Professional Documents

Culture Documents

RioPipeline2011 IBP1525 11

Uploaded by

dmlsfmmOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RioPipeline2011 IBP1525 11

Uploaded by

dmlsfmmCopyright:

Available Formats

IBP1525_11

HDD AS AN ALTERNATIVE SOLUTION FOR SHORE APPROACH

OF OFFSHORE PIPELINES IN BRAZILIAN SCENARIOS

Antonio Roberto de Medeiros1, Danilo Machado L. da Silva2

Rafael F. Solano3, Jakson Siqueira4

Copyright 2011, Brazilian Petroleum, Gas and Biofuels Institute - IBP

This Technical Paper was prepared for presentation at the Rio Pipeline Conference & Exposition 2011, held between September,

20-22, 2011, in Rio de Janeiro. This Technical Paper was selected for presentation by the Technical Committee of the event. The

material as it is presented, does not necessarily represent Brazilian Petroleum, Gas and Biofuels Institute opinion or that of its

Members or Representatives. Authors consent to the publication of this Technical Paper in the Rio Pipeline Conference &

Exposition 2011.

Abstract

The objective of this work is to present a study regarding to solutions for shore approach of offshore pipelines in

Brazilian scenarios. An overview of offshore pipeline installation in Brazil is presented and the developments and

solutions adopted during the last few decades are discussed.

The benefits of HDD as an alternative solution for shore approach of offshore pipelines in Brazilian scenarios are

presented. Of course, the challenges involved in HDD shore crossings are also highlighted.

Issues related to the quality and reliability of HDD projects are discussed. Experiences and lessons learnt from

HDD shore crossings in Brazil are presented and discussed, as well as, critical points in design, planning and executing

these projects.

Introduction

When compared to the pipelaying history from the first developments until the present, the offshore pipelaying

history in Brazil is very recent. This is particularly true when considered pipelines that come to crossing the landfall.

A historical study of the marine pipelines installed on the Brazilian coast lead to the first challenges faced in the

initial phases of the import lines installation. These lines where necessary to supply the refining complex still in

implementation and, in a second phase, at the beginning of the offshore discoveries in Brazil, to ensure the transport of

production to refineries in the country.

Although the Brazilian continental proportion with oil and gas field discovered all over the coast, the Brazilian

pipeline mesh is still very small. However, promising growth potential of that mesh is foreseen for the coming years,

which include pipelines that come to shore. It should be noted that with the no flaring and the gas valorization policies,

which are fully in line with the optimization of the world energy resources, and reduction in CO2 production, the

transportation of the gas associated with the deep water oil fields development, is a new challenge which must be

addressed. In general, deep water fields have been oil fields with associated gas, where the valorization of the gas has

been a secondary issue. This situation is now changing and the demand for gas gathering and gas export pipeline

systems linking deep water fields to onshore terminals and liquefaction plants will increase, making the offshore pipeline

installation and the shore approach solution a critical factor in this process, not only due to technical challenges, but also

due to environmental issues (Silva et al., 2011).

The environmental protection concerns are significantly increasing in Brazil and there are very restrictive

requirements from the environmental agency. These requirements are even more restrictive when related to coastal

zones, for several reasons regarding to fauna and flora as well as regarding to economic activities such as fishery and

tourism. Therefore, all the maximum requirements leading to the minimal impact and potential degradation of these

locations are applied for shore approach projects.

In this context HDD emerges as an alternative method in which the environmental issues can be minimized.

The directional drilling method for performing pipeline crossings of a wide variety of surface obstructions was

developed in the 1970s. Since then, the advantages of the HDD technique have been considered by the pipeline

industry. The technology has been applied as the most environmentally responsible and economical method of installing

pipeline beneath obstacles on many projects worldwide.

______________________________

1

Technical Specialist SUBSEA7 Rio de Janeiro, Brazil

Senior Engineer Det Norske Veritas, DNV Rio de Janeiro, Brazil

3

Pipeline Engineer PETROBRAS Rio de Janeiro, Brazil

4

Design and Construction Technician PETROBRAS Rio de Janeiro, Brazil

2

Rio Pipeline Conference & Exposition

The HDD industry has undergone many improvements since its early days. Engineering and technological

developments have enabled larger, more accurate, and more complex pipeline installations by HDD.

The advantages that HDD could bring to pipeline shore approaches, compared with the conventional shore pull,

open-cut methods, are now accepted and several pipelines shore approaches were installed worldwide. The main reason

is that HDD can mitigate environmental impact and provide greater burial depths.

It should be noted however, that the risks that are associated with typical crossings also apply to shore approaches

where they are combined with specific risks related to working in the marine environment. In fact, shore approaches

using horizontal directional drilling are much more complex and challenging to complete than typical surface to surface

installations. The increased challenges and complexity arise from an inability to readily access the exit location, less

geotechnical information associated with ocean floor sediments, elevation differences between entry and exit locations,

complexity of coordinating diving operations, tidal and storm influences, bore stability and drilling fluid management,

casing and product pipe installation strategies, and buoyancy control (Duyvestyn, 2005; Smith, N., 2003).

This work presents a discussion regarding to solutions for shore approach of offshore pipelines in Brazilian

scenarios. It starts at the beginning of the offshore pipeline installation history in Brazil at the first steps into shallow

ocean waters until the current HDD shore approach designs.

Shore Approach Methods used in Brazil

When an export pipeline coming from offshore to onshore facilities is designed a shore approach solution need to

be provided and the shore approach is a very complex project in the offshore pipeline installation. At this phase the

pipeline on-bottom stability is analyzed for surf zone, the possibility of using concrete coating is verified as well as the

necessary burial depth, the pipeline installation stress analysis is performed, the potential for local scour is also verified.

Also in this phase, all the conditions related to the pipeline installation are studied. The installation method is defined,

considering time and preliminary costs, the feasible methods, environmental legislation, regulations and order

requirements from regulatory agencies (such as ANP and IBAMA1) and the Brazilian Navy. The burial technique is also

defined.

