Professional Documents

Culture Documents

HDPE Smooth Geomembrane Technical Data Sheet

Uploaded by

Agun GunawanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HDPE Smooth Geomembrane Technical Data Sheet

Uploaded by

Agun GunawanCopyright:

Available Formats

TECHNICAL DATA SHEET

Geomembrane HDPE Smooth

UNIT

Solmax

430-9000

Every roll

mm

0.75

ASTM D-5199

Every roll

mm

0.68

Resin Density

ASTM D-1505

1/Batch

g/cc

< 0.940

Melt Index - 190/2.16 (max.)

ASTM D-1238

1/Batch

g/10 min

1.0

Sheet Density (8)

ASTM D-792

Every 10 rolls

g/cc

> 0.94

Carbon Black Content (9)

ASTM D-4218

Every 2 rolls

2.0 - 3.0

Carbon Black Dispersion

ASTM D-5596

Every 10 rolls

Category

Cat. 1 / Cat. 2

OIT - standard (avg.)

ASTM D-3895

1/Batch

min

100

Tensile Properties (min. avg) (2)

ASTM D-6693

Every 2 rolls

kN/m

11

13

kN/m

21

700

PROPERTY

TEST METHOD

FREQUENCY

Thickness (min. avg.)

ASTM D-5199

Thickness (min.)

(1)

Metric

SPECIFICATIONS

Strength at Yield

Elongation at Yield

Strength at Break

Elongation at Break

Tear Resistance (min. avg.)

ASTM D-1004

Every 5 rolls

93

Puncture Resistance (min. avg.)

ASTM D-4833

Every 5 rolls

265

Dimensional Stability

ASTM D-1204

Per formulation

Stress Crack Resistance (SP-NCTL)

ASTM D-5397

1/Batch

hr

500

Oven Aging - % retained after 90 days

ASTM D-5721

Per formulation

%

80

50

HP OIT (min. avg.)

ASTM D-5885

UV Resistance - % retained after 1600 hr

HP-OIT (min. avg.)

SUPPLY SPECIFICATIONS

GRI-GM-11

Per formulation

ASTM D-5885

(Roll dimensions may vary 1%)

Roll Dimension - Width

8.00

Roll Dimension - Length

280.0

Area (Surface/Roll)

2240

NOTES

1. Testing frequency based on standard roll dimensions and one batch is approximately 180,000 lbs (or one railcar).

2. Machine Direction (MD) and Cross Machine Direction (XMD or TD) average values should be on the basis of 5 specimens each direction.

8. Correlation table is available for ASTM D792 vs ASTM D1505. Both methods give the same results.

9. Correlation table is available for ASTM D1603 vs ASTM D4218. Both methods give the same results.

* All values are nominal test results, except when specified as minimum or maximum.

* The information contained herein is provided for reference purposes only and is not intended as a warranty of guarantee. Final determination of suitability

for use contemplated is the sole responsability of the user. SOLMAX assumes no liability in connection with the use of this information.

MF-CQ-34

(Rev. 02 / 10-04-07)

Revision Date :

2014-11-19

You might also like

- PLATE (4239 023 21830) : Outside Dimensions (CM) Quantities (PCS) Weights (KG)Document3 pagesPLATE (4239 023 21830) : Outside Dimensions (CM) Quantities (PCS) Weights (KG)ree_haningNo ratings yet

- Indole 2 Carboxylic Acid, 99% MSDSDocument5 pagesIndole 2 Carboxylic Acid, 99% MSDSsonyamayorNo ratings yet

- Composite Bopp FilmDocument1 pageComposite Bopp FilmTahir MahmoodNo ratings yet

- PMMA Test MethodDocument8 pagesPMMA Test MethodFirman MuttaqinNo ratings yet

- E 96 - e 96M - 15Document13 pagesE 96 - e 96M - 15ruben carcamoNo ratings yet

- Iso 7854 en PDFDocument6 pagesIso 7854 en PDFSantosh ShettyNo ratings yet

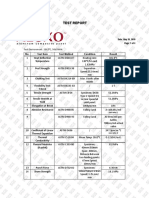

- Test Report: Page: 1 of 4 Date: May 26, 2010Document4 pagesTest Report: Page: 1 of 4 Date: May 26, 2010rqfsiypisnvabmtusrNo ratings yet

