Professional Documents

Culture Documents

Yakima Plastic Wood

Yakima Plastic Wood

Uploaded by

henryjjcCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Yakima Plastic Wood

Yakima Plastic Wood

Uploaded by

henryjjcCopyright:

Available Formats

AboutYakima

About Yakima

Yakima Wood Plastic Composite decking is made using plastic and natural organic fibers, creating a

revolutionary composite of improved, user-friendly material that out-performs other traditional pure

wooden and plastic material. The manufacturer has developed a wide range of WPC product designs

for outdoor and commercial applications.

Yakima Composite decking does not need to be stained or sealed, which will save you time and money

now and in the future. With better material and advanced processing techniques, Yakima WPC decking

are free from conventional wood problems such as splitting, warping, and decay, reducing the cost and

need for replacement or repairs. Here are a few valuable benefits when choosing Yakima WPC for your

home or business.

z Environmentally friendly- 100% recycled material and 100% recyclable

z Saving time and money- easy maintenance and installation

z Longer usage/ life cycle- resistant to rot and wood eating organisms

z Stronger and more flexible than traditional wood products

z Standard woodworking tools can be used.

Colors

Beige

Grey

Walnut

1/14

Mahogany

TableofContents

About Yakima..1

Deck Component3

Tools....4

Framing and installation.5

Fastening.7

Deck Spacing and Gapping..8

Weathered Colors...11

Yakima Properties..12

Yakima Care & Maintenance..13

2/14

DeckComponent

Yakima Grooved Composite Decking

Yakima Deck Clips and Screws

Yakima Fascia Board

2x4Wood Joists

Yakima Deck Clips -Found everywhere where Yakima Composites are sold.

Composite Deck Screws Yakima composites work well with most composite decking screws found in most

local hardware stores.

Note: All composites expand and contract; our clips are designed to prevent the buckling that occurs with the use

of too many screws.

3/14

Tools

Yakima composites work well with standard woodworking tools

It is recommended that all blades and router to have carbide tips

Sanding is not recommended as it will change the surface texture and appearance of the

composite

Proper clothing and safety equipment are recommended when working with all tools and

equipments.

Miter Saw: Standard miter saws can be used to cut Yakima decking to size. 10-12

saw blades with 30 or less teeth are recommended to create a smooth, clean cut.

Screw Guns: Screw guns can be used to fasten Yakima solid decking. It is an

easy fastening solution that will save you from back pains. Note that screw guns

cannot be used to fasten hidden fasteners in the Yakima grooved decking system.

Drills: Standard drills and drill bits can be used when drilling into Yakima composites.

When drilling into Yakima solid decking, it is recommended to occasionally lift the drill

to prevent shavings from building up in the hole. Build up of shavings in the hole

makes it harder to drill. This is not necessary for the voided profiles. Tip: Shavings

can be used to cover screws for a smoother appearance.

Router: Extraordinary profiles with detailed shapes and patterns can be created with

the router. Routers are not recommended for beginner carpenters. Note that routing

changes the surface texture and appearances of Yakima composites. Do not route

any part of the Yakima Railing system as it changes the structural integrity of the

system.

4/14

FramingandInstallation

Framing

5/16x8 carriage bolts and nuts

with washer (required at all posts)

Fasten at minimum

1 off edge of board

4x4 Post

Joist spacing can

only be a maximum

of 16 off center

2x4 Wood Joist

Rim joist: 2x8 0r larger, check with local code

authority for size requirements of rim and wood

Joist

NTS (Not Scale)

5/14

Installation

Before you install: We recommend that wherever possible you purchase all of the boards required for your

project from one batch in order to avoid any possible color variation that may occur between different

manufacturing runs. The natural fibers used in the manufacture of Yakima composite decking allow some color

variation between boards and will enable the overall color to lighten, creating a weathered color effect over time.

Allow 8-12 weeks of full exposure to sunlight in order for the majority of the color weathering to occur.

The grain of Yakima composite decking will reflect light differently depending on the orientation of the boards. To

ensure the same look across the deck it is necessary to run all deck boards in the same direction as the grain.

Laying out the deck boards before fixing allows you to check your color mix and grain orientation (this is an

important step in the installation method ensuring that each board is the same temperature prior to any cutting).

Grooved Systems with Hidden Fasteners

1. Place 1st piece of Yakima decking at the edge perpendicular to the wood joist.

Notch the Yakima composite to accommodate for the 4x4 Post.

2. Fasten screws at the edge of deck boards at a minimum of 1 from the edge on

all sides. Note that screws are needed around opening of 4x4 Post also.

