Professional Documents

Culture Documents

Two Phase (Gas - Oil) Vertical Separator: As Per "Petroleum and Gas Field Processing - Hussein K. Abdel-Aal, Mohamed Aggour, M. A. Fahim"

Uploaded by

Vu TranOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Two Phase (Gas - Oil) Vertical Separator: As Per "Petroleum and Gas Field Processing - Hussein K. Abdel-Aal, Mohamed Aggour, M. A. Fahim"

Uploaded by

Vu TranCopyright:

Available Formats

INDEX

Two Phase (Gas - Oil) Vertical Separator: As per "Petroleum and Gas Field Processing Hussein K. Abdel-Aal, Mohamed Aggour, M. A. Fahim"

SCHEMATIC

Qo

3000 bbl/d

0.75

o

35.0 API

0.50

514.7 psia

'o

l

P

T

t

Z

g

o

100 F

o

560 R

3 minutes

0.9

0.012 cP

dm

150 Micron

T'

Oil rate

Gas specific gravity

Oil density

Oil specific gravity

Operating pressure

Operating temperature

Operating temperature

Retention time (Refer Table 1)

Gas compressibility

Gas viscosity

Smallest oil droplet size to be removed

CALCULATIONS

Step 1:

Determine gas and oil properties

3

g

Gas operating density

2.07 lb/ft

31.2 lb/ft

Cd

1.10 Assume

0.52 ft/s

66

1.07

u

Re

Cd

Error

0.00

Step 3:

D2

= 2.7

Oil operating density

Click me

Drag coefficient

Settling velocity of oil droplet

Reynolds no.

Use goal seek to get error zero, by changing

asssumed Cd

Dmin

Check for gas capacity constraint

2

6754 in

Minimum allowable vessel diameter for separation

82.2 in

of oil droplets down to 100 micron

Step 4:

Check for liquid capacity constraint

dh

75000

Try different combinations of D.

TABLE 1

Ls, ft

d, in

h, in

SR

30

83.3

13.3

36

57.9

11.2

42

42.5

10.4

48

32.6

10.0

54

25.7

10.0

60

20.8

10.1

5.3

3.7

3.0

2.5

2.2

2.0

66

17.2

10.3

1.9

TABLE 2 (Ref. API 12J)

Oil Gravities

Above 35 oAPI

72

14.5

10.5

1.8

20 to 30 oAPI

78

84

90

SR

D

EQUATIONS

Determine Cd

Step 2:

Ls

Yellow boxes are input boxes.

INPUT PARAMETERS

Qg

60 mmscfd Gas rate

12.3

10.6

9.3

11.3 ft

3.8

36.0 in

10.9

11.2

11.6

1.7

1.6

1.5

Seam to seam length (select from Table 1)

Slenderness ratio (typical value 3 to 4) (select from Table 1)

Separator diameter (select from Table 1)

NOTES

1. As per GPSA, typical vertical H/D ratios are normally in the 2 to 4 range.

10 to 20 API

Retention time,

1

1 to 2

2 to 4

You might also like

- Proyek Mini LPG Plant Lapangan JataDocument6 pagesProyek Mini LPG Plant Lapangan JataDIANTORONo ratings yet

- Distributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979From EverandDistributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979T. J. HarrisonNo ratings yet

- Distillation Column1Document49 pagesDistillation Column1chaitanyavura0% (1)

- Dynamic Process Simulation When Do We Really Need ItDocument4 pagesDynamic Process Simulation When Do We Really Need ItDenis GontarevNo ratings yet

- Sample Problem StatementDocument2 pagesSample Problem Statementsunildubey02No ratings yet

- Control Engineering For Chemical EngineersDocument11 pagesControl Engineering For Chemical EngineersYoga WiranotoNo ratings yet

- Comparison of Advanced Distillation Control Methods: Final Technical ReportDocument47 pagesComparison of Advanced Distillation Control Methods: Final Technical ReportAjit Jadhav0% (1)

- New Microsoft Office Word DocumentDocument15 pagesNew Microsoft Office Word DocumentSwapnil RaulNo ratings yet

