Professional Documents

Culture Documents

EN10346-2009-8.5.4 Surface Inspection PDF

Uploaded by

balanoiu_ionOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EN10346-2009-8.5.4 Surface Inspection PDF

Uploaded by

balanoiu_ionCopyright:

Available Formats

BS EN 10346:2009

EN 10346:2009 (E)

8.5.4

Surface inspection

8.5.4.1 The product surface shall be visually inspected for verification of conformance with the requirements

in 7.4 to 7.6.

8.5.4.2 Unless otherwise agreed at the time of enquiry and order, only one surface shall be inspected at the

manufacturer's works. If requested, the manufacturer shall inform the purchaser whether the inspected

surface is the top surface or the bottom surface.

Small edge cracks which may occur in the case of mill edges are not justification for rejection.

8.5.4.3 Roughness (Ra) measurements, where applicable (see 7.5.3), shall be carried out in accordance

with EN 10049.

8.5.5

Coating mass

8.5.5.1

General

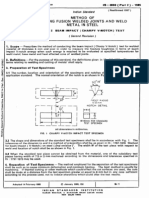

The coating mass shall be determined from the difference in mass of the samples before and after the coating

has been removed chemically. In the test with specimen according to Figure 1, the triple spot test value is the

arithmetic mean of the three test results. Each individual result shall meet the requirements of the single spot

test as given in Table 11.

Other methods e.g. non-destructive tests may be used for continuous checks at the manufacturer's works.

In cases of dispute, the methods described in Annex A (Z, ZF, ZA and AZ) or Annex B (AS) shall be used.

8.5.5.2

Special method for determination of the mass of the Fe-Al-Si alloy layer

If it has been agreed to determine the mass of the Al-Fe-Si alloy layer resulting from aluminium-silicon alloy

(AS) coating (see 7.4.6), the method for its determination given in Annex C shall be applied.

8.6

Retests

The requirements of EN 10021 shall apply. In the case of coils, the retest specimens shall be taken from a

distance of at least one lap away, but with a maximum of 20 m from the end of the coil.

9

9.1

Marking

A label shall be attached to each coil or bundle containing at least the following information:

a)

name or mark of the manufacturer's works;

b)

designation (consisting of 5.1b) and 5.1f) to 5.1k));

c)

nominal dimensions of the product;

d)

identification number;

e)

order number;

f)

mass of the coil or bundle.

Bar coding according to EN 606 can supplement marking, when the abovementioned minimum information is

also given in clear text.

30

You might also like

- Painting SpecificationDocument40 pagesPainting SpecificationIkram Syed100% (4)

- AAC2010 Guideline For Hard Anodic Oxide CoatDocument3 pagesAAC2010 Guideline For Hard Anodic Oxide CoatPalaNo ratings yet

- Astm C 144Document2 pagesAstm C 144Gia Guallar50% (2)

- Api-582-2016-Welding-Guidelines-For-The-Chemical-Oil-And-Gas-Industries-Apiasme-Practice-Test Clause 11.3Document4 pagesApi-582-2016-Welding-Guidelines-For-The-Chemical-Oil-And-Gas-Industries-Apiasme-Practice-Test Clause 11.3Ahmed ElsharkawNo ratings yet

- BS 3900 Pull Off TestDocument9 pagesBS 3900 Pull Off TestHassan FekiNo ratings yet

- Astm D2203Document2 pagesAstm D2203JesusNo ratings yet

- Astm C 144-2004Document2 pagesAstm C 144-2004Nikolay DrumevNo ratings yet

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- BS 598 104 1989 PDFDocument18 pagesBS 598 104 1989 PDFEnd EndNo ratings yet

- Guidelines Non-Destructive Examination Steel CastingsDocument15 pagesGuidelines Non-Destructive Examination Steel CastingsRicky WCKNo ratings yet

- Astm c33-99 Standard Specification For Concrete AggregatesDocument8 pagesAstm c33-99 Standard Specification For Concrete AggregatespparreraNo ratings yet

- Astm C 142Document2 pagesAstm C 142e110807No ratings yet

- Astm B150 & B150M - 03Document6 pagesAstm B150 & B150M - 03jtek01No ratings yet

