Professional Documents

Culture Documents

Style EJ403: Installation Instructions

Uploaded by

Tanmoy Dutta0 ratings0% found this document useful (0 votes)

15 views1 pageEJ

Original Title

EJ 403 Install

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentEJ

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views1 pageStyle EJ403: Installation Instructions

Uploaded by

Tanmoy DuttaEJ

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

ROMAC

INDUSTRIES,

INC.

INSTALLATION INSTRUCTIONS

Read installation instructions first before installing. Check parts to ensure that no damage has occurred during transit and that no

parts are missing. Also check the diameter of the pipe and the range marked on the coupling to ensure you have the proper size

Expansion joints are not recommended for buried applications.

Style EJ403

Single End Expansion Joint with Limit Rods

Step 1 The expansion joint has been assembled and

Step 5 Tighten the packing gland bolts to 5 - 10 foot

shipped with the slip pipe in the closed (contracted) position.

The slip pipe must be properly positioned based on the

temperature at the time of installation.

pounds to hold the slip pipe in position.

Step 2 Check to be certain that the slip pipe is in the

Step 7

Step 3 Note:

Step 8 Expansion joints should be installed in an accessible location for further inspection and maintenance

when necessary. As the packing wears in service, adjust

the packing gland as necessary to stop leakage.

closed position. Place reference marks on body and slip

pipe for positioning of slip pipe and loosen the bolts so that

the slip pipe can be positioned.

do not move the lock nuts on the end

of the limit rods. These nuts are located to limit the maximum travel of the joint. If the lock nuts are moved and

need to be returned to their proper location, push the slip

pipe into the joint until it stops. The distance from the limit

ring to the contact side of the lock nuts should equal the

maximum travel of the expansion joint. Tighten the nuts

in this position.

Step 6 Install the expansion joint in the pipeline.

As the pipeline is pressurized, tighten the

packing gland bolts to compress the packing. Use sufficient torque to prevent leakage. Tightening further will only

cause premature packing wear.

Step 4 The distance the slip

Document #30-9-EJ403-0011

05/05/2014

pipe is to be withdrawn is calculated by the formula below:

Temp. Installation Temp.

slip pipe is

{(Max. Oper.

) x (Total Travel of Joint)} = Amount

to be withdrawn

Total Temperature Range

Example: Maximum Operation Temperature

Minimum Operating Temperature

Total Temperature Range

Installation Temperature

Total Travel of Joint

140

-20

160

80

10"

{140 - (-20 )} = 160

{(140160- 80) x (10)} = 3.75 inches

Caution: When reinstalling parts with stainless steel hardware there may be a loss in pressure holding ability

due to worn or damaged threads during the original installation.

21919 20th Avenue SE Suite 100 Bothell, WA 98021 Phone (425) 951-6200 1-800-426-9341 Fax (425) 951-6201

You might also like

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- PVC & CPVC Basket Strainers: Installation & Maintenance Service InstructionsDocument2 pagesPVC & CPVC Basket Strainers: Installation & Maintenance Service InstructionsTheresa NguyenNo ratings yet

- VAAS Fig 740 and 730 Series IOMDocument9 pagesVAAS Fig 740 and 730 Series IOMCarlos GutierrezNo ratings yet

- Welded Body Ball ValveDocument20 pagesWelded Body Ball ValveBisoyiNo ratings yet

- Handling Precautions: Butterfly Valves (Common To All Models)Document9 pagesHandling Precautions: Butterfly Valves (Common To All Models)xaaabbb_550464353No ratings yet

- AHU InstallationDocument14 pagesAHU InstallationAyyappan VeeraputhiranNo ratings yet

- Iom Cam Ball t31Document20 pagesIom Cam Ball t31Albino Felix HernandezNo ratings yet

- Maintenance Instruction Manual: Severe Service Control ValvesDocument9 pagesMaintenance Instruction Manual: Severe Service Control Valvesابزار دقیقNo ratings yet

- IOM Manual For CAMAROON Ball ValvesDocument20 pagesIOM Manual For CAMAROON Ball ValvesSathish Kumar Pt100% (2)