- Line Sizing of The Main Production Header (A Gas / Liquid Two Phase Line)Document12 pagesLine Sizing of The Main Production Header (A Gas / Liquid Two Phase Line)Engr TheyjiNo ratings yet

- Air-Cooled Exchanger Design and SizingDocument19 pagesAir-Cooled Exchanger Design and Sizingnafees ahmadNo ratings yet

- Illustrative Example: A Blending Process: An Unsteady-State Mass Balance For The Blending SystemDocument22 pagesIllustrative Example: A Blending Process: An Unsteady-State Mass Balance For The Blending SystemHermes Yesser Pantoja CarhuavilcaNo ratings yet

- Unlock Separator SizingDocument42 pagesUnlock Separator SizingmortezasabetiNo ratings yet

- 08b PDFDocument38 pages08b PDFProcess EngineerNo ratings yet

- Brochure SimSci SIM4MEServicesForDynamicSimulation 08-10Document12 pagesBrochure SimSci SIM4MEServicesForDynamicSimulation 08-10harry_chemNo ratings yet

- PID Tuning Tips - The Fast Way To Tune Slow LoopsDocument4 pagesPID Tuning Tips - The Fast Way To Tune Slow Loopstomaz_filhoNo ratings yet

- Tutorial 1 - Fluid Flow and Heat Transfer in A Mixing Elbow PDFDocument56 pagesTutorial 1 - Fluid Flow and Heat Transfer in A Mixing Elbow PDFJay KrishnaNo ratings yet

- Cascade TuningDocument18 pagesCascade TuningDidik RiswantoNo ratings yet

- 10 1016@j Jngse 2016 01 016Document37 pages10 1016@j Jngse 2016 01 016saiful bahriNo ratings yet

- Fuzzy Self Tuning of PID Controller For Multivariable ProcessDocument5 pagesFuzzy Self Tuning of PID Controller For Multivariable ProcessJournal of ComputingNo ratings yet

- Pressure Measuring InstrumentsDocument7 pagesPressure Measuring Instrumentspaves007No ratings yet

- BLOWDOWN AND VENT STUDYDocument238 pagesBLOWDOWN AND VENT STUDYUmair A. KhanNo ratings yet

- Design Separation Columns GuideDocument8 pagesDesign Separation Columns GuideDewi ApriyaniNo ratings yet

- Distillation Tower DesignDocument66 pagesDistillation Tower DesignHavocFireNo ratings yet

- Process Design Engineering Test-1Document6 pagesProcess Design Engineering Test-1Vague FruitsNo ratings yet

- Equilibrium Stage Processes Flash VaporizationDocument30 pagesEquilibrium Stage Processes Flash Vaporizationj0haNN3sNo ratings yet

- Chapter 12Document58 pagesChapter 12Nigel KowNo ratings yet

- Petronas Design Manual: Column SizingDocument10 pagesPetronas Design Manual: Column SizingHazizi AkmarNo ratings yet

- Distillation: Unit Operations (Che 347/ 251)Document27 pagesDistillation: Unit Operations (Che 347/ 251)Amira KormainNo ratings yet

- Process Simulation EssentialsDocument26 pagesProcess Simulation EssentialsaalbuhseNo ratings yet

- Stripping Notes PDFDocument28 pagesStripping Notes PDFnimi khalidNo ratings yet

- Vapor Pressure of A Liquid SolutionDocument40 pagesVapor Pressure of A Liquid Solutionintania660% (1)

- GBH Enterprises, LTD.: GBHE-PEG-MAS-608Document79 pagesGBH Enterprises, LTD.: GBHE-PEG-MAS-608arch0wnzNo ratings yet

- Thermosyphon Reboiler Hydraulics: ResultDocument5 pagesThermosyphon Reboiler Hydraulics: ResultVaishnavi RaghavNo ratings yet

- 245 NGL Deethanizer Capacity ExpansionDocument1 page245 NGL Deethanizer Capacity ExpansionRafeek Emad AbdElkader0% (1)

- Distillation Notes 2011Document40 pagesDistillation Notes 2011samuelgranthamNo ratings yet