The main methods used in Brazil for shore approaches are shown in Figure 1.

Figure 1 Typical shore approach section and methods used in Brazil.

Associated to the shore pull and lateral deflection methods, post and pre-trenching techniques are usually used. A

description of the horizontal directional drilling method, the focus of this work, is presented as follows.

2.1 Horizontal Directional Drilling (HDD)

Horizontal directional drilling (HDD) is an alternative construction method in the trenchless industry and it has

experienced rapid growth in the construction industry over the past few decades. The horizontal-directional-drilling

process represents a significant improvement over traditional open cut method for installing pipelines beneath

obstructions, such as rivers, highways, railroads, islands and others. HDD is also increasingly being utilized for shore

approach of offshore pipelines mainly because it has less environmental impact in certain cases vs. alternative methods.

Installation of a pipeline by HDD is generally accomplished in three stages.

The first stage involves drilling a small-diameter pilot hole along a designed directional path;

The second stage consists of enlarging (reaming) the pilot hole to a diameter that will support the pipeline and;

The third stage consists of pulling the pipeline back into the enlarged hole.

In HDD operations for shore approach, as schematically shown in Figure 2, a drilling rig is positioned on shore

with the support of a lay barge or an installation vessel for pipeline installation and marine operations. Thus, the

operation consists of performing a directional drilled pilot hole of size and depth according to the planned and designed

1

ANP Agncia Nacional do Petrleo (National Petroleum Agency) / IBAMA - Instituto Brasileiro do Meio Ambiente e dos Recursos Naturais

Renovveis (National Environmental Protection Agency)

Rio Pipeline Conference & Exposition

profile, then, the second stage takes place and the pilot hole is reamed until reach the necessary diameter to pulling the

pipeline. In general, the pull is from sea to shore.

Figure 2 HDD Shore Approach, schematically.

This method ensures that the pipeline will not be subject to instability due to wave and currents actions. It prevents

damages caused by dropped objects, such as anchors from small vessels, etc. The depth of cover also provides

mitigation to thermal expansion effects, such as global buckling, in HT pipelines.

2.2 Selection of the Appropriated Method

In general, environmental issues are decisive factors during the definition of the most appropriated method to be

used for the pipeline installation through the shore area. That occurs because it is required by the environmental

agencies the preservation of local life. A permission to work can be denied, for instance, due to sea turtles season,

tourism, local community, etc. From a technical point of view, the shore approach also presents some essential issues,

such as points related to the pipeline on-bottom stability as well as the integrity of the pipeline in the surf zone.

Therefore, the selection of the most appropriate method shall meet technical and environmental issues beyond the

management aspects of costs and schedules. All this makes the selection of the shore approach method a crucial point

for a successful operation. The decision is based on the full knowledge of all possible alternatives and the necessary

adjustments due to demands of the project, associated with preliminary studies of the region, risk analysis and

technologies involved. Of course, costs and schedules are also considered.

It is clear that the design of shore approach is very complex due to the severe environmental conditions and high

dynamic and interaction between waves, currents and sediment transportation in the surf zone. Moreover, the surf zone

may present particular difficulties for the site investigation, for the installation design and operation as well as for the

pipeline on-bottom stability throughout the design life.

The stability and the coastal dynamics are critical parameters in shore approach operations, especially with regard

to pipeline burial. The burial height will also influence the selection of the method to be adopted. It should be noted that,

because of the constant movement of waves and currents, and constant transportation of bottom sediments, the design

assumptions for shore approach varies and depends on each location. Moreover, the intense bottom movement the

changes in the shoreline may cause the pipeline exposure. Therefore, conventional techniques start to present limitations

to fulfill all technical and environmental constraints.

Each shore approach method, see Figure 1 and Table 1, has specific features that take into consideration the

environment, the economic occupation of the region, if it is a commercial area, a touristic area, a fishing area, a

populated area, an environmental protection area, a private area, a military area, etc. Also takes into account the

particularity of the site and nature at the place, its importance to the flora and fauna, its heterogeneity (rare vegetation,

unusual shrubs, herbs), soil type, geology, geophysical features, incidence of waves, winds and current, type of seabed

sand, clay, rocks, coral or existence of other provisions facilities in the installation location.

In any of alternative methods for shore approaches, a detailed design of the installation operation is required and

must be performed in accordance with detailed procedures developed based on a careful and complete analysis of the

site, which include a survey for a proper geotechnical, geophysical and geological subsurface characterization as well as

the seabed characteristics, meteorological and oceanographic information. These studies will allow the accurate

definition of potential problems and risks to be faced, providing the necessary understand to perform corrective action.

In fact, the main points to be considered in shore approach designs are the safety and on-bottom stability of the

pipelines.

Rio Pipeline Conference & Exposition

Table 1 Summary of the shore approach methods characteristics.

Shore Pull

The shore pull methods are relatively simple, but the pipelines is exposed to mechanical damage

and on-bottom stabilities, which lead to a necessity of complementary actions such as opening

trenches for the pipeline burial.

On the other hand there is no limitation regarding to length, there are shore pull on the Brazilian

coast running up to 4.5 km.

Lateral Deflection

The lateral deflection method has some limitations and is rarely used for shore approaches.

The lateral deflection presents the same problems of the shore pull alternatives and also need a

further intervention in order to provide pipeline burial and the requested stability.

For a detailed description on lateral deflection procedures, see (Silva et al., 2007).

Horizontal Directional Drilling

Accuracy in designed path;

There is no need of large excavations or landfill;

It reaches high depths;

There is an equipment mobility enabling quick assembly almost at any location;

Reduced environmental impact on the beach;

Area for mobilization of the drill rig is relatively small.

