Professional Documents

Culture Documents

Comprehensive List of Causes

Comprehensive List of Causes

Uploaded by

Gnanaprakasam ArumugamCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Comprehensive List of Causes

Comprehensive List of Causes

Uploaded by

Gnanaprakasam ArumugamCopyright:

Available Formats

People

Comprehensive List of Causes

A

DESCRIPTION OF

INCIDENT

TOOL

FOR

ROOT

CAUSE

ANALYSIS

Parts

Solutions

IMPLEMENTATION & RESEARCH PHASES:

EVIDENCE GATHERING

ANALYSIS PHASE:

IDENTIFICATION OF CRITICAL FACTORS

Document the type / severity of

event

Gather relevant evidence

Implementation phase = direct evidence (scene and witnesses)

Organise all evidence

Map evidence

Cover the who / what / when /

where / how as known at the time

Research phase = indirect evidence (written sources)

Identify critical factors

Consider People / Parts / Position / Paper

Use CLC to identify all immediate and root causes

Paper

Positions

POSSIBLE IMMEDIATE CAUSES

ACTIONS

1.

1-1

1-2

1-3

1-4

1-5

1-6

1-7

1-8

1-9

1-10

1-11

FollowingProcedures

Violation by individual

Violation by group

Violation by supervisor

Operation of equipment without authority

Improper position or posture for the task

Overexertion of physical capability

Work or motion at improper speed

Improper lifting

Improper loading

Shortcuts

Other

2.

2-1

2-2

2-3

2-4

2-5

2-6

2-7

2-8

CONDITIONS

Use of Tools or Equipment

Improper use of equipment

Improper use of tools

Use of defective equipment (aware)

Use of defective tools (aware)

Improper placement of tools, equipment or

materials

Operation of equipment at improper speed

Servicing of equipment in operation

Other

3.

3-1

3-2

3-3

3-4

3-5

3-6

3-7

3-8

3-9

Use of Protective Methods

Lack of knowledge of hazards present

Personal protective equipment not used

Improper use of proper personal protective

equipment

Servicing of energized equipment

Equipment or materials not secured

Disabled guards, warning systems or safety

devices

Removal of guards, warning systems or safety

devices

Personal protective equipment not available

Other

4.

4-1

4-2

4-3

4-4

4-5

4-6

4-7

4-8

4-9

Inattention / Lack of Awareness

Improper decision making or lack of judgment

Distracted by other concerns

Inattention to footing and surroundings

Horseplay

Acts of violence

Failure to warn

Use of drugs or alcohol

Routine activity without thought

Other

5.

5-1

5-2

5-3

5-4

5-5

5-6

5-7

5-8

5-9

5-10

Protective Systems

Inadequate guards or protective devices

Defective guards or protective devices

Inadequate personal protective equipment

Defective personal protective equipment

Inadequate warning systems

Defective warning systems

Inadequate isolation of process or equipment

Inadequate safety devices

Defective safety devices

Other

6.

6-1

6-2

6-3

6-4

6-5

6-6

6-7

6-8

6-9

6-10

Tools, Equipment & Vehicles

Defective equipment

Inadequate equipment

Improperly prepared equipment

Defective tools

Inadequate tools

Improperly prepared tools

Defective vehicle

Inadequate vehicle for the purpose

Improperly prepared vehicle

Other

7.

7-1

7-2

7-3

7-4

7-5

7-6

7-7

7-8

7-9

7-10

7-11

7-12

Work Exposures to

Fire or explosion

Noise

Energized electrical systems

Energized systems, other than electrical

Radiation

Temperature extremes

Hazardous chemicals

Mechanical hazards

Clutter or debris

Storms or acts of nature

Slippery floors or walkways

Other

8.

8-1

8-2

8-3

8-4

8-5

8-6

Work Place Environment / Layout

Congestion or restricted motion

Inadequate or excessive illumination

Inadequate ventilation

Unprotected height

Inadequate work place layout

controls less than adequate

displays less than adequate

labels less than adequate

locations out of reach or sight

conflicting information is presented

Other

POSSIBLE SYSTEM CAUSES

PERSONAL FACTORS

1.

1-1

1-2

1-3

1-4

1-5

1-6

1-7

1-8

1-9

1-10

1-11

Physical Capability

Vision deficiency

Hearing deficiency

Other sensory

deficiency

Reduced respiratory

capacity

Other permanent

physical disabilities

Temporary

disabilities

Inability to sustain

body positions

Restricted range of

body movement

Substance

sensitivities or

allergies

Inadequate size or

strength

Diminished capacity

due to medication

1-12 Other

o Not Applicable

2.

