Professional Documents

Culture Documents

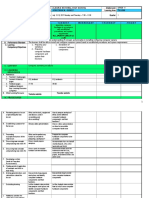

SEW Drive Engineering: Produkttraining Type Codes

SEW Drive Engineering: Produkttraining Type Codes

Uploaded by

Rufoman22Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SEW Drive Engineering: Produkttraining Type Codes

SEW Drive Engineering: Produkttraining Type Codes

Uploaded by

Rufoman22Copyright:

Available Formats

Produkttraining

SEW drive engineering

Type Codes

I3

Preface

These documents have been prepared to supplement the information

provided in the training. However, the combination of exercises followed by

proposed solutions means that they are also suitable for private study.

These documents supplement the documentation available from SEW. They

have been prepared as conscientiously as possible. We do not accept any

liability for mistakes. Equally, we cannot accept liability for any damage or

follow-on damage resulting from mistakes.

Please do not hesitate to contact the authors if you have any questions or

suggestions.

Persons responsible: DriveAcademy Product Training +49 7251 75-3911

Produkttraining

14.03.2008

Inhalt

1.

1.1

1.2

1.3

1.4

1.5

Standard Gearmotors

Standard Gear Units

Components on the input side

Standard Motors

Motor Options

DR Standard Motors with Options

1

2

4

6

8

10

2.

2.1

2.2

2.3

Motor Options

Brake Rectifiers

Motor Feedback Systems

Motor Plug Connectors

12

12

16

18

3.

Condition Monitoring

20

4.

4.1

4.2

Servo Gearmotors

Servo Gear Units

Synchronous Motors

22

22

26

5.

5.1

5.2

5.3

5.4

5.5

5.6

Industrial Gear Units

MC Series

M Series

CN Series

P Series Planetary Gearmotor

Q Series Planetary Gearmotor

X - Series Helical and Bevel-Helical Gear Units

28

29

30

31

32

33

34

6.

6.1

6.2

6.3

6.4

6.5

6.6

6.7

6.8

6.9

6.10

6.11

6.12

6.13

Dezentrale Installation

MOVIMOT Standard

MOVIMOT D Standard

MOVIMOT MD

MOVIMOT Options

MOVIMOT with AS-Interface

MOVI-SWITCH

Field Distributor

Bus Interfaces

Modular Terminal Box

MOVITRANS

MOVIFIT

MOVIPRO

MOVIGEAR

36

36

38

40

41

46

48

50

56

60

62

70

73

74

7.

7.1

7.2

7.3

MOVITRAC Inverter Range

MOVITRAC 31C

MOVITRAC 07A

MOVITRAC B

76

76

77

78

8.

8.1

8.2

8.3

MOVIDRIVE Inverter Range

MOVIDRIVE MDX..A

MOVIDRIVE compact MCX..A

MOVIDRIVE MDX..B

80

80

82

84

9.

MOVIAXIS Servo Inverter

86

10.

Controller MOVI-PLC basic and advanced

88

11.

11.1

11.2

11.3

11.4

11.5

Safety Technology MOVISAFE

Drive Technology with Integrated Safety Technology

Safety Technology Decentralized Installation

Safety Technology Servo

Modular Safety Monitor MOVISAFE

Electromechanics and Mechanics

91

91

92

96

96

97

12.

DOP Operator Panels

13.

Braking Resistors

100

14.

EMC

102

Produkttraining

98

14.03.2008

1.

1.

Standard Gearmotors

Standard Gearmotors

The unit designation of the gearmotor starts from the components on the

output end.

R97 CV132S4 /BMG/HR/TF/AV1H/IS

SEW motor options

SEW standard motor

SEW standard gear unit

R97

Produkttraining

CV132S4/BMG/HR/TF/AV1H/IS

14.03.2008

1.

1.1

Standard Gearmotors

Standard Gear Units

Helical-worm gear unit:

S gear unit

Helical-bevel gear unit:

K gear unit

Spiroplan gear unit:

W gear unit

Helical gear unit:

R gear unit

Parallel-shaft helical gear unit:

F gear unit

Overhead conveyor gear unit:

H gear unit

Produkttraining

14.03.2008

1.

Standard Gearmotors

R

gear unit design

07 to 187 Gear unit size

B Foot-mounted version

G Rubber buffer

T Torque arm

R Reduced backlash version

gear unit design

07 to 187 Gear unit size

B Foot-mounted version

G Rubber buffer

T Torque arm

R Reduced backlash version

gear unit design

07 to 187 Gear unit size

B Foot-mounted version

G Rubber buffer

T Torque arm

R Reduced backlash version

gear unit design

0 Standard design overhead trolley

system

1 Reinforced design overhead trolley

system

07 to 187 - Gear unit size

F Flange-mounted version

Z Flange-mounted version B14

gear unit design

3 to 6 gear unit size overhead trolley

system

07 to 187 Gear unit size

No letter - Foot-mounted version

X Single-stage foot-mounted

version

F Flange-mounted version

M Extended bearing hub

A Hollow shaft

H Hollow shaft with shrink disc

V Multiple-spline version

T TorqLOC clamping joint

K Helical-bevel gear unit

S Helical-worm gear unit

W Spiroplan gear unit

gear unit type:

R

F

K

S

W

H

Produkttraining

Helical gear unit

Parallel-shaft helical gear unit

Helical-bevel gear unit

Helical-worm gear unit

Spiroplan gear unit

Overhead conveyor gear unit

14.03.2008

1.

1.2

Standard Gearmotors

Components on the input side

AD

AR/W

AD/ZR

AR/WS

Input cover

Adapter with torque limiting coupling and speed monitor

Input cover with centering shoulder

Adapter with torque limiting coupling and slip monitor only in

combination with VARIBLOC variable speed gear unit

AD/RS

Input cover with backstop

/W

Speed monitor

AD/P

Input cover with motor mounting platform

/WS

Slip monitor

AM

Adapter for mounting IEC/NEMA motors

AT

Adapter with hydraulic centrifugal coupling

AQ

Adapter for mounting servomotors AT/RS adapter with hydraulic

centrifugal coupling and backstop

AR

Adapter with torque limiting coupling AT/BM(G) adapter with

hydraulic centrifugal coupling and disk brake

Produkttraining

14.03.2008

1.

Standard Gearmotors

MK Swing Base

MK _ _ _ _ _ _ MTS

MTS Mechanical thermal monitoring unit

BTS Proximity-type thermal monitoring unit

T

Torque arm

Coupling size

Gear unit size

Swing base

Produkttraining

14.03.2008

1.

Standard Gearmotors

1.3

Standard Motors

Asynchronous motors

foot-mounted DT../ DV..

flange-mounted DFR.., DFT../ DFV..

DAS.. AC aseptic motors

Asynchronous-synchronous motors

foot-mounted CT../ CV..

flange-mounted CFT.., CFV..

Further motor types:

- Explosion-proof motors:

- Efficiency motors:

- Single-phase motors:

- Torque motors:

eDFT/eDFV..

DTE/DVE..

EFR/EFT/EFV..

MFT/MFV..

Example: DT80N4

80 = Shaft height h = Motor size

N4 = 4-pole performance class

Produkttraining

14.03.2008

1.

Standard Gearmotors

S D F T 90 L 8/2

Performance class

D/K/L/LS/M/ML/N/S

Pole

2/4/6/8/4-2/6-2/8-2/12-2/6-4/8-4/

Size

56/63/71/80/90/100/112/132/160/180/200/225/250/280/

Performance class

D/K/L/LS/M/ML/N/S

Pole

2/4/6/8/4-2/6-2/8-2/12-2/6-4/8-4/

Design

F - Flange-mounted design (optional, only for motors

without gear unit)

Additional features (optional)

E - Energy-efficient motors

Size

56/63/71/80/90/100/112/132/160/180/200/225/250/280/

Performance class

D/K/L/LS/M/ML/N/S

Pole

2/4/6/8/4-2/6-2/8-2/12-2/6-4/8-4/

Development status

T - Size 56 and 71-100

V - Size 100-225

R - Size 63

Additional features (optional)

E - Energy-efficient motors

Size

56/63/71/80/90/100/112/132/160/180/200/225/250/280/

Performance class

D/K/L/LS/M/ML/N/S

Development status

T - Size 56 and 71-100

V - Size 100-225

R - Size 63

Version

F - Flange-mounted version (optional, only for motors

without gear units)

AS - Aseptic

Size

56/63/71/80/90/100/112/132/160/180/200/225/250/280/

Additional features (optional)

E - Energy-efficient motors

Development status

T - Size 56 and 71-100

V - Size 100-225

R - Size 63

Motor type

D - AC asynchronous motor

C - Asynchronous servomotor

M - Torque motor

E - Single-phase motor

Version

F - Flange-mounted version (optional, only for motors

without gear units)

AS - Aseptic

Motor type

D - AC asynchronous motor

C - Asynchronous servomotor

M - Torque motor

E - Single-phase motor

Additional features (optional)

S - Smooth pole changing (only for 6/2 and 8/2pole

motors, size 90 to 132S, standard here)

e - Explosion-proof motors in unit categories

II2G and II2D

Produkttraining

14.03.2008

1.