- ASTM A842 - Corpo de Prova OmegaDocument4 pagesASTM A842 - Corpo de Prova OmegaFabiano MonteiroNo ratings yet

- BS 598-104-1989Document18 pagesBS 598-104-1989hibonardo100% (1)

- BS 812-Part 113-90Document10 pagesBS 812-Part 113-90anish_am2005No ratings yet

- Astm C33 PDFDocument8 pagesAstm C33 PDFJorge R. Vega C100% (4)

- Astm C33Document8 pagesAstm C33Rafael100% (1)

- Asme Section II A-2 Sa-476 Sa-476mDocument6 pagesAsme Section II A-2 Sa-476 Sa-476mAnonymous GhPzn1xNo ratings yet

- 30t-65-Moldable Exothermic Pad MaterialsDocument3 pages30t-65-Moldable Exothermic Pad MaterialsCharlie ChongNo ratings yet

- Appendix Supply, Fabrication and Installation of Bearing AssembliesDocument3 pagesAppendix Supply, Fabrication and Installation of Bearing AssembliesakhilkuwarNo ratings yet

- High-Carbon Anti-Friction Bearing Steel: Standard Specification ForDocument4 pagesHigh-Carbon Anti-Friction Bearing Steel: Standard Specification Fornelwan_topanNo ratings yet

- Gypsum Lath: Standard Specification ForDocument2 pagesGypsum Lath: Standard Specification ForBehnamZBNo ratings yet

- Synthetic Rubber Proofed/Coated Fuel Pump Diaphragm Fabric-Specification (Document9 pagesSynthetic Rubber Proofed/Coated Fuel Pump Diaphragm Fabric-Specification (Ved PrakashNo ratings yet

- B551 07Document10 pagesB551 07Srinivasan KrishnamoorthyNo ratings yet

- Iron-Phosphorus Powder Metallurgy (P/M) Parts For Soft Magnetic ApplicationsDocument6 pagesIron-Phosphorus Powder Metallurgy (P/M) Parts For Soft Magnetic ApplicationsJosé Ramón GutierrezNo ratings yet

- D897 617621-1Document3 pagesD897 617621-1Fernando Cardeño LopezNo ratings yet

- Steel Sheet, Metallic Coated and Polymer Precoated For Corrugated Steel PipeDocument4 pagesSteel Sheet, Metallic Coated and Polymer Precoated For Corrugated Steel PipeGustavo SuarezNo ratings yet

- A 823 - 99 Qtgymy05oq - PDFDocument7 pagesA 823 - 99 Qtgymy05oq - PDFMung Duong XuanNo ratings yet

- Pressure Vessel Plates, Alloy Steel, Nickel: Standard Specification ForDocument3 pagesPressure Vessel Plates, Alloy Steel, Nickel: Standard Specification Fordoshi78No ratings yet

- Bang So Sanh LinhDocument24 pagesBang So Sanh LinhMinh Vuong TranNo ratings yet

- A 972 - A 972M - 00 Qtk3mi9botcytqDocument4 pagesA 972 - A 972M - 00 Qtk3mi9botcytqfekihassanNo ratings yet

- ASTM-Designation G109 99aDocument5 pagesASTM-Designation G109 99aJorge LeconaNo ratings yet

- ASTM G109.1044239-1 (Corrosion of of Embedded Steel)Document6 pagesASTM G109.1044239-1 (Corrosion of of Embedded Steel)Sripriya Rengaraju100% (3)

- Steel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)Document3 pagesSteel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)Ajesh Kumar MuraleedharanNo ratings yet

- CASES OF ASME BOILER AND PRESSURE VESSEL CODEDocument10 pagesCASES OF ASME BOILER AND PRESSURE VESSEL CODENilesh Pathare0% (1)

- 7.5.5.2asme Sec Viii Div 2 2017Document3 pages7.5.5.2asme Sec Viii Div 2 2017James100% (2)

- Austenitic Ductile Iron Castings For Pressure-Containing Parts Suitable For Low-Temperature Service (Metric)Document5 pagesAustenitic Ductile Iron Castings For Pressure-Containing Parts Suitable For Low-Temperature Service (Metric)Mohd LokmanNo ratings yet

