Professional Documents

Culture Documents

Patente Troturadora

Uploaded by

danielss chOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Patente Troturadora

Uploaded by

danielss chCopyright:

Available Formats

US 20130119575A1

(19) United States

(12) Patent Application Publication

(10) Pub. N0.: US 2013/0119575 A1

Whaley et al.

(54)

(43) Pub. Date:

PLASTIC WASTE RECYCLING APPARATUS

May 16, 2013

Publication Classi?cation

AND SYSTEM

(51)

(71) Applicant: NEXTLIFE ENTERPRISES, LLC,

Boca Raton, FL (US)

(72)

Inventors: Ronald Lee Whaley, Boca Raton, FL

(52)

(US); Anilkumar Rasiklal Shah, B0021

Int. Cl.

B02C 18/22

B29C 47/10

(2006.01)

(2006.01)

B02C 23/40

us CL

(2006.01)

USPC .............................. .. 264/140; 241/42; 241/98

Raton, FL (US); Huimin Zhao,

Zhangjiagang City (CN)

(73) AssigneeZ NEXTLIFE ENTERPRISES.J LLC

B O C a Raton FL (Us)

(57)

ABSTRACT

process and apparatus for recycling plastic'Waste material,

including shreddmg the Waste mater1al 1n a umversal shredder

apparatus and Washing the Waste material. The apparatus and

(21) Appl' No: 13/623,518

method includes a dryer apparatus for drying substantially all

moisture from the plastic, and an agglomeration process that

(22)

Flled'

is performed in an agglomeration apparatus Which receives

sep' 20 2012

the dry ?lm material from the dryer and creates a course mix

.

Related U's' Apphcatlon Data

(63)

of cho

ed material. Multi 1e in-line extruders

rocess the

cleanegpplastic With ?lterp screens positioned pafter each

Continuation-in-part of application No. 13/294,893,

extruder to mix and ?lter the plastic into a ?nal uniform mixed

?led on Nov. 11,2011.

product harvested by a pelletiZer.

Patent Application Publication

May 16, 2013 Sheet 1 0f 18

LE

YA;

WW co

US 2013/0119575 A1

Patent Application Publication

May 16, 2013 Sheet 2 0f 18

FIG. 2A

FIG. 2B

US 2013/0119575 A1

Patent Application Publication

May 16, 2013 Sheet 3 0f 18

FIG. 3A

US 2013/0119575 A1

Patent Application Publication

May 16, 2013 Sheet 4 0f 18

US 2013/0119575 A1

mm.QE

mm?wmw

0

O

O

O

m

0m.0 00o0, 0

_O U_Q OQO0Q

Patent Application Publication

2. \

May 16, 2013 Sheet 5 0f 18

US 2013/0119575 A1

Patent Application Publication

EXTR\U~DE

May 16, 2013 Sheet 6 0f 18

US 2013/0119575 A1

Patent Application Publication

May 16, 2013 Sheet 7 0f 18

US 2013/0119575 A1

FIG.6

Patent Application Publication

SEXTR~UDE TORAGE

May 16, 2013 Sheet 8 0f 18

US 2013/0119575 A1

Patent Application Publication

May 16, 2013 Sheet 9 0f 18

US 2013/0119575 A1

Patent Application Publication

May 16, 2013 Sheet 10 0f 18

US 2013/0119575 A1

Patent Application Publication

May 16, 2013 Sheet 11 0f 18

US 2013/0119575 A1

FIG.9

Patent Application Publication

May 16, 2013 Sheet 12 0f 18

US 2013/0119575 A1

F10IG.

254

WAS102HER

UNIVERSAL GRINDE (CPRUISMHAEY)

Patent Application Publication

May 16, 2013 Sheet 13 0f 18

US 2013/0119575 A1

108

11 4

FIG.

\W.

04

Patent Application Publication

May 16, 2013 Sheet 14 0f 18

_.

co

US 2013/0119575 A1

4/2

v-

N

_

d

_'

r-

y

D

2

(\l

\

.

LL

Patent Application Publication

May 16, 2013 Sheet 15 0f 18

%

|

US 2013/0119575 A1

RIGID

v?"""