Standard Gearmotors

1.4

Motor Options

Further options:

RS

Z

LN

C

Backstop

Additional flywheel mass (flywheel fan)

Low Noise fan guard

Protection canopy for fan guard

VR

VS

VE

V

UWU51A

24 VDC forced cooling fan

1x 230 V forced cooling fan

Explosion-proof 1x 230 V forced cooling fan

3x 400 V forced cooling fan

Switched-mode power supply for VR forced cooling fan

(1x 230V input voltage 24VDC output voltage)

Non-ventilated

RH1M

RH1L

Resolver

Resolver for brakemotors

KK

KK5

KK6

Terminal box

Terminal box for radial encoder

Terminal box for axial encoder

Produkttraining

14.03.2008

1.

Standard Gearmotors

BMG /HR /TF /AV1H /IS

IS

Integrated plug

connector motor

AV1H Motor encoder

TF

TH

Temperature sensor

Thermostat

bimetallic switch

KTY

Temperature sensor with

almost linear

characteristic curve

PT100 Temperature sensor

linear characteristic

curve

HR

HF

-T

Manual brake release,

automatically

disengaging

Manual brake release,

lockable

Stage brake

BMG/BM/B/BR/BC/BP disk

brakes

Produkttraining

14.03.2008

1.

1.5

Standard Gearmotors

10

DR Standard Motors with Options

Asynchronous motors

Foot-mounted design

Flange-mounted design

Foot and flangemounted design

Example: DRS112M4

112

112 = shaft height in mm = motor size

M4 = length M, 4-pole

Produkttraining

14.03.2008

1.

Standard Gearmotors

11

DR S 132 M C 4 BE11 HR /FG /TF /Z /DUB

Brake monitoring options

DUB Function, wear,

or function and wear monitoring

Further options (added with "/")

Z

Flywheel fan

AL

Metal fan

V

Forced cooling fan

U

Non-ventilated

OL

Non-ventilated, closed B side

C

Protection canopy for fan guard

LF

Air filter

RS

Backstop

DH

Condensation drain hole

2W

2. shaft end

ERF Reinf. bearing (only BG 315)

NS

Relubrication device (only BG 315)

NIB Isolated bearing (only BG 315)

RI

Reinf. winding insulation > 500 V

Therm. motor protection

TF

Temperature sensor (PTC)

TH

Bimetallic switch (thermostat)

TS

Temperature sensor

KY

Temperature detection via KTY

PT

Temperature detection via PT100

Flange-mounted designs

FG

Attached motor for 7 series gear

unit

FF

IEC flange with bores (B5)

FT

IEC flange with threads (B14)

FI

IEC foot-mounted motor, possibly

with shaft height indication

FM

Attached motor for 7 series gear

unit with IEC feet

FE

IEC flange with bores and IEC

feet (B35)

FY

IEC flange with threads and IEC

feet (B34)

FL

Flange deviating from IEC

FC

NEMA C-Face

FK

Special flange acc. to drawing and

IEC feet

Brake option

HR

Manual brake release, disengaging

HF

Manual brake release, lockable

Brake type with max. braking torque

BE11 BE brake type with max. 110 Nm

Number of poles

Rotor material

C

Copper (only for M,L,H) from

BG100

_

Aluminum

Length

K

Only for BG 315

S

M

L

MC

Length M with copper rotor

LC

Length L with copper rotor

HC

Length H with copper rotor

Size

71/80/90/100/112/132/160/180/

200/225//315

Efficiency class/technical des.

S

Standard EFF2 (IE1 new) (prev.

DT/DV)

E

High efficiency / EFF1(IE2 new)

(prev. DTE/DVE)

P

Premium efficiency(IE3 new)

L

Asynchronous servo (prev. CT/CV)

M

Torque motor (prev. MT/MV)

K

Single-phase motor (prev. ET/EV)

DR series

Produkttraining

14.03.2008

2.

Motor Options

2.

Motor Options

2.1

Brake Rectifiers

12

Assignment of motor type to brake system

AC asynchronous motors

Motor type

Brake system

DT56..

BMG

DT63..

BR

DT71.. DT80..

BMG

DT80..

BMG

DT90.. DV100..

BMG

DV100..

BMG

DV112..-DV132S..

BMG

DV132M..-DV160M

BM

DV160L..-DV225

BM

BM32/62

DV250M..-DV280S..

BMG

DV250M..-DV280S..

BMG

DR AC asynchronous motors

Motor type

Brake system

DR71..

BE05

BE1

DR80..

BE05

BE1

BE2

DR90..

BE1

BE2

BE5

DR100..

BE2

BE5

DR112..

BE5

BE11

DR132

BE5

BE11

DR160..

BE11

BE20

DR180

BE20

BE30

BE32

DR200 / DR225

BE30

BE32

BE60

DR315

BE120 BE122

BE62

Asynchronous servomotors

Motor type

Brake system

CT71D4

BMG

CT80N4

BMG

CT90L4

BMG

CV100 M/L 4

BMG

CV132 S 4

BMG

CV132 M/ML-160M 4

BM

CV160 L 4

BM

CV180 M/L 4

BM

CV200L 4

BM

Synchronous servomotors

Motor type

Brake system

DFS 56M/L/H

B

CM71 S/M/L

BR

CM90 S/M/L

BR

CM112 S/M/L/H

BR

Produkttraining

14.03.2008

2.

Motor Options

13

Brakemotors ATEX II2G EEX de II B T3

AC asynchronous motors

Motor type

Brake system

eDT71D4..../HR/TF

BC

eDT80K4..../HR/TF

BC

eDT80N4..../HR/TF

BC

eDT90S4..../HR/TF

BC

eDT90L4..../HR/TF

BC

eDV100LS4..../HR/TF BC

eDV100L4..../HR/TF

BC

B...:Brake rectifiers for installation in/on terminal box

Voltage

24 VDC

42-150AC

150-500 AC

Standard

excitation

BS24

Terminal

block

BG 3.0

brown

BG 1.5

black

BG 1

black

BGE 3.0

blue

UR 11

Litz wire

brown

BG 1.5

red

UR 15

Litz wire

black

For DT63 and

IS1

Fast excitation

BSG

white

Fast

de-excitation

SR 11 Litz wire white 1 mm2

SR 15 Litz wire brown 6 mm2

Special brake rectifiers

Produkttraining

Voltage

230-575 VAC

Normal

excitation

High-speed

excitation

BG 1.4

BGE 1.4

14.03.2008

2.

Motor Options

14

BM..: Brake rectifiers for installation in control cabinet

Voltage

24 VDC

Standard excitation

Fast excitation

Control via FI with fast

excitation and separation of

the DC circuit

Integ. separation of the DC

circuit with UR

Fast excitation with anticondensation heater

BMV5

white

42-150AC

150-500 AC

BMS 3

brown

BME 3

blue

BMS 1.5

black

BME 1.5

red

BMK 3

pink

BMK 1.5

turquoise

BMP 3

light blue

BMH 3

yellow

BMP 1.5

gray

BMH 1.5

green

Special brake rectifiers

Voltage

24 VDC

BMU

High-speed excitation

Control via FI with

high-speed excitation

and cut-off in the DC

circuit

42150 VAC

BMD

with diode

for EMC

interf.

immunity

BMK 1.5B

with LED

BMP 3.1

iBMP 3.1

Integ. cut-off in the DC

circuit with UR for

DR315

Wide voltage range

230575 VAC

(terminal

box)

BMR

High-speed excitation

BST1.0..: Safety-oriented brake module

Produkttraining

14.03.2008

2.

Motor Options

15

Evaluation electronics for installation in terminal box

Current relay: Integrated in terminal box for separation of the DC

SR

circuit.

SR

Motor current 10A

Brake current 1 A

Current relay

SR15 (Brake current 1 A, motor current 50A)

BSR

Combination of brake rectifier (B..) and current relay (SR)

UR

Voltage relay: Voltage-evaluation electronics integrated in terminal

box for separation of the DC circuit.

Suitable for inverter operation and pole-changing motors.

UR

Brake voltage 150V

Brake current 1 A

Voltage relay

UR15 (Brake current 1 A, brake voltage 500V)

BUR

Combination of brake rectifier (B..) and voltage relay (UR)

Beispiel:

B..1.5 Brake current 1.5 A

B..3.0 Brake current 3.0 A

Brake rectifiers for decentralized technology

BGM

Brake rectifier for

230VAC 500VAC brake

blue

URM

DC circuit disconnection for

110VAC 230VAC brake

black

BSM

Control unit for

24VDC brake

white

Produkttraining

14.03.2008

2.

2.2

Motor Options

16

Motor Feedback Systems

Solid shaft encoders / shaft-centered

XV1.

AV1Y

AV1H

Spread-shaft encoders / shaft-centered

ES1.

AS1H

ES7.

