Professional Documents

Culture Documents

S.U Carburetter Type HS (Austin America)

S.U Carburetter Type HS (Austin America)

Uploaded by

Jordan L0 ratings0% found this document useful (0 votes)

11 views6 pagesCarburetter

Adjusting, tuning and servicing instructions

For Austin America, MG 1100 and others cars.

Original Title

S.U Carburetter type HS (Austin America)

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCarburetter

Adjusting, tuning and servicing instructions

For Austin America, MG 1100 and others cars.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views6 pagesS.U Carburetter Type HS (Austin America)

S.U Carburetter Type HS (Austin America)

Uploaded by

Jordan LCarburetter

Adjusting, tuning and servicing instructions

For Austin America, MG 1100 and others cars.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 6

AKD 4780. C

THE

@®

CARBURETTER

Type HS

TUNING, ADJUSTING, ano SERVICING

INSTRUCTIONS

Mark for reassembly and remove piston/suction chamber unit.

Disconnect mixture control wire.

‘Screw the jet adjusting nut (1) until the jet Is fush with the

bridge of the earburetter oF fully up if this position eannot be

‘obtained.

pep

The Type HS Carburetter

1. dee adjusting nue 4 Rontliiaon tere,

ieee 5 Twremda eet rene

3. Pistonjuetion chamber. 6, Piston lifting pin.

TUNING

Single carburetters

Replace the piston/suction chamber unit as marked.

‘Check that the piston falls frely onto the bridge when the

cing pin (6's released. Wf not, see Icems 15, 16, and 17.

. Turn down the jet adjusting nut (1) two complete turns

op Prw

‘A. Restart the engine and adjust the throttle adjusting sew (5) 0

ive desired Idling as indicated by the glow of the ignition

y warning light.

‘A. Warm engine up to normal temperature. B. Turn the jet adjusting nut (1) up to weaken or down to richen

BL Swlech off engine. unl the fastest Idling speed consistent with even running is

Unscrew the throttle adjusting screw until i is just clear of ies obtained.

stop and the throttle Is closed. C._Readjust the hrotle adjusting serew (5) to give correct idling

».

Set throtde adjusting screw 1 turns open, necessary

The effect of misture strength on exhoust smoke

‘A. TOO WEAK: Irregular note splashy misfire, and colourless,

8 CORRECT: Regular and even note.

€. TOORICH: Regular or rhythmical misfire, blackish.

tich

oa correct

ENGINE

a weak

‘A. Check for correct mixture by gently pushing the lifting pin up

about ¥ in. (8 mm, after free movement has been taken up.

‘The graph illustrates the elect on engine p.m. when the iting

‘alses the piston, indicating the mixture strength.

RICH MIXTURE:

CORRECT MIXTURE:

WEAK MIXTURE:

‘A. Reconnect the mixture control wire with about 1 in. (16 mm.)

fee movement before it tarts to pull onthe jet lever.

8. Pull the mixture contro! knob until che linkage ls about to move

the carburetter jet and adjust the fastidle screw to give an

‘engine speed of about 1,000 p.m. when hot.

Finally top up the piston damper with the recommended engine oil

‘until the levels $ In. (13 mm.) above the top ofthe hollow piston

rod.

Note

(On dust-prooted carburetters, identified by a transverse hole drilled

ln the neck of the suction chambers and no vent hole in the

‘damper cap, the oil level should be Jin. (13 mm.) below the top

‘of the hollow piston rod.

TUNING

Multi-carburetters

Remove the ale cleaners and carry out item fa for single on all

‘earburetters then:

‘A. Turn the jot adjusting nuts (1) on all carburetters up to weaken

‘or down to richen the same amount until the fastest Idling speed

consistent with evan running Is obtained.

1. Read he hott ang sree (0g corres ing

df

®.

C._ Carry out items 2 and 3a for single earburettas, then addition

aly:

2

‘A Rar he angina due he hae ting serv on AS te rule ntrecnneon camping iar) he

cach carburetter to ive the desired idling speed as indicated by link pin Is -006 in. (45 mm.) away from the lower edge of the

{the glow ofthe ignition warning light. {ork (ee inset). Tighten the clamp bolts.

8. Compare the Intensity ofthe intake “hist’on all carburetcers _B_ With both je levers at their lowest position, set the jet inter-

and leer the throttle adjusting screws until the ‘hiss’ Is the ‘connection lever clamp bots (8) so that both ets commence to

same, ‘move simultaneously.

