Professional Documents

Culture Documents

Aluminium Summary

Aluminium Summary

Uploaded by

rakukulappullyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aluminium Summary

Aluminium Summary

Uploaded by

rakukulappullyCopyright:

Available Formats

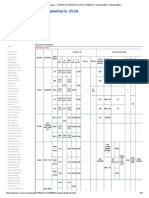

ALUMINIUM SUMMARY OF GRADES

CHEMICAL COMPOSITION LIMITS %

GRADE &

TEMPERING

AL % Si % Fe %

Min REM

MECHANICAL PROPERTIES

Cu

Mn

Mg

Cr

Zn

Ti

5.0

2011-T4

Max

Min REM

0.40 0.70 6.00

-

0.40 4.0 0.05

Yield

Elongation *Corrosion *Machining

Tensile

Strength Strength A5 min. Resistance

%

Thickness >25mm >25mm

Others

mm

Mpa

Mpa

Min

Min.

See

Note

Round

ALL

275

125

14

D,D

A,A

6061-T6

Round

6-40

275

125

10

A,C

C,B

Plate

40-75

270

115

10

A,C

C,B

Round

ALL

260

240

B,B

B,C

6061 is heat treatable, structural alloy

with medium strength and

extrudability. It is easily weldable and

has good corrosion resistance.

D,B

Highest strength in heat treatable

alloys due to tight micro-structural

control. Adequate machinability and

improved stress corrosion control.

Used for highly stressed structural

parts & is excellent for drop drilling,

good tool wear and differientiated

thread rolling.

0.40 0.40 0.10 1.00 4.9 0.25 0.25 0.15

Min REM 0.40

Max

Min REM

0.15

0.80 0.04

0.80 0.70 0.50 0.15 1.20 0.35 0.25 0.15

-

1.2

2.1 0.18 5.1

Round

ALL

7075-T6

Max.

Free machining aluminium alloy due

to the additions of lead and bismuth.

Applications requiring high machining

such as gears, machine parts and

screw machining products not

requiring decorative finishings.

0.30

5083-H112

Max

DESCRIPTION &

TYPICAL APPLICATIONS

0.40 0.50 2.0 0.30 2.9 0.28 6.1 0.20

77 Ksi

66Ksi

C,C

Highest strength alloy among nonheat treatable alloys. Good

resistance to corrosion. Used in

shipbuilding, drilling rigs, general

engineering and transport

industries.Should not be used

temperatures above 65C.

Note:

2011 others Bi 0.20 0.60% Pb 0.20 0.60%

Relative ratings in decreasing order of merit = A B C D (Where A=Highest). Two ratings e.g. AC are for annealed & hardest tempers.

Grades are stocked with differing tempering Used as examples only for Mechanical Properties.

DISCLAIMER: This specification is for information purposes only. Global Metals takes no responsibility for the suitability of the steels referred to in this specification without prior notification. Global Metals takes no responsibility for any errors1 or omissions, or for any consequences

resulting from its use.

You might also like

- Alloy 6005A: We Are AluminumDocument2 pagesAlloy 6005A: We Are AluminumLeo PardNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- BS3100 A2Document11 pagesBS3100 A2AlexNo ratings yet

- ASTM A514 GR B Data Sheet 2012 04 01 PDFDocument2 pagesASTM A514 GR B Data Sheet 2012 04 01 PDFMarco BacianNo ratings yet

- Kaiser Aluminum Shapes Soft Alloy PDFDocument18 pagesKaiser Aluminum Shapes Soft Alloy PDFgerrzen64No ratings yet

- Steel Data ChartDocument2 pagesSteel Data Chartsmartcad60No ratings yet

- ASTM A514 GR H Data Sheet 2012 04 02 PDFDocument2 pagesASTM A514 GR H Data Sheet 2012 04 02 PDFRodolfoMarínNo ratings yet

- Chemical Composition of ASTM ASME SA516 Grade 60 70 Steel PlateDocument2 pagesChemical Composition of ASTM ASME SA516 Grade 60 70 Steel PlateVarun Malhotra100% (1)

- Material Cross Reference TableDocument3 pagesMaterial Cross Reference TableLuis Pol SistiNo ratings yet

- Chemical Composition of ASTM ASME SA516 Grade 60 70 Steel PlateDocument2 pagesChemical Composition of ASTM ASME SA516 Grade 60 70 Steel PlateIbadurrahman KahfiNo ratings yet

- Astm A516Document11 pagesAstm A516Kokoh Aji LesmanaNo ratings yet

- Hollow Bar Ovako 280Document3 pagesHollow Bar Ovako 280fernandojNo ratings yet

- 34 CR Ni Mo 6Document4 pages34 CR Ni Mo 6InaamNo ratings yet

- 20Mncr5: Steel GradeDocument4 pages20Mncr5: Steel GradeAhmad ShujaNo ratings yet

- Is 2062Document2 pagesIs 2062niketpatel3121No ratings yet

- 42 CR Mo 4Document4 pages42 CR Mo 4Alin ChehadeNo ratings yet

- 34crnimo6: Steel GradeDocument4 pages34crnimo6: Steel GradeAndrea FerrerNo ratings yet

- Data Sheet A-10: Alloy TypeDocument3 pagesData Sheet A-10: Alloy Typemohamed AdelNo ratings yet

