Professional Documents

Culture Documents

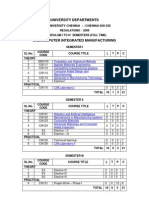

Me2037 Maintenance Engineering L T P C

Uploaded by

amanpurushoth0 ratings0% found this document useful (0 votes)

90 views1 pagesyllabus

Original Title

Me2037 Maintenance Engineering l t p c

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentsyllabus

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

90 views1 pageMe2037 Maintenance Engineering L T P C

Uploaded by

amanpurushothsyllabus

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

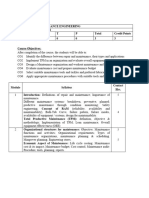

ME2037 MAINTENANCE ENGINEERING L T P C

(COMMON TO MECHANICAL AND PRODUCTION) 3 0 0 3

OBJECTIVES:

To enable the student to understand the principles, functions and practices adapted

in industry for the successful management of maintenance activities.

To explain the different maintenance categories like Preventive maintenance,

condition monitoring and repair of machine elements.

To illustrate some of the simple instruments used for condition monitoring in industry.

UNIT I PRINCIPLES AND PRACTICES OF MAINTENANCE PLANNING

9

Basic Principles of maintenance planning Objectives and principles of planned

maintenance activity Importance and benefits of sound Maintenance systems

Reliability and machine availability MTBF, MTTR and MWT Factors of availability

Maintenance organization Maintenance economics.

UNIT II MAINTENANCE POLICIES PREVENTIVE MAINTENANCE

9

Maintenance categories Comparative merits of each category Preventive

maintenance, maintenance schedules, repair cycle - Principles and methods of

lubrication TPM.

UNIT III CONDITION MONITORING

9

Condition Monitoring Cost comparison with and without CM On-load testing and offload

testing Methods and instruments for CM Temperature sensitive tapes Pistol

thermometers wear-debris analysis

UNIT IV REPAIR METHODS FOR BASIC MACHINE ELEMENTS

10

Repair methods for beds, slideways, spindles, gears, lead screws and bearings Failure

analysis Failures and their development Logical fault location methods Sequential

fault location.

UNIT V REPAIR METHODS FOR MATERIAL HANDLING EQUIPMENT

8

Repair methods for Material handling equipment - Equipment records Job order

systems -Use of computers in maintenance.

TOTAL: 45 PERIODS

TEXT BOOKS:

1. Srivastava S.K., Industrial Maintenance Management, - S. Chand and Co., 1981

2. Bhattacharya S.N., Installation, Servicing and Maintenance, S. Chand and Co.,

1995

REFERENCES:

1. White E.N., Maintenance Planning, I Documentation, Gower Press, 1979.

2. Garg M.R., Industrial Maintenance, S. Chand & Co., 1986.

3. Higgins L.R., Maintenance Engineering Hand book, McGraw Hill, 5th Edition, 1988.

4. Armstrong, Condition Monitoring, BSIRSA, 1988.

5. Davies, Handbook of Condition Monitoring, Chapman &Hall, 1996.

6. Advances in Plant Engineering and Management, Seminar Proceedings - IIPE,

1996.

You might also like

- Pathways Rw1 2e U7 TestDocument9 pagesPathways Rw1 2e U7 TestGrace Ann AbanteNo ratings yet

- Nursing Process & Patient Care ModalitiesDocument6 pagesNursing Process & Patient Care ModalitiesNur SanaaniNo ratings yet

- Definition For SpringDocument18 pagesDefinition For SpringamanpurushothNo ratings yet

- Redox ChemistryDocument25 pagesRedox ChemistrySantosh G PattanadNo ratings yet

- Bruce MoenDocument4 pagesBruce MoenGeorge Stefanakos100% (5)

- Natural Gas Engines 2019Document428 pagesNatural Gas Engines 2019Паша Шадрёнкин100% (1)

- Maintenance EngineeringDocument4 pagesMaintenance EngineeringDharshan Kofi0% (1)

- Operation and Troubleshooting of Static EquipmentDocument3 pagesOperation and Troubleshooting of Static EquipmentEhab Abowarda100% (1)