- 68 25 Haze Gard I PDFDocument6 pages68 25 Haze Gard I PDFshubhendra mishraaNo ratings yet

- PA66-RG301: Flame Retardant, 30% Glass Fiber Reinforced PA66Document2 pagesPA66-RG301: Flame Retardant, 30% Glass Fiber Reinforced PA66watnaNo ratings yet

- D1828-01 (2013) Standard Practice For Atmospheric Exposure of Adhesive-Bonded Joints and StructuresDocument3 pagesD1828-01 (2013) Standard Practice For Atmospheric Exposure of Adhesive-Bonded Joints and Structuresjose floresNo ratings yet

- Astm D1755 - 09Document6 pagesAstm D1755 - 09Deisabel Crespo100% (1)

- Impact Attenuation of Playing Surface Systems and Materials: Standard Test Method ForDocument6 pagesImpact Attenuation of Playing Surface Systems and Materials: Standard Test Method ForElif SarıoğluNo ratings yet

- PVC-1091 General Purpose Vinyl Suspension Resin for Pipes & ExtrusionsDocument1 pagePVC-1091 General Purpose Vinyl Suspension Resin for Pipes & ExtrusionsGabs GabrielaNo ratings yet

- Astm F903Document10 pagesAstm F903MohammedZoheb Hussain100% (2)

- Astm D3654-D3654M - 06 2011 PDFDocument6 pagesAstm D3654-D3654M - 06 2011 PDFdamaso taracenaNo ratings yet

- Astm D494Document3 pagesAstm D494Jony Gutiérrez Abanto0% (1)

- Short Course Mechanical-TestingDocument35 pagesShort Course Mechanical-TestingAndrei CostacheNo ratings yet

- ASTM D-1922-03a (Tear Resistance of Plastic Film by Pendulum Method)Document9 pagesASTM D-1922-03a (Tear Resistance of Plastic Film by Pendulum Method)T Aaa100% (1)

- Polymer Lab ManualDocument48 pagesPolymer Lab ManualShaukat AliNo ratings yet

- D 3194 - 17Document3 pagesD 3194 - 17Salma Farooq100% (1)

- Gloss MeterDocument2 pagesGloss Meterravi00098No ratings yet

- D 3307 - 04 - RDMZMDCDocument5 pagesD 3307 - 04 - RDMZMDCdanoninoNo ratings yet

- Nitrosamine Generating Accelerators in Curing of RubberDocument3 pagesNitrosamine Generating Accelerators in Curing of RubberkarlosmpNo ratings yet

- Drop Test of Loaded Containers by Free Fall: Standard Test Method ForDocument13 pagesDrop Test of Loaded Containers by Free Fall: Standard Test Method ForGyanendra Narayan NayakNo ratings yet

- PVC Technology: Chapter 12Document74 pagesPVC Technology: Chapter 12AndriNo ratings yet

- Selection of Test Methods For Ethylene Propylene Diene Terpolymer (EPDM) GeomembranesDocument3 pagesSelection of Test Methods For Ethylene Propylene Diene Terpolymer (EPDM) Geomembranesmohamed abd eldayemNo ratings yet

- ElmendorfTear ASTM D1922Document34 pagesElmendorfTear ASTM D1922Sukrito Kumar MittraNo ratings yet

- CDE ATI - Surface Treatment Info Pack PDFDocument6 pagesCDE ATI - Surface Treatment Info Pack PDFNithya SelvakumaranNo ratings yet

- TDS PU Sealant Bamco BSSL - Eng - 2014 Rev.03Document4 pagesTDS PU Sealant Bamco BSSL - Eng - 2014 Rev.03JoeNo ratings yet

- Astm D790Document2 pagesAstm D790HTCNo ratings yet

- DC 781 Acetoxy SealantDocument3 pagesDC 781 Acetoxy SealantL.S.No ratings yet

- ASTM D395 Rubber Compression Testing FixtureDocument6 pagesASTM D395 Rubber Compression Testing FixtureHazel EbordeNo ratings yet

- Burst Testing of Flexible Package Seals Using Internal Air Pressurization Within Restraining PlatesDocument8 pagesBurst Testing of Flexible Package Seals Using Internal Air Pressurization Within Restraining PlatesraulNo ratings yet