2-1

2-2

2-3

2-4

2-5

Physical

Condition

Previous injury or

illness

Fatigue

due to

workload

due to lack of

rest

due to

sensory

overload

Diminished

performance

due to

temperature

extremes

due to oxygen

deficiency

due to

atmospheric

pressure

variation

Blood sugar

insufficiency

Impairment due

to drug or alcohol

use

3.

3-1

3-2

3-3

3-4

3-5

3-6

3-7

3-8

Mental State

Poor judgment

Memory failure

Poor coordination

or reaction time

Emotional

disturbance

Fears or phobias

Low mechanical

aptitude

Low learning

aptitude

Influenced by

medication

3-9 Other

o Not Applicable

4. Mental Stress

4-1 Preoccupation with

problems

4-2 Frustration

4-3 Confusing

directions /

demands

4-4 Conflicting

directions /

demands

4-5 Meaningless or

degrading activities

4-6 Emotional overload

4-7 Extreme judgment /

decision demands

4-8 Extreme

concentration /

perception

demands

4-9 Extreme boredom

4-10 Other

o Not Applicable

2-6 Other

o Not Applicable

JOB FACTORS

5. Behavior

5-1 Improper performance

is rewarded

saves time or effort

avoids discomfort

gains attention

5-2 Improper supervisory

example

5-3 Inadequate

identification of critical

safe behaviors

5-4 Inadequate

reinforcement of

critical safe behaviors

proper

performance is

criticized

inappropriate peer

pressure

inadequate

performance

feedback

inadequate

disciplinary process

5-5 Inappropriate

aggression

5-6 Improper use of

production incentives

5-7 Supervisor implied

haste

5-8 Employee perceived

haste

6. Skill Level

7.

6-1 Inadequate

assessment of

7-1

required skills

6-2 Inadequate

practice of skill

6-3 Infrequent

performance of

skill

6-4 Lack of coaching

on skill

6-5 Insufficient review

of instruction to

establish skill

7-2

6-6 Other

o Not Applicable

5-9 Other

o Not Applicable

Training / Knowledge

Transfer

Inadequate knowledge

transfer

inability to

comprehend

inadequate

instructor

qualifications

inadequate training

equipment

misunderstood

instructions

Inadequate recall of

training material

training not

reinforced on the job

inadequate refresher

training frequency

7-3 Inadequate training

effort

inadequate training

program design

inadequate training

goals / objectives

inadequate new

employee

orientation

inadequate initial

training

inadequate means

to determine if

qualified for job

7-4 No training provided

need for training not

identified

training records

incorrect or out of

date

new work methods

introduced without

training

decision made not to

train

8.

7-5 Other

o Not Applicable

o Not Applicable

8-1

8-2

8-3

8-4

8-5

8-6

8-7

8-8

8-9

Management /

Supervision / Employee

Leadership

Conflicting roles /

responsibilities

unclear reporting

relationships

conflicting reporting

relationship

unclear assignment of

responsibility

conflicting assignment

of responsibility

improper or

insufficient delegation

of authority

Inadequate leadership

standards of

performance missing

or not enforced

inadequate

accountability

inadequate or

incorrect performance

feedback

inadequate work site

walk-through

inadequate safety

promotion

Inadequate correction of

prior hazard / incident

Inadequate identification

of worksite / job hazards

Inadequate management

of change system

Inadequate incident

reporting / investigation

system

Inadequate or lack of

safety meetings

Inadequate performance

measurement &

assessment

Other

9.

Contractor

10. Engineering /

Selection &

Design

Oversight

10--1 Inadequate technical

10

9-1 Lack of contractor

design

pre-qualifications

design input

9-2 Inadequate

obsolete

contractor pre design input not

qualifications

correct

9-3 Inadequate

design input not

contractor selection

available

9-4 Use of non -approved

design output

contractor

inadequate

9-5 Lack of job oversight

design input

9-6 Inadequate oversight

infeasible

design output

9-7 Other

unclear

o Not Applicable

design output not

correct

design output

inconsistent

no independent

design review

10--2 Inadequate

10

standards,

specifications, and /

or design criteria

10--3 Inadequate

10

assessment of

potential failure

10--4 Inadequate

10

ergonomic design

10--5 Inadequate

10

monitoring of

construction

10--6 Inadequate

10

assessment of

operational

readiness

10--7 Inadequate

10

monitoring of initial

operation

10--8 Inadequate

10

evaluation and / or

documentation of

change

11.