- Applicable Standards: ASTM A792 ASTM A792 EN10215Document14 pagesApplicable Standards: ASTM A792 ASTM A792 EN10215ersinNo ratings yet

- Alloy Steel Plates TdsDocument6 pagesAlloy Steel Plates TdsSrikanth SrikantiNo ratings yet

- En3a 070M20Document1 pageEn3a 070M20Debrup Banerjee100% (2)

- Rail Specification S & CorrosionDocument94 pagesRail Specification S & CorrosionGowthami Priya HanumuthuNo ratings yet

- ASTM A514 Grade S: General Product DescriptionDocument2 pagesASTM A514 Grade S: General Product DescriptionAGUSTINNo ratings yet

- Aluminium Casting Alloy (AL - Si12) : Home About Us Processes Design Quality Products Technical ContactDocument3 pagesAluminium Casting Alloy (AL - Si12) : Home About Us Processes Design Quality Products Technical Contactrafdinal.sNo ratings yet

- Equivalent Standards - A - SA516-70, A - SA515-70, ST52-3, S355J2+N, SAILMA 350HI, SAILMA 450HIDocument10 pagesEquivalent Standards - A - SA516-70, A - SA515-70, ST52-3, S355J2+N, SAILMA 350HI, SAILMA 450HIPuneet BahriNo ratings yet

- EN24 Properties and Chemical CompositionDocument1 pageEN24 Properties and Chemical CompositionMani MaranNo ratings yet

- Data Sheet ASTM A514 Grade B 2017-04-19 221 371857150 enDocument2 pagesData Sheet ASTM A514 Grade B 2017-04-19 221 371857150 enkanteron6443No ratings yet

- Material Properties and Chemical CompositionDocument20 pagesMaterial Properties and Chemical CompositionMani Maran89% (9)

- Case Hardening Alloy Steel Bar 6587 Atlas 6587: Colour Code: Signal Red (Band) - BlackDocument3 pagesCase Hardening Alloy Steel Bar 6587 Atlas 6587: Colour Code: Signal Red (Band) - BlackCelsoNo ratings yet

- PNS49Document14 pagesPNS49jbcast86No ratings yet

- ASTM A335 Pipe Specification1 PDFDocument8 pagesASTM A335 Pipe Specification1 PDFRoberto EliasNo ratings yet

- ASTM A335 Pipe Specification1Document8 pagesASTM A335 Pipe Specification1Rupam BaruahNo ratings yet

- Robofil M 700Document1 pageRobofil M 700Martin DunneNo ratings yet

- Aluminium 6082 Spec SheetDocument3 pagesAluminium 6082 Spec SheetDeepak KumarNo ratings yet

- A537 CL2Document1 pageA537 CL2AssemNo ratings yet

- En 10305 1 Sunny SteelDocument6 pagesEn 10305 1 Sunny Steelmohamed belkadiNo ratings yet

- CHP 1 ProjectDocument11 pagesCHP 1 ProjectDhyey KalariyaNo ratings yet

- Alloy Steel Astm A217 Grade Wc6 1Document1 pageAlloy Steel Astm A217 Grade Wc6 1didi sudiNo ratings yet

- Aluminium Alloy 6061 - Composition, Properties, Temper and ApplicationsDocument4 pagesAluminium Alloy 6061 - Composition, Properties, Temper and ApplicationsMadhu SudanNo ratings yet

- Chemical Composition: IS: 2062 Specification of Structural Steel For FabricationDocument2 pagesChemical Composition: IS: 2062 Specification of Structural Steel For FabricationppglNo ratings yet

- Plate Asme Sa516 Grade 70Document10 pagesPlate Asme Sa516 Grade 70Deaz AmbrsNo ratings yet

- ASTM Steel PipeDocument3 pagesASTM Steel Pipehilwa6_731153219No ratings yet

- Aisi 200 SeriesDocument19 pagesAisi 200 Seriessgupta_192494No ratings yet

- Steel Grade: Material Data SheetDocument7 pagesSteel Grade: Material Data Sheetispat_jagadeeshNo ratings yet

- Leaded Tin Bronze C54400Document3 pagesLeaded Tin Bronze C54400nfcastingsNo ratings yet

- AAMRADocument50 pagesAAMRARona Khairol Pratama100% (1)

- BD e 2013Document32 pagesBD e 2013Vijay KumarNo ratings yet

- 34 CR Ni Mo 6Document4 pages34 CR Ni Mo 6Krzysztof WrzeszczNo ratings yet

- Kaiser Aluminum 6061 Pipe Tube PDFDocument2 pagesKaiser Aluminum 6061 Pipe Tube PDFgerrzen64No ratings yet

- 12Cr1MoV Alloy Steel PipeDocument5 pages12Cr1MoV Alloy Steel PipeFerry KurniawanNo ratings yet

- Kaiser Aluminum Soft Alloy Tube PDFDocument31 pagesKaiser Aluminum Soft Alloy Tube PDFgerrzen64No ratings yet

- Astm A517 GR B: General Product DescriptionDocument2 pagesAstm A517 GR B: General Product Descriptionjuan vargas tarazonaNo ratings yet

- 1.7734-DatasheetDocument4 pages1.7734-DatasheetMax PrzybyllaNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Pipeline and Energy Plant Piping: Design and TechnologyFrom EverandPipeline and Energy Plant Piping: Design and TechnologyRating: 5 out of 5 stars5/5 (2)