- FS1-Episode 10Document4 pagesFS1-Episode 10Mark Gerald Lagran82% (11)

- Industrial Engineering and ManagementDocument205 pagesIndustrial Engineering and Managementsubra maniNo ratings yet

- ME1012 MaintanceDocument1 pageME1012 MaintanceSenthilkumar NaganathanNo ratings yet

- Engineering Economics and Cost Analysis FundamentalsDocument5 pagesEngineering Economics and Cost Analysis FundamentalsjeyganishNo ratings yet

- Syallabus Me & orDocument2 pagesSyallabus Me & ortamil thendralNo ratings yet

- IV Year - II Semester L T P C 4 0 0 3 Production Planning and ControlDocument13 pagesIV Year - II Semester L T P C 4 0 0 3 Production Planning and Controlrajeshchindu186No ratings yet

- Design Hydraulic Pneumatic SystemsDocument2 pagesDesign Hydraulic Pneumatic SystemsGokul raj SNo ratings yet

- RTPMDocument2 pagesRTPMG. RajeshNo ratings yet

- Mechatronics Syllabus BreakdownDocument34 pagesMechatronics Syllabus BreakdownArchana MaskeNo ratings yet

- Maintenance EngineeringDocument2 pagesMaintenance EngineeringroscillaNo ratings yet

- SBTET AP C-14 SYLLABUS DME VI SemesterDocument41 pagesSBTET AP C-14 SYLLABUS DME VI Semesterthirukumar100% (4)

- 4-2 SyllabusDocument4 pages4-2 SyllabussimalaraviNo ratings yet

- Text Books:: 2. Ansel Ugural, "Mechanical Design - An Integral Approach", 1 Edition, Tata Mcgraw-Hill Book Co, 2003Document6 pagesText Books:: 2. Ansel Ugural, "Mechanical Design - An Integral Approach", 1 Edition, Tata Mcgraw-Hill Book Co, 2003Liaqat ahmedNo ratings yet

- SyllubusDocument1 pageSyllubuskssudhagarNo ratings yet

- Maintenance and Safety EngineeringDocument2 pagesMaintenance and Safety EngineeringMech HodNo ratings yet

- Me6504 Metrology and Measurements L T P CDocument1 pageMe6504 Metrology and Measurements L T P CajitsssNo ratings yet

- Practice: Methodology, Problems and Difficulties - Economics of Reliability EngineeringDocument3 pagesPractice: Methodology, Problems and Difficulties - Economics of Reliability Engineeringgurjotsingh29No ratings yet

- Anna University Electives GuideDocument22 pagesAnna University Electives GuidePatNo ratings yet

- Pom IeDocument5 pagesPom IepmagrawalNo ratings yet

- 7 ThsemsyllabusDocument8 pages7 ThsemsyllabusDhakshina KNo ratings yet

- Maintenance-EngineeringDocument67 pagesMaintenance-Engineeringmohan rajNo ratings yet

- Me 1012 MeDocument5 pagesMe 1012 MesureshkumarNo ratings yet

- COMPOSITE MATERIALS AND PROPERTIESDocument6 pagesCOMPOSITE MATERIALS AND PROPERTIESKrishnaVkNo ratings yet

- Maintenance Engineering Question BankDocument4 pagesMaintenance Engineering Question BankRockroll AsimNo ratings yet

- S8Document7 pagesS8Gopu KrishnaNo ratings yet

- Maintence and Safety PDFDocument97 pagesMaintence and Safety PDFariNo ratings yet

- 070 - ME8501 Metrology and Measurements - Anna University 2017 Regulation Syllabus PDFDocument2 pages070 - ME8501 Metrology and Measurements - Anna University 2017 Regulation Syllabus PDFSidhu Vev Sidhu0% (1)

- Puter Integrated Manufacturing SyllabusDocument41 pagesPuter Integrated Manufacturing SyllabusJoswa CaxtonNo ratings yet

- (332-345) IE - ElectiveDocument14 pages(332-345) IE - Electivegangadharan tharumarNo ratings yet