There are limitations regarding to the crossing distances;

Must be conducted within a small window of time and synchronized with other installation

operations to prevent the hole remains open;

Need support marine support at exit point side;

Depends on the available draft for support vessels;

Project highly dependent on the available geophysical and geotechnical information;

The beginning of shore approaches in Brazil

The first shore approaches in Brazil occurred in Dom Joo Mar field, at Todos os Santos Bay, in So Francisco do

Conde/BA, Northeast Brazil. Those shore approaches occurred at mud areas, in a region with rocks formations on the

seabed and maximum water depths of 15 meters. Similar shore approaches, in sheltered waters, occurred later in the

Guanabara Bay, Rio de Janeiro, in maximum water depths of 21 meters.

3.1 Dom Joo Mar 1954

The first oil discovery in offshore waters occurred in the Dom Joo Mar field, an area of 47 km2. Two thirds of this

field is under Todos os Santos bay waters. The offshore part of the field was developed in two steps: Dom Joo Mar

North in 1954 with the DJ-129 well, and Dom Joo Mar South in 1955 with the DJ-105 well.

The D. Joo Mar field was not in the open sea. Its geographical constitution had typical sheltered waters

characteristics, surrounded by mangroves and protected from oceanic influence by a natural coastline. There were no

beaches, or surf zone waves, only small waves caused by winds or high speed vessels. Meteocean and environmental

characteristics very different from an offshore field, as it is known today. The first pipelay operations in the Todos os

Santos Bay sheltered waters, had neither detailed studies for installation nor well-defined criteria for projects. There

were no criteria, for instance, for on-bottom stability calculations, mechanical design, routing selection or free spans.

The most important thing at that time was to support the production, providing the required flow rate from the start point

to the target point. Initially, these pipelines had neither concrete coating nor anticorrosive coating. These pipes were the

same type used in drilling wells, they were threaded onboard without protective coatings. In the early 70s, just after

some pipes began to present pitting damages, nearly two decades after installation, the replacement of these pipes have

started, at this time a protective epoxy coating was used. After that, other materials were also used as anticorrosive

coatings.

3.2 REDUC / Ilha Dgua / Pier Principal and Ilha Dgua / Ilha Redonda 1961

The historical documentation of submarine pipelay operations in Brazil points to the construction, in 1961, of

pipelines from the Duque de Caxias refinery, in Rio de Janeiro, to the interconnection at the Ilha Dgua, where the gas

and the crude oil were imported for refining, and, subsequently, the sub products of the refinery processes were

exported, Figure 3.

4

Rio Pipeline Conference & Exposition

Figure 3 REDUC Ilha Dgua.

At the time, the first pipeline installation at the Guanabara Bay, Rio de Janeiro - RJ, the pipeline installation

technology was already well developed. The pipeline already had anticorrosive coating and a concrete coating due to

on-bottom stability issues, this concrete coating served also as a mechanical protection against accidental actions such as

dropped objects. It should be noted that the difficulty to approach the shore at the Guanabara Bay, near the REDUC,

was overcome with relative ease, although the water depth of 0.80m and 26 pipelines with 0.95m of diameter, there

were no environmental controls as there are today. Thus, a trench 30m wide and more than 2 km long was easily opened,

buoys were attached to the pipeline and it was towed through these channels.

3.3 TEDUT / Monobia de Tramanda 1968

Only in 1968, in TEDUT - Terminal Almirante Dutra, the first shore approach occurred through no sheltered

water. The operation was recorded by the famous Reporter Esso, from Tupi TV. That was a shore crossing to connect a

single point mooring buoy, used to collect oil from tankers, in order to transport it to the refinery REFAP, still in

construction at that time. A 34 pipeline was assembled on shore in Tramanda/RS, in an area perpendicular to the

shoreline, and was towed into the sea using buoys, Figure 4. There was a large shore line, with a plan bottom without

any obstacles, the surf zone was the only challenge. The pipeline was laid directly on the seabed without any bottom

preparation, being buried naturally, over the time, by the movement of waves and sea currents.

Figure 4 Floating shore pull, Tramanda/RS.

3.4 Guaricema / Atalaia (PGA-03 / EPA) 1971

With the discovery of the Guaricema field in 1968, Sergipe coast, it was necessary to transport the oil offshore for

onshore separation (oil / gas / water separation). After separation the oil would be pumped to the maritime terminal of

Carmpolis, TECARMO. And, it was performed in Sergipe the first shore approach connecting an offshore field to an

onshore terminal. It was a 16 inches pipeline, 16 km long connecting the Guaricema platform No 03 to the Atalaia

production station (PGA-3 / EPA) in Aracaju/SE. The construction began with an old and poorly equipped barge, the

LB-4, owned by INGRAM, which was later bought by McDermott. This pipeline was assembled onshore in 1971, with

the barge positioned at 1200m from the shore, in water depths of 6 m, and pulled from shore to sea using floats, as

shown in Figure 5. Once positioned, the pipeline was sunk without any bottom preparation. It was naturally buried by

5

Rio Pipeline Conference & Exposition

the waves and currents. This pipeline was completed by DB-20 from McDermott. After that, other field discoveries in

different regions of Brazil had advanced techniques for installing pipelines in shore approaches.

Figure 5 Shore Approach, Guaricema 1971.

Figure 6 Shore Approach, Guamar 1982.

3.5 Guamar - RN (Praia do Minhoto) - Gasodutos ECUB/PUB-2 1982

The 4.5 km long shore approach at Praia do Minhoto was the world record at the time. A real challenge that even

the Brown & Root and McDermott declined the contract because of the potential risks due to adverse conditions at Natal

coast. The region presented a large crossing length with submerged rocks formations, tidal variation of 3.3 m, waves up

to 2m high, 1 node current velocity and local depth of only 5m at 5 km from the shore. The two pipelines (6" and 26)

were launched by the BGL-1 (a laybarge owned by Petrobras) and pulled by a constant tension winch onshore. All

design and installation engineering as well as logistics and resources were developed and provided by Petrobras since,

as previously mentioned, the biggest companies have declined this challenge. The GEINP (from the Portuguese, Grupo

Especial de Instalaes de Produo) was created inside the SEGEN (from the Portuguese, Servio de Engenharia) at

Petrobras. This especial group was responsible for building jackets and oil and gas pipelines along the Brazilian coast.

