Professional Documents

Culture Documents

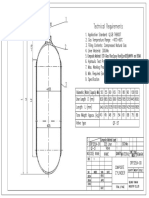

Boiler Expansion Vessel

Boiler Expansion Vessel

Uploaded by

abthakurCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Boiler Expansion Vessel

Boiler Expansion Vessel

Uploaded by

abthakurCopyright:

Available Formats

Boiler expansion vessels

The expansion vessel within a sealed system boiler takes the place of the feed & expansion tank in

an open-vented heating system. It allows the system to be pressurised and maintain a fairly steady

pressure while the water inside expands as it heats up. Having an internal pressure above that of the

atmosphere prevents air getting in and causing corrosion.

The way water behaves with temperature is shown in one way in the following graph, which shows

the percentage change in density relative to 4oC, where its density is highest. At low temperatures,

below 20oC, changes are relatively small, but by 80oC, the density has fallen by 2.8%:

Percentage density change

Percentage change in density of water v temperature

0.00

-0.50 0

-1.00

-1.50

-2.00

-2.50

-3.00

-3.50

-4.00

-4.50

20

40

60

80

100

120

Temperature celsius

Another way of putting this is that under the same pressure, the water occupies 2.8% greater volume

than it did when cold.

Water isn't, as you sometimes hear, incompressible, but it is pretty hard to compress. If you apply 1

bar of pressure, its volume shrinks by only around 46ppm (parts per million). If you had 100 litres

of water and wanted to pressurise it to 1 bar using a piston in a 22mm pipe, that piston would only

have to move 14.5mm.

If instead of allowing the water volume to increase by 2.8% as it heats up to 80oC, we kept it in a

pressure vessel and didn't let it expand at all, the vessel would have to withstand 603 bar, that is,

603 atmospheres of pressure! (Not in my house, thanks!)

The expansion vessel is a practical solution for a sealed system. The water is allowed to expand,

pushing a membrane behind which is pressurised air. This is a very neat solution: a vessel of only

around 10 litres in capacity can cope with small to moderate sized domestic heating systems: no

feed & expansion tank, and no pipework in the loft, at risk of freezing in winter.

However, everything involves a trade-off. Over time, as with a tyre, air escapes from the expansion

vessel. (At worst, its internal membrane can split.)

As the internal air pressure (with the system cold) falls, the air is less able to resist the expansion of

water, and the heated pressure rises. When it reaches (generally) 3 bar, the boiler's pressure relief

valve opens, allowing water out of the pressure relief outlet pipe. When the system cools, the

pressure will have fallen. As the process repeats, eventually the system pressure will fall below

Page 1 of 2

what's needed to operate the boiler, and it will decline to fire.

The remedy seems simple re-pressurise using the filling loop pressure restored job done.

Unfortunately, it isn't so the cycle will repeat itself use of the filling loop will become more

frequent, as will the discharges of water. Worse, the pressure relief valve spring may weaken over

time so that it releases water at lower and lower pressures and needs to be replaced.

What needs to be done is to isolate and drain the boiler to release the water pressure, and re-charge

the expansion vessel using, typically, a foot-pump. The main bugbear for me at the moment is the

inaccuracy of air pressure gauges (and just because a gauge has a digital readout doesn't make it

more accurate). That noted, I've yet to come across an expansion vessel that didn't need recharging.

Here are some facts and observations, some resulting from calculation:

When an entire system has been drained and re-filled, some of the pressurising air will be in

pipes and radiators and not just the expansion vessel. This air has to be released first.

When a system is pressurised, the expansion vessel's internal air pressure equals the water

pressure as indicated on the system pressure gauge (usually in the boiler).

For this reason, in order to pressurise a system at all, the water pressure has to exceed the

expansion vessel air charge pressure (or the water isn't pushing on the membrane).

If the air charge pressure is low, more water will enter the expansion vessel, leaving less

room for water expansion due to heat.

So, allowing for gauge inaccuracy, charge the expansion vessel to the upper end of the

range allowed by the manufacturer (usually somewhere between 0.5 and 0.9 bar, depending

on the vessel).

Go easy on over-filling with water, and stick to the manufacturer's recommended cold

system pressure, commonly 1 bar.

Keeping the system water temperature low helps to keep the pressure rise down. It also

helps to increase the efficiency of a condensing boiler (return water that's too hot prevents

condensation of the combustion water vapour). That's achieved by radiator balancing,

though people seldom want this done unless there's an acute problem.

Since the volume increase in heated water is in proportion to the total volume of water,

large systems will need an additional expansion vessel fitted external to the boiler on the

return. To take an extreme example of 80oC water expanding by 2.8% and an 8 litre

expansion vessel, a cold system containing 8 x 100/2.8 = 286 litres would expand by the

entire 8 litres of the vessel. One manufacturer with an 8 litre vessel states a limit of 143

litres before an external vessel is needed, exactly half of this, allowing at most half the

vessel to be taken up by expanding water.

Different manufacturers have different criteria for specifying when an external expansion

vessel must be used, so it's best as always, to follow their instructions.