PLASTIC

l/

UNIVERSAL SHREDDER

70\

K66

4, 18

METAL SEPARATOR

72

HOT WATER SOAK

100

110

AGITATION

FINES SEPARATOR

l/

WASTE

COLLECTION

WATER TANK

\90

| LIGHT PLASTIC DRYER | [HEAVY PLASTIC DRYER|\

COLOR

/184

SEPARATOR

COLOR

/192

SEPARATOR

EXTRUDER 410ml @

@ Imam) EXTRU DER

| STORAGE l

216

190

186

216

I STORAGE |

196

216

216'

228{ PELLETIzER

22s PELLETIZER

U @\230

230-) @

DRYER

DRYER

FIG. 13

Patent Application Publication

May 16, 2013 Sheet 16 0f 18

US 2013/0119575 A1

Patent Application Publication

May 16, 2013 Sheet 17 0f 18

US 2013/0119575 A1

FIG. 15

Patent Application Publication

May 16, 2013 Sheet 18 0f 18

US 2013/0119575 A1

May 16,2013

US 2013/0119575 A1

PLASTIC WASTE RECYCLING APPARATUS

AND SYSTEM

CROSS-REFERENCE TO RELATED

APPLICATIONS

[0001] This application is a Continuation-In-Part applica

tion of co-pending US. application Ser. No. 13/294,893 (?led

Nov. 11, 2011), Which application is entirely incorporated

herein by reference and made a part hereof.

STATEMENT REGARDING

FEDERALLY-SPONSORED RESEARCH OR

DEVELOPMENT

[0002] Not applicable.

TECHNICAL FIELD

[0003]

The present invention relates to an assembly and

the Waste plastic and subjecting the crushed material to a heat

and passing the material through a trough With a speci?c

piping With a spiral shape. US. Pat. No. 6,588,597, issued to

Arakane et al., discloses a system for treating plastic material

that includes dry cleaning of the material, Which includes

crushing the plastic into small pieces and applying a mechani

cal impact force on the particles in an effort to clean the plastic

of debris Without the use of a Wash liquid. Additionally, US.

Patent No. 5,143,308, issued to Halley et al. discloses a recy

cling system in Which plastic material is separated by the type

of plastic, and the material is ground and converted into ?akes

for processing to remove contaminants from the surface of the

?akes. Finally, US. Pat. No. 5,894,996, issued to Williams,

discloses a method for reclaiming plastic Which includes the

steps of fragmenting the plastic and sizing the fragments to

remove certain siZe fragments prior to continuing With addi

tional steps to loosen contamination from the selected frag

ments in a speci?cally structured vessel.

system for recycling plastic Waste material. More speci?

[0007]

cally, the present invention relates to an apparatus and method

resolved the need for a reliable and commercially feasible

for recycling plastic ?lm and/or rigid plastic material that

includes Washing and purifying the recycled plastic, as Well

process and assembly that recycles plastic material into a

versatile highly puri?ed state. Thus, there remains a need for

a plastic recycling system that is both economical and reliable

as processing the plastic material into a puri?ed course

ground mixture, to administer into an extruder apparatus to

create extruded plastic pellets that may be used to manufac

ture plastic products, including consumer packaging prod

ucts.

These methods and assemblies, hoWever, have not

for producing high volume of recycled plastic material that

has the purity for use in manufacturing a variety of products,

including food packaging products and the desire for such

plastic material to meet FDA approval for food-contact pack

aging. Further, there is a need for a process that includes

BACKGROUND

[0004] Popular use of plastic to manufacture consumer and

industrial products results in a substantial amount of plastic

Waste being available for recycling into material for again

manufacturing such products, but very little is recycled an

used in this manner. Despite public interest in reclaiming

materials form Waste and the rise in plastic Waste collection

efforts, most plastic Waste is buried in land?lls and is never

recycled. A main reason plastic recycling is not more Widely

practiced is that conventional recycling processes commer

cially viable for large volume of material do not yield plastic

free of contaminants such that the plastic has the purity for

universal use in manufacturing processes. For example, con

ventionally processed recycled plastic is not suitable for cer

tain manufacturing processes such as the process for making

plastic ?lm products. Similarly, conventional recycled plastic

is not suitable for use in manufacturing food packaging for

Which strict compliance With speci?c criteria must be met,

including US. Food and Drug Administration guidelines and

approval criteria. It is desirable for recycled plastic material to

meet such guidelines and to be suitable to manufacture a

variety of products Without restriction. As a result of such

limited applicability of conventional recycled material, there

is generally less demand for the material.