11--1

11

11--2

11

11--3

11

11--4

11

11--5

11

11--6

11

11--7

11

10-9 Other

o Not Applicable

For each identified critical factor, consider if any of the listed root

cause categories apply. If 'yes,' circle the specific root cause.

If none of the root causes in the category apply, then check the

'not applicable' box at the bottom of the column.

11-8

Work Planning

Inadequate work

planning

Inadequate preventive

maintenance

assessment of

needs

lubrication /

servicing

adjustment /

assembly

cleaning /

resurfacing

Inadequate repair

communication of

needed repair

scheduling of work

examination of

parts

parts substitution

Excessive wear and

tear

inadequate

planning for use

extension of service

life

improper loading

use by untrained

people

use for wrong

purpose

Inadequate reference

materials or publications

Inadequate audit /

inspection / monitoring

no documentation

no correction

responsibility

assigned

no accountability

for corrective action

Inadequate job

placement

appropriate

personnel not

identified

appropriate

personnel not

available

appropriate

personnel not

provided

12.

12--1

12

12--2

12

12--3

12

12--4

12

12--5

12

12--6

12

12--7

12

12--8

12

12--9

12

12--10

12

12-11

Purchasing, Material

Handling & Material

Control

Incorrect item

received

inadequate

specifications to

vendor

inadequate

specifications on

requisition

inadequate control

on changes to

orders

unauthorized

substitution

inadequate product

acceptance

requirements

no acceptance

verification

performed

Inadequate research

on materials /

equipment

Inadequate mode or

route of shipment

Improper handling of

materials

Improper storage of

materials or spare

parts

Inadequate material

packaging

Material shelf life

exceeded

Improper identification

of hazardous

materials

Improper salvage

and / or waste

disposal

Inadequate use of

safety and health data

13. Tools & Equipment

13--1 Inadequate

13

assessment of needs

and risks

13--2 Inadequate human

13

factors / ergonomics

considerations

13--3 Inadequate standards

13

or specifications

13--4 Inadequate availability

13

13--5 Inadequate adjustment

13

/ repair /

maintenance

13--6 Inadequate salvage

13

and reclamation

13--7 Inadequate removal /

13

replacement of

unsuitable items

13--8 No equipment record

13

history

13--9 Inadequate equipment

13

record history

14.

14--1

14

14--2

14

14--3

14

13-10 Other

o Not Applicable

14--4

14

14--5

14

Other

o Not Applicable

14-6

Work Rules / Policies /

Standards / Procedures (PSP)

Lack of PSP for the task

lack of defined responsibility

for PSP

lack of job safety analysis

inadequate job safety

analysis

Inadequate development of PSP

inadequate coordination with

process / equipment design

inadequate employee

involvement in the

development

inadequate definition of

corrective actions

inadequate format for easy

use

Inadequate implementation of

PSP, due to deficiencies

contradictory requirements

confusing format

more than one action per

step

no check- off spaces provided

inaccurate sequence of steps

confusing instructions

technical error / missing

steps

excessive references

potential situations not

covered

Inadequate enforcement of PSP

inadequate monitoring of

work

inadequate supervisory

knowledge

inadequate reinforcement

non-compliance not

corrected

Inadequate communication of

PSP

incomplete distribution to

work groups

inadequate translation to

appropriate languages

incomplete integration with

training

out of date revisions still in

use

Other

15.

15--1

15

15-13

1515--14

15

Communication

Inadequate horizontal

communication

between peers

Inadequate vertical

communication

between supervisor

and person

Inadequate

communication

between different

organizations

Inadequate

communication

between work groups

Inadequate

communication

between shifts

Inadequate

communication

methods

No communication

method available

Incorrect instructions

Inadequate

communication due to

job turnover

Inadequate

communication of

safety and health

data, regulations or

guidelines

Standard terminology

not used

Verification /

repeat back

techniques not used

Messages too long

Speech interference

15-15

Other

15--2

15

15--3

15

15--4

15

15--5

15

15--6

15

15--7

15

15-8

1515--9

15

15--10

15

15--11

15

15--12

15

o Not Applicable\

o Not Applicable

Other

o Not Applicable

CORRECTIVE PHASE: PROPOSALS FOR CORRECTIVE ACTION

Align with Getting HSE Right elements

ELEMENTS OF GETTING HSE RIGHT

Leadership and

Accountability

Risk Assessment and

Management

People, Training and

Behaviours

Working with

Contractors and Others

Facilities Design and

Construction

Operations and

Maintenance

Management of

Change

Information and

Documentation

Customers and

Products

Community and

Stakeholder Awareness

Crisis and Emergency

Management

Incidents Analysis and

Prevention

Assessment, Assurance

and Improvement

You might also like

- Behavior Based SafetyDocument27 pagesBehavior Based SafetySuresh KumarNo ratings yet