Horizontal Directional Drilling in Brazilian Scenarios

In the Brazilian offshore scenario, this idea came from Shell, in joint venture with Petrobras in 1990. There were

times of high risk contracts and the two companies worked together after the discovery of the Merluza field in the Santos

Basin, So Paulo.

4.1 Merluza shore approach, 16 Praia Grande / SP 1990/1991

The consortium Petrobras and Pecten (Shell) provided the first application of this installation technique for shore

approaches in Brazil. It occurred on the coast of Santos, So Paulo state, during the construction of a 16, 212 km long

gas pipeline (PMZL-1 / Praia Grande). The sore approach project (1200m) came from IntecSea (1989), and the pipeline

was launched by Castoro VIII, Saipem.

This first HDD for shore approach in Brazil came to fulfill the need of crossing an extensive beach area with

shallow water, clay soil and high marine traffic (in the route of vessels to the Santos Port). The preliminary survey, two

shallow holes, indicated a sandy soil in the average depth of the drill path.

The first bore hole, started from shore to sea, had a very shallow drill path, just following the coast topography

with 4 to 5 meters depth of cover. After 500m of drilling pilot hole mud came up on the beach and was abandoned after

numerous unsuccessful attempts with additives (mica and crushed shells).

The second bore hole was started and due to high torque to rotate the column a tripping out of the column was

necessary and a 10, 156m in length casing was installed. This high torque motivated a discussion regarding to change

the punch-out but there was no agreement between all parties and the operation continued. After punch-out, a reamer

was connected to start the back reaming and the pullback operation simultaneously. The very high torque needed to

rotate the 1200m column and reamer during this operation caused a column break at joint 32 from the probe.

Unfortunately, all attempts to remove the column have failed and part of the pipeline and almost the entire drill string

was lost.

The third bore hole was started using a new column. At the punch-out, with a 800m pilot hole, it was connected a

22 reamer on the drill string and a barrel reamer at the product pipe end, once again to try a simultaneous back-reamer

and pullback from sea to shore. During pullback, the product pipe got stuck because the column break. At that point the

pipeline was crossing the beach at a depth of 5 to 6m, near the low tide line. A cofferdam was built to find the pipeline

pull head, a tie-in was performed and the pipeline was continued in a 3m depth trench to shore.

6

Rio Pipeline Conference & Exposition

After all these problems (soil fracture, bore hole collapse, stuck tools, loss of drill string, loss of product pipe) the

work took almost two years to be completed. Such problems occurred due to an insufficient site investigation, which

included a poor geophysical and geological knowledge of subsoil. The pipeline was finally installed in 1991 and buried

for more 70 km from the coast toward PMZL-1.

4.2 Terminal Norte Capixaba (TNC), 16 So Mateus / ES 2004

In 2004, with worldwide developed technology, this alternative was again used in shore approaches in Brazil. And

them, the idea initially proposed by Shell and Petrobras in joint venture, was again utilized to perform a shore approach

in an environmental protected area (a turtle spawning area), at the Esprito Santo state.

Figure 7 TNC / Shore approach scenario.

The two horizontal directional drilling performed in the Terminal Norte Capixaba (Barra Nova do Sul beach) were

a success in terms of drilling and pullback. However there were some lessons learned of paramount importance for the

future of this technique. The most important lesson was the need for research and previous knowledge of the

underground features, in other words, the soil investigation plays a decisive role in the proper design and successful

operation. Information regarding to this project can found in (Solano et al., 2004) and (Azevedo et al., 2005).

4.3 Camarupim gas pipeline, 24 Praia de Cacimbas / ES 2008/2009

After the success of the two previous operations, the HDD was again considered as a reasonable alternative for

shore approaches. This time, it was used to crossing the Cacimbas beach, at Linhares/ES. Cacimbas beach can be

compared to Barra Nova do Sul beach, it also presents riparian vegetation, large sand section and it is also an

environment protected area due to sea turtles. For this shore crossing, a JD-500 Rig (500.000 lbs of tension capacity)

was used as the main rig, and a second rig, type AA-140, with 140.000 lbs of tension capacity. This second rig was

assembled and arranged on the deck of a marine barge to support and handling the drill pipes and to provide the

required tension at the exit point to successfully complete the forward reamer operation. The hole was reamed in three

steps: 1st Step: reamed to 26"; 2nd Step: reamed to 34"; and 3rd Step: reamed to 38".

Figure 8 HDD at Cacimbas beach, drill rig onshore and at the support barge.

This project presented several problems: at first, the punch-out point occurred far from the planned target area.

Therefore, a new pilot hole had to be performed. The second bore hole collapsed during the reamer phase, and tools got

stuck but could be recovered. After that, a third bore hole was started. The third bore hole followed the planned path and

reached the target area. Even so, due to the bad weather and long time waiting for better conditions, the opened hole

started to collapse at the exit point. The exit point was partially repaired and the pullback operation was started. During

the pullback operation, the drill column and product pipe got stuck. It occurred remain only 300m to complete the

operation. With approximately 300 m of drill column and about 900 m of the product pipe inside the hole, numerous

efforts to release the entire column were considered, including the use of a big hammer at the offshore side to kick the

pipeline tail. In this scenario, at the same time that the shore rig pulled the column, the offshore rammer was used,

unfortunately without success. With the columns (drill column + product pipe) still stuck, there was also a new attempt

7

Rio Pipeline Conference & Exposition

of pulling using a third and larger drill rig, again without success. Once decided for the loss of the drill column and the

product pipe, a fourth bore hole was initiated. At the beginning of the fourth hole, an obstacle of great proportions was

found, an oversized concrete block, abandoned buried in the proximities of the new drill path. Therefore, a new drill

path was planned. And then, the fifth and last hole was started. This last attempt, 887m long, was accomplished in

record time, with absolute success, and the new product pipe was successfully installed.

