Professional Documents

Culture Documents

Determinación de La Clasificación de Areas

Uploaded by

electrofuerteCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Determinación de La Clasificación de Areas

Uploaded by

electrofuerteCopyright:

Available Formats

Originally appeared in:

November 2008, pgs 47-50.

Used with permission.

SpecialReport

plant safety and environment

Determining the proper hazardous

area classification

Heres a common-sense approach using a basic four-part process

J. E. Johnston, Bath Engineering Corporation, Corpus Christi, Texas

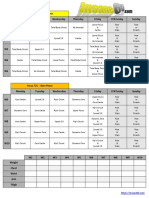

Fig. 1

100 UEL

4.0 LEL

Group B

hydrogen

36 UEL

2.7 LEL

Group C

ethylene

Explosive range by vapor grouping.

HYDROCARBONPROCESSING November 2008

Explosive range

2.5 LEL

Group A

acetylene

Explosive range

75 UEL

Explosive range

100

90

80

70

60

50

40

30

20

10

0

Explosive range

Class I areas. These are locations where flammable gases or

vapors are or may be present in the air in quantities sufficient to

produce an explosive or ignitable mixture. In Class I areas that

utilize the division concept methodology, two distinct divisions

are predicated on the operational interpretation of normal vs.

abnormal and frequent vs. infrequent.

Division 1 locations where ignitable concentrations of flammable gases or vapors can exist are due to:

Under normal operating conditions

Frequently because of maintenance or repair

Frequent leakage

Below grade where adequate ventilation does not exist

When releases from faulty process equipment operations

result in the simultaneous failure of electrical equipment.

Division 2 locations where ignitable concentrations of flammable gases or vapors can exist are:

Failure of closed containment systems

Abnormal operation or failure of processing and ventilation

equipment

Area is adjacent to a Division 1 location.

In Class I areas that utilize the division concept methodology,

four distinct groups are based solely on the liquid or gas ease of

ignitability and its corresponding range of flammability. Fig. 1

illustrates this concept.

Group Aatmospheres that contain acetylene

Group Bflammable gas or vapor atmospheres having either

a maximum experimental safe gap (MESG) less than or equal to

0.45 mm or a minimum ignition current (MIC) ratio less than

or equal to 0.40 mm.

Group Cflammable gas or vapor atmospheres having either

an MESG greater than 0.45 mm and less than or equal to 0.75

mm or an MIC ratio greater than 0.40 mm and less than or equal

to 0.80 mm.

Group Dflammable gas or vapor atmospheres having either

an MESG greater than 0.75 mm or an MIC ratio greater than

0.80 mm.

The explosive ranges, as indicated in Fig. 1, are based on

normal atmospheric pressure and temperature. As the mixture

temperature increases, the flammable range shifts downward. As

the mixture temperature decreases, the flammable range shifts

upward. It can be easily determined from examining the graph

that the mixture volatility is much greater for Group A mixtures

compared to Group D mixtures.

Classes of combustible liquids include Class II which is any

liquid with a flash point greater than 100F and less than 140F.

Class III liquids are liquids with a flash point greater than 140F.

Class III liquids are further divided as either Class IIIA liquids

or Class IIIB liquids. Class IIIA liquids have a flash point greater

than 140F and less than 200F. Class IIIB liquids have a flash

point greater than 200F. The Occupational Safety and Health

Administration states in 1910.106 (a)(18)(iii) that, when a combustible liquid is heated to within 30F of its flash point, it shall

be handled in accordance with the requirements of the next lower

class of liquids. If the material is a combustible liquid that is not

Volume, %

he concept of assessing and limiting the risk associated

with installing electrical devices in areas where potentially

explosive atmospheres may be present is referred to as

area classification. Hazardous area classification assessment is a

probability analysis and risk assessment evaluation of a manufacturing or process area processing a potentially flammable

atmosphere that focuses exclusively on minimizing or eliminating electrical energy as a potential ignition source. Hazardous area classification is not intended to be a secondary line of

defense against poor process design, poor facility and equipment

maintenance, faulty equipment operation, or catastrophic vapor

releases. Hazardous areas are divided into three distinct classes

that totally depend on the material type that is encountered in

the process.