Hollow shaft encoders

Resolver

EH1S

RH1M / RH1L / RH3M /

RH5M

U proximity sensor

Few pulse encoder

Built-in encoder

NV 26

ES12 / ES22

ES16 / ES26

EI7. / EI7S

AI7W

Produkttraining

14.03.2008

2.

Motor Options

17

T

Electrical interface

C

R

S

T

B

2/6

A

E

I

P

Y

D

N

M

H

W

= 24 HTL signal with invers. + N

= 24V TTL signal with invers. + N

= 24V Sine encoder with invers. + N

= 5V TTL signal with invers. + N

= 24V HTL without inversion with N

= no. of pulses/ U proximity sensor

= Mounting adapter

= EnDat interface

= Interbus interface

= Profibus interface

= SSI interface

= DeviceNet interface

= CanBus interface

= Modulation resolver

= Hiperface interface

= RS485 (electronic nameplate)

Development status / Variant

1-9

7

A

12

16

22

26

= mech. / electr. design

= Designation for DR motor

= Mounting adapter

= A track 2 pulses / rotation HTL

= A track 6 pulses / rotation HTL

= A+B track 2 pulses / rotation HTL

= A+B track 6 pulses / rotation HTL

Mechanical design

S

V

H

G

I

F

= Spread-shaft shaft-centered non-positive

connection

= Solid shaft flange-centered positive

connection

= Hollow shaft

= Shock-proof shaft-centered non-positive

connection

= Built-in encoder

= Flange-mounted design

Encoder type

E

A

N

X

K

R

Produkttraining

= Encoder

= Absolute encoder

= Proximity sensor

= Special encoder

= Combination encoder

= Resolver

14.03.2008

2.

Motor Options

2.3

18

Motor Plug Connectors

Integrated IS plug connector

Phnix APG plug connector

Harting AS.. plug connector

Harting modular AM.. plug connector

Produkttraining

14.03.2008

2.

Motor Options

19

A S B 1

Electrical interface / contact assignments for plug connectors / signal plug

connector

0

M12 signal plug connector: DC 24 V supply e.g. AVS0

Motor/brake motor: no wiring diagram

1

Motor/brake motor: standard wiring diagram, 6 ends of the motor winding by

customer M12 signal plug connector: standard wiring diagram, e.g. for

MOVIMOT or MOVI-SWITCH

2

Han Modular: Motor/brake motor: 6 ends of the motor winding by customer

M12 signal plug connector: Data cable, e.g. PROFIBUS DP

3

Wiring diagram for MOVIMOT or MOVI-SWITCH power supply input

4

Hybrid: Motor/brake motor, wiring diagram for assembly of MOVIMOT or MOVISWITCH close to the motor (including MOVIMOT /MOVI-SWITCH with field

mounting platform or MOVIMOT field distributors Z.7/Z.8)

5

Reserved

6

Hybrid: MOVIMOT power supply input and communication

(e.g. field distributors Z.3/Z.6, field control unit)

7

CT/CV motor star/delta wiring diagram set at the factory

8

Star or delta can be selected and set at the factory, 3 ends connected by customer

9

Internal voltage supply for brake

Star or delta can be selected and set at the factory, 3 ends connected by customer

AG Reserved

H

Hybrid: Power supply input, control signals and/or DC 24 V

e.g. MOVIMOT , MOVI-SWITCH on field control

K

M12 signal plug connector (combination): AS-interface

S

M12 signal plug connector (combination): SENSOR I/O

W

Hybrid: Power supply input and control signals for MOVI-SWITCH on field

distributor Z.3

X

Customer-specific contact assignment

Mechanical design

A

Standard housing (not EMC), 2 clamp closure

B

EMC housing, 2 clamp closure

C

EMC housing, 2 clamp and locking plate closures, contacts gold plated

D

Standard housing (not EMC), 1 clamp closure

E

EMC housing, 1 clamp closure

F

Standard housing (not EMC), locking plate closure

G

EMC housing, screw connection

K

ECOFAST EMC B housing, 1 clamp closure

L

EMC housing, 7/8"-, 1 3/8"- screw connection, pin (male)

N

EMC housing, 2 clamp closure, articulated frame CA, module frame negated

R

M12 7-pole + PE

S

M12 standard coding (A coding)

T

M12 B coding

U

Click-stop connection

X

Customer-specific mechanical design / type of closure

plug connector type / manufacturer type

B

Han-Modular (1C and 1E module), pin (male)

C

Han 10 E, crimp prefabrication, leading switch contacts (e.g. TH), pin (male)

D

Han-Modular (2C and 1E module), pin (male)

E

Wieland revos MOT

F

Brad Power TM 1Rxxx / CRxxx series, pin (male)

G

Han Q4/2; socket (female)

H

Han Q4/2; pin (male)

I

Reserved

J

Han 6 HsB

K

Han-Modular 1C module axial screw contacting clamping area to 10 mm2 (AWG8)

and 1E-module, pin (male)

L

Han 10 E, socket (female)

M

Han modular (2E-module), pin (male)

N

Han Q8/0; pin (male)

O

Han Q8/0; socket (female)

P

Phoenix PLUSCON VARIOCON VC (male)

R

Han 6 E, pin (male)

S

Han 10 E, pin (male)

T

Han 16 E, pin (male)

U

Wieland podis CON flat cable output, pin (male)

V

M12 plug connector (male)

W

M12 socket (female)

Z

M12 combination AS-interface, 24 V and I/O sensor (e.g. MOVIMOT with

integrated AS-interface)

X

Customer-specific plug connector type/combination

Plug connector mounting position

A

Mounted plug connector

K

Cable end with plug connector

SM.. plug connector motor with size and connection cross section

SB.. plug connector motor + brake with size and connection cross section

IS

Integrated SEW plug connector

IV

Industrial plug connector for DR motors; refer to "connector data" for the

description

Produkttraining

14.03.2008

3.

3.

Condition Monitoring

20

Condition Monitoring

Condition-based maintenance

DUV10A

DUO10A

DUB10A

DU V 10 A

Version

Type

V vibration

O oil-ageing

B brake

Diagnostic Unit

Produkttraining

14.03.2008

3.

Condition Monitoring

21

Control cabinet and drive component thermography

CDM - maintenance management

Produkttraining

14.03.2008

4.

4.

Servo Gearmotors

22

Servo Gearmotors

BSHF202 BR CM71S /BR/HR/TF/AS1H/SB60

SEW motor options

SEW servomotor

SEW servo ear unit

4.1

Servo Gear Units

Planetary gear unit

PSF../PSKF..

Helical-bevel servo gear unit

BSF../BSKF.

Helical-bevel servo gear unit with

hollow shaft and shrink disc

BSHF..

Produkttraining

Planetary gear unit with flange

block shaft

PSBF..

Helical-bevel servo gear unit with

flange block shaft

BSBF..

Planetary gear unit

PSC..

14.03.2008

4.

Servo Gearmotors

BSHF

202 B

23

R

Gear unit version

If 3rd character is a B, 4th character is

possible

BS.. R - Reduced backlash version

<= 3`

Gear unit version

B

- Foot and front threaded

holes

BS.. R - Reduced backlash version

<= 3`

PSF..R - Reduced backlash version

T

- Torque arm

I

- BSHF/I helical-bevel servo

gear unit with hollow shaft

and shrink disc opposite the

output end

Gear unit size:

End digit 2 = 2-stage

BS.. 202/ 302/ 502/ 602/ 802

PS.. 121/ 122/ 221/ 222/ 321/ 322/ 521/

522/ 621/ 622/ 721/ 722/ 821/ 822/ 921/

922

Gear unit type

All in B 5 flange

BSF

- Helical-bevel servo gear unit

with solid shaft

BSKF - Helical-bevel servo gear unit

with solid shaft and key

BSBF - Helical-bevel servo gear unit

with flange block shaft

BSHF - Helical-bevel servo gear unit

with hollow shaft and shrink

disc

PSF

- Planetary gear unit with

flange

PSKF - Planetary gear unit with

flange and keyway

PSBF - Planetary gear unit with

flange block shaft

PSC.. - Servo gear unit with B5 drive

flange and solid shaft

PSKC.. - Servo gear unit with B5 drive

flange and solid shaft with

key

PSCZ.. - Servo gear unit with B14

drive flange and solid shaft

PSKCZ.. - Servo gear unit with B14

drive flange and solid shaft

with key

Produkttraining

14.03.2008

4.

Servo Gearmotors

24

EBH.. adapter modules for BSF.. helical-bevel servo gear units

Helical-bevel servo gear units with adapter

Produkttraining

14.03.2008

4.

Servo Gearmotors

25

EPH.. adapter modules for PSF.. planetary servo gear units

Planetary servo gear units

with adapter

Planetary servo gear units

with adapter

Produkttraining

14.03.2008

4.

Servo Gearmotors

4.2

26

Synchronous Motors

Synchronous motors

synchronous motors

DFS.., CFM..,

synchronous motors

CMP..

synchronous motors

CMD..