Several lessons can be learned from this Project as presented in (Bernardi et al., 2009), a discussion of these

lessons and those from other projects will be presented further in this work.

4.4 Sul Capixaba gas Pipeline, 12 Praia do Alm / ES 2009

In 2009, once again HDD was selected to be used for shore approach in an environmental protection area, very

popular in summer seasons, with high tourism potential. The Alm beach was defined as the point of shore approach of

the Sul Capixaba gas pipeline, at Anchieta/ES. Again, this beach is a protected area due the sea turtles seasons. The

pipeline installation was defined to occur in a not populated area, without nearby facilities but with a large sand section

and rocks formations on the seabed. Figure 9 presents an overview of the HDD project and site. A 2km pipeline was

installed by the Seven Navica vessel, from Subsea7.

This HDD was successfully accomplished in record time, although a two weeks fishery that occurred due to

column break.

Figure 9 HDD at Alm beach, Sul Capixaba Gas Pipeline.

Additional information regarding to this project can be found in (Solano et al., 2007).

Discussions and Lessons Learnt

There are several advantages of the directional drilling installation method over alternative construction methods.

Environmental issues are minimized as operations are limited to relatively small areas when compared to the complete

crossing length as in other methods.

HDD provide an optimum depth of cover in the design of a crossing leading to maximum protection for the

pipeline from anchors and future dredging and reduces long-term maintenance costs. Beach erosion risks are minimized

and construction activities in surf zones can be avoided.

However, HDD is a very complex procedure not well understood by most contractors. Only few companies have

the required competence in this procedure. The experience the lessons from previous projects can be decisive for a

successful operation.

The main lessons that can be learnt from previous HDD shore approaches in Brazil are: there is mandatory a

detailed site investigation including geophysical, geological and geotechnical studies to proper understand the soil

characteristics. It is necessary to provide compatibility between geological and geotechnical investigations

(identification of soil discontinuities, fractures and features of the site). It is also mandatory to have complete and

detailed plans and procedures, including contingency scenarios. Attention shall be given to some issues in the design

phase: definition of important parameters, such as, bending radius, pipe stress analysis, equipment selection, geometry

and shape of hole, tracking and surveying, available equipments at the support barge, diving team, pipeline on-bottom

stability, risk analysis, etc. (Silva et al., 2009)

Sea states must also be considered in the planning for pipe fabrication and handling procedures. Tidal currents can

jeopardize a poorly stabilized or inadequately protected pipestring. For large diameter pipelines, the inherent

buoyancy of the pipe requires that special attention be applied to provide stability prior to installation and secure

handling during the pullback operation.

Rio Pipeline Conference & Exposition

The submerged weight of pipe in seawater is an important consideration. The submerged weight was sufficient for

on-bottom stability during lay and handling during the HDD operations. The buoyant weight of the pipeline in the

drilled hole is also a determining factor for pull force requirements and rig selection.

The logistical challenges associated with working in remote HDD locations are similar to those encountered on

shore approaches. Planning of the work and maintaining contingencies become very important processes.

A mechanical failure or delay during the pullback operation can be catastrophic. For shore approaches remedial

measures are generally more limited than those available onshore. As is always the case, the possibility of

recovering from a "stuck pipe" situation greatly diminishes with time. In a marine environment where currents or

tidal movement may be acting at the exit point, the time factor is of great importance since silting action is an

added risk.

There is no easy fast way to tackle rock formations. The task need to be performed using good quality tools in a

patient and controlled drilling operation. The initial increased outlay will nearly always be offset by the savings

through superior penetration rates, less tripping and decreased risk of tool failure (and subsequent fishing time).

It is impossible to prepare for every occurrence in a drilling activity. However an ability to quickly react in order to

change adverse conditions is vital. With this general thought in mind, brainstorming sessions during the planning

stage can often save time when a particular occurrence takes place.

Regarding to environmental matters, the licenses and permitions to work issues need to be considered in the

schedule. The licensing process in the oil segment consists of several stages. For each project, several licenses are

necessary, a Preliminary license as well as Installation and Operation licenses, to be issued the regulatory agencies. In

shore approach projects, there are always a municipal, a state and one or more federal agencies involved, acting in its

coverage area, whether onshore or offshore, according to the law. The project should estimate and considered the time

to obtain such licenses, based on the legislation and the complexity of the project. In some cases, additional studies can

also be required by such agencies prior issue of environmental licenses, which can cause a delay to the project.

Final Remarks

The HDD has the advantage of causing minimal intervention and disturbance at the beach when compared to other

alternatives to shore approach. It requires, however, some characteristics of the seabed in order to allow the necessary

marine operations. The HDD utilization in the Brazilian coast is increasing. Moreover, studies of on-bottom stability

associated with lift and drag forces acting on the pipelines as well as thermo-mechanical studies related to HT/HP

pipelines have pointed to important issues leading to the scenario of using horizontal directional drilling to cross the surf

zone due to the guarantee of stability and protection of the product pipe.

As discussed in this work a horizontal directional drilling shall not be started without an appropriated investigation

of the site. The selection of this method should be done only after the complete understanding of the geophysical

correlation with the geological and geotechnical data (with precise description of the different structural discontinuities,

associated fractures and features of the investigated area), to properly support the horizontal directional drilling design,

planning and execution.

Site investigation is the best investment in a HDD project. These investigations enable a suitable design for the

HDD profile. Of course, as any other method, to ensure a successful installation, a detailed procedure shall be prepared

for the operation, complying contingency procedures for all phases of the operation. And in general, when problems are

identified it is often too late to initiate corrective action.

Besides all potential problems, risks and challenges, HDD is foreseen as a very suitable and attractive method for

future shore approaches in Brazil.

References

Bernardi, T.P., Neto, V.A., Siqueira, J., 2009, Shore Approach of Camarupim Pipeline. Rio Pipeline Conference &

Exposition 2009, Rio de Janeiro, Brazil.