3. Place the 2nd deck board with a slight gap between the two boards.

4. Slide the hidden fasteners T-clip C-4 between the two boards; Place one at

each joist locations.

5. Make sure to put a clip K-2 in the middle between every two boards so that

the decking boards will not move at any condition.

6. After all hidden fasteners are placed, fasten the fasteners on the joist.

7. Continue placing hidden fasteners and Yakima decking until end. Hidden

Fasteners are designed to create even spacing between deckboards, so

simply slide decking tight to hidden fasteners.

ClipK2,antiwalking

8. Place final piece as you did with the first piece. Notch decking for 4x4 Post

and use screws to fasten the edges of the deck boards (minimum 1 from

edge).

Note: Yakima will not be responsible for those who do not follow the installation

guide.

Non Grooved Systems with Screws

1. Place 1st piece of Yakima decking at the edge perpendicular to the wood joist. Notch the Yakima composite to

accommodate for the 4x4 Post.

2. Fasten screws at the edge of deck boards at a minimum of 1 from the edge on all sides. Note that screws are

needed around opening of 4x4 Post also.

6/14

3. Fasten deck boards to joist system with screws made from the following materials: hot dipped, galvanized,

ceramic coated or stainless steel.

4. Continue placing Yakima decking until the end. Please refer to the Deck Spacing/ gapping section for

spacing requirements. In general, a minimum of 1/4 gap is required.

Note to always fasten at a minimum of 1 from the edge off the deckboards.

Fastening

We recommend screws to fasten Yakima composite decking. Stainless steel, hot dipped galvanized, or

ceramic-coated screws will provide the longest service life. Using composite screws and pre-drilling can

minimize the effects of mushrooming. Pre-drilling is recommended, although not required, for fastening at least

1 away from the edge of the board. Fastening less than 1 away from the edge of the board, though not

recommended, would require pre-drilling.

Fastening:

Yakima decking can be purchased with a grooved profile that allows decking to be installed

with Yakima hidden fasteners as shown in the picture. This hidden fastener system is a great

way to conceal fasteners and wood joists. It is also a great way to ensure proper spacing

between deck boards.

Yakima composites can easily be fastened with the above recommended screws. Yakima

composites are engineered to accept screws readily.

When installing the Yakima fascia trim, match the edge of the fascia to the top of the deck

boards to ensure a consistent level. Be sure to fasten Yakima fascia to the wood joists. Both

Screws (recommended) and nails could be used for fastening fascia.

Fastening Tips:

When fastening Yakima with screws, fasten perpendicular to the deck boards at a minimum

of 1 from all edges of the board.

When fastening at butt joints, additional wood joists should be added so that both boards can

be fastened at the minimum 1 from all edges.

.

When fasteners cannot be fastened at the recommended 1 from on edge, it is possible to

fasten boards at an angle. Because of the physical nature of the composite material,

7/14

fastening at an angle will not cause splitting. Angling the fastener from a minimum 1 away from the edge can

allow you to fasten deck boards to the joist without additional screws. However, pre-drilling is recommended.

After fasteners are installed, shavings may be used to cover the fasteners for a smoother

finish. Simply fill the divot with shavings and tap gently with a hammer.

The breaker board is used on larger decks to help minimize the gapping requirements when

long (over 10 feet) boards are being used in continuous runs. We do not recommend the

traditional butt joining of boards in this instance. The preferred method of deck design

incorporates the use a breaker board that is run across the deck at 90 degrees between the

ends of the long boards so that the gapping requirement is halved (with the gap evenly

distributed to either side of the breaker board). Additional joists/support is required in the

substructure wherever a breaker board is being used. Because deck clips cannot be used on a breaker board we

recommend that they are glued to the joists/supports or screwed directly through the board if using timber joists

(we do not recommended direct screw fixing to steel joists).

DeckingSpacingandgapping

Decking Spacing:

Yakima composite decking requires a minimum of 12 high, continuous airspace below

joists as well as along three side of the deck to allow for cross ventilation.

Slightly slope the deck

(1/16 per foot) away from the house to allow for water runoff.

When installing a deck over living space, proper flashing is essential

8/14

Allow proper spacing between deck boards for drainage, and expansion and contraction of the boards. A

minimum of 1/4 is suggested. It is recommended that the spacing/gap does not exceed 3/8. Yakima hidden

fastening system is already engineered for perfect spacing every time. Simply install grooved Yakima decking

tight to the hidden fasteners.