- HSE Inspection Report EMAAR StoresDocument3 pagesHSE Inspection Report EMAAR StoresYasir Bin NaseerNo ratings yet

- 001 Alignment MatrixDocument17 pages001 Alignment MatrixBea Mok100% (1)

- Heat Stress ChecklistDocument8 pagesHeat Stress ChecklistVictor kakaNo ratings yet

- Equipment Inspection ChecklistDocument4 pagesEquipment Inspection ChecklistBharathi SilambarasanNo ratings yet

- FM 03-03 Management Review Minutes of Meeting - Issue 3Document3 pagesFM 03-03 Management Review Minutes of Meeting - Issue 3MohamedNo ratings yet

- Safe DrivingDocument28 pagesSafe Drivingraighnejames19No ratings yet

- Training ReportDocument2 pagesTraining ReportisukuruNo ratings yet

- Behavior Based Safety & You!!! Part IDocument19 pagesBehavior Based Safety & You!!! Part Igeorge_rusuNo ratings yet

- Safety Training Needs Assessment FormDocument7 pagesSafety Training Needs Assessment FormArnab NagNo ratings yet

- 02-003 Environmental PolicyDocument6 pages02-003 Environmental PolicyJoachimNo ratings yet

- MS 17222011 and ISO 45001Document4 pagesMS 17222011 and ISO 45001aminsubriNo ratings yet

- Rigging & Lifting Operations - 150305 (EB)Document30 pagesRigging & Lifting Operations - 150305 (EB)S RNo ratings yet

- Example JSADocument3 pagesExample JSAnattwa2010No ratings yet

- Contractor Environ & Safety FormDocument6 pagesContractor Environ & Safety Formsieged_rj3165No ratings yet

- QP-11.0 Culture Survey-EnglishDocument2 pagesQP-11.0 Culture Survey-EnglishKamonrat PangareanNo ratings yet

- HSE PRO 02 F01b Contractor Pre-Qual Questionnaire - 2016-08Document4 pagesHSE PRO 02 F01b Contractor Pre-Qual Questionnaire - 2016-08DKY EDPAPNo ratings yet

- Lead Safety in ConstructionDocument27 pagesLead Safety in ConstructionalimarhoonNo ratings yet

- Form 105, Internal Quality Audit RecordDocument2 pagesForm 105, Internal Quality Audit RecordadiqualityconsultNo ratings yet

- Compressed Fire Risk Assessment TemplateDocument9 pagesCompressed Fire Risk Assessment TemplateReaz UddinNo ratings yet

- 07 LSR Pack Road Safety Seat BeltsDocument6 pages07 LSR Pack Road Safety Seat Beltspreventing becejNo ratings yet

- Safety Course OutlinesDocument5 pagesSafety Course OutlinesAd ZamanNo ratings yet

- General Fire InspectionDocument3 pagesGeneral Fire InspectionmuradhamoudNo ratings yet

- Workplace InspectionDocument11 pagesWorkplace Inspection123alNo ratings yet

- OHSE Subbypack Contractors ARSDocument43 pagesOHSE Subbypack Contractors ARSrumplestilkinsNo ratings yet

- Occupational Health and Safety Management System (OSHAS 18001)Document8 pagesOccupational Health and Safety Management System (OSHAS 18001)rslapena100% (1)

- Project HSE Manual (Draft)Document30 pagesProject HSE Manual (Draft)Julio GregorioNo ratings yet

- Fire Extinguisher Training: Health, Safety & Environment DeptDocument33 pagesFire Extinguisher Training: Health, Safety & Environment DeptRosano D. ManamtamNo ratings yet

- Chelston Decorators Health and Safety PolicyDocument13 pagesChelston Decorators Health and Safety PolicySam MurrayNo ratings yet

- Hope Certificate - IOSH-11654Document1 pageHope Certificate - IOSH-11654Muhammad ImranNo ratings yet