Duyvestyn, G., 2005, Design and Construction Challenges for HDD Shore Crossings. Proc. of No-Dig Conference,

North American Society for Trenchless Technology NASTT, Orlando, Florida, USA.

Silva, D.M.L., Souza Jr., H.A., DAngelo Aguiar, L.A., Souza, A.P.F., 2011, Challenges on Designing Pipelines for the

Brazilian Pre-Salt Scenarios. Rio Pipeline Conference & Exposition 2011, Rio de Janeiro, Brazil.

Silva, D.M.L., Rodrigues, M.V., Vens, A., Medeiros, A.R., 2009, Methodology for Definition of Bending Radius and

Pullback Force in HDD Operations. Rio Pipeline Conference & Exposition 2009, Rio de Janeiro, Brazil.

Rio Pipeline Conference & Exposition

Silva, D.M.L., Bahiense, R.A., Jacob, B.P., Torres, F.G.S., Medeiros, A.R., Costa, M.N.V., 2007, Analysis of a Lateral

Deflection Method for the Installation of an Offshore Pipeline. Rio Pipeline Conference & Exposition 2007, Rio de

Janeiro, Brazil.

Smith, N., 2003, Horizontal Directional Drilling (HDD) for Shore Approach Applications. Rio Pipeline Conference &

Exposition 2003, Rio de Janeiro, Brazil.

Solano, R.F., Genaio, M.C., Ayres, A., Cezar, G.S., 2007, Design and Installation Challenges of Jubarte Gas Pipeline

in the Shore Approach Area. International Offshore and Polar Engineering Conference ISOPE, July 16, 2007,

Lisbon, Portugal.

Solano, R.F., Azevedo, F.B., Vaz, M.A., Cardoso, C.O., 2004, Design and Installation of Buried Heated Pipelines at

the Capixaba North Terminal Offshore Brazil. 23rd International Conference on Offshore Mechanics and Arctic

Engineering OMAE, June 2025, 2004, Vancouver, British Columbia, Canada.

Azevedo, F.B., Solano, R.F., Hallai, J.F., Bomfimsilva, C.T.,, 2005, Final Design and Installation Constraints of a

Shallow Water Oil Pipelines at the Capixaba North Terminal Offshore Brazil. 24th International Conference on

Offshore Mechanics and Arctic Engineering OMAE 2005, June 1217, 2005, Halkidiki, Greece.

10

You might also like

- F. Master Catalog enDocument20 pagesF. Master Catalog enshaggy0078No ratings yet

- Separator GazeDocument4 pagesSeparator Gazestef11_127571No ratings yet

- Applied Thermal Engineering: SciencedirectDocument12 pagesApplied Thermal Engineering: SciencedirectGabriel Lopez BarajasNo ratings yet

- BTJ Book V1 N1 2008 FinalDocument228 pagesBTJ Book V1 N1 2008 Finalleonal626No ratings yet

- 15550Document2 pages15550khalid764No ratings yet

- HRSG Steam Velocity AnalysisDocument3 pagesHRSG Steam Velocity Analysisaliscribd46No ratings yet

- Avoidable Loads On Shell Steam Boiler SystemsDocument8 pagesAvoidable Loads On Shell Steam Boiler Systemsgeorgecis100% (1)

- What Is ISO Rating of Gas TurbinesDocument2 pagesWhat Is ISO Rating of Gas TurbinesAlvinmor100% (1)

- Performance Det in GTsDocument8 pagesPerformance Det in GTsAlpha BetaNo ratings yet

- Simulation of Nitrogen Liquefaction CycleDocument4 pagesSimulation of Nitrogen Liquefaction CycleBalaji Kumar ChoudhuryNo ratings yet

- Fisher Specification Manager SoftwareDocument4 pagesFisher Specification Manager SoftwarehrtoroNo ratings yet

- NTF-DS-CV-001 Data Sheet Control Valve Rev.BDocument4 pagesNTF-DS-CV-001 Data Sheet Control Valve Rev.BRicardo NapitupuluNo ratings yet

- H Section 1 Conventional Heat Generation Boiler General Description PDFDocument579 pagesH Section 1 Conventional Heat Generation Boiler General Description PDFNicolas Pallero FernandezNo ratings yet

- Pumps System March 2015Document108 pagesPumps System March 2015Anonymous YcAZv5qF67No ratings yet

- Optimization of Natural Gas Pipeline Design PDFDocument10 pagesOptimization of Natural Gas Pipeline Design PDFrasnowmah2012No ratings yet

- 2010 Issue2Document28 pages2010 Issue2sivakumar990No ratings yet

- DLT 1027-2006 工业冷却塔测试规程-enDocument30 pagesDLT 1027-2006 工业冷却塔测试规程-en郭允超No ratings yet

- Astm d2015 1996 PDFDocument11 pagesAstm d2015 1996 PDFJeffersonCárdenasNo ratings yet

- SEC A Bekasi Design SpecDocument20 pagesSEC A Bekasi Design Speccharleselitb92No ratings yet

- Manifold Vapor e CondensadoDocument4 pagesManifold Vapor e CondensadoAline Pires Dias RibeiroNo ratings yet

- Siemens: Made in GermanyDocument1 pageSiemens: Made in GermanyHatem MomaniNo ratings yet

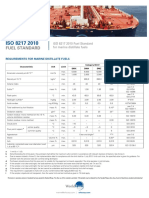

- ISO 8217 2010 Tables 1 Amp 2 1Document2 pagesISO 8217 2010 Tables 1 Amp 2 1Prashant Kumar SinghNo ratings yet

- HRSG DescriptionDocument25 pagesHRSG DescriptionFahim Kazmi100% (1)

- Steinmueller Broschuere 1Document46 pagesSteinmueller Broschuere 1andri.motoGNo ratings yet

- The Process Piping: Introduction To Ori Ce FlangeDocument6 pagesThe Process Piping: Introduction To Ori Ce FlangeMohamed AdelNo ratings yet

