Professional Documents

Culture Documents

HX

Uploaded by

Praful PatilCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HX

Uploaded by

Praful PatilCopyright:

Available Formats

25 Commerce Road, Orillia, Ontario, Canada L3V 6L6

Phone (705) 325-2781

Fax (705) 325-5887

ALLOY DATA SHEET

HEAT RESISTANT ALLOY

HX

REVISION: 04/91

DESCRIPTION

HX is an Ni-Cr-Fe alloy with moderate creep-rupture strength, good ductility and exceptional carburization

resistance. Properties and applications are not unlike those of HW alloy, but the presence of additional

chromium and nickel raise the oxidation resistance, making this composition suitable for extended service at a

higher temperature of 2125oF.

COMPOSITION

Min %

Max %

C

0.35

0.75

Mn

Si

2.0

2.5

Cr

15

19

Ni

64

68

Mo

0.5

P

0.04

S

0.04

APPLICATIONS

Furnace components, trays, hangers, carburizing retorts, heat treatment pots, heating elements, lead pots,

enameling tools.

PRODUCT FORMS

Horizontal and vertical centrifugal castings; static castings.

PHYSICAL PROPERTIES

Density (lbs/in3)

CARBURIZATION

0.294

RESISTANCE

Melting Point(oF)

2350

(Gas-1064 hours @ 1760oF)

Thermal Conductivity

(Btu/h/ft2/ft/oF)

7.2

14.5

15.7

Thermal Expansion

(10-6in/in oF)

7.8

8.1

8.5

8.8

9.2

9.5

10.7

Magnetic Permeability

11.3

2

@ 212oF*

@ 1600oF*

ALLOY

GRADE

WEIGHT GAIN

mg/mm2

@ 1800oF*

@ 70-1000oF

HH

0.58

HT

0.38

@ 70-1200oF

@ 70-1400oF

HU

0.24

HW

0.14*

@ 70-1600oF

@ 70-1800oF

HX

0.16

@ 70-2000oF

@ 1200-1600oF

*Intrapolated value.

@ 1200-1800oF

*Estimated value

MECHANICAL PROPERTIES (Typical Values)

U.T.S.

Y.S.

El.

K.S.I.

K.S.I.

%

70

65

36

9

1400

1600

21

18

48

1800 oF

11

7

40

ASTM Spec A297

60

Min.

HEAT RESISTANT ALLOY HX Page 2

SERVICE TEMPERATURE

The alloy is suitable for service at temperatures up to approximately 2125 oF.

COMPARATIVE OXIDATION RATES (mm / year)

(500 hour cyclic tests)

GRADE

HT

HU

HW

HX

1832

0.20

0.10

0.11

1922

0.54

0.24

0.35

0.23

2012

1.4

0.54

0.47

2102

3.2

1.1

1.5

0.89

2204 oF

7.2

2.2

1.6

WELDABILITY

HX alloy has good weldability by the SMAW, and GTAW processes.

CREEP-RUPTURE PROPERTIES

Long term creep-rupture properties were extrapolated from Larson-Miller Parameter versus stress plots.

RUPTURE-STRESS-KSI

HOURS

1400

1500

1600

1700

1800

1900

2000

2100

1.2

100

AVG.

12.0

8.8

6.3

4.6

3.3

2.35

1.7

1,000

AVG.

8.3

5.9

4.2

3.0

2.1

1.45

1.0

10,000

AVG.

5.8

4.0

2.7

1.9

1.3

0.89

100,000

AVG

4.0

2.7

1.8

1.2

AVG

1400

6.4

1500

4.5

oF

CREEP-STRESS-KSI

%/HOUR

0.0001

1600

3.2

1700

2.3

1800

1.6

1900

0.95

2000

0.62

2100

oF

Note: Creep and rupture stresses are subject to periodic revisions as the results from long term tests become

available.

RELATED SPECIFICATIONS

ASTM: A 297 (HX); A608 (HX 50)

Nearest wrought grade: None

HEAD OFFICE, FOUNDRY & INTERNATIONAL SALES

Kubota Metal Corporation, Fahramet Division

25 Commerce Road, P.O. Box 1700,

Orillia, Ontario, Canada, L3V 6L6.