CMS.. synchronous

motors with integrated

ball screw

Synchronous linear motors

SL2-Basic

SL2-Advance System

SL2-Power System

DLD asynchronous

linear motor

Produkttraining

14.03.2008

4.

Servo Gearmotors

27

DFS

Synchronous motor size 56

CMP

Synchronous motor sizes 40 / 50 / 63

CFM

Synchronous motor sizes 71 / 90 / 112

CMD

Current-controlled direct motor

sizes 55 / 70 / 93 / 138

CMS

CMS.. synchronous motors with integrated ball screw

SL2

SL synchronous linear motor sizes Basic / Advance /

Power System

DLD

DLD asynchronous linear motor

DFY

Synchronous motor sizes 71 / 90 / 112 - Old design

Produkttraining

14.03.2008

5.

5.

Industrial Gear Units

28

Industrial Gear Units

MC - Series Compact

M - Series

CN - Series

P - Series

Planetary gearmotor

Q - Series

Planetary gearmotor

X - Series

Helical and bevel-helical gear

units

Produkttraining

14.03.2008

5.

5.1

Industrial Gear Units

29

MC Series

MC 2 R L S F 05

Size:02...09

Gear unit mounting:

F

T

Foot-mounted

Torque

Input shaft design (LSS):

S

H

Solid shaft

Hollow shaft (key or shrink disk connection)

Mounting position:

L

V

E

Horizontal

Vertical

Upright

Gear unit type:

R

P

Bevel-helical gear unit

Helical gear unit

Number of gear stages:

2

3

2-stage

3-stage

Industrial gear unit series: MC

EBD design - Extended Bearing Distance

EZ 1 2 B

Options:

B

G

L

External bearing oil-lubricated (standard)

External bearing grease-lubricated (=Drywell for output

shaft pointing downwards)

Leakage display

Bearing type:

3

2

1

Bearing type 3

Bearing type 2

Bearing type

Shaft type:

1

2

Solid shaft type 1 (MC..S) or hollow shaft (MC..H)

Solid shaft type 2

EN Foot mounting

EF Flange mounting

EZ Alternatively, foot mounting or preparation for customer

flange

Produkttraining

14.03.2008

5.

5.2

Industrial Gear Units

30

M Series

M 3 R V S F 80

Size:

Vertical

50.....90

Horizontal 50...100

Gear unit mounting:

F

Foot mounted

T

Torque

Input shaft (LSS) type:

S

Solid shaft

H

Hollow shaft (keyed or shrink disc

connection)

Mounting position:

No design. Horizontal

V

Vertical

Gear unit type:

R

Bevel-helical gear unit

P

Helical gear unit

Number of gear unit stages:

2

2-stage

3

3-stage

4

4-stage

5

5-stage

M series industrial gear units

Produkttraining

14.03.2008

5.

5.3

Industrial Gear Units

31

CN Series

3 PKC 280

ST

Application indicator

E

ST

SH

EXT

PP

P

POM

PM

Special design

Reinforced version

Reinforced version

Extruder gear unit

Stoffauslser

Stoffauslser

Palm oil

Paper machine

Gear unit size

80-800

Gear unit type:

K

T

P

V

Bevel gear

Shaft mounted version

vertical LSS Low Speed

Shaft

HSS High Speed Shaft at the

long gear unit side

Vertical type

PC...N Helical gear unit, foot mounted

PKC...N Helical-bevel gear unit, foot mounted

Horizontal type

C...N

Helical gear unit, foot mounted

KC...N Helical-bevel gear unit, foot mounted

TC...N Shaft-mounted helical gear unit

TKC...N Shaft-mounted helical-bevel gear unit

TKCV...N Shaft-mounted helical-bevel gear unit

Output shaft on long

gear unit side

Number of gear stages:

1-5

Produkttraining

14.03.2008

5.

5.4

Industrial Gear Units

32

P Series Planetary Gearmotor

P H F 041 / KF107DV160M4

Primary gearmotor

Planetary gear unit accessories:

/1T Foot mounting

/2T Flange mounting

Planetary gear unit size:

001 ... 081

Planetary gear unit mounting:

...

F

Foot mounting

Flange mounting

Output shaft design [LSS]:

H

...

Hollow shaft with shrink disk

Solid shaft with key

Planetary gear unit

Produkttraining

14.03.2008

5.

5.5

Industrial Gear Units

33

Q Series Planetary Gearmotor

P30 051 N 160 - 110 / VVN

Special features:

N

without special features

L

with fan

Output shaft:

V

Solid shaft

H

Hollow shaft

Input shaft:

V

Solid shaft

Mounting position:

010

Coaxial planetary gear unit,

horizontal output shaft

020

Vertical output shaft,

output downward

040

Vertical output shaft,

output upward

Reduction ratio:

Mounting type:

N

Flange

F

Foot mounted

T

Torque arm

Gear unit size:

Input stage:

0

Coaxial planets

Number of stages:

2,3,4

Planetary gear unit

Produkttraining

14.03.2008

5.

5.6

Industrial Gear Units

34

X - Series Helical and Bevel-Helical Gear Units

X.F..

X.K..

Produkttraining

14.03.2008

5.

Industrial Gear Units

35

220 /B

Gear unit accessories:

/ B = Foot mounting

/ T = Torque arm

/ F = Flange mounting

Gear unit size:

180...250

Output shaft type:

S

= Solid shaft with key

R = Solid shaft without key1)

L

= Splined solid shaft1)

A = Hollow shaft with key

H = Hollow shaft with shrink disk

V

= Splined hollow shaft1)

Gear unit version:

F

= Helical gear unit

K = Bevel-helical gear unit (standard version)

Number of gear stages:

2

= 2-stage

3

= 3-stage

4

= 4-stage

X-series industrial gear unit

Produkttraining

14.03.2008

6.

Dezentrale Installation

6.

Dezentrale Installation

6.1

MOVIMOT Standard

36

Gearmotor with matching frequency inverter

Features:

- Two directions of rotation

- Simple positioning with two speeds

- Choice of acceleration speeds

- Deceleration and continues speed control

Motor nameplate:

Produkttraining

14.03.2008

6.

Dezentrale Installation

37

Electronics name plate in the MOVIMOT top part:

Electronics name plate in the MOVIMOT top part for assembly close

to the motor:

Produkttraining

14.03.2008

6.

6.2

Dezentrale Installation

38

MOVIMOT D Standard

DR motor with matching frequency inverter

Features:

- two directions of rotation

- two fixed setpoints

- RS485 interface via RJ10 connector

- selectable acceleration and deceleration ramps

Motor nameplate:

Produkttraining

14.03.2008

6.

Dezentrale Installation

39

MOVIMOT top part electronics nameplate:

MOVIMOT top part electronics nameplate for mounting close to the

motor:

Produkttraining

14.03.2008

6.

Dezentrale Installation

6.3

MOVIMOT MD

40

Decentralized drive unit with a synchronous servomotor and a

matching powerful drive inverter.

Typecode motor:

Produkttraining

14.03.2008

6.

6.4

Dezentrale Installation

41

MOVIMOT Options

MLU..A 24 V voltage supply

107

MLU11A for MOVIMOT with 380 to 500 VAC

supply voltage

L1 (YE MLU11A / BN MLU21A)

L2 (YE MLU11A / BN MLU21A)

24 (RD)

( BU )

MLU21A for MOVIMOT with 200 to 240 VAC

supply voltage

MLU13A voltage supply 24 V

Integrated in the modular terminal box

Can be combined with internal braking

resistor

Can be combined with BEM/URM brake

control

MLG..A speed control module (-100...+100% of fmax) with voltage supply

107

MLG11A for MOVIMOT with 380 to 500 VAC

supply voltage

L1 (YE MLG11A / BN MLG21A)

L2 (YE MLG11A / BN MLG21A)

24V (RD)

(BU)

RS+ (OG)

RS- (GN)

MBG11A speed control module

MLG21A for MOVIMOT with 200 to 240 VAC

supply voltage

Speed adjustment in the range -100...+100%

of fmax

Up to MOVIMOT units can be controlled at

the same time

Produkttraining

RS+

RS-

24V

90

MBG11A

14.03.2008

6.

Dezentrale Installation

MDG11A diagnostics unit

42

Displays the operating status, output current

and fault codes

MWA21A setpoint converter

75

Converts and analog setpoint and control

signals to an RS485 signal.

Up to 31 MOVIMOT units can be controlled

MWF11A setpoint generator for MOVIMOT

3 fixed setpoints can be set

Start, stop and rapid stop ramps can be set

separately

Analog or frequency setpoint generator can be

selected

Setpoint speed displayed in %

Several inverters can be run on MWF

Produkttraining

14.03.2008

6.

Dezentrale Installation

43

MNF11A line filter for size 1

Integrated in the modular terminal box

Can be combined with internal braking

resistor

Can be combined with BEM/URM brake

control

DIM Drive Ident Module

Motor data (motor family)

Brake data

User parameters

MFG11A keypad for manual control

Produkttraining

14.03.2008

6.

