Professional Documents

Culture Documents

Behaviour of A Blast Loaded Laced Reinforced Concrete Structure

Behaviour of A Blast Loaded Laced Reinforced Concrete Structure

Uploaded by

kalpeshOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Behaviour of A Blast Loaded Laced Reinforced Concrete Structure

Behaviour of A Blast Loaded Laced Reinforced Concrete Structure

Uploaded by

kalpeshCopyright:

Available Formats

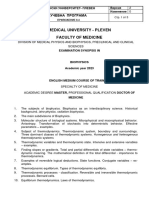

Defence Science Journal, Vol. 62, No. 5, September 2012, pp. 284-289, DOI: 10.14429/dsj.62.

820

2012, DESIDOC

Behaviour of a Blast Loaded Laced Reinforced Concrete Structure

N. Anandavalli*, N. Lakshmanan, Nagesh R. Iyer, Amar Prakash,

K. Ramanjaneyulu, J. Rajasankar, and Chitra Rajagopal#

#

CSIR-Structural Engineering Research Centre, Chennai, India

Centre for Fire, Explosive and Environment Safety, New Delhi, India

*

E-mail: anandi@serc.res.in

ABSTRACT

According to existing provisions, large separation distance has to be maintained between two conventional

explosive storage structures to prevent sympathetic detonation. In this paper, reduction of the separation distance

with the use of earth covered laced reinforced concrete (LRC) storage structure is demonstrated, which will result

in saving of land cost. Details of blast resistant design of 75T (NEC) storage structure based on unit risk principle

are presented. Performance of the storage structure is evaluated in an actual blast trial. Strain and deflection profiles

are obtained from the trial. Based on these, the storage structure is found to be re-usable after the blast trial.

Keywords: Laced reinforced concrete, storage structure, separation distance, blast resistant design

1. INTRODUCTION

The unit risk principle states that an accidental explosion

occurring in one unit should not trigger a similar explosion in

adjacent units, thus preventing a sympathetic explosion. To

ensure this condition, specified minimum separation distance

has to be maintained between explosive storage structures.

For conventional storage structures made of reinforced cement

concrete (RCC), this distance is large, thus requiring a huge

area of land. In present day scenario, land cost in very high and

in turn, storage structures becomes expensive. Earth covered

magazines help in reducing this distance and to prevent

sympathetic explosion. But, serviceability of the explosives

stored in these magazines is not ensured.

Laced reinforced concrete (LRC) structures have been

advocated, where high-intensity non-uniform blast loads are

encountered, i.e., close-in detonation1-5.

LRC consists of reinforcement on both faces

of a structural element and are continuously

tied by lacing. Structural components made

of LRC can achieve support rotation as high

as 4, compared to that made of RCC which

can achieve a maximum of only about

2 support rotation. Moreover, structural

integrity is also enhanced by using lacings.

Inter structure distance can be reduced

further by using LRC structures.

Design details of elements of LRC

storage structure and the behaviour of such

structure subjected to air blast loading

are presented in this paper. Reduction of

separation distance with the use of LRC

storage structure is demonstrated.

2. BLAST RESISTANT DESIGN

An explosion is a phenomenon resulting from sudden

release of a tremendous amount of energy. This energy release

sets up a blast wave, which travels at high speed in radial

directions from the centre of explosion. The blast wave induces

sudden increase in pressure to a value above the ambient

atmospheric pressure known as side-on overpressure, which

immediately begins to decrease exponentially with time. After

a short time, the pressure behind the front may drop below

the ambient pressure. During such a negative phase, a partial

vacuum is created and air is sucked in. This is also accompanied

by high suction winds that carry the debris for long distances

away from the explosion source. Typical time history of blast

pressure is shown in Fig. 1. As the blast wave travels rapidly

Figure 1. Time history of blast pressure.

Received 2 February 2011, revised 13 July 2012, online published 14 September 2012

284

Anandavalli, et al.: BeHavioUr of a Blast Loaded Laced Reinforced Concrete StrUctUre

away from the source, its peak pressure and velocity decrease.

Consequently, as it strikes a structure, a reflected shock wave is

formed. This has the effect of increasing the blast pressure. The

value of the reflected pressure depends on the incident angle

and the incident side-on overpressure.