- TBV Series 21 20 Cryogenic Flanged Ball ValveDocument5 pagesTBV Series 21 20 Cryogenic Flanged Ball ValveJosip PobranNo ratings yet

- Iom WKM 310FDocument4 pagesIom WKM 310FNasir NaqviNo ratings yet

- Installation, Assembly and Test Procedure: Kamos Patented Kammprofil GasketDocument16 pagesInstallation, Assembly and Test Procedure: Kamos Patented Kammprofil Gasketjayhuacat7743No ratings yet

- Method Statement of Gasket, Flange, Fittings and Valves Tightening SequenceDocument6 pagesMethod Statement of Gasket, Flange, Fittings and Valves Tightening SequenceRuel CabonceNo ratings yet

- Full-Faced Expansion Joints: InstallationDocument3 pagesFull-Faced Expansion Joints: InstallationChiranjeevi AnilNo ratings yet

- Hot-Tapping ProceduresDocument2 pagesHot-Tapping ProceduresBensmatNo ratings yet

- Features/Description: 054-0240-001 CSU-1 Tubing Tester, 2-3/8" 054-0240-001Document3 pagesFeatures/Description: 054-0240-001 CSU-1 Tubing Tester, 2-3/8" 054-0240-001scignoniNo ratings yet

- Cam-Tite Ball Valve Operating Instructions: WarningDocument3 pagesCam-Tite Ball Valve Operating Instructions: WarningSubbarayan SaravanakumarNo ratings yet

- OCTG Running and Pulling TpsDocument11 pagesOCTG Running and Pulling Tpskaveh-bahiraeeNo ratings yet

- Bronze Gate Valve Installation, Operation and Maintenance Instructions InstallationDocument1 pageBronze Gate Valve Installation, Operation and Maintenance Instructions InstallationacastromNo ratings yet

- Iom MVT ValvesDocument5 pagesIom MVT ValvesNaser JahangiriNo ratings yet

- Sandblaster ManualDocument12 pagesSandblaster ManualgmelloyNo ratings yet

- GUIDANCE NEEDLE VALVESDocument2 pagesGUIDANCE NEEDLE VALVESRoo FaNo ratings yet

- XB 13 InstallDocument8 pagesXB 13 InstalljbozakNo ratings yet

- Safety Valves For Power PlantDocument56 pagesSafety Valves For Power Planttek_surinder100% (1)

- Condensate Collection (CCA/CCAF/CCM) and Steam Distribution (MSD/SMSD) Manifolds Installation, Operation and Maintenance InstructionsDocument4 pagesCondensate Collection (CCA/CCAF/CCM) and Steam Distribution (MSD/SMSD) Manifolds Installation, Operation and Maintenance InstructionsMarcial NuñezNo ratings yet

- 5r55e Valve Body SonnaxDocument8 pages5r55e Valve Body SonnaxjoshetoNo ratings yet

- Ideal Installation: I & M Mark 68G SeriesDocument4 pagesIdeal Installation: I & M Mark 68G SeriesByron PanchiNo ratings yet

- Installation and Maintenance Instructions Ball Valves, Fully WeldedDocument6 pagesInstallation and Maintenance Instructions Ball Valves, Fully WeldedvictorbirlanNo ratings yet

- KINKA KIKAI Installation Operation and Maintenance ManualDocument30 pagesKINKA KIKAI Installation Operation and Maintenance ManualyosNo ratings yet

- Fccu Expansion Joint InspectionDocument6 pagesFccu Expansion Joint InspectionIlker FaIthNo ratings yet

- 6 Way InstructionsDocument2 pages6 Way InstructionsFercho NoriegaNo ratings yet

- Bomba de Doble DiafragmaDocument3 pagesBomba de Doble DiafragmaOmar Horna PinedoNo ratings yet

- PHE Method StatementDocument3 pagesPHE Method Statementzampacaanas0% (1)

- G3 Gland Sealed Stop Valve-Installation Maintenance Manual PDFDocument2 pagesG3 Gland Sealed Stop Valve-Installation Maintenance Manual PDFchanNo ratings yet

- Standard Gate Valves ManualDocument8 pagesStandard Gate Valves ManualmechanikyNo ratings yet