Joist Spacing:

Yakima has a sufficient live load rating to span 16 on center for joist supports when

using the 5/4 boards (both solid and voided). If a diagonal board layout is desired, we

recommend a 12 on center joist spacing. For more specific spacing and loading

requirements/ recommendation, please contact your local representative or visit us at

www.Yakimawood.com

Gapping:

Yakima boards are designed to be installed with adequate gapping around the boards to aid air flow. Using

Yakima deck clips to fix the boards to the joists provides an automatic inch gap between the sides of each

board and is the preferred fixing method. Installations made without adequate air flow or a gap between the sides

of each board may void the warranty.

Yakima composite decking expands and contracts lengthways due to changes in temperature (there is minimal

change to the width of the board). It is critical to understand the board temperature prior to cutting in order to

determine the gap requirements when installing the decking as hot boards will shrink and cool boards will grow.

The longer the board the greater the potential for a change in length due to temperature change. All boards

should be the same temperature during installation. The boards should be unstacked so that each board is

exposed to the same amount of direct sunlight and will therefore absorb the same amount of radiant heat (if the

deck is enclosed or in the shade it is still important to have all of the boards at the same temperature by

spreading them evenly over the deck surface prior to installation).

An 18 foot long board will grow by approximately inch (1/4 inch at each end) over a 54 Fahrenheit increase in

the temperature of the board. The board will contract by the same amount if the temperature of the board cools

by 54 Fahrenheit.

Even on a day of mild temperatures and minimum temperature change the boards may vary in temperature by

54 Fahrenheit or more if moved between direct sunlight and shade.

A 1/8 to 1/4 gap for butt joins between short boards should be employed when cooler boards are being installed.

No gaps are required between the butt joins when the boards are installed hot. Butt joins should always occur

over a double joist or cleat (minimum 3.5 in x 1.8 in) to allow for proper fixing.

It is highly recommended that boards over 10 feet in length are not butted end to end (this applies for either a

continuous run of boards or an angled or mitered joint). Running long boards with a butt join may result in a gap

of more than 10mm once the boards have cooled and contracted. The preferred method of deck design is to use

a breaker board run across the deck at 90 degrees to the long boards so that the gapping requirement is

effectively halved (refer to the breaker board fixing information above).

Gapping around posts or other protrusions in the decking requires careful consideration.

9/14

We do not recommend checking out a gap in a continuous board in order to go around a deck protrusion.

Our recommendation is to cut the board at the protrusion so that one end of the board finishes before the

protrusion and can be gapped according to the information above. The other end of the board can be checked

out around the protrusion allowing 1/4 inch for the side gap.

As mentioned in the substructure information any protrusions should have joists fitted around them so that the

end gaps can be fully supported.

Itiscriticaltofollowthespacingchartbelowforproperdeckperformance.

Nonadherencetothefixingrecommendationsmayvoidyourwarranty.

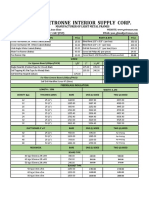

YakimaCompositeDeckingDomesticFixingSpecifications

Maximum joist distance (centre to centre) laid at 90 to the joist

16 in*

Maximum joist distance (centre to centre) laid at 60 to the joist

12 in*

Maximum joist distance (centre to centre) laid at 45 to the joist

12 in*

Maximum joist distance (centre to centre) laid at 30 to the joist

Maximum stringer spacing for stairs (centre to centre) Note: Stair installation using

Yakima should always include a riser board)

Minimum ground Clearance

10 in*

10 in**

Minimum spacing between boards (side to side)

.25 in

Minimum spacing at end of boards (abutting a wall)

.25 in

Minimum spacing from side wall

.25 in

Maximum overhang of boards past supporting joist

Spacing required for end gaps or where boards meet protrusions in the deck (for

boards up to 10 feet long)

2 in

Spacing required for end gaps for boards over 10 feet is not recommended

Minimum spacing for screw fixings from the edge of the board

10 in

0- .25 in

Use

breaker

board

1 in

*Maximum recommended OC spans. Closer joist spacings will improve the overall quality and performance of

the deck. A joist spacing of 12 in will improve the decks performance and a joist spacing of 10 in will give better

performance again.

** Contact Yakima for information relating to batten fixing over concrete where the minimum ground clearance

may be less than 10 in.

10/14

WeatheredColors

Yakima offers you a wide selection of colors that are both vibrant and long lasting. Superior ultraviolet

inhibitors have been added in our formulation to reduce color fading due to extensive sun exposure. A

slight change in color will occur in the first few months, but the color would then stabilize and last

throughout its lifetime. Please refer to the weathered color charts for reference.