Dezentrale Installation

44

MWS21A Bus diagnostics (MOVIMOT fieldbus diagnostics kit, part no. 823180X)

USB11A Interface converter USB / RS485

DGB60B hand-held terminal

Produkttraining

14.03.2008

6.

Dezentrale Installation

45

Motor and brake tester (part no. 831 331 8)

Used to measure the resistance of the motor

and brake coil windings

Wiring tester (part no. 823 088 9)

Used to check the wiring is correct

Produkttraining

14.03.2008

6.

6.5

Dezentrale Installation

46

MOVIMOT with AS-Interface

MOVIMOT with integrated AS-interface as multiple-speed drive

Features:

CW, CCW direction of rotation

Switchover between 2 setpoints

Setpoint f1 can also be scaled

Ready sigal sent to controller

MOVIMOT diagnostics via status LED

Additional functions integrated as standard

Addressing via M12 (AS-interface address 1-31)

Connection option for 2 external sensors

Additional LED for AS-interface status

Additional diagnostics inteface via modular jack 4/4 (RJ11) plug connector

Produkttraining

14.03.2008

6.

Dezentrale Installation

47

Motor nameplate:

RE1A/ASA3/AVT1

Electronics nameplate in MOVIMOT top part:

Electronics nameplate in MOVIMOT top part for assembly close to

the motor:

RE2A/AVSK/ALA

Produkttraining

14.03.2008

6.

Dezentrale Installation

6.6

MOVI-SWITCH

48

Gearmotor with integrated switching and protection function.

Type: MSW 1 E:

Features:

- One direction of rotation

- Semiconductor switch

element

- TF evaluation

- Brake control

- Binary control

- Motors to 3 kW

- IP65

- Dimensions: 120x160x75

Motor nameplate:

S 37

Produkttraining

14.03.2008

6.

Dezentrale Installation

49

Type:MSW 2 S

Features:

- Two directions of rotation

- Reversing relay

- TF evaluation

- Phase monitoring

- Supply system monitoring

- Diagnostics LED

- Brake control

- Binary or AS-Interface control

- Motors to 3 kW

- IP65

- Dimensions: 155x180x115

Motor nameplate:

K 47

Electronics nameplate in MOVI-SWITCH top part for assembly close

to the motor:

Produkttraining

14.03.2008

6.

6.7

Dezentrale Installation

50

Field Distributor

Type code of the fieldbus inteface

MF P 2 1 D

D

= Version

Connection technology I/Os

1 = Terminals

2 = Terminals or M12 plug connector

3 = Fiber optic cable (only Interbus)

Number of I/Os

2 = 4 inputs / 2 outputs

3 = 6 inputs

Bus system

P = Profibus

I

= Interbus (CU and LWL)

D = DeviceNet / CAN open

C = CANopen

K = AS-Interface

MF = MOVIMOT/Fieldbus

MQ = Intelligent, programmable bus interface

Produkttraining

14.03.2008

6.

Dezentrale Installation

51

MF.../Z.3

Communication interface with

I/Os (I/Os can only be used in

combination with M12 plug

connectors

Common connection

compartment for bus and

power supply

Pluggable motor connection

Produkttraining

14.03.2008

6.

Dezentrale Installation

52

MF.../Z.6/AF.

Communication interface with

I/Os

Separate connection

compartment for bus and

power supply

Pluggable motor connection

Maintenance switch (triple

lockable)

Produkttraining

14.03.2008

6.

Dezentrale Installation

53

MF.../MM.../Z.7

Communication interface with

I/Os

Common connection

compartment for bus and

power terminals

Pluggable motor connection

Integrated MOVIMOT inverter

1) If the field distributor is used in combination with a drive without

mechanical holding brake, then the field distributor must be ordered with

integrated braking resistor (see the following example):

Produkttraining

14.03.2008

6.

Dezentrale Installation

54

MF.../MM.../Z.8/AF.

Communication interface with

I/Os

Separate connection

compartment for bus and

power supply

Pluggable motor connection

Integrated MOVIMOT inverter

Maintenance switch (triple

lockable)

1) If the field distributor is used in combination with a drive without

mechanical holding brake, then the field distributor must be ordered with

integrated braking resistor (according to the following example):

MME.. ECOFAST

Produkttraining

14.03.2008

6.

Dezentrale Installation

55

Hybrid cables

Connect field distributors with drives

Combine the power transmission, control voltage and communication in

one cable sheath

Ensure optimum EMC shielding and cable impedances

Are supplied as prefabricated cables with plug connectors

Connection between MF/Z.3. or MF../.6. field distributors and

MOVIMOT

Connection between MF/Z.8. field distributors and AC motors

Connection between MF/Z.8. field distributors and AC motors with

APG4 plug connectors

Connection between MF/Z.8. field distributors and AC motors with

ASA4 plug connectors

Connection between MF/Z.8. field distributors and AC motors with

IS plug connectors

Produkttraining

14.03.2008

6.

Dezentrale Installation

6.8

Bus Interfaces

56

Bus interfaces for MOVIMOT and MOVI-SWITCH

MF Z 21

1)

MF P 22

MF P 21

red terminal imprint

2)

MF Z 11

MF I32

MF I22

MF I21

Produkttraining

black terminal imprint

14.03.2008

6.

Dezentrale Installation

57

2)

MF Z 11

MF I 33 B

with fiber optic cable and

Rugged Line connector

(Phoenix Contact)

MF I 23 B

black terminal imprint

MF Z 31

2)

MF O32

MF O22

MF O21

Produkttraining

black terminal imprint

14.03.2008

6.

Dezentrale Installation

58

2)

MF Z 31

MF D32

MF D22

MF D21

Produkttraining

black terminal imprint

14.03.2008

6.

Dezentrale Installation

59

Intelligent, programmable bus interfaces for MOVIMOT and MOVISWITCH

Produkttraining

14.03.2008

6.

6.9

Dezentrale Installation

60

Modular Terminal Box

Size 1 motors DT71.. to DT90..

Frame height 72:

Frame height 90:

Base plates size 1 motors DT71.. to DT90..

Produkttraining

14.03.2008

6.

Dezentrale Installation

61

Size 2 motor DV100..

Frame height 72:

Base plates size 2 motor DV100..

Produkttraining

14.03.2008

6.

Dezentrale Installation

6.10

62

MOVITRANS

MOVITRANS contactless energy transfer system

Produkttraining

14.03.2008

6.

Dezentrale Installation

63

1. Stationary components

TPS Stationary converter 16 kW

Produkttraining

14.03.2008

6.

Dezentrale Installation

64

TAS track compensation and

medium-frequency cable connection

Control cabinet installation

Produkttraining

14.03.2008

6.

2.

Dezentrale Installation

65

Installation equipment (track assembly)

TLS medium-frequency cable

TVS connection distributor

To connect medium-frequency cables via

terminals

Produkttraining

14.03.2008

6.

Dezentrale Installation

66

TCS compensation box

To compensate the track inductance;

installed directly on the track

Produkttraining

14.03.2008

6.

Dezentrale Installation

67

TIS installation component for line cable

routing

Installation plate

Produkttraining

14.03.2008

6.

Dezentrale Installation

68

THM pick-up

Flat design for connection to TPM via

plug-in connection

THM pick-up

U-shaped design for connection to TPM

via plug connection

Produkttraining

14.03.2008

6.

Dezentrale Installation

69

3. Mobile components

TPM connection module for pick-ups

with power output

Connection cable for TPM12B output

Produkttraining

14.03.2008

6.

6.11

Dezentrale Installation

70

MOVIFIT

MOVIFIT Field Integrated Technology

Field distributor with application-oriented drive and communication

functions.

MOVIFIT-MC

MOVIFIT for MOVIMOT Control

Up to 3 MOVIMOT gearmotors with

integrated frequency inverter

(up to 3 kW)

Line protection

MOVIFIT-SC

MOVIFIT for Motor Switch Control

Electronic motor switch:

1-channel motor switch, 2 directions of rotation,

up to 4.0 kW

2-channel motor switch, 1 direction of rotation,

2 x 2.2 kW

MOVIFIT-FC

MOVIFIT for Frequency Control

Integrated frequency inverter

0.37 kW to 1.5 kW or 2.2 kW to 4.0 kW

Fulfills safety category 3, section 6 of DIN EN

954-1

Produkttraining

14.03.2008

6.

Dezentrale Installation

71

Overview of EBOX types

MT F 11 A 007-503-P 1 0 A-00/S11

Option version

Option type

A

- Analog I/O

S

- PROFIsafe

EBOX design

00

- DT/DV and DZ

01

- DAS motors

10-16 - DR motors

A

- Version

Function level

0

- Classic

1

- Technology (MOVI-PLC)

2

- System (MOVIVISION)

1

Generation

Coding of the Ethernet

protocol variant

For Ethernet:

2

3

Profinet

Ethernet IP / Modbus TCP

Communication

P

- PROFIBUS

D

- DeviceNet

E

- Ethernet

T

- Safe Ethernet, HIMA

Z 10 - Slave

Supply phases

- MTM version

3

- 3-phase (AC)

Supply voltage

- MTM version

MC power (MOVIFIT-MC)

000 - MTM version

FC power (MTF version)

003 - 0.37 kW

015

005 - 0.55 kW

022

007 - 0.75 kW

030

011 - 1.1 kW

040

1.5 kW

2.2 kW

3.0 kW

4.0 kW

SC power (MTS version)

015 - 1.5 kW

040 - 4.0 kW

Version A

Series

11

- Standard

12

- HygienicPlus

Unit type

M

- MOVIFIT - MC

S

- MOVIFIT - SC

F

- MOVIFIT - FC

MT

Produkttraining

- MOVIFIT family

14.03.2008

6.