TUNING

Multi-carburetters (continued)

14

‘A. Reconnect the mixture control wire with about rin. (16 mm.)

free movement before i starts to pull on the jot levers.

‘8. Pullthe mixture control knob until the linkage Is about to move

‘the carburetter jets, and adjust the fat idle screws, compar

Ing the Intensity ofthe air intake ‘hiss to give an engine speed

‘of about 1,000 rpm. when hot.

G_Refe the air cleaners and recheck for correct mixture a6

described in item 12.

ADJUSTING AND SERVICING

Jet Centring

15

‘The piston should fll realy onto the carburetter bridge with a click

‘when the lifting pin is released wich the jet in the fully up

positon. if fe will only do this with the jet lowered then the

[et unit requires re-centring. This is done a8 follows:

Remove the jet head screw to release the control linkage.

‘Withdraw the jet, disconnecting the fuel fed pipe union in the

{lost-chamber, and removing the rubber sealing washer. Remove

‘the jet locking spring and adjurting nut.

C._ Replace the jet and insert the ful feed pipe connection into the

Aoat-chamber.

Pre

D. Sheken the jet locking mut until the ssembly free to rotate,

‘A. Remove the piston damper and apply pressure to the top of the

piston rod with a pencil.

ts, Tigi sh for cag oping bare Sen che

Jee bearing.

C. Finally check again a in item 45,

1D. Rese the jet locking spring and adjusting nut. Before replacing

‘the fuel fed pipe into the float-chamber, fit the rubber sealing

‘washer over the end of the plastic pipe so that atleast in.

{810m ot pe protrudes nt), Remsamble the control

the piston dampers with the recommended engine oil

jones

Using a pecrol-moistened cloth, clean the Inside bore of the

piston.

C._Lightly oil the piston rod only and reassemble as marked.

1. Refill piston damper (see item 8).

ADJUSTING AND SERVICING

(continued)

Float-chamber fuel level

‘A. Remove and invert the flat-chamber lid.

With the needle valve held in the shut-off position by the weight

‘of the float only, there should be a to 4 In. (2 t0 48 mm.)

{3p beeween the float lever andthe rim ofthe float-chamber id

C._The float may be set by bending at the crank.

Needle size and position

‘A. The needle size is determined during engine development and

will provide the correct mixture strength unless extremes of

‘temperature, humidity or altltude are encountered, Ataltitudes

‘exceeding 6,000 ft (1830 m, a weaker needle will be necessary.

A different needle may aio be necessary any alteration to the

‘sandard specification of the exhaust system, air cleaner, cam

shaft, or compression ratio ls made.

To check thatthe correct needle Is ited: mark for reassembly

and remove the plston/suction chamber unit.

Slacken the needle clamping screw, extract the needle, and

‘check its identifying mark against the recommendation,

Replace the correct needle and lock It in pottion 40 that the

shoulder on the shank is ush with the piton base.

‘Resssemble the platon/suction chamber unit as marked,

poe

Faults

Symptom coe Remedy eam No.

Era nang Shing pon:

Scaling ting Dirty piston and sctonchamber| Clan

Lack of power Jc ot of conre Reconere

High fol coneumption ent needle Peeew

astion a php Low damper oll evel Top op

Incorrect ol grade (co thin) | Replat with correct grade

Foellekfrom lostchamberffeed. | Rubber sealing washer dplced or

tips uen mage esew ”

Floatchamber toodng Dirty or worn four-chamber | Clean or rnew valve (Wash | See Diamanding and

edie ave (ry fe omen) Resvrbly Leer

Puncture font Fenew

Incorrect fel evel Check tnd rest ave ”

Printed in England by The Mlld Prox Limited, Conley Ofer. 2415 (440) 868-4007

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Sbu A Price List 2021: Size in MM WXHXD SN Article No. Unit Price 2021 CategoryDocument35 pagesSbu A Price List 2021: Size in MM WXHXD SN Article No. Unit Price 2021 Categoryrikirik2008No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Rtlo 16718BDocument42 pagesRtlo 16718Bjames santiago100% (1)

- Priolube Wall Chart 06-15 WEBDocument1 pagePriolube Wall Chart 06-15 WEBRafael Nakazato RecioNo ratings yet

- Guide Vane Actuating Unit: Retrofit For Isotherm TurbocompressorsDocument4 pagesGuide Vane Actuating Unit: Retrofit For Isotherm TurbocompressorsHABINSHUTI FERDINANDNo ratings yet