Beige

Grey

Mahogany

Walnut

11/14

YakimaProperties

Physical, Mechanical, and Thermal Properties

Physical, Mechanical, and Thermal Properties

Test Methods and Value

Property

ASTM

PSI

MPI

Tensile Strength

D638

1806

12.45

Bend Strength

D790

3084

21.26

Flexural Strength

D790

275181

1897.31

Flexural Modulus

D6109

2781

19.79

HDT 264

D6109

302032

2082.44

Specific Gravity

D648

212

1.46

Nail withdrawal

D729

0.8-1.2

Water absorption

D1544

802

Shore D Hardness

GB2411-80

68

12/14

YakimaCareandMaintenance

Yakima composite building materials are virtually maintenance free, so very little care or

maintenance is required. Here are some tips to keeping your deck looking new:

Mold and Mildew

Yakima has and antifungal guard added during formulation and an additional antimicrobial surface

coating. This means your Yakima material is protected against mold, mildew and germs, including

bacteria. We recommend that you periodically clean your Yakima material by washing dirt and debris

from the surface the deck. Do not allow twigs and other sources of microbes to build up between the

boards.

If mold or mildew develops, use a standard deck wash containing sodium hypochlorite. Spray on the

solution in concentrated form to a slightly dampened deck surface. Allow 20 minutes for the chemical to

set and then simply wash off using a standard garden hose. You can use a pressure washer but do not

use more than 1200 PSI or hold wand close to the deck surface as this may cut into the surface of the

deck causing unwanted scratches.

Heavy Stains

Staining may occur from oil, grease, dark wine, mayonnaise, butter, charcoal, red clay, or rust,

damaging your deck surface. The first action is to clean the spot immediately. The best results will occur

by cleaning immediately after the damage happens, before it soaks in to the cellulose fiber. If immediate

cleaning is not possible, try to lift the stain from the surface using a degreaser or detergent in hot water.

If you are not satisfied with the result of either method, try rubbing alcohol and a wire brush, brushing in

the direction of the grain to maintain surface finish). You can lighten the color of the stain by using

bleach but be careful to not lighten the color more than the rest of the deck as this will create a blemish.

Always test your cleaning solution in an out-of-the-way place to avoid ruining the aesthetics of your

Yakima product. Additional cleaners such as oxalic acid or phosphoric acid also provide more power

when removing stains. Be careful not to mix these cleaners together, however. In addition, always allow

for proper ventilation and respiratory protection. Refer to the manufacturer suggested precautions

when using any cleaning products.

If all else fails, you can sand the face of the board as the stain will not penetrate past the surface to the

interior. Please note that if you sand an area, it will not have the same grain pattern as the rest of the

deck. Use a protective mat or plastic caps to protect against constant metal contact from sources such

as furniture legs, grills or planter stands. Constant metal contact may produce rust stains.

13/14

Ice and Snow

Always use a plastic shovel to remove snow from your deck surface. This will not scratch the surface

like a metal shovel. If you use a metal shovel, do not chip at the deck surface. Use salt to remove ice

from the surface of your deck. Salt will not cause harm or react with the composite formulation. Remove

the salt from the deck surface when convenient. Note, however, that prolonged exposure is not

recommended.

Fire or Storm Damage

Yakima Yakima works well with the Cabot line of deck stains. A custom formulation of color fast

properties allows you to recover and maintain the rich beauty of the original color. Yakima does fade to

a slightly lighter color due to the bleaching nature of the natural cellulose fibers contained within the

product. Contact your nearest Cabot dealer to learn more.

Refinishing

Yakima works well with the Cabot line of Deck stains. A custom formulation of color fast properties

allows you to recover and maintain the rich beauty of the original color. Yakima does fade to a slightly

lighter color due to the bleaching nature of the natural cellulose fibers contained within the product.

Please specify the color you purchased from your dealer when ordering. Contact your nearest Cabot

dealer to learn more. Always be careful not to drag furniture or heavy items across your deck as it will

leave scratches on the surface.

Painting

Yakima does not require any painting over the life of the product. If you want to change the color of

the decking, railing, fencing or furniture products, use a paint recommended for surface coating

applications. The paint will not penetrate the surface of the material like traditional wood. Additionally,

the paint will last much longer that it does with wood due the fact that water does not penetrate the

interior of the board causing the paint to lift from the surface. Always wait until the surface weathers

before painting to provide more cellulose exposure for the paint to adhere to. Always test a piece of

Yakima product before applying to the whole project to ensure that desired results are achieved.

Miscellaneous

Always place concentrated heavy items where the deck board is contact with the joist substructure.