End of document

Page 2 of 2

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Is 513 PDFDocument13 pagesIs 513 PDFManeesh Bangale100% (5)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 7 Cyclone Dust CollectorDocument22 pages7 Cyclone Dust Collectorritastoica100% (2)

- R 02 Danieli Corus - Blast Furnace Cast HouseDocument11 pagesR 02 Danieli Corus - Blast Furnace Cast HouseSaptarshi Sengupta100% (1)

- Durometer Conversion Table PDFDocument1 pageDurometer Conversion Table PDFabthakurNo ratings yet

- Crown Cork - Seal Case Study Presentation - CROWN CORK and SEALDocument10 pagesCrown Cork - Seal Case Study Presentation - CROWN CORK and SEALChicagoERGNo ratings yet

- Beamex White Paper - Weighing Scale Calibration ENGDocument8 pagesBeamex White Paper - Weighing Scale Calibration ENGabthakurNo ratings yet

- API Calcs Rev1 Version 2Document107 pagesAPI Calcs Rev1 Version 2JithuJohnNo ratings yet

- Aerospace Structural Metals HandbookDocument91 pagesAerospace Structural Metals Handbookcharles_boyle_3100% (1)

- Gap Analysis ChecklistDocument5 pagesGap Analysis ChecklistabthakurNo ratings yet

- Application Note: Measurements On FM Transmitters For Acceptance, Commissioning and MaintenanceDocument89 pagesApplication Note: Measurements On FM Transmitters For Acceptance, Commissioning and MaintenanceabthakurNo ratings yet

- Calibration WeightsDocument5 pagesCalibration WeightsabthakurNo ratings yet

- Data SheetDocument2 pagesData SheetabthakurNo ratings yet

- Vernier CalipersDocument32 pagesVernier CalipersabthakurNo ratings yet

- Company Profile - Shubh CastingsDocument5 pagesCompany Profile - Shubh CastingsabthakurNo ratings yet

- Astm b117 1973 PDFDocument10 pagesAstm b117 1973 PDFabthakurNo ratings yet

- Esa STM 276Document61 pagesEsa STM 276abthakurNo ratings yet

- Timber Design Lecture 1 - POLINGA, IRISH M.Document18 pagesTimber Design Lecture 1 - POLINGA, IRISH M.blehNo ratings yet

- CRP325-00-50 120 L (Drawing of Gas Cylinder)Document1 pageCRP325-00-50 120 L (Drawing of Gas Cylinder)Cristhian Junior Acosta ParadaNo ratings yet

- Is.15528.2004 0 PDFDocument25 pagesIs.15528.2004 0 PDFHarikrishnaNo ratings yet

- MSDS - GBH7107Document2 pagesMSDS - GBH7107pankaj111No ratings yet

- Bracket ConnectionDocument9 pagesBracket ConnectionSaurabh PandeyNo ratings yet

- Pozzolith 300RDocument6 pagesPozzolith 300RAnush Upulwan Malawara ArachchiNo ratings yet

- Dishank - Agrawal Summer Internship ReportDocument26 pagesDishank - Agrawal Summer Internship ReportDishank AgrawalNo ratings yet

- Pulsation DampnerDocument2 pagesPulsation DampnerEliezer Mendez Gonzalez0% (1)

- Abstract (Replacement of Cement With Glass Powder in Concrete)Document9 pagesAbstract (Replacement of Cement With Glass Powder in Concrete)pawan kumar100% (5)

- MCI Protection of ConcreteDocument4 pagesMCI Protection of Concretejack21abNo ratings yet

- Wood and SteelDocument31 pagesWood and SteelHlinaNo ratings yet

- Electric Motor HandbookDocument40 pagesElectric Motor HandbookOscar ParraNo ratings yet

- Cutting and Installing Crown MoldingDocument5 pagesCutting and Installing Crown Moldingcaliangel1No ratings yet

- Automation & Sanitization: OmnilogicDocument5 pagesAutomation & Sanitization: OmnilogicJoni MoonNo ratings yet

- Maharashtra Metro Rail Co. LimitedDocument29 pagesMaharashtra Metro Rail Co. LimitedSumit BhagatNo ratings yet

- TC 102Document17 pagesTC 102Suresh Nanre100% (1)

- Mechanicaa: Department of Mechanical EngineeringDocument11 pagesMechanicaa: Department of Mechanical Engineeringr_b_vijay100% (1)

- Question Bank - Module 2Document3 pagesQuestion Bank - Module 2Mohammed ElsheikhNo ratings yet

- Normas para BiocombustiblesDocument3 pagesNormas para BiocombustiblesRicardo Cedeño CaboNo ratings yet

- Efe DaveDocument44 pagesEfe DaveEmmanuelNo ratings yet

- AerobicBiodegrad SE2-12Document3 pagesAerobicBiodegrad SE2-12SiddharthBhasneyNo ratings yet

- Manual Control Emerson PDFDocument8 pagesManual Control Emerson PDFFredy RodriguezNo ratings yet

- Compact Hydro ECOBulb (E)Document15 pagesCompact Hydro ECOBulb (E)Anonymous OuY6oAMggx100% (1)

- Concrete Volute PumpsDocument8 pagesConcrete Volute PumpsvijayunityNo ratings yet