- MDF PropertiesDocument10 pagesMDF PropertiesFernandoNo ratings yet

- S BraneDocument16 pagesS Branemsr22No ratings yet

- Mont Belvieu, Texas Ethane Storage Hub: Warnings For AppalachiaDocument7 pagesMont Belvieu, Texas Ethane Storage Hub: Warnings For AppalachiaJames BruggersNo ratings yet

- 1 s2.0 S1226086X14001221 MainDocument6 pages1 s2.0 S1226086X14001221 MainJorge Rodriguez HerreraNo ratings yet

- Data Sheets Co2 SystemDocument56 pagesData Sheets Co2 SystemBolivarNo ratings yet

- Spe 194597 MS PDFDocument17 pagesSpe 194597 MS PDFMANISH GUPTANo ratings yet

- Power Magazine - July 2016Document73 pagesPower Magazine - July 2016sergey500No ratings yet

- Brochure LNG 2019Document6 pagesBrochure LNG 2019ddNo ratings yet

- 6.C.b Industrial Waste Incineration GB2009Document21 pages6.C.b Industrial Waste Incineration GB2009AgungGhaniKramawijayaNo ratings yet

- Design and Analysis of A Small-Scale Natural Gas Liquefaction Process N2 and CO2Document8 pagesDesign and Analysis of A Small-Scale Natural Gas Liquefaction Process N2 and CO2Williams Javier Ramos VasquezNo ratings yet

- Technologies For High Performance and Reliability of Geothermal Power PlantDocument4 pagesTechnologies For High Performance and Reliability of Geothermal Power Plantsum1else4No ratings yet

- Calentador Catalitico CATCODocument4 pagesCalentador Catalitico CATCOmauricio_rrNo ratings yet

- 2-1 Tech Spec Ashuganj R0Document181 pages2-1 Tech Spec Ashuganj R0Anup Mitra100% (1)

- Curvas de FuncionamientoDocument12 pagesCurvas de FuncionamientoENMANUELNo ratings yet

- Design and Analysis of Pressure Vessel Using PV Elite SoftwareDocument8 pagesDesign and Analysis of Pressure Vessel Using PV Elite SoftwareVitor OlivettiNo ratings yet

- Chebeir2019 PDFDocument16 pagesChebeir2019 PDFAndrea RodriguezNo ratings yet

- Colombia Oil Almanac V 0.9Document149 pagesColombia Oil Almanac V 0.9tatagalgo100% (1)

- PD - 8010 5 2015Document78 pagesPD - 8010 5 2015jasonNo ratings yet

- The Simulation of Natural Gas Gathering Pipeline NetworkDocument5 pagesThe Simulation of Natural Gas Gathering Pipeline Networkjeff_shawNo ratings yet

- Pipesys Tutor PDFDocument30 pagesPipesys Tutor PDFElmy Zola GintingNo ratings yet

- Brochure - Flownex Software Fired Heater Design PDFDocument11 pagesBrochure - Flownex Software Fired Heater Design PDFdatalogger123456No ratings yet

- Venture Global Calcasieu Pass, LLC Transcameron Pipeline, LLCDocument32 pagesVenture Global Calcasieu Pass, LLC Transcameron Pipeline, LLC1mmahoney100% (2)

- The Erosional Velocity EquationDocument2 pagesThe Erosional Velocity EquationAiman AzaharNo ratings yet

- Gas Turbines Technical PerformanceDocument2 pagesGas Turbines Technical PerformanceRoozbeh PNo ratings yet

- CASE STUDY-Rockwell PetroleumDocument2 pagesCASE STUDY-Rockwell Petroleumanurag10julyNo ratings yet

- BLOOM ENERGY Final PresentationDocument6 pagesBLOOM ENERGY Final PresentationAlagappan AngamuthuNo ratings yet

- Penjelasan TLEsDocument28 pagesPenjelasan TLEsFauzi IhsanNo ratings yet

- Indirect Heater - SchlumbergerDocument31 pagesIndirect Heater - SchlumbergerMarwenNo ratings yet

- Ipc2012 90620Document17 pagesIpc2012 90620Marcelo Varejão CasarinNo ratings yet

- Transat Particles in PipesDocument17 pagesTransat Particles in Pipesمحمد توفيق عراقيNo ratings yet

- Strength Calcul SheetDocument379 pagesStrength Calcul Sheetmustufa akolawalaNo ratings yet

- Performance Analysis of Combined Cycle Power Plants A Case Study PDFDocument11 pagesPerformance Analysis of Combined Cycle Power Plants A Case Study PDFJonatan Daniel ArangoNo ratings yet

- Incineration SolidWaste ManagementDocument16 pagesIncineration SolidWaste Managementsai ramanaNo ratings yet

- (Polish Maritime Research) Development of New Technologies For Shipping Natural Gas by SeaDocument9 pages(Polish Maritime Research) Development of New Technologies For Shipping Natural Gas by SeafarshidianNo ratings yet

- Oilfield Review Winter 2012Document60 pagesOilfield Review Winter 2012yips0001No ratings yet

- Poster Floating Offshore Tcm109 295523Document1 pagePoster Floating Offshore Tcm109 295523dmlsfmmNo ratings yet

- DNV OS-F101 - 2013-10 Submarine Pipeline SystemsDocument372 pagesDNV OS-F101 - 2013-10 Submarine Pipeline Systemsseantbt100% (1)

- DNV SB Offshorepipe Tcm109-282603Document10 pagesDNV SB Offshorepipe Tcm109-282603dmlsfmmNo ratings yet

- OMAE2013-10851: Pipeline Shore Approach Installation by Horizontal Directional DrillingDocument9 pagesOMAE2013-10851: Pipeline Shore Approach Installation by Horizontal Directional DrillingdmlsfmmNo ratings yet

- Go Strong.: Floating Offshore InstallationsDocument10 pagesGo Strong.: Floating Offshore InstallationsdmlsfmmNo ratings yet

- Poster Going Safer Tcm109-288080Document1 pagePoster Going Safer Tcm109-288080dmlsfmmNo ratings yet