Blast loading differs from other dynamic loads mainly

due to its transient and impulsive nature6,7,8. Moreover, blast

loading on various parts of the structure can have different

intensities and pulse durations. Peak pressures realised are

much higher than the static collapse load of the structure and

their duration are very small compared to the natural period

of the structure. It is uneconomical to design such structures

to behave elastically. Therefore, energy-dissipating capability

has to be utilised in the design of such structures.

The approach to the design of a structure, capable of

surviving the effects of high intensity, but short duration loads,

has to be different from the one adopted for the conventional

design. The structure has to be designed as a flexible system,

permitting their joints to deform considerably. The stresses

in the elements must be allowed to go beyond the elastic

limit, so that the available strength in the post-yield region

is fully utilised. This approach, called the elasto-plastic

design approach, also utilises the enhanced yield strength due

to high strain-rates possible in the case of blast and impact

loads. The low probability of occurrence and repetition of

shock loads allow the designer to utilize the energy-absorbing

characteristics of a carefully designed structure. This means

that the structure should be engineered to be as ductile as

possible9,10.

If the structure is located far from burst point, it is

subjected to fairly uniform blast loads. RCC with additional

detailing is suffice to resist such loads. Structures that are

located near by an explosion threat are exposed to nonuniform high intensity blast loads. These structures must

be designed for close-in pressure values and are susceptible

to local failure of structural elements. For such structures,

RCC is not sufficient and a material that can permit large

deflections and maintaining the structural integrity is actually

required. LRC has enhanced ductility and is suitable for

close-in design range.

3. LACED REINFORCED CONCRETE

Conventional RCC is known to have limited ductility

and confinement capabilities. These properties are especially

required for structures present in the blast loading environment.

The structural properties of RCC can be improved by

modifying the concrete matrix and/or by suitably detailing the

reinforcements. LRC as shown in Fig. 2 consists of continuously

bent shear lacings along with longitudinal reinforcements on

both faces of a structural element. LRC enhances the ductility

and provides better concrete confinement. Moreover, LRC is

cost effective compared to RCC for structures that are to be

designed for impulsive loading of a given magnitude.

Resistance-deflection curve shown in Fig. 3 demonstrates

the flexural action of a typical RCC element. Initially, the

resistance increases with the deflection until yielding of

the reinforcement takes place. After the reinforcement

exhibits plastic deformation, any further deflection, can

Figure 2. Typical laced reinforced concrete (LRC) structural

element.

Figure 3. Resistance-deflection curve for flexural reinforced

concrete elements.

therefore, occur without any additional resistance. At a

deflection corresponding to 2 support rotation, the concrete

in compression crushes. For elements without shear

reinforcement, i.e., without confinement of concrete, this

crushing of the concrete results in failure of the element. For

elements with single leg stirrups or lacing, the reinforcement

enters into its strain hardening region as the element further

deflects. Element with single leg stirrup loses its structural

integrity and fails at 4 support rotation. On the other hand,

lacing by its truss action will restrain the reinforcement

through its entire strain hardening region until tension failure

of the reinforcement occurs. While the TM manual4 suggests

a plastic support rotation capacity of 12, the tests conducted

at CSIR-SERC1 showed that it varied only between 6 to

8. The results of the above investigations suggested a

plastic hinge rotation of 4 at support and 8 at centre for

continuous construction. The continuous lacings are inclined

between 45 and 60 to horizontal. Thus, Fig. 3 demonstrates

significance of shear resistance in enhancing the ductility of

a flexural element. A sudden shear failure is obvious in the

event of inadequate capacity. However, studies have shown

that under cyclic loading the failure rotation is reduced and

hence a conservative estimate of 4 support rotation has been

suggested for design purposes1,2.

285

Def. SCI. J., Vol. 62, No. 5, SEPTEMBER 2012

4. DESIGN OF 75T (NEC) STORAGE

STRUCTURE

Donor and acceptor storage structures are nearby each

other and explosion takes place in the former due to which

latter one is subjected to air blast loading. According to existing

provisions5, for conventional explosive storage structure,

adjacent structure is to be constructed with a separation distance

of 2.4 W1/3 (m) where W is the charge weight in kg. In this

study, separation distance between two storage structures has

been reduced to 0.7 W1/3. For a charge weight of 75 T (NEC),

in real terms the separation distance is reduced from about

101 m to 30 m. Internal dimensions of the 75T (NEC) storage

structure are 9.5 m x 15 m x 3.6 m. Haunches are provided at

junction of walls and wall with roof and floor slab. General

arrangement of donor and acceptor storage structures is shown

in Fig. 4.