- Standard Specification For Wrought Copper-Alloy Bearing and Expansion Plates and Sheets For Bridge and Other Structural UseDocument5 pagesStandard Specification For Wrought Copper-Alloy Bearing and Expansion Plates and Sheets For Bridge and Other Structural UseHugoStiglicNo ratings yet

- A159-83 R11 Automotive Gray Iron CastingsDocument5 pagesA159-83 R11 Automotive Gray Iron CastingsAnand KumarNo ratings yet

- Astm A1004-A1004m R-2004Document3 pagesAstm A1004-A1004m R-2004Jorge ToribioNo ratings yet

- Editable 1Document16 pagesEditable 1Brayand Colonia MarquinaNo ratings yet

- Shotcrete Specification SummaryDocument7 pagesShotcrete Specification SummaryJuanPaoloYbañezNo ratings yet

- Et Ohe 13Document15 pagesEt Ohe 13hardeepsingh_0850% (2)

- Austempered Ductile Iron Castings: Standard Specification ForDocument8 pagesAustempered Ductile Iron Castings: Standard Specification ForJosé Ramón GutierrezNo ratings yet

- Potential Expansion of Portland-Cement Mortars Exposed To SulfateDocument3 pagesPotential Expansion of Portland-Cement Mortars Exposed To SulfatezhunsheanNo ratings yet

- Lowcarbongalvanizedsteelwires, Formedwiresandtapesfor Armouringofcables - SpecificationDocument8 pagesLowcarbongalvanizedsteelwires, Formedwiresandtapesfor Armouringofcables - SpecificationShrikant KajaleNo ratings yet

- Is 1626 Part 2Document11 pagesIs 1626 Part 2Sheetal JindalNo ratings yet

- Gypsum Lath: Standard Specification ForDocument2 pagesGypsum Lath: Standard Specification ForGrato Jr SingcoNo ratings yet

- Carbon Steel Girder Rails of Plain, Grooved, and Guard TypesDocument3 pagesCarbon Steel Girder Rails of Plain, Grooved, and Guard TypesAjesh Kumar MuraleedharanNo ratings yet

- 28b. IS 3600 - 2 - 1985 PDFDocument2 pages28b. IS 3600 - 2 - 1985 PDFhhr2412No ratings yet

- Astm A874Document3 pagesAstm A874DendeNo ratings yet

- Steel, Sheet, Carbon, For Pressure VesselsDocument4 pagesSteel, Sheet, Carbon, For Pressure VesselsCarlos BernussiNo ratings yet

- Specification FOR 53gradeordinaryportlandcement: Indian StandardDocument20 pagesSpecification FOR 53gradeordinaryportlandcement: Indian StandardVivekChaudharyNo ratings yet

- Astm A1007-2002Document9 pagesAstm A1007-2002Jorge ToribioNo ratings yet

- Civil Engineering Structures According to the Eurocodes: Inspection and MaintenanceFrom EverandCivil Engineering Structures According to the Eurocodes: Inspection and MaintenanceNo ratings yet

- Joining of Polymer-Metal Hybrid Structures: Principles and ApplicationsFrom EverandJoining of Polymer-Metal Hybrid Structures: Principles and ApplicationsSergio T. Amancio FilhoNo ratings yet

- Aalco Metals LTD - Stainless Steel EN Standards For Stainless Steel HR Plate - 65 PDFDocument3 pagesAalco Metals LTD - Stainless Steel EN Standards For Stainless Steel HR Plate - 65 PDFbalanoiu_ionNo ratings yet

- BS EN 10346 Types of Steel Surface QualitiesDocument1 pageBS EN 10346 Types of Steel Surface Qualitiesbalanoiu_ionNo ratings yet

- Stainless Steel SpecificationDocument2 pagesStainless Steel SpecificationmariusdejNo ratings yet

- According To ISO/IEC Guide 22 and EN45014: Declaration of ConformityDocument1 pageAccording To ISO/IEC Guide 22 and EN45014: Declaration of Conformitybalanoiu_ionNo ratings yet

- En 10225 Chemical & Mechanical ProprietiesDocument2 pagesEn 10225 Chemical & Mechanical Proprietiesbalanoiu_ionNo ratings yet