Professional Documents

Culture Documents

WPQR WPSAmerica

Uploaded by

César Augusto Quiroga MontenegroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WPQR WPSAmerica

Uploaded by

César Augusto Quiroga MontenegroCopyright:

Available Formats

Welding Performance Qualification Record (WPQR)

Welding Code: AWS D1.1

Company Name: WPSAmerica.com

Company Address: info@WPSAmerica.com, 1 (877) WPS-WELD

Welders Name: Elvis Tom Jones

Identification No: ETJ-2005

Type of welder: Welder

Welding Performance Qualification Record WPQR No. DEMO-SMAW-WPQR

Welding Procedure Specification WPS No. DEMO-SMAW-WPS

Qualification Date: 12, 12, 2005

Rev. 0

BASE METALS USED

Material Specification, Type or Grade: ASTM A 36

Welded to

Material Specification, Type or Grade: ASTM A 36

Variables

Welding Process

Process Type

Electrode (Single or Multiple)

Current Type/Polarity

Backing (Yes or No)

Testing Position(s) and Qualified Welding Position(s):

Groove

Fillet

Vertical Progression

Plug or Slot Welds

Base Metals Thickness in (mm):

Groove

Fillet

Plug or Slot Welds

Base Metals Diameter in (mm) (Pipe or Tube):

Groove

Fillet

Filler Metal Specification (SFA)

Filler Metal Classification (AWS Classified)

Filler Metal F-Number

Gas/Flux (SAW)

Other Variable (coating type/thickness, etc.)

Plate

Pipe

Box Tube

Sheet

Plate

Pipe

Box Tube

Sheet

Actual Values Used

SMAW

Manual

Single

DCEP

Without backing

Qualification Range

SMAW

Manual

Single

2G on Plate

F, H

F, H

n/a

F

With or without

n/a

3/8 in. (10 mm)

1/8 in. (3 mm) to 3/4 in. (20 mm)

Unlimited

Qualified

Plate tested

24 in. (600 mm) OD and over

24 in. (600 mm) OD and over

A5.1

E7018

4

n/a

n/a

Any AWS A5 Class Approved

4, 3, 2, 1

n/a

n/a

Results

Visual Inspection of Completed Weld (D1.1, 4.9.1): Acceptable

YES

NO

Guided Bend Test Type and Results (D1.1, 4.31.5): One Root and One Face Bend Specimens

Result and Comments: Acceptable criteria based on AWS D1.1, Clause 4.8.3.3 measured values

Fillet-Weld Test Results (D1.1, 4.31.2.3 and 4.31.4.1):

Appearance: n/a

Fillet Size in (mm): n/a

Fracture Test Root Penetration: n/a

Macroetch: n/a

(Describe the location, nature, and size of any crack or tearing of the specimen.)

Result and Comments: Groove weld test qualifies fillet weld test as well

Inspected by: Tom Jones, AWS Certified Welding Inspector (CWI)

Test Number: 1012-Stick

Organization: Testing Lab Data, Inc.

Date: 12, 12, 2005

Alternative * Radiographic Test Results (D1.1, 4.31.3.2) : * In lieu of Guided Bend Test, except for GMAW-S

Film Identification No.

n/a

n/a

Results

n/a

n/a

Remarks

n/a

n/a

Film Identification No.

n/a

n/a

Results

n/a

n/a

Remarks

n/a

n/a

Film interpreted by: n/a

Test Number:

Organization:

Date:

Other information: Guide bend test conducted instead of RT. This WPQR demo form has been created by WPSAmerica.com Online Welding Software

We, the undersigned, certify that the statements in this record are correct and that the test welds were prepared, welded, and tested in conformance with the

requirements of Clause 4 of AWS D1.1/D1.1M:2010, Structural Welding Code-Steel.

Manufacturer/ Contractor

Authorized By:

Welding Engineer

Name: Joe Smith

Title: Welding Engineer

Signature: J. S.

Date: 14, 12, 2005

Name: James Bond

Title: QA Manager

Signature: J. B.