Figure 4. General arrangement of storage structures.

M25 grade concrete and Fe415 grade reinforcement steel

are used. Side walls are of 350 mm thickness and are designed

as one way slab. Front and rear walls are also designed as

one way slabs. Roof is designed as two way slab and is of

450 mm thickness. Resistance requirement is calculated by

equating the areas of the resistance-deflection and pressuretime curves. Reinforcement percentages are calculated such

that the resistance provided by them is more than the demand.

Percentages of main reinforcement in side walls and roof slab

are 0.56 per cent and 0.39 per cent respectively. Lacings of 12

mm diameter are provided at 350 mm and 350 mm c/c in side

walls and roof slabs respectively. Percentage reinforcements

in secondary direction in side walls and roof slab are provided

respectively as 0.19 per cent and 0.27 per cent.

5. BLAST TRIAL

Two storage structures were constructed as per the design

at a separation distance of 30 m. Donor storage structure was

loaded with explosive and blast trial was carried out. During

this trial, performance of the acceptor storage structure was

monitored. Acceptor storage structure was instrumented in

order to assess its behaviour.

6. INSTRUMENTATION

Instrumentation of the acceptor storage structure was

carried out with strain gages and reflectors. It was proposed

to obtain the strain profile on the wall near to the donor (left

wall) and deflection profiles of the left wall and roof slab.

Pellets were pasted on the walls to obtain the residual strain at

selected locations, where maximum strains were expected in

the acceptor. Permanent strains were measured using pfender

gauges. For deflection measurements, reflectors were fixed on

wall and roof and total station was used for measurement.

6.1 Pellet Arrangement

On the left wall, an arrangement of pellets as shown in

Fig. 5 was proposed. Initially, the expected yield line pattern

was marked. Pellet locations were marked with pencils at

100 mm centre-to-centre (c/c) spacing. At the corners, pellet

locations were marked perpendicular to the 45 line. After this,

surface at pellet locations was smoothened with emery paper.

Then, the area was cleaned with acetone solution. Pellets were

pasted with the help of cyanoacrylate (CN) adhesive. After

fixing the first pellet, it was allowed to set. Then, pfender gauge

was used to position the next pellet in the line. Care was taken

to choose the gauge spacing of pellets such that it had large

range for tensile strain measurement.

6.2 Target Arrangement for Measurement of

Deflection

Arrangements of targets (reflectors) on the left wall and

roof are shown in Figs. 6 and 7, respectively. On the left wall,

locations of targets were marked. The surface was prepared

with the help of emery paper. Then, the area was cleaned with

acetone solution. Reflectors were pasted with due care for the

angle of reflection to the line of sight of total station.

Figure 5. Arrangement of pellets on the inner surface of left wall of acceptor.

286

Anandavalli, et al.: BeHavioUr of a Blast Loaded Laced Reinforced Concrete StrUctUre

Figure 6. Location of targets (Reflectors) on left wall.

Figure 9. Actual arrangement of targets in left wall.

Figure 10. Arrangement of targets in roof slab.

tied between the two angles. Deflection profile was obtained by

measuring the distance between roof surface and string.

Figure 7. Location of targets (Reflectors) on the surface of

roof.

Figure 8. Arrangement for target to measure deflection of

roof.

7. DATA RECORDED

A precision theodolite/total station was used for

measurement of deflection. Total station was placed inside

the acceptor and initialized. The benchmark was targeted and

horizontal angle was set to zero. Initial readings were noted.

Then, reflectors at other places were targeted one by one and

readings were recorded. Angles and distance measurements

were taken before and after the trial, with respect to same

reference point (benchmark).

8. RESULTS AND OBSERVATIONS

Crater of approximately 42 m in diameter and 7 m deep

was formed. Fragments were found scattered in all radial

directions. Acceptor was found to be intact and serviceable

after the trial as seen from Fig. 11.