Dezentrale Installation

72

Overview of ABOX types

MTA12A-503-S01 1-M 00-00 /BW1

Option 1 type

BW1 - braking resistor BW1 (only MTF)

BW2 - braking resistor BW2 (only MTF)

ABOX design

00 - Series

30

- (MTF) 2 motor operation switch (only for

S0x, S4x, S5x, S6x)

Maintenance switch type

- No switch

00 - No rotary knob

01 - Rotary knob

Maintenance switch design

- No switch

D - Switch disconnector

M - Motor protection switch with line protection

Communication

1

- PROFIBUS

2

- DeviceNet

3

- Ethernet (Cu)

Connection configuration

S = Standard

H = HARTING

01= Cable bushings (MTM)

02= Cable bushings (MTF/MTS)

41=

I/Os

42=

51=

52=

61=

62=

11 = (MTM) HANModular-ABOX

with M12 for I/Os,

(MTM) hybrid ABOX with M12 for

bus a. plug

connector

(MTS/MTF) hybrid ABOX with M12 12 = (MTS/MTF)

for I/Os

HAN-Modular(MTM) hybrid ABOX with M12 for

ABOX with M12 for

I/Os and bus

I/Os, bus a. plug

(MTS/MTF) hybrid ABOX with M12 connector

21 = (MTM) HANfor I/Os and bus

Modular-ABOX

(MTM) hybrid ABOX with M12

with M12 for I/Os,

for I/Os and push-pull RJ45 for

push-pull RJ45 a.

Ethernet

(MTS/MTF) hybrid ABOX with M12 plug connector

22 = (MTS/MTF)

for I/Os and push-pull RJ45 for

HAN-ModularEthernet

ABOX with M12 for

I/Os, push-pull

RJ45 a. plug

connector

Supply phases

3

- 3-phase (AC)

Supply voltage

50 - 380 V to 500 V

Version A

Series

11 - Standard

12 - HygienicPlus

Housing type

A

- Connection box

MT

Produkttraining

- MOVIFIT family

14.03.2008

6.

Dezentrale Installation

6.12

73

MOVIPRO

MOVIPRO decentralized control unit

MOVIPRO

is an optimized, decentralized drive control for mobile and stationary

applications

Produkttraining

14.03.2008

6.

6.13

Dezentrale Installation

74

MOVIGEAR

Mechanical designs

MOVIGEAR with TorqLOC hollow MOVIGEAR MGFA.4 with hollow

shaft mounting system

shaft and key

MOVIGEAR SBI

Single Line Basic Installation

Produkttraining

MOVIGEAR SNI

Single Line Network Installation

14.03.2008

6.

Dezentrale Installation

75

MG F A S 2 DSM SNI

Installation technology

SNI = Single Line Network Installation

SBI = Single Line Basic Installation

Motor type

Size

2 = Torque class 200 Nm

4 = Torque class 400Nm

Housing mounting

T = Drive with torque arm

G = Rubber buffer as torque arm

(only with MGF.G4)

S = Housing with threads for mounting a

torque arm

Shaft design

A = Mounted gear unit, hollow shaft with key

T = TorqLOC hollow shaft mounting system

Gear unit type

F = Parallel shaft helical gear unit

Product family

MG = MOVIGEAR

G IO 1 2 A

Version

Design

2 = 4 digital inputs + 2 digital outputs

Version

Functionality

IO = Digital I/Os

Product family

G = Option for MOVIGEAR

Produkttraining

14.03.2008

7.

MOVITRAC Inverter Range

76

7.

MOVITRAC Inverter Range

7.1

MOVITRAC 31C

MOVITRAC 31 C 110 - 503 - 4 - 00

Version

00 = Standard

Quadrants

4= 4Q with brake chopper

Connection type

3= 3 Phasen

Connection voltage

50= 380 - 500 VAC

23= 200 - 240 VAC

Motor power

110 = 11 kW

150 = 15 kW

Version C

Option cards (X21 ):

FEN 31C Speed detection

FPI 31C Position detection

FIT 31C TF/TH evaluation

Option cards (X20):

FEA 31C: Input/output function

FIO 31C: Digital input/output function

FRS 31C: Synchronous operation controller

FFP 31C: PROFIBUS interface

FFI 31C: Interbus interface

FFD 31C: DeviceNet interface

Accessories:

FBG31C Keypad

USS21A Serial interface

Software:

Software ROM 5 MCDTOOLS

EPLAN Makros

Produkttraining

14.03.2008

7.

MOVITRAC Inverter Range

7.2

77

MOVITRAC 07A

MC 07 A 0022 2 B 1- 4- 00

Version

00 = Standard

10 = LOGODrive

Quadrants

4= 4Q with brake chopper

Connection type

1= 1 phase

3= 3 phase

Interference suppression

0= No filter

A= Interference suppression A

B= Interference suppression B

Supply voltage

2= 200 - 240 VAC

5= 380 - 500 VAC

Motor power

0022 = 2.2 kW

Version A

MOVITRAC 07

Accessories / options:

UBP11A Parameter module

FHS DIN-rail installation

UWS21A Interface adapter (RS-485 / RS-232)

UWS21B Interface adapter (RS-485 / RS-232)

UWS11A Interface adapter (RS-232 / RS-485 ) on mounting rail attachment

USB11A Interface adapter (RS485 / USB)

Fieldbus interfaces

UFP11A PROFIBUS

UFD11A DeviceNet

UFI11A

Interbus

UFO11A CANopen

Software:

Software ROM 4 MOVITOOLS

EPLAN Makros

Produkttraining

new: MOVITOOLS MotionStudio

14.03.2008

7.

MOVITRAC Inverter Range

7.3

78

MOVITRAC B

Accessories / options:

FBG11B

Keypad with LED display and parameter memory

MBG11B

Setpoint generator

DBG60B

Keypad with plaintext display

DBM60B

Door mounting for DBG60B keypad

DKG60B

Extension cable 5m for DBG60B

FSC11B

Communication interface with RS-485 and SBUS

FIO11B

Analog module

DFP21B

PROFIBUS gateway

UOH11B

Gateway housing for fieldbus expansions or MOVI-PLC controller

UBP11A

Parameter module

UWS21A

Interface adapter (RS-485 / RS-232)

UWS21B

Interface adapter (RS-485 / RS-232)

UWS11A

Interface adapter (RS-232 / RS-485 ) on mounting rail attachment

USB11A

Interface adapter (RS485 / USB)

FHS11B

Mounting rail installation BG0XS

FHS12B

Mounting rail installation BG0S

FHS13B

Mounting rail installation BG0L

FKB11B

Base for resistors in flat design BG0XS

FKB12B

Base for resistors in flat design BG0S / BWXXX-003

FKB13B

Base for resistors in flat design BG0L / BWXXX-003

DHP11B

MOVI-PLC basic

DHE41B

MOVI-PLC advanced ETHERNET

DHP41B

MOVI-PLC advanced PROFIBUS Slave DP-V1

DHD41B

MOVI-PLC advanced DeviceNet Slave

DHP11B-T0

MOVI-PLC basic

DHP11B-T1

MOVI-PLC basic in technology version I

DHP11B-T2

MOVI-PLC basic in technology version II

DHE41B

MOVI-PLC advanced ETHERNET interface

OMH41B-T..

Memory cards for MOVI-PLC advanced

With technology activation T0, T1, T2

Fieldbus interface gateway

UFP11A

PROFIBUS as external gateway

DFP21B

PROFIBUS integrated in MOVITRAC B

DFP21B/UOH11B PROFIBUS integrated in MOVITRAC B, integrated in UOH11B Gateway

housing.

DFE32B

PROFINET, integrated in MOVITRAC B

DFE32B/UOH11B PROFINET, integrated in MOVITRAC B, integrated in UOH11B Gateway

housing.

UFD11A

DeviceNet as external Gateway

DFD11B

DeviceNet integrated in MOVITRAC B

DFD11B/UOH11B DeviceNet integrated in MOVITRAC B, integrated in UOH11B Gateway

housing.

UFI11A

Interbus as external Gateway

UFO11A

CANopen as external Gateway

DFE24B

EtherCAT, integrated in MOVITRAC B

DFE24B/UOH11B EtherCAT, integrated in MOVITRAC B, integrated in UOH11B Gateway

housing

Software:

MOVITOOLS MotionStudio

EPLAN macros

Produkttraining

14.03.2008

7.

