Professional Documents

Culture Documents

Weld Poster Explaination

Weld Poster Explaination

Uploaded by

Ahmed Abo ElkomsanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Weld Poster Explaination

Weld Poster Explaination

Uploaded by

Ahmed Abo ElkomsanCopyright:

Available Formats

Weld poster Explanation

Eric Sawyer

11/2/2015

Permissible stresses in welds

The permissible stress in welds is based on the American Institute of Steel Construction

(AISC) building codes. AISC uses the yield strength to determine the max allowable

stress. The comparable safety factors are also shown in the chart. These are minimum

safety factors and maximum stress conditions. These permissible stresses could be used

to determine the necessary size of the weld. If the fillet weld is loaded in torsion the

following equations can then be back solved to find either the length or leg height of the

weld.

'

V

A

''

Mr

J

J .707 h Ju

The primary and secondary shear stress must be combined to obtain a total shear stress

this will equal the max allowable shear stress. Then h can be found which is the leg

height of the weld. Length of the weld is imbedded in Ju. Values of Ju can be found in

table 9-2 (Shigley, page 392).

For fillet welds in bending:

My

I

.707 h Iu

The stress is again known from the permissible shear stress calculation. The leg length

(h) or other weld dimensions can then be solved for. Length of weld and/or distance

between welds are again imbedded in Iu. Values of Iu can be found in table 9-3 (Shigley,

page 396-397).

Type of loading

Tension

Bearing

Bending

Simple compression

shear

Type of weld

Butt

Butt

Butt

Butt

Butt or fillet

Permissible stresses

0.60Sy

0.90Sy

0.60-0.66Sy

0.06Sy

0.40Sy

Safety factor (n)

1.67

1.11

1.52-1.67

1.67

1.44

Stress Concentration Factors in Welds

Stress concentration factors should be use for parent metal as well as weld. There is often

a trade off between stress concentration and over all size of weld. As the size of the weld

grow so does the strength; unfortunately so dose the stress concentration, so the over all

strength may be about the same. It is more important however, to focus design of weld

process and components based on time and economic factors rather than machinability.

For a reinforced butt weld the reinforcement on the top of the weld will increase the

throat area thus decreasing stress in the weld. However, the stress concentration factor at

the edge of the weld may negate any advantages gained from the reinforcement.

Therefore it may be equal as strong to make a flat weld with out the reinforcement and

Weld Poster

Sawyer

with out the stress concentration. The same idea applies to the T-butt (fillet) weld. If the

fillet weld is done in such a way to have a very concave shape the transitions will be

much more gradual and the stress concentration less. However as the weld becomes

more concave in shape the throat area becomes less and the stress then increases.

Post Weld Processes

Welding always causes some distortion, shrinkage or warpage along with changes to the

micro-structure of the parent material. Welding processes can be grouped into two levels;

common welds and critical welds. Common welds are still very high quality welds.

However for such situations other factors drive the design (such as deflection) so the

stress safety factor is quite high by the time the deflection is with in limits. Such would

include welds on vehicles frames, bridges, buildings and steam pipes. Most welds fall

into this category. For such applications a full re-heat-treatment of part after welding is

impractical to impossible. The best post weld procedure for this level of welds is stress

relieving. Critical welds would be welds subjected to very high stresses or weld on very

exotic material. After the weld process is done the entire part is re-heat-treated (heat,

quench, temper) so the weld and heat affected zone is restored to the properties of the

parent metal. Such processes are slow, expensive and performed in only the most crucial

applications.

Post weld processes temperatures will differ depending on the composition of the

material. The specific processes/temperatures on the chart should be acceptable for

common, low carbon, mild steels.

Process

Stress Relieving

(mild steel)

Stress Relieving

(alloy steel)

Stress Relieving

(Al alloys)

Annealing

(most steels)

Normalizing

(most steels)

Procedure

Heat to approximately 1125F then

slow cool (50F per hour) back to

room temperature

Heat to a temperature well below the

temper temperature for the particular

steel

Heat to a temperature well below the

age temperature for the particular

aluminum

Heat to austenite, slow cool (50F per

hour) back to room temperature

Heat to austenite, quench in room

temperature air

Effects

Reduce or eliminate residual stresses caused by

distortion and shirking from welding process

No micro-structural changes

Eliminate all effects of heat treatment or cold

work due to manufacturing or welding

Return material to softest weakest condition but

increase % elongation and ductility

Increases tensile and yield strengths but decreases

ductility

You might also like

- Hydrogen CrackingDocument9 pagesHydrogen CrackingMuhammed SulfeekNo ratings yet

- QRA Frequency AnalysisDocument17 pagesQRA Frequency AnalysisDaniel Tham100% (1)

- SS 564-1-2013 - PreviewDocument11 pagesSS 564-1-2013 - PreviewDaniel ThamNo ratings yet