Initially, expected yield line pattern was mapped on

For roof slab, since angle of reflection between the total

station and vertical line at reflector location was more, total

station could not trace the reflected ray. So, an arrangement was

made by pasting a steel L-angle piece at the reflector location.

Reflector was pasted on the surface of L-angle as shown in Fig.

8. Actual arrangement of reflectors in the left wall and roof slab

are shown in Figs. 9 and 10, respectively.

6.3 Alternate Arrangement to Obtain Deflection

Profile

An alternate arrangement for obtaining deflection at a

number of points was made. Two angles were attached to the

opposite walls at the same height from the floor. A string was

Figure 11. Intact acceptor after trial.

287

Def. SCI. J., Vol. 62, No. 5, SEPTEMBER 2012

Figure 13. Average strain profile in the left wall.

Figure 12. Mapped crack pattern on roof slab of acceptor.

the roof slab and crack pattern as observed on the roof were

mapped on the sheet as shown in Fig. 12. Cracks at the middle

of the roof slab were parallel to the longer span and were

extending nearly to quarter spans, after which they propagated

at an angle of 45. Cracks were found to follow the expected

yield line pattern.

8.1 Strain Profile

From the readings taken before and after the trial using

Pfender gauge, the strain profile of the left wall was obtained.

Average strain profile of left wall is shown in Fig. 13. The

estimated permanent strain values on the concrete surface

of the left wall was around 420 microstrains at nearly midheight indicating the concrete has cracked. Strain values in

reinforcement, at the same location, realized during testing was

estimated as 2490 microstrains.

Figure 14. Deflection profile of left wall at mid span.

8.2 Deflection Profile

Deflection profile of left wall is shown in Fig. 14.

Deflection variation along short and long spans is shown in

Figs. 15 and 16 respectively. Maximum permanent deflection

at centre of roof was measured to be around 40 mm. Residual

support rotation was calculated to be 0.46, which is much

below the permissible value of 4.

9. CONCLUSIONS

Reduction of separation distance between two explosive

storage structures from the existing provision of 2.4W1/3 to

0.7W1/3 has been demonstrated with the efficient use of blast

resistant LRC storage structure. Details of design of the storage

structure, instrumentation for measurement of response are

presented. Residual surface strains on left wall were measured

using pfender gauges. Deflection measurements at left wall

and roof slab were taken using total station. Strain and deflection

profiles were obtained from the trial data. Crack mapping on roof

slab was carried out. In general, the acceptor storage structure

was found to withstand the blast trial test. In addition, the

acceptor structure was found to be serviceable after the blast.

288

Figure 15. Deflection profile of roof along short span.

Figure 16. Deflection profile of roof along long span.

Anandavalli, et al.: BeHavioUr of a Blast Loaded Laced Reinforced Concrete StrUctUre

ACKNOWLEDGEMENTS

Authors wish to thank Director, Centre for Fire Explosive

and Environment Safety (CFEES), New Delhi for support

and permission to participate in the blast trial conducted by

CFEES and measure the structural response. Services rendered

by the staff of Structural Testing Laboratory, CSIR-Structural

Engineering Research Centre (SERC) and Shri. S.G.N. Murthy,

Principal Scientist, Electronics and Networking Unit, CSIRSERC during the blast trial are duly acknowledged. This paper

is published with the kind permission of Director, CSIR-SERC,

Chennai.

REFERENCES

1. Parameswaran, V.S.; Lakshmanan, N.; Srinivasulu,

P.; Krishnamoorthy, T.S.; Balasubramanian, K.;

Thandavamoorthy, T.S. & Arumugam, M. Application

of laced reinforced concrete construction techniques

to blast-resistant structures. Structural Engineering

Research Centre, Chennai. SERC Report No. RCC-SR86-1. October 1986.

2. Lakshmanan, N.; Parameswaran, V.S.; Krishnamoorthy,

T.S. & Balasubramanian, K. Ductility of flexural members

reinforced symmetrically on the tension and compression

faces. Indian Concr. J. 1991, 381-388.

3. Lakshmanan, N.; Balasubramanian, K.; Krishnamoorthy,

T.S.; Bharatkumar, B.H.; Udhayakumar, V.; Jayaraman, R.