9.5 UEL

2.1 LEL

Group D

propane

Cloud footprint

1.5

1.0

0.5

0.0

Study folder: Area

classification study

audit no. 351

Model: New vessel/pipe

Source

Weather: Category 1.5/F

Material: Gasoil

Averaging time:

Flammable (18.75 s)

C/L offset 0 ft

Legend: Concentration

Time: 1.405 s

0.2001%

0.4%

3.7%

0.5

Cloud height, ft

3 yd2 @ 0.2001%

1 yd2 @ 0.4%

0 yd2 @ 3.7%

2.0

Cloud width, ft

Study folder: Area

classification study

audit no. 351

Model: New vessel/pipe

Source

Weather: Category 1.5/F

Material: Gasoil

Averaging time:

Flammable (18.75 s)

Height 3.28 ft

Legend: Concentration

Time: 1.405 s

1.0

1.5

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

2.0

Distance downwind, ft

Fig. 2

Side view

4.8

4.6

4.4

4.2

4.0

3.8

3.6

3.4

3.2

3.0

2.8

2.6

2.4

2.2

2.0

1.8

1.6

1.4

1.2

1.0

Distance downwind, ft

Class III liquid vapor cloud dispersion.

heated to within 30F of its flash point, then the area does not

need to be classified. The other and most encountered scenario

is when the combustible liquid is heated within the process to

several hundred degrees in excess of its flash point. This is typical

in refinery and petrochemical operations in the US.

Fig. 2 represents a vapor dispersion model of a Class IIIB mixture in a typical refinery operation. Both the vapor cloud footprint

and side view are shown, and has a flash point of 180F. The release

scenario is 500 lbs of product through a 0.1 in. orifice leak in a

vessel. The process pressure is 220 psig at 675F. The area shown

in green is the vapor cloud mass that is above the lower flammable

limit and below the upper flammable limit. This mass is in the

explosive or flammable region. The ignitable portion of the vapor

cloud extends outward some 14 ft. Notice that the flammability

range was reduced significantly by the increase in process temperature (from 6 to 13.5% in air to 0.4 to 3.7% in air).

Class II areas. These are hazardous locations because combustible dust is present. Combustible dust is defined as any solid

material 420 microns or less in diameter that present a fire or an

explosion hazard when dispersed in air. Like Class I areas, Class II

areas are also divided into two distinct divisions that again depend

on operational interpretation of normal vs. abnormal.

Division 1 is a location where combustible dust is present in

the air:

Under normal operating conditions, in quantities sufficient

to produce an explosive or ignitable mixture

The dust is electrically conductive. Dusts are considered to

be electrically conductive if the electrical resistivity of the solid

material from which the dust is formed has a value of less than

105 ohm-cm.

Releases from faulty operation of process equipment result

in the simultaneous failure of electrical equipment, causing the

electrical equipment to become a source of ignition.

Division 2 is a location where combustible dust is:

Present in the air only under abnormal operating conditions in

quantities sufficient to produce an explosive or ignitable mixture.

Accumulations are normally insufficient to interfere with

the normal operation of electrical equipment or other apparatus,

but combustible dust could be in suspensions in the air due to

infrequent process equipment malfunctions.

Accumulations on, in, or in the vicinity of the electrical

equipment could be sufficient to interfere with the safe dissipation of heat from electrical equipment, or could be ignitable by

abnormal operation or electrical equipment failure.

The following information contained in Table 1 is a rule-ofthumb guideline in determining dust layer accumulation vs. the

required classification. The dust accumulations in Table 1 are based

upon a 24 hr build-up on horizontal surfaces.

In Class II areas, three distinct groups are based primarily on

the physical characteristics of the dust:

Group Eatmospheres that contain combustible metal

dusts, including aluminum, magnesium and their commercial

alloys, or other combustible dusts whose particle size, abrasiveness and conductivity present similar hazards in the use of

electrical equipment.

Group Fatmospheres containing combustible carbonaceous

dusts that have more than 8% total entrapped volatiles or that

have been sensitized by other materials so that they present an

explosion hazard. Representative combustible dusts that fall into

this grouping are coal, carbon black, charcoal and coke.

Group Gatmospheres containing other combustible dusts,

including flour, grain, wood flour, plastic and chemicals.

Explosion severity is a measure of the damage potential of the

energy released by a dust explosion. The US Bureau of Mines (USBM)

has defined the equation for calculating explosion severity as:

(P P)2

Explosion severity = max

(Pmax P )1

where:

Pmax = maximum explosion pressure

P = maximum rate of pressure rise

Subscript 1 refers to the values used for Pittsburgh seam coal.

where:

HYDROCARBONPROCESSING November 2008

plant safety and environment

Pmax = 8.1 bar

P = 214 bar/sec

Subscript 2 refers to the values for the specific dust in question.