- Confined SpaceDocument121 pagesConfined SpaceS RNo ratings yet

- Safety AttitudeDocument15 pagesSafety AttitudeJhon SihalohoNo ratings yet

- MTC IMS FO 14A Monthly Safety ReportDocument7 pagesMTC IMS FO 14A Monthly Safety ReportsouravrobinNo ratings yet

- MSDS Sodium Hydroxide (50 Solution)Document11 pagesMSDS Sodium Hydroxide (50 Solution)bbmokshNo ratings yet

- Improving Safety Communication SkillsDocument25 pagesImproving Safety Communication SkillsMalahayati ZamzamNo ratings yet

- Coshh Assessment FormDocument4 pagesCoshh Assessment FormLsri MurthyNo ratings yet

- Weekly Safety Meeting Minutes - 06 September 2023Document5 pagesWeekly Safety Meeting Minutes - 06 September 2023Manyaks Nyathi HopaneNo ratings yet

- Welcome To Emarat: Heat StressDocument19 pagesWelcome To Emarat: Heat StressSYED NEYAZ AHMADNo ratings yet

- Sample Malpractice and Maladministration Policy (2018 01 15 08 44 34)Document6 pagesSample Malpractice and Maladministration Policy (2018 01 15 08 44 34)Sachin SahooNo ratings yet

- Emergency PlanDocument1 pageEmergency Planapi-285003764No ratings yet

- Ineco Hse Manual-SignedDocument27 pagesIneco Hse Manual-SignedTantely RazafimahatratraNo ratings yet

- SAFETY CAMPAIGN On Student of Islamic Boarding School As Electric Al Technician in Pondok XDocument13 pagesSAFETY CAMPAIGN On Student of Islamic Boarding School As Electric Al Technician in Pondok XWhina R Ayma100% (1)

- Accident Investigation Report Rev 00Document3 pagesAccident Investigation Report Rev 00Arunava BasakNo ratings yet

- VACC Automotive Environmental GuideDocument40 pagesVACC Automotive Environmental Guidesgvfnbfhg100% (1)

- Riskman Template-FinalDocument3 pagesRiskman Template-Finalapi-238786020No ratings yet

- Quarterly Safety Inspection ChecklistDocument2 pagesQuarterly Safety Inspection ChecklistAJ CompilationNo ratings yet

- 7.2 Ror Rev#4 IsoDocument31 pages7.2 Ror Rev#4 IsoMohamed Thowfeek100% (1)

- RFSSB-EHS-P-004 HIRARC Procedure PDFDocument4 pagesRFSSB-EHS-P-004 HIRARC Procedure PDFNajman HamdiNo ratings yet

- Heat StressDocument2 pagesHeat StressVivian GonzalesNo ratings yet

- 02-007 Machine and Equipment PolicyDocument7 pages02-007 Machine and Equipment PolicyJoachimNo ratings yet

- Full Manual HandlingDocument68 pagesFull Manual HandlingStewart SpenceNo ratings yet

- @waterfront: Health, Safety & Environment (Hse)Document6 pages@waterfront: Health, Safety & Environment (Hse)AmiibahNo ratings yet

- Procedure For Performance Monitoring and MeasurementDocument5 pagesProcedure For Performance Monitoring and MeasurementDaniel Cheng MahsaNo ratings yet

- Questions of Lifting AccessoriesDocument4 pagesQuestions of Lifting AccessoriesOwais MalikNo ratings yet

- Accident - Incident InvestigationDocument7 pagesAccident - Incident InvestigationAdeel AhmedNo ratings yet

- Job Interview One-Sheeter - Your Personal Cliffs Notes: Five Key Points: This Is Why I Rock: Areas For DevelopmentDocument1 pageJob Interview One-Sheeter - Your Personal Cliffs Notes: Five Key Points: This Is Why I Rock: Areas For DevelopmentPortNo ratings yet

- Leadership Is Driving Home Safe Till The Destination. There Is Nothing Like "Almost Reached."Document21 pagesLeadership Is Driving Home Safe Till The Destination. There Is Nothing Like "Almost Reached."hr_darshanNo ratings yet

- Horse Pony GuideDocument12 pagesHorse Pony Guidebeowolf12No ratings yet

- Sample Investigation Improvement Checklist Incident Investigation GuidelineDocument2 pagesSample Investigation Improvement Checklist Incident Investigation GuidelineAndy DolmanNo ratings yet