& Natarajan, K. Analytical model for strength evaluation

of laced reinforced concrete beams under shear. CSIRStructural Engineering Research Centre, Chennai. SERC

Report No. GAP 02641-RR-3. September 2007.

4. Department of Army, Navy and the Air Force. TM

5 1300: Structures to resist the effects of accidental

explosions. Washington D.C., U.S.A. 1990.

5. Storage and Transport of Explosives Committee, Centre

for Fire Explosive and Environment Safety. STEC

Pamphlet No. 21: Design and construction manual for

blast resistant structures using laced reinforced concrete.

New Delhi. 1996.

6. Kinney, G.F. & Graham, K.J. Explosive shocks in air.

Springer Verlag, New York. 1985.

7. Dusenberry, D.O. Handbook for blast resistant design of

buildings. John Wiley & Sons, New Jersey, 2010.

8. Cormie, David; Mays, Geoff & Smith, Peter. Blast effect

on buildings. Thomas Telford, UK, 2009.

9. Dharaneepathy, M.V.; Madheswaran, C.K. & Anandavalli,

N. Investigations on shock response of structural

components and structures. CSIR-Structural Engineering

Research Centre, Chennai. SERC Report No. OLP06641/

SVL-RR-99-1. April 1999.

10. Dharaneepathy, M.V.; Madheswaran, C.K. & Anandavalli,

N. Development of design aids for shock-resistant

structures. CSIR-Structural Engineering Research Centre,

Chennai. SERC Rep. No. OLP-8241/SVL-RR-2000-1.

March 2000.

11. Bureau of Indian Standards. Criteria for blast resistant

design of structures for explosions above ground. IS:

4991-1968. New Delhi.

Contributors

Ms N. Anandavalli received her ME

(Structural Engineering) from PSG College of

Technology, Coimbatore. Currently working

as a Senior Scientist, Shock and Vibration

Group at CSIR-Structural Engineering

Research Centre (SERC), Chennai, India.

Her research interests include: Dynamic

behaviour of structures under shock loads,

and finite element analysis.

Dr N. Lakshmanan received his PhD

from the Indian Institute of Technology

Madras, Chennai. He is former Director,

CSIR-SERC, Chennai, India. His research

interests include: Dynamic behaviour of

reinforced concrete structures under wind,

blast and earthquake loading, design of

heavy-duty structures, and industrial structures

subjected to wind loading.

Dr Nagesh R. Iyer received his PhD from

Indian Institute of Science, Bengaluru.

Currently working as a Director, CSIR-SERC,

Chennai, India. His research interests include:

Finite element methods, computational

structural mechanics, performance evaluation

of structures, fracture mechanics, damage

mechanics, innovative sustainable and/or

engineered materials.

Mr Amar Prakash received his MTech

(Earthquake Engg. & Structural Dynamics)

from University of Roorkee, India. Presently

working as a Scientist at Shock and Vibration

Group, CSIR-SERC, Chennai. His research

interests include: Mesh free methods,

impact load on structures.

Dr K. Ramanjaneyulu received his PhD

from Indian Institute of Science, Bengaluru.

Currently working as Chief Scientist and

Head, Advanced Concrete Testing and

Evaluation Laboratory at CSIR-SERC,

Chennai. His research interests include

: Reinforced concrete behaviour, health

monitoring of bridges.

Dr J. Rajasankar received his PhD from

Indian Institute of Technology Madras,

Chennai. Currently working as Senior

Principal Scientist and Head, Shock and

Vibration Group, CSIR-SERC, Chennai.

His research interests include : Finite

element analysis, computational structural

dynamics, damage mechanics.

Ms Chitra Rajagopal Currently working as Scientist-G &

Associate Director and Head, Explosive Safety at Centre for

Fire Explosive and Environment Safety, DRDO, Delhi.