- Resol FlowSol B Installation ManualDocument8 pagesResol FlowSol B Installation ManualDan JungNo ratings yet

- Rofi Operation and Maintenance ManualDocument3 pagesRofi Operation and Maintenance ManualSteve NewmanNo ratings yet

- With Bonnet: ModelDocument10 pagesWith Bonnet: Modeltoto-gmbhNo ratings yet

- JC 2648 Seal IOM Manual PDFDocument4 pagesJC 2648 Seal IOM Manual PDFRené Mora-CasalNo ratings yet

- Installation Manual - Eaton Model 53BTX SizesDocument6 pagesInstallation Manual - Eaton Model 53BTX SizesGrafton MontgomeryNo ratings yet

- Installation / Operation / Maintenance Instructions Magnetic Level GaugeDocument6 pagesInstallation / Operation / Maintenance Instructions Magnetic Level GaugeHumayun NawazNo ratings yet

- Fluidtecq Fluidtecq Fluidtecq Fluidtecq: Operation and Maintenance ManualDocument12 pagesFluidtecq Fluidtecq Fluidtecq Fluidtecq: Operation and Maintenance ManualmehtahemalNo ratings yet

- Swagelok TighteningDocument4 pagesSwagelok TighteningiswantmachooNo ratings yet

- Installation, Operation & Maintenance Manual: Virgo Engineers LimitedDocument47 pagesInstallation, Operation & Maintenance Manual: Virgo Engineers LimitedSreenivasNo ratings yet

- Checks To Be Carried Out On Receipt of The Actuator: ! - #$ Flow ControlDocument4 pagesChecks To Be Carried Out On Receipt of The Actuator: ! - #$ Flow ControlSyko GuyNo ratings yet

- Jones Hydrant OM 8-21-09Document6 pagesJones Hydrant OM 8-21-09RktBatamNo ratings yet

- Sno 450 XRDocument20 pagesSno 450 XRMelvin HrsNo ratings yet

- 7-7 Annual Hose Test ProcedureDocument5 pages7-7 Annual Hose Test ProcedureDavi LaraNo ratings yet

- Code of Practice SMW FDocument10 pagesCode of Practice SMW FardaneNo ratings yet

- Enimex - BVFL - GB PDFDocument6 pagesEnimex - BVFL - GB PDFAlienshowNo ratings yet

- Apex Packaged Refrigeration System Installation GuideDocument22 pagesApex Packaged Refrigeration System Installation GuideelmiracellNo ratings yet

- PTFE Expansion Joint Instructions 1Document1 pagePTFE Expansion Joint Instructions 1DDNo ratings yet

- Commercial Pumps: Installation and Operating InstructionsDocument8 pagesCommercial Pumps: Installation and Operating InstructionsrakeshamechNo ratings yet

- ArtMolds Pressure Pot Owner's ManualDocument4 pagesArtMolds Pressure Pot Owner's ManualAnonymous Wyb8Y1No ratings yet

- Pellet Stove ManualDocument17 pagesPellet Stove ManualDan DareNo ratings yet

- FIS113eng Hi Temp BellowsDocument8 pagesFIS113eng Hi Temp Bellowsmahesh_eilNo ratings yet

- Weflo Nrs Gate Op and MaintDocument5 pagesWeflo Nrs Gate Op and MaintyusufNo ratings yet

- Butt WeldingDocument4 pagesButt WeldingHürol KoçoğluNo ratings yet

- Washing Machine Service Manual Safety GuideDocument57 pagesWashing Machine Service Manual Safety GuideDavid Lovato100% (2)

- STI/14846/1 Dec.2000Document8 pagesSTI/14846/1 Dec.2000Tanmoy DuttaNo ratings yet

- Is 341-1973Document18 pagesIs 341-1973Karishma Prabhu100% (1)

- Bearing For GearboxDocument32 pagesBearing For Gearboxeng13100% (1)

- Glenfield Air ValvesDocument16 pagesGlenfield Air ValvesTanmoy DuttaNo ratings yet