- ME6012 MaintainanceDocument5 pagesME6012 MaintainanceBHUVANESH NNo ratings yet

- Me1001 Unconventional Machining Process 3 0 0 100Document22 pagesMe1001 Unconventional Machining Process 3 0 0 100francislutherking8707No ratings yet

- Renewable Energy Sources Professional ElDocument6 pagesRenewable Energy Sources Professional Elசற்குணத்தமிழன் செNo ratings yet

- Industrial EngineeringDocument2 pagesIndustrial EngineeringKaran VirkNo ratings yet

- Maintenance Engineering QB DSEC 2013Document5 pagesMaintenance Engineering QB DSEC 2013Surya Narayan PandaNo ratings yet

- Aviation Maintenance ManagementDocument2 pagesAviation Maintenance ManagementNikiNo ratings yet

- SyllabusDocument1 pageSyllabusShankar NarayananNo ratings yet

- MAINTENANCE ENGINEERING SyllabusDocument2 pagesMAINTENANCE ENGINEERING Syllabus132 Arindam DattaNo ratings yet

- Mech 6th Sem SyllabusDocument14 pagesMech 6th Sem SyllabusArun ManoNo ratings yet

- Internal CombustionDocument26 pagesInternal CombustionakbsrajNo ratings yet

- Metrology and Measurements: An IntroductionDocument1 pageMetrology and Measurements: An Introductionk.l yuvarajNo ratings yet

- Manufacturing Management L T P C 3 0 0 3Document2 pagesManufacturing Management L T P C 3 0 0 3IyappanNo ratings yet

- 7th SemDocument17 pages7th SemShankar MukalNo ratings yet

- Course Module (VI Sem)Document7 pagesCourse Module (VI Sem)Vijay KumawatNo ratings yet

- Eighth Semester Syllabus MechDocument25 pagesEighth Semester Syllabus MechNabeel KhanNo ratings yet

- 7th Semester Mechanical Engineering Syllabus (MG University)Document13 pages7th Semester Mechanical Engineering Syllabus (MG University)Amit CherianNo ratings yet

- Total Quality Management, S.C. Sharma, M.P. Poonia, Khanna Publishing HouseDocument2 pagesTotal Quality Management, S.C. Sharma, M.P. Poonia, Khanna Publishing HouseDr-Gurpreet SinghNo ratings yet

- IE404 Industrial Engineering Quality Control and Inspection MethodsDocument2 pagesIE404 Industrial Engineering Quality Control and Inspection Methodsnandan144No ratings yet

- Anna University Curriculum for ME Manufacturing EngineeringDocument34 pagesAnna University Curriculum for ME Manufacturing EngineeringAnantha NarayananNo ratings yet

- Unit 1Document13 pagesUnit 1Vinay LuckyNo ratings yet

- State Board of Technical Education &training, Tamilnadu Diploma in Engineering / Technology Syllabus N - SchemeDocument15 pagesState Board of Technical Education &training, Tamilnadu Diploma in Engineering / Technology Syllabus N - SchemeIsrael Dharmaraj100% (1)

- Industrial Engineering and Management SyllabusDocument33 pagesIndustrial Engineering and Management SyllabusSahil KumarNo ratings yet

- IE404 - Industrial Engineering Course OverviewDocument2 pagesIE404 - Industrial Engineering Course OverviewRam RenNo ratings yet

- In-depth Pump Technology TrainingDocument2 pagesIn-depth Pump Technology TrainingehabwardaNo ratings yet

- Mtech Ie PDFDocument15 pagesMtech Ie PDFAnonymous 1kUvpdbWGNo ratings yet

- CIM SYSTEMS DESIGN MACHINE ELEMENTSDocument6 pagesCIM SYSTEMS DESIGN MACHINE ELEMENTSBala NarayanasamyNo ratings yet

- Maintenance Engineering Question BankDocument5 pagesMaintenance Engineering Question BankSengottaiyan MalaisamyNo ratings yet

- Manufact Engg FDocument31 pagesManufact Engg FtskcbeNo ratings yet

- Ic EngineDocument31 pagesIc EngineamanpurushothNo ratings yet

- Cad QBDocument7 pagesCad QBamanpurushothNo ratings yet

- PG Project Format2014Document28 pagesPG Project Format2014amanpurushothNo ratings yet