MOVITRAC Inverter Range

79

MC 07 B 0022 - 2 B 1- 4- 00

Version

00 = Standard

0T = With integr. Line filter

Quadrants

4= 4Q with brake chopper

Connection type

1= 1 phase

3= 3 phases

Interference suppression

0= No filter

A= Interference suppression A

B= Interference suppression B

Supply voltage

2= 200 - 240 VAC

5= 380 - 500 VAC

Motor power

0022 = 2.2 kW

Version B

MOVITRAC

Produkttraining

14.03.2008

8.

MOVIDRIVE Inverter Range

8.

MOVIDRIVE Inverter Range

8.1

MOVIDRIVE MDX..A

80

Control cards (CONTROL slot):

MDF:

No encoder evaluation for standard frequency inverter applications

MDV

Incremental encoder evaluation for CFC or VFC speed control with

asynchronous motors

MDS

Resolver evaluation only for synchronous servo systems

(CM and DY motors)

Option cards (Option2 slot ):

DIO11A

Terminal expansion

DIP11A

Absolut encoder connection

DRS11A

Phase-synchronous operation (only for use with MDV and MDS)

Fieldbus connection option cards (Option1 slot):

DFP11A / DFP21A: PROFI-BUS

DFC11A:

CAN-BUS

DFO11A:

CANOpen-BUS

DFI11A / DFI21A:

Interbus

DFD11A:

DeviceNet

Accessories:

DBG11A

USS21A

DBG11A

DBG11A

USS21A

UWS11A

DWI11A

Keypad

Serial interface

Keypad

Keypad

Serial interface

Interface adapter (RS-232 / RS-485 ) on

mounting rail attachment

5 V encoder power supply

Software:

Software ROM 4 MOVITOOLS

EPLAN Macros

Produkttraining

new: MOVITOOLS MotionStudio

14.03.2008

8.

MOVIDRIVE Inverter Range

Produkttraining

81

14.03.2008

8.

MOVIDRIVE Inverter Range

8.2

82

MOVIDRIVE compact MCX..A

MOVIDRIVE MCH..A

Control modes:

MCF:

Only VFC (voltage-controlled); without encoder

MCV, MCH: -VFC (voltage-controller); with and without encoder

-CFC (current-controller); only with encoder

MCS:

only CFC (current-controller); with resolver

Accessories:

DBG11B

Keypad

DBG11A

Keypad

USS21A

Serial interface

UWS11A

Interface adapter (RS-232 / RS-485 ) on mounting rail attachment

USB11A

Interface adapter (RS485 and RJ10 / USB) with cable

DWI11A

5V encoder power supply

Software:

Software ROM 4 MOVITOOLS

EPLAN Macros

Produkttraining

new: MOVITOOLS MotionStudio

14.03.2008

8.

MOVIDRIVE Inverter Range

83

MOVIDRIVE compact

MCV 41 A 0055-5A3-4-00

Version

Quadrants

Type of supply

Input filter

Rated supply voltage

00 = Standard / 0T = Technology

4 = 4Q (with brake chopper)

3 = 3-phase

A = installed / 0 = not installed

5 = 380...500 VAC / 2 = 200...240 VAC

Recommended motor power 0055 = 5.5 kW

Version A

Type series and generation

Type:MCF = flux control mode without encoder for asynchronous motors

VFC operating modes (VFC = Voltage Flux Control) only

MCV = flux control mode without and with encoder for

asynchronous motors

VFC and CFC operating modes (CFC = Current Flux Control)

MCS = flux control mode with resolver for synchronous motors

SERVO operating modes

MCH = flux control mode with encoder (Hiperface, sin/cos or TTL) for

asynchronous or synchronous motors

Produkttraining

14.03.2008

8.

MOVIDRIVE Inverter Range

8.3

84

MOVIDRIVE MDX..B

Option cards:

DEH11B: HIPERFACE encoder card

DER11B: Resolver card

DIO11B: Terminal expansion board

DIP11B: Absolute encoder connection

DRS11B: Phase-synchronous operation

DHP11B-T0

MOVI-PLC basic

DHP11B-T1

MOVI-PLC technology version I

DHP11B-T2

MOVI-PLC technology version II

OST11B

Additional RS485 interface for MOVI-PLC control

DHE41B

OMH41B-T..

MOVI-PLC advanced ETHERNET interface

Memory cards for MOVI-PLC advanced

with technology activation T0, T1, T2

DHF41B

MOVI-PLC advanced Ethernet interface

additionally with PROFIBUS and DeviceNet interface

Memory cards for MOVI-PLC advanced

with technology activation T0, T1, T2

OMH41B-T..

Option cards for fieldbus connection:

DFP21B:

PROFIBUS interface

DFI11B / DFI21B: INTERBUS interface

DFD11B:

DeviceNet interface

DFE11B

MODEBUS TCP interface

DFE12B

PROFINET IO interface

DFE13B

EtherNet / IP interface

DFE24B

EtherCAT interface

DFC11B

Isolated CAN / CANopen interface

DFS11B

PROFIsafe interface

Accessories:

DWI11A

UWS11A

UWS21A

UWS21B

USB11A

DBG60B

DBM60B

DKG60B

DAT11B

DAE14B

DAE15B

DWE11B

DWE12B

DCP12A

DCP13A

DCP15A

DCP16A

DMP11B

5V encoder power supply

Interface adapter (RS-232 / RS-485 ) on mounting rail attachment

Interface adapter (RS232 / RS485)

Interface adapter (RS232 / RS485)

Interface adapter (RS485 / USB)

Keypad

Door mounting for keypad DBG60B

Extension cable 5m for DBG60B

Terminal adapter

X14 encoder adapter Sub D 9-pole in Sub D 15-pole

X15 encoder adapter Sub D 9-pole in Sub D 15-pole

HTL TTL interface adapter for single-ended HTL encoders

HTL TTL interface adapter for push-pull HTL encoders

Cable set for DC link connection MDX60/61B0005...0110-> MDR

Cable set for DC link connection MDX60/61B0150...0300-> MDR

Cable set for DC link connection MDX60/61B0370...0750-> MDR

Cable set for DC link connection MDX60/61B0900...1320-> MDR

Mounting panel for replacing MDX60A BG2 with MDX61B BG2S

Software:

Software ROM 4 MOVITOOLS

EPLAN Macros

Produkttraining

new: MOVITOOLS MotionStudio

14.03.2008

8.

MOVIDRIVE Inverter Range

85

MDX61 B 0055 - 5 A 3 - 4 00

Design

00

= Standard

00/L = Coated

circuit board

0T = Technology

0T/L = Coated

circuit board

Quadrants

= 4Q (with

brake chopper)

Connect. type

= 3-phase

B

Radio interf.

Suppression on A

0

the line side

= Rad. interf. supp. B

= Rad. interf. supp. A

= No radio interf. supp.

Supply voltage

5

2

= AC 380 ... 500 V

= AC 200 ... 240 V

Rec. motor

power

0055 = 5.5 kW

Version B

Series

Produkttraining

60

= Not option-capable

61

= Option-capable

14.03.2008

9.

9.

MOVIAXIS Servo Inverter

86

MOVIAXIS Servo Inverter

MOVIAXIS MX multi-axis servo inverter

Master module

MXM80A-000-000-00/Option

MOVIAXIS master module

Options

DHP11B-T..

MOVI-PLC basic

in designs: T0 T1 T2

DHE41B

OMH41B-T.

MOVI-PLC advanced ETHERNET interface

Memory cards for MOVI-PLC advanced

with technology activation T0, T1, T2

DHF41B

MOVI-PLC advanced Ethernet interface

additionally with PROFIBUS and DeviceNet interface

Memory cards for MOVI-PLC advanced

with technology activation T0, T1, T2

OMH41B-T.

UFF41B

Profibus DP-V1 gateway with TCP/IP and Data management

Software:

Software ROM 7 MOVITOOLS MotionStudio

Produkttraining

14.03.2008

9.

MOVIAXIS Servo Inverter

87

MX A 80 A -004 50 3 - 00

00

XX

=

=

Series design

Special design

3-phase connection

50

V = AC 380 - 500 V supply voltage

Designs:

004 = Rated current for axis modules,

e.g. 004 = 4 A

050 = Dissipatable energy for DC link discharge

module

e.g. 050 = 5000 Ws

010 = Rated power for supply module, e.g. 010 =

10 kW

050 = Capacity for capacitor, buffer or damping

module

e.g. 050 = 5000 F

060 = Power for 24 V switched-mode power

supply e.g. 060 = 600 W

Version

Designs:

80

= Standard design

For axis/supply modules:

Brake chopper and external braking

resistance

81

= Design with a safety relay in the axis

module

For axis/supply modules:

Braking resistance and capacitor module

integrated (only for 10 kW)

82

= Design with two safety relays in the axis

module

Unit type:

A

= Axis module

B

= Buffer module

C

= Capacitor module

D

= Damping module

M

= Master module

P

= Supply module with brake chopper

R

= Supply module with regeneration

S

= 24 V switched-mode power supply module

Z

= DC link discharge module

MOVIAXIS

MOVIAXIS MX communication components

X _ _ 11 A

Version

Version status

Design:

GH,

GS

FP

FA

FE

SE

IO

IA

Multi-encoder card

=

=

=

=

=

=

=

PROFIBUS DP V1 fieldbus interface

K-Net fieldbus interface

EtherCAT fieldbus interface

EtherCAT-based systembus

Input/output card

Analog input/output card

Option component for MOVIAXIS

Produkttraining

14.03.2008

10.