Phone (705) 325-2781

Fax (705) 325 5887

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Continuum Common Beam FormulasDocument5 pagesContinuum Common Beam FormulasRavi MulimaniNo ratings yet

- Everything You Need To Know About Flatteners and Levelers For Coil ProcessingDocument6 pagesEverything You Need To Know About Flatteners and Levelers For Coil ProcessingPraful PatilNo ratings yet

- Equipment Differences: Flattener vs Straightener vs LevelerDocument13 pagesEquipment Differences: Flattener vs Straightener vs LevelerPraful PatilNo ratings yet

- How To Choose and Use Vibratory Feeders and ConveyorsDocument16 pagesHow To Choose and Use Vibratory Feeders and Conveyorssrusti02No ratings yet

- Axial Piston PumpDocument6 pagesAxial Piston PumpPraful PatilNo ratings yet

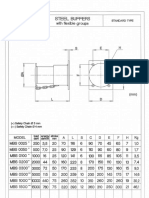

- GALVI Buffers Catalogue PDFDocument5 pagesGALVI Buffers Catalogue PDFPraful PatilNo ratings yet

- Gearmotor BasicsDocument8 pagesGearmotor BasicsKyriakos MichalakiNo ratings yet

- 6177-4 Hertz Contact StressesDocument10 pages6177-4 Hertz Contact StressesVictor GearNo ratings yet

- GALVI Buffers CatalogueDocument5 pagesGALVI Buffers CataloguePraful PatilNo ratings yet

- Two Wattmeter Method (E)Document11 pagesTwo Wattmeter Method (E)sonivishal2002100% (2)

- Moment Distribution Method: Rotational StiffnessDocument0 pagesMoment Distribution Method: Rotational Stiffnessomar_sool2No ratings yet

- 4058 73 DA1 001 01 Refractory Dry Out CycleDocument6 pages4058 73 DA1 001 01 Refractory Dry Out CyclePraful PatilNo ratings yet

- Fluid MechanicsDocument41 pagesFluid MechanicsRian SteveNo ratings yet

- Principles of Screening and Sizing PDFDocument63 pagesPrinciples of Screening and Sizing PDFestramilsolutionNo ratings yet

- Steel Buffer - Leaflet Standard TypeDocument1 pageSteel Buffer - Leaflet Standard TypePraful PatilNo ratings yet

- IPSS For Pulling and Lifting MachinesDocument4 pagesIPSS For Pulling and Lifting MachinesPraful PatilNo ratings yet

- Control & On-Off Valve - Forbes MarshallDocument12 pagesControl & On-Off Valve - Forbes MarshallPraful Patil100% (1)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Fuels and CombustionDocument26 pagesFuels and CombustionEjaz AhmedNo ratings yet

- Gas CylindersDocument49 pagesGas CylindersTravis WoodNo ratings yet

- Hydraulic BasicsDocument189 pagesHydraulic BasicsPraful PatilNo ratings yet

- Heat Resistant Alloy HK40 Data SheetDocument2 pagesHeat Resistant Alloy HK40 Data SheethawyegNo ratings yet

- Control & On-Off Valve - Forbes MarshallDocument12 pagesControl & On-Off Valve - Forbes MarshallPraful Patil100% (1)

- Emmision STD Petrochemplants IndiaDocument189 pagesEmmision STD Petrochemplants IndiaFinigan JoyceNo ratings yet

- Heat Resistant Alloy HK40 Data SheetDocument2 pagesHeat Resistant Alloy HK40 Data SheethawyegNo ratings yet

- Gearmotor BasicsDocument8 pagesGearmotor BasicsKyriakos MichalakiNo ratings yet

- (Handbook) High Performance Stainless Steels (11021)Document95 pages(Handbook) High Performance Stainless Steels (11021)pekawwNo ratings yet

- Mechanical Columns Buckling FailureDocument19 pagesMechanical Columns Buckling FailurePraful Patil100% (1)

- HCDocument2 pagesHCPraful PatilNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)