- So Many Tuning Rules, So Little Time: Control Talk ColumnsDocument36 pagesSo Many Tuning Rules, So Little Time: Control Talk ColumnsIvan BevandaNo ratings yet

- High Gas Volume Vertical Knock-Out Drum Liquid RemovalDocument3 pagesHigh Gas Volume Vertical Knock-Out Drum Liquid RemovalArynda Dimas SadewoNo ratings yet

- NGL SeparationDocument6 pagesNGL SeparationhoustonmathNo ratings yet

- Keep Advanced Control Systems OnlineDocument29 pagesKeep Advanced Control Systems OnlineBisto MasiloNo ratings yet

- Furnace Control SystemDocument9 pagesFurnace Control SystemMUHAMMAD ASJAD AAMIR AAMIR AMINNo ratings yet

- Ammonia Plant Simulation 25.08.2016Document81 pagesAmmonia Plant Simulation 25.08.2016Manish Gautam100% (1)

- Process Engineer - PSV Installation-GuideDocument3 pagesProcess Engineer - PSV Installation-GuideMannu SatPuteNo ratings yet

- Distillation: Prepared By: DEEDAR ALI QURESHI Assist By: PHAIXA ABBASI, Former Student of CHM KU. ReferencesDocument76 pagesDistillation: Prepared By: DEEDAR ALI QURESHI Assist By: PHAIXA ABBASI, Former Student of CHM KU. ReferencesIrshad SheikhNo ratings yet

- CHEMCAD 7 User Guide PDFDocument154 pagesCHEMCAD 7 User Guide PDFadfNo ratings yet

- Definition & Types of Reboilers - A. Thermosiphon - : Reboiler CircuitsDocument2 pagesDefinition & Types of Reboilers - A. Thermosiphon - : Reboiler CircuitsWade ColemanNo ratings yet

- 10.6. Liquid-Liquid Separation: 10.6.1. Decanters (Settlers)Document6 pages10.6. Liquid-Liquid Separation: 10.6.1. Decanters (Settlers)ashishkapoorsrmNo ratings yet

- Distillation Final RevDocument118 pagesDistillation Final Revgad480No ratings yet

- Design For Sieve Plate ColumnDocument7 pagesDesign For Sieve Plate ColumnAyushi Jain100% (1)

- Structured PackingDocument8 pagesStructured PackingUsama IqbalNo ratings yet

- Thermosyphon Reboiler (Horizontal) GPSADocument6 pagesThermosyphon Reboiler (Horizontal) GPSAsyamsudin2006No ratings yet

- CMPAPPP Separator Vessel and Filter Design GuideDocument18 pagesCMPAPPP Separator Vessel and Filter Design GuideJWilson73No ratings yet

- Design of Distillation Column PDFDocument25 pagesDesign of Distillation Column PDFRobert DsouzaNo ratings yet

- Vapor Liquid Equilibrium of Water + Ethanol + GlycerolDocument8 pagesVapor Liquid Equilibrium of Water + Ethanol + GlycerolcsandrasNo ratings yet

- Sieve Tray Column: Design of HC Process Equipments PE 350Document14 pagesSieve Tray Column: Design of HC Process Equipments PE 350Shreya Sahajpal KaushalNo ratings yet

- Horizontal Three Phase Separator DesignDocument5 pagesHorizontal Three Phase Separator DesignAymen KhlifiNo ratings yet

- Unit 5/P - I M P & V: ART Easurement of Ressure AcuumDocument31 pagesUnit 5/P - I M P & V: ART Easurement of Ressure Acuumgowri26No ratings yet

- Flare System DesignDocument2 pagesFlare System Designomar alnasserNo ratings yet

- Process Designing Breather Valves API StandardsDocument15 pagesProcess Designing Breather Valves API StandardsGuglielmoNo ratings yet

- BSR-ICD-PRO-001-F-004 Document Update Form-U058Document8 pagesBSR-ICD-PRO-001-F-004 Document Update Form-U058Vu TranNo ratings yet

- 8474L-024-PID-0021-124-2.0-Compare With Rev 2Document1 page8474L-024-PID-0021-124-2.0-Compare With Rev 2Vu TranNo ratings yet