[0005] Accordingly, it is desirable to avoid contaminants in

recycled plastic material, such as cellulose (paper ?ber) and

adhesives (residual of glue). It is also desirable to avoid

blends of different types of plastic polymers, such as contami

nants of polystyrene in recycled polypropylene material.

multi-stage Washing mechanisms for removing non-plastic

contaminants from the material being recycled, While main

taining the ability for the material to be transported via a

screW-type conveyer system to the extruder apparatus. This

may include the interim step of accumulating and/or storing

the material in a hopper prior to the extrusion process. This

solves the potential problem of clumping and packing of the

material prior to the extrusion process, such as may occur

With plastic ?lm material that has been thoroughly Washed

and has the tendency to tightly pack and/or clump due to

stickiness. Thus, there is a need for a method and apparatus

that further processes the plastic material to maintain the

movability and ?oWable state of the material. These and other

objectives are met With the invention disclosed herein, pro

viding solutions heretofore unavailable.

BRIEF SUMMARY

[0008] It is an object of the present invention to provide an

assembly for recycling plastic Waste material that has an

intake for introducing the Waste material into a universal

shredder having a shredder blade and an output for directing

shredded plastic Waste material toWard a shredder conveyor

apparatus that is con?gured to convey the shredded material

toWard a rigid plastic recycling line or to a plastic ?lm recy

cling line. The rigid plastic recycling line has a rigid material

grinding assembly and a Water bath assembly for separating

the rigid plastic material by density, and the rigid line also has

at least one dryer apparatus for drying each type of separated

rigid material. The ?lm recycling line has a ?lm grinding

These types of contaminants are typical in plastic material

assembly and a hot Washer apparatus and an agitation device

generated from conventional recycling equipment and pro

for soaking the plastic ?lm and mixing the plastic for addi

cesses available today.

[0006] There have been attempts to address issues of the

tional Washing, folloWed by a Water bath for separating the

debris and Waste products from the plastic ?lm. The ?lm line

also includes an agglomeration process that is performed in

purity of recycled plastic material. For example, the US. Pat.

No. 5,667,151 issued to Miura et al. discloses a process for

an apparatus that agitates a batch of ?lm and results in the

collection of plastic Waste that includes the steps of crushing

material to be further cut into small pieces of plastic, resulting

You might also like

- United States Patent (191 Oct.' 29, 1991: Patent Number: Date of PatentDocument14 pagesUnited States Patent (191 Oct.' 29, 1991: Patent Number: Date of PatentAdrianaSarmientoNo ratings yet

- Us5236603 PDFDocument13 pagesUs5236603 PDFTobias De SomerNo ratings yet

- Astm Article Bio Deg PlasticsDocument7 pagesAstm Article Bio Deg PlasticsAnonymous kTVBUxrNo ratings yet

- US20100160201A1Document26 pagesUS20100160201A1Enrique Franco ArizaNo ratings yet

- Eng. Journal Wate ManagementDocument6 pagesEng. Journal Wate ManagementrahmatfadlizNo ratings yet

- Art 00008Document21 pagesArt 00008Ahmet AltunNo ratings yet

- Research Paper Biodegradable PlasticDocument4 pagesResearch Paper Biodegradable PlasticAkshayNo ratings yet

- Solid-Liquid Filtration: A User’s Guide to Minimizing Cost and Environmental Impact, Maximizing Quality and ProductivityFrom EverandSolid-Liquid Filtration: A User’s Guide to Minimizing Cost and Environmental Impact, Maximizing Quality and ProductivityRating: 5 out of 5 stars5/5 (2)

- Project Report For Waste Plastic Processing Unit 1 TPDDocument16 pagesProject Report For Waste Plastic Processing Unit 1 TPDManju MysoreNo ratings yet

- Life Cycle Engineering of Plastics: Technology, Economy and EnvironmentFrom EverandLife Cycle Engineering of Plastics: Technology, Economy and EnvironmentL. LundquistNo ratings yet

- Self-Cleaning Materials and Surfaces: A Nanotechnology ApproachFrom EverandSelf-Cleaning Materials and Surfaces: A Nanotechnology ApproachWalid A. DaoudRating: 5 out of 5 stars5/5 (1)

- E9750 IranArzeDocument62 pagesE9750 IranArzeRasyid SetyawanNo ratings yet

- Us 20140363742Document24 pagesUs 20140363742chokribNo ratings yet

- Full Report BioplasticsDocument31 pagesFull Report BioplasticsKhairul Anwar50% (4)

- The Sustainable Solution: Plastic Granulate Production in Action: Money from trashFrom EverandThe Sustainable Solution: Plastic Granulate Production in Action: Money from trashNo ratings yet