- OMAE2012-8: Fatigue Life Analysis For A Steel Catenary Riser in Ultra-Deep WatersDocument5 pagesOMAE2012-8: Fatigue Life Analysis For A Steel Catenary Riser in Ultra-Deep WatersdmlsfmmNo ratings yet

- 1999 OMAE99 PIPE-5037 Bai - Bending Moment Capacity of PipesDocument13 pages1999 OMAE99 PIPE-5037 Bai - Bending Moment Capacity of Pipesdmlsfmm100% (1)

- 2002 DrillTec - Shore Approach by Way of Horizontal Directional DrillingDocument4 pages2002 DrillTec - Shore Approach by Way of Horizontal Directional DrillingdmlsfmmNo ratings yet

- Omae2013 10851Document9 pagesOmae2013 10851dmlsfmmNo ratings yet

- Pap 0354Document20 pagesPap 0354dmlsfmmNo ratings yet

- OMAE2008-57487: Pipeline-Laybarge Interaction Model For The Simulation of S-Lay Installation ProceduresDocument10 pagesOMAE2008-57487: Pipeline-Laybarge Interaction Model For The Simulation of S-Lay Installation ProceduresdmlsfmmNo ratings yet

- Dynamic Relaxation Procedures For The Definition of Initial Static Configurations of Flexible LinesDocument17 pagesDynamic Relaxation Procedures For The Definition of Initial Static Configurations of Flexible LinesdmlsfmmNo ratings yet

- Cil01 526Document12 pagesCil01 526dmlsfmmNo ratings yet

- RioPipeline2009 IBP1048 09Document8 pagesRioPipeline2009 IBP1048 09dmlsfmmNo ratings yet

- Flyer HDD JIP ProposalDocument2 pagesFlyer HDD JIP ProposaldmlsfmmNo ratings yet

- 2015 HDD SupDocument69 pages2015 HDD Supberroui100% (1)

- HDDDocument13 pagesHDDAshok SwamiNo ratings yet

- Abr Sinai Onshore Gas Pipeline PDFDocument42 pagesAbr Sinai Onshore Gas Pipeline PDFhamza2085100% (1)

- Thrust Force For Pipeline 3Document3 pagesThrust Force For Pipeline 3Raakze MoviNo ratings yet

- ASTT - Guidelines For Horizontal DirectiDocument45 pagesASTT - Guidelines For Horizontal Directiamir_hayfa100% (1)

- Palm Jumeirah: Building Material and ConstructionDocument19 pagesPalm Jumeirah: Building Material and ConstructionVanshika DograNo ratings yet

- DirectoryDocument34 pagesDirectoryVineet 01No ratings yet

- 33 05 07.13 Utility Horizontal Directional Drilling (HDD) - 201912201346448977Document11 pages33 05 07.13 Utility Horizontal Directional Drilling (HDD) - 201912201346448977Ayman ElMawardyNo ratings yet

- S Civ Cab - 00Document19 pagesS Civ Cab - 00HARINo ratings yet

- 2016 - MAG 608 - Horizontal Directional DrillingDocument6 pages2016 - MAG 608 - Horizontal Directional DrillingSen HuNo ratings yet

- Tipper Inspection CertDocument6 pagesTipper Inspection CertikponmwonsaNo ratings yet

- Tender EstimateDocument36 pagesTender Estimateamitkbharti6784No ratings yet

- S TR CIVIL CAB (Rev.0 2016) 1648785465976Document30 pagesS TR CIVIL CAB (Rev.0 2016) 1648785465976Vimala PonnusamyNo ratings yet

- Final ReportDocument19 pagesFinal ReportAbdul Azeez100% (1)

- Cost Analysis HDD PDFDocument89 pagesCost Analysis HDD PDFGeorgius Edo Sriputra Pratama100% (1)

- ASTT - Guidelines For Horizontal DirectiDocument45 pagesASTT - Guidelines For Horizontal DirectiFerdie TolosaNo ratings yet

- Trenchless Booklet A11yDocument22 pagesTrenchless Booklet A11yaz_zakiNo ratings yet

- A-Conventional Offshore Course - Part2pipelines and Risers PDFDocument99 pagesA-Conventional Offshore Course - Part2pipelines and Risers PDFMuhammad Geovani100% (3)

- HDDTB 15 PDFDocument4 pagesHDDTB 15 PDFdakidofdaboomNo ratings yet

- HDD Procedure - HDD PengaponDocument46 pagesHDD Procedure - HDD PengaponBubu Keke Caca100% (3)

- Pipeline Nadhir - Saudi AramcoDocument23 pagesPipeline Nadhir - Saudi Aramcowaseemiqbal133No ratings yet

- TR 46 HDD GuidelinesDocument78 pagesTR 46 HDD GuidelinesKhuram ShahNo ratings yet

- Cigre 398-Underground and Submarine Cables PDFDocument118 pagesCigre 398-Underground and Submarine Cables PDFsorry2qaz100% (3)

- Horizontal Directional Ground Investigation Reducing Tunnelling Risks by Minimising Geological UncertaintyDocument16 pagesHorizontal Directional Ground Investigation Reducing Tunnelling Risks by Minimising Geological UncertaintyfreezefreezeNo ratings yet

- HDD Hk250t enDocument2 pagesHDD Hk250t enuriNo ratings yet

- HDD - Method Statement-Newest June 19, 2017Document7 pagesHDD - Method Statement-Newest June 19, 2017Niyas PulpadanNo ratings yet

- No Dig Technology PptsDocument29 pagesNo Dig Technology PptsDeep ShahNo ratings yet

- DriscoPlex 4100 HDPE PDFDocument16 pagesDriscoPlex 4100 HDPE PDFMarquinho LsNo ratings yet

- Trenching For Underground CablesDocument25 pagesTrenching For Underground CablesSpyros Linaras100% (1)

- Under Ground CablesDocument25 pagesUnder Ground CablesBadri Harish100% (2)