Ignition sensitivity is a measure of the ease by which a cloud

of combustible dust can be ignited. The USBM has defined the

equation for calculating ignition sensitivity as:

(T E M c )1

Ignition sensitivity = c

(Tc E M c )2

where:

Tc = minimum ignition temperature

E = minimum ignition energy

Mc = minimum explosion concentration

Subscript 1 refers to the values used for Pittsburgh seam coal.

where:

Tc = 591C

E = 160 mj

Mc = 70 g/m3

Subscript 2 refers to the values for the specific dust in question.

Dusts that have ignition sensitivities equal to or greater than 0.2

or explosion severities equal to or greater than 0.5 are considered to

have enough volatility to warrant locations processing these dusts

to be classified. The material published by the USBM is no longer

in print and copies are hard to find.

Class III areas. These are hazardous locations because easily

ignitable fibers and flyings are present. In Class III areas, there are

no groupings as in Class I and Class II areas. There are, however,

divisions that are based on how the material is processed. Division

1 is a location where easily ignitable fibers producing combustible

flyings are handled, manufactured or used. Division 2 is a location

where easily ignitable fibers are stored or handled other than in the

manufacturing process.

Risk-assessment methodology development. A risk-

assessment methodology must be developed prior to beginning

the actual area classification assessment itself. This methodology

sets the ground rules by which the assessment is conducted. The

deliverables presented at the completion of the assessment methodology are:

Key members of the assessment team are identified, along

with their respective roles and responsibilities required to support

the assessment process. Typically, this core team will consist of an

operations representative, a mechanical integrity representative, the

individual who is conducting the actual assessment and a process

engineer.

The assessment concept point source vs. the blanket classification will be determined.

All potential point sources of emissions will be identified.

Point sources are process equipment that continuously or intermittently release flammable vapors into the atmosphere during routine

modes of operation. Typical equipment that should be considered

are: mechanical pumps seals, valve packing, overpressure protection devices, filters, compressor seals, process drains and vents and

all hydrocarbon-containing pressure vessels.

Such terms as normal vs. abnormal and frequent vs. infrequent are operationally defined.

How to address the following scenarios is determined: the extent

of classified areas that extend beyond unit battery limits, the extent of

classified areas that extend into roadways, areas where ignition sources

other than electrical are present under normal operating conditions,

SpecialReport

TABLE 1. Dust layer accumulation vs. classification

Dust layer thickness Recommended classification

Greater than 18 in. (3 mm)

Division 1

Less than 18 in. (3 mm), but color not discernable

Division 2

Surface color discernable under the dust layer

Unclassified

areas where pipe bridges and racks either cross or are adjacent to

roadways, the impact of facility or unit operational history, and the

discovery of errors and omissions in documentation.

How the various codes and standards writing organizations

will apply. Typically, the National Fire Protection Association

(NFPA) is used for all petrochemical applications and the American Petroleum Institute (API) is used for refinery applications.

It is determined whether the division or zone concept will be

utilized. Typically, the division concept is used in the US and the

zone concept is used in Canada and Europe.

The authority that has jurisdiction is identified.

Area classification assessment. Once the risk assessment

methodology is developed, then the actual process of classifying

the area is ready to begin. A typical assessment study will include

seven basic steps:

Step 1. Obtain the required documentation that was determined

from the assessment methodology. Provide a lower level view of the

process for equipment identification and process arrangements.

Step 2. Field-survey the area in question to determine if the

plot plans are accurate and verify location of all point sources of

emissions.

Step 3. Determine the classified area extent that surrounds each

point source of emission. This will determine the role that each

point source will play in the overall composite area classification

diagram. The extent of classification diagrams should come from

NFPA 497 for petrochemical applications, API RP500 for petroleum refinery applications and/or gas dispersion modeling software

tools. Gas/vapor dispersion modeling software should be utilized

when one out of these three scenarios exists:

1) Extreme process conditions are encountered such as large

flowrates > 250 gpm, pressures > 275 psig and liquids with a vapor

pressure > 70 psia at operating temperature.

2) Combustible liquids are heated to temperatures > 100F of

their respective flash points.

3) The stream composition is a complex mixture of hydrocarbons.

Step 4. Develop the composite area classification plan drawing

that embellishes the contribution of all point sources.