- FN PaperDocument3 pagesFN Papershaurya pratapNo ratings yet

- Literature Review On Plastic Waste RecyclingDocument4 pagesLiterature Review On Plastic Waste Recyclingea5zjs6a100% (1)

- Food and Beverage Packaging Technology - (2011) (1) (223-227)Document5 pagesFood and Beverage Packaging Technology - (2011) (1) (223-227)Aracely Flores GarmaNo ratings yet

- College of Engineering Cagayan State UniversityDocument16 pagesCollege of Engineering Cagayan State UniversityErika Antonio GutierrezNo ratings yet

- Eco-efficient Rendering Mortars: Use of Recycled MaterialsFrom EverandEco-efficient Rendering Mortars: Use of Recycled MaterialsNo ratings yet

- Recycled Polyester: Manufacturing, Properties, Test Methods, and IdentificationFrom EverandRecycled Polyester: Manufacturing, Properties, Test Methods, and IdentificationNo ratings yet

- Composition of Plastic Waste Collected Via Kerbside v2Document36 pagesComposition of Plastic Waste Collected Via Kerbside v2ArunNo ratings yet

- Design and Manufacture of Plastic Components for Multifunctionality: Structural Composites, Injection Molding, and 3D PrintingFrom EverandDesign and Manufacture of Plastic Components for Multifunctionality: Structural Composites, Injection Molding, and 3D PrintingRating: 4.5 out of 5 stars4.5/5 (4)

- Project Report On Biodegradable Carry Bags and Garbage BagsDocument7 pagesProject Report On Biodegradable Carry Bags and Garbage BagsEIRI Board of Consultants and PublishersNo ratings yet

- Plastic Recycling ThesisDocument7 pagesPlastic Recycling Thesisamandabarbergilbert100% (2)

- Plastics and The EnvironmentDocument783 pagesPlastics and The EnvironmentBerlin Anand100% (4)

- Plastic Recycling: Science Progress February 2007Document25 pagesPlastic Recycling: Science Progress February 2007Mohammed Mostafa El HaddadNo ratings yet

- Plate and Frame FiltrationDocument30 pagesPlate and Frame FiltrationRays Shearer100% (2)

- Costing of RoadDocument12 pagesCosting of RoadBeatrice KunguNo ratings yet

- Plastics RecylingDocument20 pagesPlastics Recylinggaurangbbhatt100% (2)

- Market Analysis: Production of Hydraulic Plastic Recyler MachineDocument6 pagesMarket Analysis: Production of Hydraulic Plastic Recyler MachineJohannis ReyNo ratings yet

- Plastic Waste Recycling Methodology v0.1Document33 pagesPlastic Waste Recycling Methodology v0.1Mohd Rafi100% (1)

- CTL Design For Recovery PaperDocument66 pagesCTL Design For Recovery Paperelena_adeeNo ratings yet

- Us6007005 AbsDocument6 pagesUs6007005 AbsQadri Al HadidNo ratings yet

- NON FWA SolutionDocument7 pagesNON FWA Solutionhaseeb ahmedNo ratings yet

- Development of Shredding and Washing Machine For Polyethylene Terephthalate (PET) Bottles Pelletizer (#532272) - 747529 PDFDocument8 pagesDevelopment of Shredding and Washing Machine For Polyethylene Terephthalate (PET) Bottles Pelletizer (#532272) - 747529 PDFDaiNguyen0% (1)

- Plastic Recycling Research PaperDocument8 pagesPlastic Recycling Research Paperehljrzund100% (1)

- Wax Alternatives StandardDocument23 pagesWax Alternatives StandardVijayakumar NarayananNo ratings yet

- Gasification of Waste Materials: Technologies for Generating Energy, Gas, and Chemicals from Municipal Solid Waste, Biomass, Nonrecycled Plastics, Sludges, and Wet Solid WastesFrom EverandGasification of Waste Materials: Technologies for Generating Energy, Gas, and Chemicals from Municipal Solid Waste, Biomass, Nonrecycled Plastics, Sludges, and Wet Solid WastesNo ratings yet

- Trickling Filter and Trickling Filter-Suspended Growth Process Design and OperationDocument19 pagesTrickling Filter and Trickling Filter-Suspended Growth Process Design and OperationMichał KisielewskiNo ratings yet

- Process Intensification Technologies for Green Chemistry: Engineering Solutions for Sustainable Chemical ProcessingFrom EverandProcess Intensification Technologies for Green Chemistry: Engineering Solutions for Sustainable Chemical ProcessingKamelia BoodhooNo ratings yet