- Intze Tank Cross Section Dimensions and DetailsDocument1 pageIntze Tank Cross Section Dimensions and DetailsamanpurushothNo ratings yet

- Cad Lab ManualDocument55 pagesCad Lab ManualamanpurushothNo ratings yet

- Syllabus R2013 PDFDocument105 pagesSyllabus R2013 PDFlogeshboy007No ratings yet

- Model Fea QPDocument4 pagesModel Fea QPamanpurushothNo ratings yet

- Ii Cia Fea QPDocument2 pagesIi Cia Fea QPamanpurushothNo ratings yet

- Emerson Field Tools Quick Start GuideDocument48 pagesEmerson Field Tools Quick Start Guidepks_2410No ratings yet

- Midterm Exam Report Python code Fibonacci sequenceDocument2 pagesMidterm Exam Report Python code Fibonacci sequenceDim DimasNo ratings yet

- 100-Word Replacement PDFDocument14 pages100-Word Replacement PDFTheodore Vijay100% (1)

- Molar Mass, Moles, Percent Composition ActivityDocument2 pagesMolar Mass, Moles, Percent Composition ActivityANGELYN SANTOSNo ratings yet

- Chapter 3 Professional Practices in Nepal ADocument20 pagesChapter 3 Professional Practices in Nepal Amunna smithNo ratings yet

- Phaser 6510WC6515 Brochure EnglishDocument4 pagesPhaser 6510WC6515 Brochure EnglishToma ObretenovNo ratings yet

- First Communion Liturgy: Bread Broken and SharedDocument11 pagesFirst Communion Liturgy: Bread Broken and SharedRomayne Brillantes100% (1)

- Section 5 - Triangles - Part 1 Answer KeyDocument48 pagesSection 5 - Triangles - Part 1 Answer KeyErryn Lowe100% (2)

- Lesson Plans by Noman Niaz MaharDocument3 pagesLesson Plans by Noman Niaz MaharNoman Niaz 13No ratings yet

- 2689 26489 1 PBDocument9 pages2689 26489 1 PBAntonio EspañaNo ratings yet

- School RulesDocument2 pagesSchool RulesAI HUEYNo ratings yet

- Petroleum Research: Khalil Shahbazi, Amir Hossein Zarei, Alireza Shahbazi, Abbas Ayatizadeh TanhaDocument15 pagesPetroleum Research: Khalil Shahbazi, Amir Hossein Zarei, Alireza Shahbazi, Abbas Ayatizadeh TanhaLibya TripoliNo ratings yet

- Emotion-WPS OfficeDocument2 pagesEmotion-WPS OfficemikaNo ratings yet

- Row and Cluster Housing Building Codes and Bye LawsDocument1 pageRow and Cluster Housing Building Codes and Bye Lawssadhana illaNo ratings yet

- Science in VedasDocument42 pagesScience in VedasPratyush NahakNo ratings yet

- Protective & Marine Coatings: Hi-Solids Alkyd Metal PrimerDocument4 pagesProtective & Marine Coatings: Hi-Solids Alkyd Metal PrimerAna CabreraNo ratings yet

- Samsung C&T AuditDocument104 pagesSamsung C&T AuditkevalNo ratings yet

- Thesis Chapter 123Document15 pagesThesis Chapter 123Chesca Mae PenalosaNo ratings yet

- GES1003 AY1819 CLS Tutorial 1Document4 pagesGES1003 AY1819 CLS Tutorial 1AshwinNo ratings yet

- EASE Module 1 Geometric RelationsDocument26 pagesEASE Module 1 Geometric RelationsMarlon MiclatNo ratings yet

- Og FMTDocument5 pagesOg FMTbgkinzaNo ratings yet

- Lab Report 4 - Group 6Document15 pagesLab Report 4 - Group 6ClarisshaNo ratings yet

- CartridgeDocument26 pagesCartridgeMnavya SaiNo ratings yet

- Lesson Plan-MethodsDocument6 pagesLesson Plan-Methodsapi-272643370No ratings yet