- SVDN-CPP-M-0006-M12-0002-Rev.07-PSV CalculationDocument38 pagesSVDN-CPP-M-0006-M12-0002-Rev.07-PSV CalculationVu TranNo ratings yet

- Component Mole % Mass % TBP, CDocument3 pagesComponent Mole % Mass % TBP, CVu TranNo ratings yet

- Output Summary for Air-Cooled Heat ExchangerDocument7 pagesOutput Summary for Air-Cooled Heat ExchangerVu TranNo ratings yet

- DdedemoDocument6 pagesDdedemoSinto GendengNo ratings yet

- Bi Quyet Kinh Doanh Tren MangDocument371 pagesBi Quyet Kinh Doanh Tren Mangblackjack_teenNo ratings yet

- 8474L 018 Pid 0021 115 6Document1 page8474L 018 Pid 0021 115 6Vu TranNo ratings yet

- Aspen HYSYS Multi-Stage Compressor Surge Analysis Tutorial PDFDocument10 pagesAspen HYSYS Multi-Stage Compressor Surge Analysis Tutorial PDFVu TranNo ratings yet

- Process Final InputDocument1 pageProcess Final InputVu TranNo ratings yet

- Component Mole % Mass % TBP, CDocument3 pagesComponent Mole % Mass % TBP, CVu TranNo ratings yet

- 9905ianvDocument6 pages9905ianvBo Cu BinNo ratings yet

- Aspen HYSYS Compressor Surge Analysis Feature TutorialDocument23 pagesAspen HYSYS Compressor Surge Analysis Feature TutorialVu Tran100% (1)

- Nbstechnicalnote1352 PDFDocument76 pagesNbstechnicalnote1352 PDFVu TranNo ratings yet

- Activated Energy Analysis in Aspen HYSYS – Crude PreheatDocument12 pagesActivated Energy Analysis in Aspen HYSYS – Crude PreheatVu TranNo ratings yet

- HYSYS Acid Gas Cleaning Examples GuideDocument4 pagesHYSYS Acid Gas Cleaning Examples GuideVu TranNo ratings yet

- Activated Energy Analysis in Aspen HYSYS – Natural GasDocument13 pagesActivated Energy Analysis in Aspen HYSYS – Natural GasVu TranNo ratings yet

- Cyclone Design and AnalysisDocument21 pagesCyclone Design and Analysisjorge FranciscpNo ratings yet

- Part 1 Answer Below Here: Calculate The Head Loss in A Pipe With FittingsDocument1 pagePart 1 Answer Below Here: Calculate The Head Loss in A Pipe With FittingsRafael ReyesNo ratings yet

- InstallDocument1 pageInstallgsaqswdeNo ratings yet

- Bi Quyet Kinh Doanh Tren MangDocument371 pagesBi Quyet Kinh Doanh Tren Mangblackjack_teenNo ratings yet

- 01 - Fluid FlowDocument76 pages01 - Fluid FlowMubarak AhmadNo ratings yet

- PumpDocument31 pagesPumpgrincheu70No ratings yet

- Aspen OLI V8 - 8 Readme PDFDocument2 pagesAspen OLI V8 - 8 Readme PDFVu TranNo ratings yet

- 1 Darcy Friction CalculatorDocument2 pages1 Darcy Friction CalculatorVu TranNo ratings yet

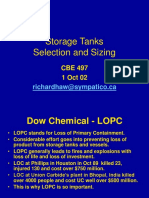

- Storage TanksDocument50 pagesStorage TanksneoNo ratings yet

- ORC Power PlantDocument22 pagesORC Power PlantMudabbir Shan AhmedNo ratings yet

- Emerson Control Valve HB Ed 3Document295 pagesEmerson Control Valve HB Ed 3Ahmed SeliemNo ratings yet

- Minor Pipe Losses (Equivalent Lengths)Document4 pagesMinor Pipe Losses (Equivalent Lengths)Hassan AbdulAzim FadilNo ratings yet

- Optimizing of Corrosion Protection Based On A Combination of Cathodic Protection CP and Coating PDFDocument9 pagesOptimizing of Corrosion Protection Based On A Combination of Cathodic Protection CP and Coating PDFVu TranNo ratings yet