- Fan 2008 - 05 Ectc PDCDocument92 pagesFan 2008 - 05 Ectc PDCBenjamin HQNo ratings yet

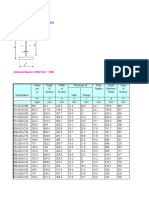

- Hot Roled SectionsDocument58 pagesHot Roled Sectionsmohamed AlasadyNo ratings yet

- Dyeing Theory PDFDocument50 pagesDyeing Theory PDFRamnath Kumar Yadav100% (1)

- Copper Pipe SupportDocument2 pagesCopper Pipe SupportAmirudin SallehNo ratings yet

- Aisi 4130Document2 pagesAisi 4130ravivelamarthyNo ratings yet

- Hoja de Datos de Seguridad de MaterialesDocument7 pagesHoja de Datos de Seguridad de MaterialesMiss IndependentNo ratings yet

- Revision Class Ix Mole ConceptDocument1 pageRevision Class Ix Mole Conceptvishal_bokaro0% (1)

- Identifying Research Gap ExampleDocument3 pagesIdentifying Research Gap ExampleNorhazerahYussopNo ratings yet

- Repsol Isplen Pr210x6eDocument2 pagesRepsol Isplen Pr210x6eSérgio BarbosaNo ratings yet

- Tutorial Insulation of Electrical CablesDocument8 pagesTutorial Insulation of Electrical CablesLedred1No ratings yet

- Separation TechniquesDocument5 pagesSeparation TechniquesSAMEERACH2009No ratings yet

- prEN 10264-2 (2017) (E)Document5 pagesprEN 10264-2 (2017) (E)Nix100% (2)

- Condominium: Design ProposalDocument3 pagesCondominium: Design ProposalVerna Lois PonferradaNo ratings yet

- Geogrid-Techgrid Technical LiteratureDocument13 pagesGeogrid-Techgrid Technical Literaturesachindagrawal90440% (1)

- What Is Peening?: Frequently Asked QuestionsDocument2 pagesWhat Is Peening?: Frequently Asked QuestionstuanNo ratings yet

- Bahan Ajar Able Deck Perawatan Dan Perbaikan KapalDocument31 pagesBahan Ajar Able Deck Perawatan Dan Perbaikan KapalFachri A. AchmadNo ratings yet

- HOLLOW-CORE SLAB SYSTEMS Information ManDocument36 pagesHOLLOW-CORE SLAB SYSTEMS Information ManEng.wissam Safaa100% (1)

- Chapter 5 Water and Solution: 5.1 Physical Characteristics of WaterDocument15 pagesChapter 5 Water and Solution: 5.1 Physical Characteristics of WaterAlan WongNo ratings yet

- PERIODIC PROPERTIES Full Test 1Document7 pagesPERIODIC PROPERTIES Full Test 1B GALANo ratings yet

- SP-2095-nternal Liquid Coating Systems For Carbon Steel Piping and Line PipesDocument50 pagesSP-2095-nternal Liquid Coating Systems For Carbon Steel Piping and Line Pipesarjunprasannan7No ratings yet

- Concrete 22Document11 pagesConcrete 22Kurt CargoNo ratings yet

- MCQS For Manfactering Process PDFDocument10 pagesMCQS For Manfactering Process PDFGet Soon WellNo ratings yet

- Aerocon Blocks Product Literature FOLDER A4Document2 pagesAerocon Blocks Product Literature FOLDER A4subhaschandraNo ratings yet

- Chapter Iii. Limit State DesignDocument19 pagesChapter Iii. Limit State DesignisaacssebulibaNo ratings yet

- Decl Indicators Germany PRODQNT: k15187074.xlsx 1Document13 pagesDecl Indicators Germany PRODQNT: k15187074.xlsx 1totpityiNo ratings yet

- Wilkinson Et Al 2015Document14 pagesWilkinson Et Al 2015Eddie van HalenNo ratings yet

- Design of Circular Slab With HoleDocument4 pagesDesign of Circular Slab With HoleSudan ShresthaNo ratings yet

- International Jurnal of ThermodinamikaDocument16 pagesInternational Jurnal of Thermodinamikaputra34100% (1)

- CE 441 Foundation Engineering 05 07 2019Document216 pagesCE 441 Foundation Engineering 05 07 2019Md. Azizul Hakim100% (1)

- Cap 2Document33 pagesCap 2Ricardo Rincon VegaNo ratings yet