10.

Controller MOVI-PLC basic and advanced

88

Controller MOVI-PLC basic and advanced

MOVI-PLC basic DHP11B-T.. control cards T0 T1 T2

MOVI-PLC basic DHP11B-Tx

For installation in

MOVIDRIVE B

MOVITRAC B

MOVIAXIS Master module

MOVI-PLC advanced DHx41B control cards

MOVI-PLC advanced

DHE41B

MOVI-PLC advanced

DHF41B

Ethernet interface

PROFIBUS interface

DeviceNet interface

For installation in

MOVIDRIVE B

MOVITRAC B

only DHE41B

MOVIAXIS Master

module

Control cards for MOVI-PLC advanced

OMH41B-T..

with technology activation T0 T1 T2

Produkttraining

14.03.2008

10.

Controller MOVI-PLC basic and advanced

89

MOVI-PLC basic and advanced drive - based

MOVIDRIVE B

Option card

Integrated in

MOVIAXIS Master module

DHP11B-T..

DHE41B with OMH41B-T..

DHF41B with OMH41B-T..

DHP11B-T..

DHE41B with OMH41B-T..

DHF41B with OMH41B-T..

Integrated in MOVITRAC B

DHP11B-T..

DHE41B with OMH41B-T..

MOVI-PLC basic and advanced drive - compact

DHP11B-Tx / UOH11B

DHE41B with OMH41B-T.. /

UOH11B

DHP11B-Tx / OST11B / UOH21B

DHF41B with OMH41B-T../ UOH21B

MOVIFIT technology function level with integrated MOVI-PLC basic

MT F 11 A 007-503-P 1 1 A-00/S11

Function level

0

- Classic

1

- Technology (MOVI-PLC)

2

- System (MOVIVISION)

Produkttraining

14.03.2008

10.

Controller MOVI-PLC basic and advanced

90

MOVI-PLC I/O system

OCC11B

CAN bus coupler

OTM21B

Terminal module

ODI81B

Digital input module

ODO81B

Digital output module

OAI41B

Analog input module (voltage)

OAI42B

Analog input module (current)

OAI43B

Analog input module (multi input)

OAO41B

Analog output module (voltage)

OAO42B

Analog output module (current)

OAO43B

Analog output module (multi output)

DHP11B-T..

MOVI-PLC basic

T0 T1 T2

DHE41B

MOVI-PLC advanced ETHERNET

interface

Memory cards for MOVI-PLC advanced

with technology activation T0, T1, T2

OMH41B-T..

DHF41B

MOVI-PLC advanced Ethernet interface

additionally with PROFIBUS and DeviceNet

interface

OMH41B-T..

Control cards for MOVI-PLC advanced

with technology activation T0, T1, T2

OST11B

Additional RS485 interface as an option for

DHP11B-T.. control card

DHP11B-T.. / UOH11B

MOVI-PLC basic compact control

DHE41B mit OMH41B-T.. / UOH11B MOVI-PLC advanced compact control

DHP11B-T.. / OST11B.. / UOH11B

MOVI-PLC basic compact control

with additional RS485 interface

DHF41B mit OMH41B-T.. / UOH11B MOVI-PLC advanced compact control

with PROFIBUS and DeviceNet interface

OMH41B-T..

Produkttraining

Memory card for MOVI-PLC advanced with

technology activation T0, T1, T2

14.03.2008

11.

Safety Technology MOVISAFE

91

11.

Safety Technology MOVISAFE

11.1

Drive Technology with Integrated Safety Technology

Drive electronics with integrated safety technology/control cabinet:

MOVITRAC B frequency inverter

Safe Stop according to cat. 3 for 3-phase AC 400 V units from 0,55 ... 75 kW

MOVIDRIVE B inverter

DFS11B PROFIsafe / PROFIBUS

with output for safe disconnection of the MOVIDRIVE

DFS12B PROFIsafe / PROFIBUS

with CAN connection for DCS21B

DFS21B PROFIsafe / PROFINET

with output for safe disconnection of the MOVIDRIVE

DFS22B PROFIsafe / PROFINET

with CAN connection for DCS21B

DCS21B safety monitor

with speed and position monitoring and PROFIsafe connection

DCS31B safety monitor

with speed and position monitoring

Produkttraining

14.03.2008

11.

11.2

Safety Technology MOVISAFE

92

Safety Technology Decentralized Installation

Decentralized applications with safe disconnection of the drive in

compliance with stop category 0 or 1 according to EN 60204-1 and failsafe protection against restart according to EN 954-1 category 3

Gearmotors with integrated MOVIMOT frequency inverter

with optional SafetyDrive package

Permitted unit combinations for SafetyDrive:

MFZ.6. field distributors

Produkttraining

14.03.2008

11.

Safety Technology MOVISAFE

93

MFZ.7. field distributors

MFZ.8. field distributors

MQS PROFIsafe with safe disconnection

Produkttraining

MQS22F

4DI/2DO (via M12 plug connector) +

2F-DI/1F-DO (2-pole)

MQS32F

6DI / 0DO (via M12plug connector) +

2F-DI / 1F-DO (2-pole)

14.03.2008

11.

Safety Technology MOVISAFE

94

Drive control for decentralized MOVIFIT field installations

MOVIFIT applications with safe disconnection of the drive in compliance with Stop

category 0 or 1 according to EN 60204-1 and fail-safe protection against restart

according to EN1037 and conformance with safety category 3 according to EN 954-1

as well as performance level d according to EN ISO 13849-1

MOVIFIT MC with safe disconnection

ab

MOVIFIT FC with safe disconnection

Produkttraining

14.03.2008

11.

Safety Technology MOVISAFE

95

MOVIFIT with S11 PROFIsafe option

ab

ab

Produkttraining

14.03.2008

11.

11.3

Safety Technology MOVISAFE

96

Safety Technology Servo

MOVIAXIS multi-axis servo inverter

Axis modules with safe Stop category 3 or 4

MX A 81 A -004 50 3 - 00

81 = Design with a safety relay in the axis

module

For axis/supply modules:

Braking resistor and capacitor module

integrated (only for 10 kW)

82 = Design with two safety relays in the axis

module

11.4

Modular Safety Monitor MOVISAFE

UCS21A

with speed and position monitoring and PROFIsafe

connection

UCS31A

with speed and position monitoring

UCS41A

with speed monitoring

Produkttraining

14.03.2008

11.

11.5

Safety Technology MOVISAFE

97

Electromechanics and Mechanics

Safety-oriented BST brake module

BMG.T double disk brake

Produkttraining

14.03.2008

12.

12.

DOP Operator Panels

98

DOP Operator Panels

DOP11B-20

LCD graphics display (monochrome) with 240x64 pixels and

backlighting

DC24V voltage supply, max. 350 mA

2 serial interfaces (RS-232, RS-422/RS-485)

IP66 membrane keypad with navigation keys, numeric keypad

and 8 function keys

16 LEDs (two colors red/green)

Ethernet 10/100Mbit

Memory expansion via USB

12 MB application memory

DOP11B-25

Touch display (16 grayscales, STN, 5.7) with 320x240 pixels

and backlighting

DC24V voltage supply, max. 450 mA

2 serial interfaces (RS-232, RS-422/RS-485)

IP66

Horizontal or vertical installation

Ethernet 10/100Mbit

Memory expansion via USB

12 MB application memory

DOP11B-30

Touch display (64k colors, CSTN, 5.7) with 320x240 pixels

and backlighting

DC24V voltage supply, max. 450 mA

2 serial interfaces (RS-232, RS-422/RS-485)

IP66

Horizontal or vertical installation

Ethernet 10/100Mbit

Memory expansion via USB

12 MB application memory

DOP11B-40

Color display (64k colors, CSTN, 5.7) with 320x240 pixels and

backlighting

DC24V voltage supply, max. 500 mA

2 serial interfaces (RS-232, RS-422/RS-485)

IP66 membrane keypad with navigation keys, numeric keypad

and 16 function keys

16 LEDs (two colors red/green)

Ethernet 10/100Mbit

Memory expansion via USB

12 MB application memory

DOP11B-50

Touch display (64k colors, TFT, 10.4) with 800x600 pixels and

backlighting

DC24V voltage supply, max. 1 A

2 serial interfaces (RS-232, RS-422/RS-485)

IP66

Horizontal vertical installation

Ethernet 10/100Mbit

Memory expansion via USB or CF

12 MB application memory

Produkttraining

14.03.2008

12.

DOP Operator Panels

99

DOP accessories/options

PCS11B

Only for DOP11B!