- Prevention and Control of Weld DistortionDocument7 pagesPrevention and Control of Weld DistortionHouman HatamianNo ratings yet

- Welding Technology - Pre and Post Weld Heat TreatDocument19 pagesWelding Technology - Pre and Post Weld Heat TreatNowsherwan MazariNo ratings yet

- 4.3. Residual Stresses and Distortion in WeldmentsDocument11 pages4.3. Residual Stresses and Distortion in WeldmentsprokulisNo ratings yet

- Miller - 2010 Welding Heavy Structural Steel SucessfulyyDocument15 pagesMiller - 2010 Welding Heavy Structural Steel SucessfulyyLleiLleiNo ratings yet

- Weld DistortionDocument5 pagesWeld DistortionNSunNo ratings yet

- Welding Steel and TankDocument39 pagesWelding Steel and Tankprasanth bhadranNo ratings yet

- Distortion in Aluminum Welded StructuresDocument3 pagesDistortion in Aluminum Welded StructuresRaron1No ratings yet

- Weld Distortion: Application Stories Process and Theory Welding How-To'S Welding Projects Welding Solutions YoutubeDocument12 pagesWeld Distortion: Application Stories Process and Theory Welding How-To'S Welding Projects Welding Solutions Youtubevampiredraak2712No ratings yet

- Design of Permanent JointsDocument80 pagesDesign of Permanent JointsRayan IsranNo ratings yet

- Hossam Mahmoud Ahmed No. 28: Faculty of Engineering. Naval Architecture and Marine Engineering DepartmentDocument14 pagesHossam Mahmoud Ahmed No. 28: Faculty of Engineering. Naval Architecture and Marine Engineering Department5030099No ratings yet

- Welding SlidesDocument334 pagesWelding SlidesAsad Bin Ala Qatari100% (13)

- Tack Weld, Soldadura ApuntaladorDocument5 pagesTack Weld, Soldadura ApuntaladorLora BoydNo ratings yet

- Prevention and Control of Weld Distortion: Print This PageDocument6 pagesPrevention and Control of Weld Distortion: Print This PageNguyễn Hữu TrungNo ratings yet

- Intoduction To WeldingDocument334 pagesIntoduction To WeldingAsad Bin Ala QatariNo ratings yet

- Fatigue DesignDocument4 pagesFatigue DesignVikas MouryaNo ratings yet

- Fatigue TestingDocument10 pagesFatigue TestingMuhammed SulfeekNo ratings yet

- PWHTDocument3 pagesPWHTZakariya SaifNo ratings yet

- Print WebDocument15 pagesPrint Webaries andhikaNo ratings yet

- Residual Stress in SteelDocument14 pagesResidual Stress in SteelAhmed BdairNo ratings yet

- TGN-D-04 Distortion Control in ShipbuildingDocument9 pagesTGN-D-04 Distortion Control in ShipbuildingKomkamol ChongbunwatanaNo ratings yet

- Elimination of Bowing Distortion in Welded StiffenersDocument8 pagesElimination of Bowing Distortion in Welded StiffenersHaris HartantoNo ratings yet

- Weld Distortion ControlDocument4 pagesWeld Distortion ControlMaria MantillaNo ratings yet

- Friction Welding: Presented By: Kapil Mahajan Ankit Dua SandeepDocument42 pagesFriction Welding: Presented By: Kapil Mahajan Ankit Dua SandeepSandeep ThakurNo ratings yet

- Application of Weldment Fatigue Methods To Conveyors Pulley DesignDocument6 pagesApplication of Weldment Fatigue Methods To Conveyors Pulley DesignIgor San Martín PeñalozaNo ratings yet

- Aug10 SteeSteellwise WebDocument3 pagesAug10 SteeSteellwise Webeng_ahmed_666No ratings yet

- Extended End-Plate Stiffener Torsional and Flexural-Torsional BucklingDocument2 pagesExtended End-Plate Stiffener Torsional and Flexural-Torsional BucklingsteelageNo ratings yet

- Chapter 2Document6 pagesChapter 2udomNo ratings yet

- Distortion WELDINGDocument106 pagesDistortion WELDINGshruthi100% (1)

- FSW of Aluminium AlloysDocument45 pagesFSW of Aluminium AlloysAlexandre Lourenção CaselattoNo ratings yet

- Paper From SDI (Structural Deck Institute) WWDocument9 pagesPaper From SDI (Structural Deck Institute) WWkiss_59856786No ratings yet

- ASME-Notch-Toughness & Supplementary Essential VariablesDocument16 pagesASME-Notch-Toughness & Supplementary Essential VariablesSuleyman Halicioglu100% (2)

- Distortion Prevent and ControlDocument14 pagesDistortion Prevent and ControlTheAnh TranNo ratings yet