Constant loading of the deck board without support may cause the decking to sag. Yakima is not

recommended for structural supports. Refer to the ASTM specifications when designing for your hot tub,

spa, outdoor kitchen or open pit barbeque and other heavy fixtures. Additionally, be careful not to drag

furniture or heavy items across your deck as it will leave scratches on the surface.

14/14

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Boysen Paints PDFDocument15 pagesBoysen Paints PDFHale100% (2)

- Test Report of MetakaolinDocument14 pagesTest Report of MetakaolinAbdul Falahitawan UfalNo ratings yet

- Leak Detection - NASA HandbookDocument469 pagesLeak Detection - NASA Handbookjack macNo ratings yet

- Title: Aim:: Terminal VelocityDocument7 pagesTitle: Aim:: Terminal VelocityericaNo ratings yet

- Ceiling PDFDocument1 pageCeiling PDFjun vincint geleraNo ratings yet

- CR ElevationDocument1 pageCR Elevationiamslime11No ratings yet

- Asme Ix: API 653 PREPARATION/ Question N°08 Close Book ResponsesDocument4 pagesAsme Ix: API 653 PREPARATION/ Question N°08 Close Book ResponseskorichiNo ratings yet

- Kiefner - Low Frequency ERW and Lap Welded Longitudinal Seam EvaluationDocument99 pagesKiefner - Low Frequency ERW and Lap Welded Longitudinal Seam EvaluationJames PhillipsNo ratings yet

- Solid StructureDocument17 pagesSolid StructureBao Duy NguyenNo ratings yet

- 01-3 MCB Board (JK1B14S1)Document4 pages01-3 MCB Board (JK1B14S1)Mini ChanNo ratings yet

- Astm - JisDocument7 pagesAstm - Jisvalli rajuNo ratings yet

- Textile TestingDocument286 pagesTextile TestingJuan Cubas100% (1)

- Part1 SimulationXpress Study 1Document9 pagesPart1 SimulationXpress Study 1Memo Gonzalez AlemanNo ratings yet

- A Case Study in Lime Production: No.2. Improved Techniques at Chenkumbi, MalawiDocument6 pagesA Case Study in Lime Production: No.2. Improved Techniques at Chenkumbi, MalawiMilian Asha Bio MuradNo ratings yet

- ASTM D 3364-99 - Flow Rates For Poly (Vinyl Chloride) With Molecular Structural ImplicationsDocument4 pagesASTM D 3364-99 - Flow Rates For Poly (Vinyl Chloride) With Molecular Structural Implicationszeqs9No ratings yet

- Limit States Design 9 ContentsDocument10 pagesLimit States Design 9 Contentssom_bs790% (4)

- Hazardous Waste DOT TrainingDocument98 pagesHazardous Waste DOT TrainingEmmanuel Winful100% (2)

- NOCOLOK Brazing Process 2018 02Document8 pagesNOCOLOK Brazing Process 2018 02Pérsio Mozart PintoNo ratings yet

- Process of Percussion Welding (With Diagram)Document5 pagesProcess of Percussion Welding (With Diagram)Karthik SubramaniNo ratings yet

- Polymer Families PDFDocument11 pagesPolymer Families PDFLucasNo ratings yet

- Phosphors For LED-based Solid-State Lighting: by Anant A. SetlurDocument5 pagesPhosphors For LED-based Solid-State Lighting: by Anant A. SetlurArun AchalamNo ratings yet

- Physics Lab Experiment 6Document6 pagesPhysics Lab Experiment 6Peter Sam CoNo ratings yet

- 3.chromatography I 2011Document28 pages3.chromatography I 2011hawyonghongNo ratings yet

- The Green Way To BuildDocument4 pagesThe Green Way To BuildnfahmiNo ratings yet

- 10.1016/j.powtec.2017.06.053: Powder TechnologyDocument46 pages10.1016/j.powtec.2017.06.053: Powder TechnologychandiniNo ratings yet

- Understanding Charge Dynamics in Elastomers Adopting Pulsed Electro Acoustic (PEA) TechniqueDocument6 pagesUnderstanding Charge Dynamics in Elastomers Adopting Pulsed Electro Acoustic (PEA) Techniquemr_InspirationNo ratings yet

- Applying Pauli Exclusion Principle and Hund's RuleDocument4 pagesApplying Pauli Exclusion Principle and Hund's RuleEmad Suliman AbusittaNo ratings yet

- Dancing Napthalene Balls ExperimentDocument1 pageDancing Napthalene Balls ExperimentPriyansh VaibhavNo ratings yet

- Catalaog Ipc-Utm 2019Document22 pagesCatalaog Ipc-Utm 2019fadil nasutionNo ratings yet

- ADocument6 pagesAIvy GalamitonNo ratings yet