289

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Open Channel Flow - HendersonDocument273 pagesOpen Channel Flow - HendersonIrmak Ünal100% (4)

- 5-2 Review Sheet With Answers-1Document6 pages5-2 Review Sheet With Answers-1machinel19830% (1)

- Bridge Design - Reinforced Concrete Bridge Deck Design To BS 5400Document11 pagesBridge Design - Reinforced Concrete Bridge Deck Design To BS 5400Lavanyan Satchithananthan100% (1)

- Product LoadDocument6 pagesProduct LoadDave Harrison Flores100% (1)

- Research Paper On Muli-Winglet AnalysisDocument4 pagesResearch Paper On Muli-Winglet AnalysisMohd Afeef BadriNo ratings yet

- Calculation For Stored EnergyDocument1 pageCalculation For Stored EnergySubbarayan Saravanakumar67% (3)

- Cooling Sea Water Service SystemDocument3 pagesCooling Sea Water Service SystemAustin UdofiaNo ratings yet

- Tank Shell Calculation: Mechanical Calculations According To en 14015Document5 pagesTank Shell Calculation: Mechanical Calculations According To en 14015paeg651250% (4)

- конспект БФ АЕО 23 - 24Document5 pagesконспект БФ АЕО 23 - 24mimrahmi7No ratings yet

- Counterfort Retaining Wall Design: ASDIP Retain 4.7.6Document9 pagesCounterfort Retaining Wall Design: ASDIP Retain 4.7.6Bassa Jean-DanielNo ratings yet

- 11th Chemistry Volume 2 Study Material EM WWW - Kalvikadal.in KalvikadalDocument49 pages11th Chemistry Volume 2 Study Material EM WWW - Kalvikadal.in KalvikadalSri RamNo ratings yet

- Publicado en La Revista PDFDocument14 pagesPublicado en La Revista PDFJake CloneyNo ratings yet

- Science Class 9thDocument221 pagesScience Class 9thNisha ShahNo ratings yet

- Geometrically Nonlinear Analysis Using Plane Stress / Strain Elements Based On Alternative Strain MeasuresDocument12 pagesGeometrically Nonlinear Analysis Using Plane Stress / Strain Elements Based On Alternative Strain MeasuresBreno NogueiraNo ratings yet

- RAC MCQs-180-set-01 V2Document24 pagesRAC MCQs-180-set-01 V2nimish lambatNo ratings yet

- R4000 Series (Steel) : Operating Guidelines Product FeaturesDocument7 pagesR4000 Series (Steel) : Operating Guidelines Product FeaturesDebraj DattaNo ratings yet

- Behavior and Design of Gusset Plate Connections in CompressionDocument17 pagesBehavior and Design of Gusset Plate Connections in CompressionNaomi PratiwiNo ratings yet

- Ventana 04 PDFDocument2 pagesVentana 04 PDFPedro IzquierdoNo ratings yet

- An Upheaval Buckling Limit State Function For Onshore Natural Gas PipelinesDocument11 pagesAn Upheaval Buckling Limit State Function For Onshore Natural Gas PipelinesRabah BrikaNo ratings yet

- Crane Beam Design: Code AISC (ASD) FY 34.5kn/cm2Document1 pageCrane Beam Design: Code AISC (ASD) FY 34.5kn/cm2Meeran MohamedNo ratings yet

- Material Balance EquationDocument10 pagesMaterial Balance EquationMurtez100% (1)

- GTS NX 2019 (v2.1) Release NotesDocument15 pagesGTS NX 2019 (v2.1) Release Notesyin hoe ongNo ratings yet

- Viscosity - WikipediaDocument7 pagesViscosity - WikipediazigaNo ratings yet

- Chapter 3 Cont'Document39 pagesChapter 3 Cont'shruthi venkataramanNo ratings yet

- Group 1 Experiment 2 Eh2203aDocument17 pagesGroup 1 Experiment 2 Eh2203aAbdullah FarhanNo ratings yet

- Energetics - CN - STDT3Document2 pagesEnergetics - CN - STDT3NkemziNo ratings yet

- Mechanics of Solids 2 Marks (All Units)Document16 pagesMechanics of Solids 2 Marks (All Units)rajapratyNo ratings yet

- Matter and ChangeDocument23 pagesMatter and ChangeDionisio BrinosaNo ratings yet

- Lokhart Martinelli - PressureDrop PDFDocument33 pagesLokhart Martinelli - PressureDrop PDFShripadagouda GoudappagoudarNo ratings yet

- Wtb7 Bolt: (BS8110:1997 Table 3.26)Document2 pagesWtb7 Bolt: (BS8110:1997 Table 3.26)Asaru DeenNo ratings yet