- Design Part 2 - TWIDocument9 pagesDesign Part 2 - TWIFreddie KooNo ratings yet

- Reduction of Residual StressDocument19 pagesReduction of Residual StressSteve HornseyNo ratings yet

- Swi Q7 & UpDocument10 pagesSwi Q7 & UppaulNo ratings yet

- 17-Residual Stress and DistortionDocument20 pages17-Residual Stress and DistortionSaif UllahNo ratings yet

- Simple Welded ConnectionDocument24 pagesSimple Welded ConnectionUtkarsh VermaNo ratings yet

- 7.1 Conventional Approaches To Design Against Brittle FractureDocument7 pages7.1 Conventional Approaches To Design Against Brittle FracturemjinspectorNo ratings yet

- AB Forging EngDocument24 pagesAB Forging EngtetirichieNo ratings yet

- Pipe Stress AnalysisDocument15 pagesPipe Stress AnalysispvmssonNo ratings yet

- 10 Residual StressDocument21 pages10 Residual StressAlaaNo ratings yet

- Present G.M.Document6 pagesPresent G.M.10march1965No ratings yet

- The Use of Heheat Straightening To Repair Damaged Steel StructuresDocument38 pagesThe Use of Heheat Straightening To Repair Damaged Steel Structuresjeanpaul CAYTANNo ratings yet

- FAILUREDocument5 pagesFAILUREMidhun K ChandraboseNo ratings yet

- Twi Fatigure TestingDocument13 pagesTwi Fatigure TestingchungndtNo ratings yet

- Introduction CHAPTER 1Document12 pagesIntroduction CHAPTER 1Sp PatelNo ratings yet

- Pipe Stress AnalysisDocument10 pagesPipe Stress AnalysisilayarasanNo ratings yet

- College of Education Akwanga, Nasarawa StateDocument14 pagesCollege of Education Akwanga, Nasarawa StatePilgrim KaterNo ratings yet

- Residual StressDocument10 pagesResidual StressbalamuruganNo ratings yet

- 1 What Causes Distortion?: Longitudinal ShrinkageDocument21 pages1 What Causes Distortion?: Longitudinal Shrinkage4romi89No ratings yet

- Eliminating Post-Weld Heat Treatment in Repair Welding by Temper Bead TechniqueDocument9 pagesEliminating Post-Weld Heat Treatment in Repair Welding by Temper Bead TechniqueSyarief NahdiNo ratings yet

- Final ProjDocument107 pagesFinal ProjNaveen KumarNo ratings yet

- 4443 31846 1 PB PDFDocument6 pages4443 31846 1 PB PDFshahgardezNo ratings yet

- 3welding AllDocument82 pages3welding AlljyothilalNo ratings yet

- PHD Thesis On Friction Stir WeldingDocument8 pagesPHD Thesis On Friction Stir Weldingdnnsgccc100% (1)

- A1010 WeldingDocument20 pagesA1010 WeldingCurious RajNo ratings yet

- Friction Stir Welding of 2XXX Aluminum Alloys including Al-Li AlloysFrom EverandFriction Stir Welding of 2XXX Aluminum Alloys including Al-Li AlloysNo ratings yet

- Kimmeridge Why KimmeridgeDocument16 pagesKimmeridge Why KimmeridgeDaniel ThamNo ratings yet

- Putin The Past Behind: Ge3244 Oil Barrel ProjectDocument51 pagesPutin The Past Behind: Ge3244 Oil Barrel ProjectDaniel ThamNo ratings yet

- Furnace Event Tree: True True True True True True True True True TrueDocument1 pageFurnace Event Tree: True True True True True True True True True TrueDaniel ThamNo ratings yet

- Safeti Assignment ConsequenceDocument18 pagesSafeti Assignment ConsequenceDaniel ThamNo ratings yet

- QRA Individual Assignment - Frequency Analysis (Daniel Tham)Document17 pagesQRA Individual Assignment - Frequency Analysis (Daniel Tham)Daniel ThamNo ratings yet

- Safeti AssignmentDocument45 pagesSafeti AssignmentDaniel ThamNo ratings yet

- 10 - DNV Safeti AwarenessDocument126 pages10 - DNV Safeti AwarenessDaniel ThamNo ratings yet

- Joy To The World C 20111217Document1 pageJoy To The World C 20111217Daniel ThamNo ratings yet

- SH5109 - 0 Module Information - Biostatistics EpidemiologyDocument10 pagesSH5109 - 0 Module Information - Biostatistics EpidemiologyDaniel ThamNo ratings yet

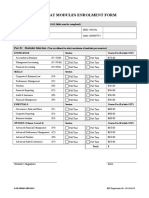

- ACCA CAT Modules Enrolment Form 30jun15Document1 pageACCA CAT Modules Enrolment Form 30jun15Daniel ThamNo ratings yet