Step 5. Develop elevation drawings to provide clarity where there

are emission sources located in multilevel process structures. A plan

view will be required for each level in the process structure.

Step 6. Conduct the compliance audit.

Step 7. Create a detailed assessment report that documents the

following information:

The rationale used to classify the areas

The critical process material information usually obtained

from the material safety data sheets

A detailed listing of all point sources of emissions that appear

on the drawings

Special out-of-the-ordinary exceptions that were taken when

classifying a particular location

The results or findings obtained from the compliance audit

HYDROCARBONPROCESSING November 2008

SpecialReport

plant safety and environment

A vapor dispersion modeling graph.

All area classification documentation should be placed under

the protection of the facilities management of change process control. As modifications are made to the facility, these documents

should be reviewed to verify the impact of these modifications.

Protection methods and hazard reduction. Hazard

reduction is where a facility reduces the probability or risk of

significant property damage and/or loss of life as the result of an

explosion or a fire. It helps ensure that installing electrical equipment in a hazardous location does not significantly raise the risk

or probability of an explosion or a fire. This is the point where

steps are taken to provide compliance with the area classification

assessment. Mitigation options are discussed and corresponding

action items are carried out.

Protection methods in Class 1 areas. It is important to

follow the key protection methods:

Physically isolate the hazard by placing or relocating the

normal arc-producing electrical devices to a nonhazardous area.

This is an attractive option when approved equipment for the

classified area is not readily or commercially available.

Confining the explosion is the most common and widely

accepted protection method. It deploys the use of devices that are

vendor-certified, through listing or labeling, as explosion-proof.

Explosion-proof means that the device enclosure is designed and

tested in a manner that guarantees if a flammable vapor enters the

enclosure and is ignited by an electrical arc or a hot surface within

the enclosure, the resulting explosion is contained within the

enclosure. The electrical apparatus contained within the enclosure

should still be operational.

Energy limiting is known as an intrinsic safety measure, that

prevents ignition by limiting the released energy resulting from

wiring and component failures or faults. Underwriters Laboratory

listed intrinsically safe electrical devices are incapable of releasing

enough energy under normal or abnormal conditions to cause

ignition of a specific hazardous atmosphere in its most easily

ignitable concentrations.

Hermetically sealed types of protection ensure that arc- or

heat-producing devices are sealed against the intrusion of the

hazardous vapor.

Pressurization is the process of supplying an enclosure with

a protective gas with or without continuous flow to prevent the

entrance of a flammable vapor, combustible dust or ignitable fiber.

Purging is the process of supplying an enclosure with a protective gas at a sufficient flow and positive pressure to reduce the concentration of any flammable vapor initially present to a safe level.

Pressurized system types. Type X reduces the classification

within a protected enclosure from Division 1 to unclassified.

The design requirements for a Type X purge system are the

following:

A positive pressure > 0.1 in. of water with equipment energized should be maintained.

Exchange four enclosure volumes of purge gas before energizing components with a required interlock.

An interlock is required to remove power from internal

electrical components in the enclosure when the purge pressure

falls below 0.1 in. of water.

Power from enclosure when enclosure is opened must be

removed.

The pressure alarm must be located in a continuously

attended area.

Type Y reduces the classification within a protected enclosure

from Division 1 to Division 2. Type Z reduces the classification

within the protected enclosure from Division 2 to unclassified.

The design requirements for a Type Y or Z purge system are:

Maintain positive pressure greater than or equal to 0.1 in. of

water with equipment energized.

Exchange four enclosure volumes of purge gas before energizing components (no interlock required).

Purge system failure must be detected with an alarm.

The oil immersion protection method is where the arc-producing or heat-generating devices are immersed in oil thereby

eliminating the intrusion of potentially hazardous vapors. This

method can only be used for Division 2 areas.

Protection methods in Class II areas. It is important to

follow the key protection methods:

Physically isolate the hazard in the same manner as for Class

I areas.

Utilization of dust ignition-proof equipment requires two

things: 1) the enclosure is dust-tight, and 2) the enclosure is constructed so that heat generated inside will not ignite a dust layer

on or a combustible cloud surrounding the enclosure.

Purging may be used as long as the NFPA 496 requirements

are followed.

Energy limiting is at the same level of protection as in Class

I areas.

Protection methods in Class III areas. These areas

employ the same methods that were utilized for Class II areas.