- Incident InvestDocument1 pageIncident InvestAndy DolmanNo ratings yet

- Investigator Name: Event Assessed: Date of Assessment: Investigation Follow-Up Checklist Addressed? Follow-Up Issues Yes NoDocument1 pageInvestigator Name: Event Assessed: Date of Assessment: Investigation Follow-Up Checklist Addressed? Follow-Up Issues Yes NoAndy DolmanNo ratings yet

- PSM Investigation Compliance Checklist Incident Investigation GuidelineDocument1 pagePSM Investigation Compliance Checklist Incident Investigation GuidelineAndy DolmanNo ratings yet

- Investigator Name: Event Assessed: Date of AssessmentDocument1 pageInvestigator Name: Event Assessed: Date of AssessmentAndy DolmanNo ratings yet

- Checklist For Developing An Incident Investigation PlanDocument1 pageChecklist For Developing An Incident Investigation PlanAndy DolmanNo ratings yet

- Investigator Name: Event Assessed: Date of Assessment:: Sample Human Factors Checklist Incident Investigation GuidelineDocument1 pageInvestigator Name: Event Assessed: Date of Assessment:: Sample Human Factors Checklist Incident Investigation GuidelineAndy DolmanNo ratings yet

- Flashback From Waste Gas Incinerator Into Air Supply Piping: Rohm and Haas Texas Inc Deer Park, TX 77536Document8 pagesFlashback From Waste Gas Incinerator Into Air Supply Piping: Rohm and Haas Texas Inc Deer Park, TX 77536Andy DolmanNo ratings yet

- Propane Tank Flare Off in Topeka Cause and Effect Chart: (Simplified Version) 12-2-02Document2 pagesPropane Tank Flare Off in Topeka Cause and Effect Chart: (Simplified Version) 12-2-02Andy DolmanNo ratings yet

- Quick Checklist For Investigators: Physical ItemsDocument4 pagesQuick Checklist For Investigators: Physical ItemsAndy DolmanNo ratings yet

- Customize This List For Your Use. See The CCPS Guideline For Investigating Chemical InformationDocument4 pagesCustomize This List For Your Use. See The CCPS Guideline For Investigating Chemical InformationAndy DolmanNo ratings yet

- Investigator Name: Event Assessed: Date of AssessmentDocument1 pageInvestigator Name: Event Assessed: Date of AssessmentAndy DolmanNo ratings yet

- Appendix G: Quick Checklist For InvestigatorsDocument5 pagesAppendix G: Quick Checklist For InvestigatorsAndy DolmanNo ratings yet

- Incident InvestDocument1 pageIncident InvestAndy DolmanNo ratings yet

- Appendix B: Professional Assistance DirectoryDocument2 pagesAppendix B: Professional Assistance DirectoryAndy DolmanNo ratings yet

- Appendix C: Photography Guidelines For Maximum ResultsDocument3 pagesAppendix C: Photography Guidelines For Maximum ResultsAndy DolmanNo ratings yet

- Appendix A: Relevant OrganizationsDocument3 pagesAppendix A: Relevant OrganizationsAndy DolmanNo ratings yet

- Incident InvestDocument16 pagesIncident InvestAndy DolmanNo ratings yet

- Appendix F: Selected OSHA and EPA Incident Investigation RegulationsDocument3 pagesAppendix F: Selected OSHA and EPA Incident Investigation RegulationsAndy DolmanNo ratings yet

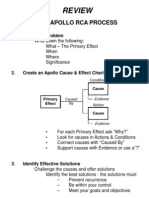

- Review: The Apollo Rca ProcessDocument1 pageReview: The Apollo Rca ProcessAndy DolmanNo ratings yet

- Incident InvestDocument17 pagesIncident InvestAndy DolmanNo ratings yet

- Checklist To Prepare For An Inspection Incident Investigation GuidelineDocument1 pageChecklist To Prepare For An Inspection Incident Investigation GuidelineAndy DolmanNo ratings yet

- Incident InvestDocument8 pagesIncident InvestAndy DolmanNo ratings yet

- Continuous Improvement For The Incident Investigation SystemDocument10 pagesContinuous Improvement For The Incident Investigation SystemAndy DolmanNo ratings yet

- Incident InvestDocument15 pagesIncident InvestAndy DolmanNo ratings yet

- An Overview of Incident Causation TheoriesDocument9 pagesAn Overview of Incident Causation TheoriesAndy DolmanNo ratings yet

- Incident InvestDocument16 pagesIncident InvestAndy DolmanNo ratings yet

- Critical Process Impact MatrixDocument1 pageCritical Process Impact MatrixAndy DolmanNo ratings yet