- D 1921 - 01 - Rde5mjeDocument5 pagesD 1921 - 01 - Rde5mjejamaljamal20100% (1)

- D 6463 - 99 Rdy0njmDocument4 pagesD 6463 - 99 Rdy0njmMarceloNo ratings yet

- Preparation of Surfaces of Plastics Prior To Adhesive BondingDocument3 pagesPreparation of Surfaces of Plastics Prior To Adhesive BondingShaker QaidiNo ratings yet

- F 2252 - 03 - RjiyntiDocument2 pagesF 2252 - 03 - RjiyntiAndres Camilo Benitez100% (1)

- ISO - 8543 - EN - Method For Determination of Mass of Textile Floor CoveringDocument6 pagesISO - 8543 - EN - Method For Determination of Mass of Textile Floor CoveringibrahimNo ratings yet

- Astm D1055-2009 PDFDocument7 pagesAstm D1055-2009 PDFcalidadcdokepNo ratings yet

- Insulation Selection Guide IIG-902Document2 pagesInsulation Selection Guide IIG-902surawutwijarnNo ratings yet

- Linear Dimensional Changes of Nonrigid Thermoplastic Sheeting or Film at Elevated TemperatureDocument2 pagesLinear Dimensional Changes of Nonrigid Thermoplastic Sheeting or Film at Elevated TemperatureStevenf2002No ratings yet

- Determining Residual Solvents in Packaging Materials: Standard Test Method ForDocument4 pagesDetermining Residual Solvents in Packaging Materials: Standard Test Method ForHernan MartNo ratings yet

- 30 Automotive Applications of Plastics: Past, Present, and FutureDocument23 pages30 Automotive Applications of Plastics: Past, Present, and FuturePatito Lisbhet Romero BuenoNo ratings yet

- Current Composites Testing ReportDocument4 pagesCurrent Composites Testing ReportMohamed RamzanNo ratings yet

- Bridge Impact Testing: Standard Test Method ForDocument5 pagesBridge Impact Testing: Standard Test Method ForAlevj DbNo ratings yet

- 3 6077 RTVDocument2 pages3 6077 RTVgkretroNo ratings yet

- Fibc Type A B C D Classification SafetyDocument2 pagesFibc Type A B C D Classification Safetydhineshbabu rNo ratings yet

- A Review On Rubber Compound Mixing in Banbury Mixer at Tire IndustriesDocument5 pagesA Review On Rubber Compound Mixing in Banbury Mixer at Tire IndustriesPrashantha NandavarNo ratings yet

- Astm d747 Pdqv6897Document5 pagesAstm d747 Pdqv6897Nayth Andres GalazNo ratings yet

- Accelerated Weathering Test Conditions and Procedures For Bituminous Materials (Fluorescent UV, Water Spray, and Condensation Method)Document3 pagesAccelerated Weathering Test Conditions and Procedures For Bituminous Materials (Fluorescent UV, Water Spray, and Condensation Method)Satya kaliprasad vangaraNo ratings yet

- Mechanical Handling of Unitized Loads and Large Shipping Cases and CratesDocument5 pagesMechanical Handling of Unitized Loads and Large Shipping Cases and CratesGabriel Herrera Gonzalez100% (1)

- ASTM D 3012 - 00 Thermal-Oxidative Stability of Polypropylene Using A Specimen Rotator Within An OvenDocument6 pagesASTM D 3012 - 00 Thermal-Oxidative Stability of Polypropylene Using A Specimen Rotator Within An Ovenalin2005No ratings yet

- Effects of Aging on Natural Rubber in Air and SeawaterDocument10 pagesEffects of Aging on Natural Rubber in Air and SeawatersdivyamitNo ratings yet

- Astm17 0901Document5 pagesAstm17 0901Erik Jhonattan Jara YpanaqueNo ratings yet

- ASTM D 1045 - 95 (Reapproved 2001) Sampling and Testing Plasticizers Used in PlasticsDocument4 pagesASTM D 1045 - 95 (Reapproved 2001) Sampling and Testing Plasticizers Used in Plasticsalin2005No ratings yet

- Astm D 333 - 96Document3 pagesAstm D 333 - 96Cynthia GutierrezNo ratings yet

- HDPE Geomembrane Specification SheetDocument1 pageHDPE Geomembrane Specification SheetAzfar Aizat ZawawiNo ratings yet