The basic requirement is to make use of dust-tight enclosures for

all normal arc-producing electrical devices. HP

BIBLIOGRAPHY

Korver, W.O.E, Part 1 Fundamentals, Electrical Safety in Flammable Gas/Vapor Laden Atmospheres, 1st Ed., William Andrews Publishing, Norwich, New York, pp. 68, 2001.

NFPA 30, Flammable and Combustible Liquids Code, 2000 Ed., NFPA, Quincy, Massachusetts, 2000.

NFPA 496, Standard for Purged and Pressurized Enclosures for Electrical Equipment, 1998 Ed.,

NFPA, Ouincy, Massachusetts, 1998.

NFPA 497, Recommended Practice for the Classification of Flammable Liquids, Gases or Vapors

and of Hazardous (Classified) Locations for Electrical Installations in Chemical Process Areas,

1997 Ed., NFPA, Ouincy, Massachusetts, 1997.

NFPA 499, Recommended Practice for the Classification of Combustible Dusts and of Hazardous

(Classified) Locations for Electrical Installations in Chemical Process Areas, 1997 Ed., NFPA,

Ouincy, Massachusetts, 1997.

ANSI/API PR5000, Recommended Practice for Classification of Locations for Electrical Installations at Petroleum Facilities Classified as Class I, Division 1 and Division 2, 2nd Ed., API

Publishing Services, Washington, DC, 1997.

ISA-12.10, Area Classification in Hazardous (Classified) Dust Locations, ISA, Research Triangle

Park, North Carolina, 1988.

ISA-RP12.4, Pressurized Enclosures, ISA, Research Triangle Park, North Carolina, 1996.

Johnston, J., A Common-Sense Approach to Hazardous Area Classification Assessment,

Instrumentation Symposium for the Process Industries, Texas A&M University, College

Station, Texas, January 2001.

Cashdollar, K., M. Hertzberg and R. Conti, RI-8988 Bureau of Mine Report of Investigations/1985, Electrical Ignition Energies and Thermal Autoignition Temperatures for Evaluating

Explosion Hazards of Dusts, United States Dept of the Interior, 1985.

Early, M., National Electrical Code Handbook, 9th Ed., NFPA, Quincy, Massachusetts, 2002.

Jim Johnston is a professional engineer for Bath Engineering

Corporation. He has become nationally recognized through his

expertise on site evaluation and compliance auditing regarding

issues on electrical safety in hazardous locations. Mr. Johnstons

knowledge is derived from his more than 34 years with the petrochemical and petroleum refining industries where he designed process safety shutdown systems, performed electrical safety reviews,

implemented compliance design solutions, participated in process safety reviews,

and installed field instrumentation application and control system designs. He has

authored several technical papers on electrical safety in hazardous locations and has

presented these papers in symposiums and participated in technical conferences

throughout the US. Mr. Johnston received his BS degree in electrical engineering

from the University of Houston.

Article copyright 2008 by Gulf Publishing Company. All rights reserved.

Printed in U.S.A.

Not to be distributed in electronic or printed form, or posted on a Website, without express written permission of copyright holder.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Area Classification GuideDocument42 pagesArea Classification Guideowenh796100% (4)

- En 61000-3-2Document9 pagesEn 61000-3-2Juan Marinero TarazonaNo ratings yet

- 01 CatsegRejibandDocument92 pages01 CatsegRejibandSherri CollinsNo ratings yet

- Aceite Hidraulico MSDS 743581Document10 pagesAceite Hidraulico MSDS 743581electrofuerteNo ratings yet

- Aceite Hidraulico - Mobil DTE 10 Excel Series - PropiedadesDocument2 pagesAceite Hidraulico - Mobil DTE 10 Excel Series - PropiedadeselectrofuerteNo ratings yet

- Aceite Hidraulico MSDS 743581Document10 pagesAceite Hidraulico MSDS 743581electrofuerteNo ratings yet

- Curso de Entrenamiento Personal de Un MesDocument1 pageCurso de Entrenamiento Personal de Un MeselectrofuerteNo ratings yet

- Metodo de Los Bloques de PotenciaDocument36 pagesMetodo de Los Bloques de PotenciaelectrofuerteNo ratings yet

- Determinación de La Clasificación de AreasDocument4 pagesDeterminación de La Clasificación de AreaselectrofuerteNo ratings yet

- English For Teachers ManualDocument112 pagesEnglish For Teachers ManualelectrofuerteNo ratings yet