- Servo Embrague - DespiecDocument2 pagesServo Embrague - DespiecjesusNo ratings yet

- R945 StageV en PI 2023 01 UnlockedDocument28 pagesR945 StageV en PI 2023 01 UnlockedMárton SzőkeNo ratings yet

- Vacuum Solenoid Valves - : Complaints, Causes & TestingDocument2 pagesVacuum Solenoid Valves - : Complaints, Causes & Testingishma100% (1)

- L1AM13 Wheels TyresDocument34 pagesL1AM13 Wheels TyresVaughan LeaworthyNo ratings yet

- Code Picture Description Unit Price: Left / Right Hand Operate Dental UnitDocument10 pagesCode Picture Description Unit Price: Left / Right Hand Operate Dental UnitalissNo ratings yet

- 2021 MasterCraft Catalog ADocument23 pages2021 MasterCraft Catalog ACorey TailleferNo ratings yet

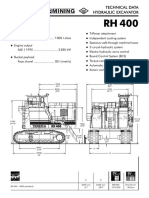

- Technical Data Hydraulic Excavator: L L L L L L L L L LDocument4 pagesTechnical Data Hydraulic Excavator: L L L L L L L L L LMeinardi NapohNo ratings yet

- Dinex EPA 10 CatalogueDocument94 pagesDinex EPA 10 CatalogueChris DentNo ratings yet

- Hoffman: Spotmaster Spotting Boards and Cabinets - The Most Complete Range of Spotting Systems!Document2 pagesHoffman: Spotmaster Spotting Boards and Cabinets - The Most Complete Range of Spotting Systems!NugagodaNo ratings yet

- Single Rear Wheels: Dimensions (MM) A Wheel Base 3450 3750 4100Document2 pagesSingle Rear Wheels: Dimensions (MM) A Wheel Base 3450 3750 4100oussamaNo ratings yet

- FZCODocument30 pagesFZCOawfNo ratings yet

- Osmonics Tonkaflo Pumps Ss Series: Installation, Operation, and Maintenance ManualDocument43 pagesOsmonics Tonkaflo Pumps Ss Series: Installation, Operation, and Maintenance ManualLeopoldo Ulloa100% (1)

- Parts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 219807-0388-B1Document34 pagesParts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 219807-0388-B1armacaNo ratings yet

- Reporting PPM D155A-6 Baskhara Sinar SaktiDocument9 pagesReporting PPM D155A-6 Baskhara Sinar SaktiCandy 888No ratings yet

- Service 9103-1390 7-02 ANSIDocument266 pagesService 9103-1390 7-02 ANSIVICTOR DAVID LOPEZ CASTILLONo ratings yet

- Schematics RPO Code ListDocument7 pagesSchematics RPO Code ListGaby VasileNo ratings yet

- Radio and Player: 2004 Toyota Tacoma (Ewd565U)Document4 pagesRadio and Player: 2004 Toyota Tacoma (Ewd565U)Herson EscobarNo ratings yet

- 16132-EN - Dual-line-Catalogue 12 - 2015Document72 pages16132-EN - Dual-line-Catalogue 12 - 2015arshad shahNo ratings yet

- To Recalibrate The WindowDocument4 pagesTo Recalibrate The WindowPuican IulianNo ratings yet

- 2019 Fiat 500 / 500 Abarth: SpecificationsDocument7 pages2019 Fiat 500 / 500 Abarth: SpecificationsLula MarquesNo ratings yet

- E5030 Petrol Engines Electronic ManagementDocument8 pagesE5030 Petrol Engines Electronic Managementomid yadegariNo ratings yet

- Despiece, A440Document6 pagesDespiece, A440AUTOPARTES 1987No ratings yet

- Air Driven Gas Booster Double Acting, Double Air Drive: Hydraulics International, IncDocument25 pagesAir Driven Gas Booster Double Acting, Double Air Drive: Hydraulics International, Incniteesh sharmaNo ratings yet

- Especificaciones Yale Erp030Document8 pagesEspecificaciones Yale Erp030ADMINISTRACIÓN ÁVALOSNo ratings yet

- Grove ATS540 SpecDocument26 pagesGrove ATS540 SpecHoward HoacNo ratings yet

- Torque Converter HousingDocument2 pagesTorque Converter HousingOecox Cah DjadoelNo ratings yet