter 8Document14 pagesDKK2462 Chapter 8rawanisephiaNo ratings yet

- Identification of Well Problems Using Well TestingDocument15 pagesIdentification of Well Problems Using Well Testingعبدالله عبدالله المصراتيNo ratings yet

- GaswelDocument1 pageGaswelnoukiNo ratings yet

- Introduction To Well TestingDocument39 pagesIntroduction To Well TestingzazoNo ratings yet

- Hydro Testing Pressure VesselDocument5 pagesHydro Testing Pressure VesselAkansha Sharma100% (1)

- HydroDocument7 pagesHydroAhmedNo ratings yet

- Testing Procedures: Pressure Test Which Is Also Called The Modified Hydrostatic Test. Hydrostatic Testing Is Also A WayDocument5 pagesTesting Procedures: Pressure Test Which Is Also Called The Modified Hydrostatic Test. Hydrostatic Testing Is Also A Wayvaresh111No ratings yet

- Hatim Kareem NimerDocument6 pagesHatim Kareem NimerAsst. Prof. Dr. Ahmed Hameed KaleelNo ratings yet

- Well Test Lecture 3Document12 pagesWell Test Lecture 3عبدالله المسلميNo ratings yet

- Reservoir Engineering 2 Unit 2Document28 pagesReservoir Engineering 2 Unit 2DHIVAKAR AppuNo ratings yet

- Hydrostatic Testing ProcedureDocument2 pagesHydrostatic Testing ProcedureAntonio ImperiNo ratings yet

- Prof. Dr. Eng: - Ahmed El-Gibaly: Suez Canal University Faculty of Pet. & Min. Eng. Petroleum Engineering DeptDocument22 pagesProf. Dr. Eng: - Ahmed El-Gibaly: Suez Canal University Faculty of Pet. & Min. Eng. Petroleum Engineering Deptcmrig74No ratings yet

- Pressure Testing: Pneumatic and Hydro Test: Chapter FiveDocument12 pagesPressure Testing: Pneumatic and Hydro Test: Chapter FivemrNo ratings yet

- Production Logging For Reservoir TestingDocument2 pagesProduction Logging For Reservoir TestingBela TarekNo ratings yet

- Packar MethodologyDocument6 pagesPackar Methodologyaitzaz561No ratings yet

- A.S.M.E. Code On General Instructions Regarding Power Plant TestsDocument34 pagesA.S.M.E. Code On General Instructions Regarding Power Plant TestsDovah KiinNo ratings yet

- Simulation of The Drop Impact Test For Moulded Thermoplastic ContainersDocument21 pagesSimulation of The Drop Impact Test For Moulded Thermoplastic ContainersIlham MaulanaNo ratings yet

- Spe 163442 PaDocument10 pagesSpe 163442 PamanuelperdomotNo ratings yet

- Engineering Failure Analysis: H.S. Da Costa Mattos, L.M. Paim, J.M.L. ReisDocument13 pagesEngineering Failure Analysis: H.S. Da Costa Mattos, L.M. Paim, J.M.L. ReisFelipe Perissé Duarte LopesNo ratings yet

- Hydrostatic Pressure Testing On Operating PipelinesDocument2 pagesHydrostatic Pressure Testing On Operating PipelinesAndres Fitria FarrelNo ratings yet

- Report On ViscosityDocument8 pagesReport On ViscosityYogesh GargNo ratings yet

- Measuring Viscosity: by Richard Crowley Contributing EditorDocument3 pagesMeasuring Viscosity: by Richard Crowley Contributing Editortrangthuan010187No ratings yet

- Well Testing Fundamentals: Senior EditorDocument2 pagesWell Testing Fundamentals: Senior EditorRoyGustavoOlivaCruzNo ratings yet

- ScratchDocument2 pagesScratchPatricia DantesNo ratings yet

- Measuring ViscosityDocument6 pagesMeasuring Viscositymorry123No ratings yet

- Baher M. EL-Gendy Section (2) B.N.Document7 pagesBaher M. EL-Gendy Section (2) B.N.Baher M. El-GendyNo ratings yet

- Standard methods for the examination of water and sewageFrom EverandStandard methods for the examination of water and sewageNo ratings yet

- HEB Beams, European Standard Wide Flang..Document2 pagesHEB Beams, European Standard Wide Flang..Adnan AtifNo ratings yet

- UC - British Universal Columns - Metric UnitsDocument7 pagesUC - British Universal Columns - Metric UnitsAdnan AtifNo ratings yet

- Hydrostatic Testing Equipment: S.NO. Item DescriptionDocument2 pagesHydrostatic Testing Equipment: S.NO. Item DescriptionAdnan AtifNo ratings yet

- Duty TimeDocument1 pageDuty TimeAdnan AtifNo ratings yet

- Penetrant Testing (PT), Is A Widely Applied and Low-Cost Inspection Method UsedDocument1 pagePenetrant Testing (PT), Is A Widely Applied and Low-Cost Inspection Method UsedAdnan AtifNo ratings yet

- Magnetic Particle TestingDocument1 pageMagnetic Particle TestingAdnan AtifNo ratings yet