Date: 14, 12, 2005

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- How To Read A Load Chart - Crane Charts For All Crane Makes & Models PDFDocument4 pagesHow To Read A Load Chart - Crane Charts For All Crane Makes & Models PDFCésar Augusto Quiroga MontenegroNo ratings yet

- Aws Bookstore. Whb-5.9 Welding Handbook..Document2 pagesAws Bookstore. Whb-5.9 Welding Handbook..César Augusto Quiroga Montenegro0% (1)

- Educational Services - ES 11b ASME Section V - 1 Day - Rev May 2015Document2 pagesEducational Services - ES 11b ASME Section V - 1 Day - Rev May 2015César Augusto Quiroga MontenegroNo ratings yet

- 924 GDocument32 pages924 Gfitokayak100% (1)

- Cmaa Safety PDFDocument2 pagesCmaa Safety PDFAbraham Valeriano ChavezNo ratings yet

- How To Read A Load ChartDocument7 pagesHow To Read A Load ChartCésar Augusto Quiroga MontenegroNo ratings yet

- ASME Training and Development-Spring-CalenderDocument11 pagesASME Training and Development-Spring-CalenderCésar Augusto Quiroga MontenegroNo ratings yet

- Welding InspectionDocument40 pagesWelding InspectionnazarasimNo ratings yet

- Tabla Caracteristicas Hiab Xs 322 Ep5 HiduoDocument1 pageTabla Caracteristicas Hiab Xs 322 Ep5 HiduoCésar Augusto Quiroga MontenegroNo ratings yet

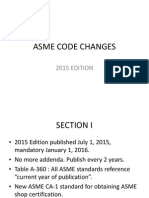

- Asme Code Changes: 2015 EDITIONDocument19 pagesAsme Code Changes: 2015 EDITIONInnocent RabiosaNo ratings yet

- Comite ModelDocument1 pageComite ModelCésar Augusto Quiroga MontenegroNo ratings yet

- TIP S de AutoCADDocument3 pagesTIP S de AutoCADCésar Augusto Quiroga MontenegroNo ratings yet

- Tabla Carga Hiab Xs 322 Ep5 HiduoDocument1 pageTabla Carga Hiab Xs 322 Ep5 HiduoCésar Augusto Quiroga MontenegroNo ratings yet

- The American Society of Mechanical Engineers - ASMEDocument3 pagesThe American Society of Mechanical Engineers - ASMECésar Augusto Quiroga MontenegroNo ratings yet

- Caracteristicas Hiab Xs 322 Ep5 HiduoDocument1 pageCaracteristicas Hiab Xs 322 Ep5 HiduoCésar Augusto Quiroga MontenegroNo ratings yet

- D1 Committee On Structural Welding - Te..Document1 pageD1 Committee On Structural Welding - Te..César Augusto Quiroga MontenegroNo ratings yet

- 20150823Document1 page20150823César Augusto Quiroga MontenegroNo ratings yet

- AWS D1.1 - Arjan Roza PDFDocument35 pagesAWS D1.1 - Arjan Roza PDFCésar Augusto Quiroga MontenegroNo ratings yet

- Caracteristicas Hiab Xs 322 Ep5 HiduoDocument1 pageCaracteristicas Hiab Xs 322 Ep5 HiduoCésar Augusto Quiroga MontenegroNo ratings yet

- Readme - EulaDocument2 pagesReadme - EulaCésar Augusto Quiroga MontenegroNo ratings yet

- HR Chapter 14Document16 pagesHR Chapter 14César Augusto Quiroga MontenegroNo ratings yet

- 5723 540-200 Brochure Issue 1Document12 pages5723 540-200 Brochure Issue 1Alexsandro CordeiroNo ratings yet

- Especificaciones DB x35Document2 pagesEspecificaciones DB x35César Augusto Quiroga MontenegroNo ratings yet

- 500e Product GuideDocument8 pages500e Product GuideCésar Augusto Quiroga MontenegroNo ratings yet

- AsmeDocument2 pagesAsmeCésar Augusto Quiroga MontenegroNo ratings yet

- OSHA ChecklistDocument2 pagesOSHA ChecklistCésar Augusto Quiroga MontenegroNo ratings yet

- Especificaciones DB x35Document2 pagesEspecificaciones DB x35César Augusto Quiroga MontenegroNo ratings yet

- Law Is The Operating System of Our Society. So Show Me The Manual!Document2 pagesLaw Is The Operating System of Our Society. So Show Me The Manual!César Augusto Quiroga MontenegroNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)