- 01.03.02.106 Spesifikasi-SOLMAX THA HDPE 2.00mm Black Smooth - 1084285 (HDS-200LM)Document1 page01.03.02.106 Spesifikasi-SOLMAX THA HDPE 2.00mm Black Smooth - 1084285 (HDS-200LM)Aswin MustaminNo ratings yet

- Lldpe Series 1.50MM Black TexturedDocument2 pagesLldpe Series 1.50MM Black TexturedBexy Nathaly DiazNo ratings yet

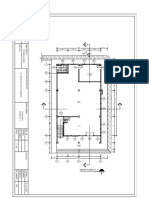

- Denah Kusen Lt.2Document1 pageDenah Kusen Lt.2Agun GunawanNo ratings yet

- Denah Kusen LT 1Document1 pageDenah Kusen LT 1Agun GunawanNo ratings yet

- Interior & Building Contractor: Living Room Bedroom Kitchen Wardrobe OfficeDocument2 pagesInterior & Building Contractor: Living Room Bedroom Kitchen Wardrobe OfficeAgun GunawanNo ratings yet

- 01 Company ProfileDocument9 pages01 Company ProfileAgun GunawanNo ratings yet

- Detail Kusen 3Document1 pageDetail Kusen 3Agun GunawanNo ratings yet

- Lce Gudang Limbah b3, DBR, PT Bap (Ok)Document5 pagesLce Gudang Limbah b3, DBR, PT Bap (Ok)Agun GunawanNo ratings yet

- GCM Interior & Building ContractorDocument1 pageGCM Interior & Building ContractorAgun GunawanNo ratings yet

- Pot ADocument1 pagePot AAgun GunawanNo ratings yet

- Business Planning OverviewDocument16 pagesBusiness Planning OverviewAgun GunawanNo ratings yet

- Analisa Harga SatuanDocument10 pagesAnalisa Harga SatuanKurnia IrianiNo ratings yet

- Harga Material 2017Document10 pagesHarga Material 2017Agun GunawanNo ratings yet

- LCE Menara Link Three Angle 68 M S.lumpurDocument3 pagesLCE Menara Link Three Angle 68 M S.lumpurAgun GunawanNo ratings yet

- Tabel Besi UjungDocument31 pagesTabel Besi UjungAgun GunawanNo ratings yet

- GCM Interior & Building ContractorDocument1 pageGCM Interior & Building ContractorAgun GunawanNo ratings yet

- Bilingual TRF 1770S-2016Document10 pagesBilingual TRF 1770S-2016Vtrock The'IlectraNo ratings yet

- Precast Concrete Frame Buildings Design GuideDocument91 pagesPrecast Concrete Frame Buildings Design GuideAmiruddin Bin Mishad50% (2)

- Variflex BrochureDocument15 pagesVariflex BrochureAgun GunawanNo ratings yet

- Round OwnDocument1 pageRound OwnAgun GunawanNo ratings yet

- PNADM117Document33 pagesPNADM117Shem Pia Civor SangannaNo ratings yet

- Data Sheet Width Flange BeamDocument32 pagesData Sheet Width Flange BeamIrvan IskandarNo ratings yet

- PNADM117Document33 pagesPNADM117Shem Pia Civor SangannaNo ratings yet

- Constr Esb750Document127 pagesConstr Esb750Erica MosesNo ratings yet

- PAKETDocument1 pagePAKETAgun GunawanNo ratings yet

- Three Stars Cable LadderDocument3 pagesThree Stars Cable LadderAgun GunawanNo ratings yet

- PAKETDocument1 pagePAKETAgun GunawanNo ratings yet

- PAKETDocument1 pagePAKETAgun GunawanNo ratings yet

- Three Stars Cable TrayDocument4 pagesThree Stars Cable TrayAgun GunawanNo ratings yet

- Analisa Harga Satuan Jasa Pemasangan Instalasi ListrikDocument95 pagesAnalisa Harga Satuan Jasa Pemasangan Instalasi ListrikAgun GunawanNo ratings yet

- GBR H11 DPDocument1 pageGBR H11 DPAgun GunawanNo ratings yet

- I. 5 - Alat-Alat ListrikDocument68 pagesI. 5 - Alat-Alat ListrikAgun GunawanNo ratings yet