- Type 4010 and 4010HD non return valvesDocument3 pagesType 4010 and 4010HD non return valvesTanmoy DuttaNo ratings yet

- Datasheet Type 40104010HD enDocument3 pagesDatasheet Type 40104010HD enTanmoy DuttaNo ratings yet

- IS 14846 Product ManualDocument5 pagesIS 14846 Product ManualKrishna Prasad KanchojuNo ratings yet

- Butterfly Valve ManualDocument5 pagesButterfly Valve ManualTanmoy DuttaNo ratings yet

- Non Return Check Valves With Lever and Counterweight PDFDocument7 pagesNon Return Check Valves With Lever and Counterweight PDFhuyenthaigiaNo ratings yet

- Butterfly Valve ManualDocument5 pagesButterfly Valve ManualTanmoy DuttaNo ratings yet

- Drawing1 Layout2 PDFDocument1 pageDrawing1 Layout2 PDFTanmoy DuttaNo ratings yet

- Product Manual For Resilient Seated Cast Iron Air Relief Valves For Water Works Purposes ACCORDING TO IS 14845: 2000Document5 pagesProduct Manual For Resilient Seated Cast Iron Air Relief Valves For Water Works Purposes ACCORDING TO IS 14845: 2000Tanmoy DuttaNo ratings yet

- Assem1 - Sheet1Document1 pageAssem1 - Sheet1Tanmoy DuttaNo ratings yet

- IS 5312 Part 1 Product ManualDocument6 pagesIS 5312 Part 1 Product ManualTanmoy DuttaNo ratings yet

- CI Tamper Proffe-ModelDocument1 pageCI Tamper Proffe-ModelTanmoy DuttaNo ratings yet

- Dual Plate 800 NB-ModelDocument1 pageDual Plate 800 NB-ModelTanmoy DuttaNo ratings yet

- Jis F7305Document1 pageJis F7305Tanmoy DuttaNo ratings yet

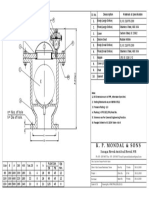

- K.P.Mondal & Sons: Works: Dasnagar, Howrah Amta Road, Howrah, West BengalDocument1 pageK.P.Mondal & Sons: Works: Dasnagar, Howrah Amta Road, Howrah, West BengalTanmoy DuttaNo ratings yet

- Bill of Materials Cast Iron Double Door Foot ValveDocument1 pageBill of Materials Cast Iron Double Door Foot ValveTanmoy DuttaNo ratings yet

- MATERIALS FOR CAST IRON NON RETURN VALVEDocument1 pageMATERIALS FOR CAST IRON NON RETURN VALVETanmoy DuttaNo ratings yet

- DJ Adaptor Body SpecificationDocument1 pageDJ Adaptor Body SpecificationTanmoy DuttaNo ratings yet

- Jis F7301Document1 pageJis F7301Tanmoy DuttaNo ratings yet

- DI Air Release Valve-ModelDocument1 pageDI Air Release Valve-ModelTanmoy DuttaNo ratings yet

- Jis F7305Document1 pageJis F7305Tanmoy DuttaNo ratings yet

- 300 NRV ModelDocument1 page300 NRV ModelTanmoy DuttaNo ratings yet

- MaskDocument1 pageMaskTanmoy DuttaNo ratings yet

- CI Sluice Valve With ActuatorDocument1 pageCI Sluice Valve With ActuatorTanmoy DuttaNo ratings yet

- Technical DetailsDocument4 pagesTechnical DetailsTanmoy DuttaNo ratings yet

- Technical DetailsDocument4 pagesTechnical DetailsTanmoy DuttaNo ratings yet

- Air Valve Kinetic 80 MM With ISVDocument1 pageAir Valve Kinetic 80 MM With ISVTanmoy DuttaNo ratings yet

- University of Chicago Press Fall 2009 CatalogueFrom EverandUniversity of Chicago Press Fall 2009 CatalogueRating: 5 out of 5 stars5/5 (1)

- University of Chicago Press Fall 2009 Distributed TitlesFrom EverandUniversity of Chicago Press Fall 2009 Distributed TitlesRating: 1 out of 5 stars1/5 (1)