Professional Documents

Culture Documents

My1008 Ug &abg020 010180

Uploaded by

amirrulasyraf0 ratings0% found this document useful (0 votes)

6 views7 pagesdwd

Original Title

MY1008-UG-&ABG020-010180

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentdwd

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views7 pagesMy1008 Ug &abg020 010180

Uploaded by

amirrulasyrafdwd

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 7

PENGERANG POWER SON BHD

(Company No. 1089480-4)

Level 51, Tower 2, PETRONAS Twin Towers

Kuala Lumpur Oty Cente

50086 Kuala Lumut, Malaysia

PETRONAS

ORRERTERGRERR

PETRONAS TECHNICAL SERVICES SON BHD

‘(Company No. 347848-X)

‘Tower 2, PETRONAS Twin Towers

‘Kuala Lumpur Oty Centre

PETRONAS £0088 Kuala Lumour Malaysia

SIEMENS SIEMENS <4 MMC.

SIEMENS AG SIEMENS Malaysia Sén Bhd “MMC Engineering Services Sdn Bhd

Sumees a3 Shomensifalayse Sen ht Unt 702, Level ama Zia,

tpeseu Jato ett Puna Oagang Save 16, Nov isenTesk Pemsian

Kaen Beating ya, Seunge, 5350 EanaurTun Rank cheas,

‘S087 Statte, Gomany ateyos 000 uns tumpar

ir

PCP-MMC-QAC-MST-UG-010180

PENGERANG COGENERATION PLANT MY1008

445484571 &ABG020

can 5" prora0 UG

= on

cove [mearoe] ava bf [| emmn toms (| Pn

aa = Sil ee

aaa = oe oe

cows [rreoras moran Wh

mans [oorooree mani METHOD STATEMENT FOR LAYING OF QUARRY

forves [owsatei frig “See | DUST BITUMEN PREMIX AT TANK FOUNDATION

a

Hersing Restricted

00/00

A Mc... MY1008-UG-&ABG020-010180 a

/6

“Seager nace wena rere Seeestanotnarnhegensgu Bl sca NEOOE MASSA ESR SANUR

PENGERANG COGEN PLANT PROJECT

‘Owner Doc. No | PCP-MMC-QAC-MST-UG-010160

MMC... reese. Rev. 00/00

Doc No MY1008-UG-&ABGO20-010180

METHOD STATEMENT FOR LAYING OF QUARRY DUST BITUMEN PREMIX AT TANK

Page 2 of 6

FOUNDATION

TABLE OF CONTENTS

1, OBJECTIVE

2. SCOPE OF WORK,

3, REFERENCE DOCUMENTS,

4, TOOLS AND EQUIPMENT.

5, WORKS PROCEDURE...

6. RECORDS...

7. SUPERVISION AND LABOUR...

8. INSPECTION AND TESTING.

" PENGERANG COGEN PLANT PROJECT

‘OwnerDoc. No | PCP-MMC-GAC-MST-UG-010160

MMC... wwner boc Rev. 00/00

Doc No | MY1008-UG-8ABG020-010180

METHOD STATEMENT FOR LAYING OF QUARRY DUST BITUMEN PREMIX ATTANK | 4. org

FOUNDATION o

1.0 OBJECTIVE

This Method Statement acts as a guideline for laying of quary dust bitumen

premix on the top of Treated Water Tanks, Demineralized Water Tank

Condensate Water Tank, Polished Condensate Water Tank and Fire Water Tank

Foundation in a safe manner and acceptable method to meet the

Tequirements and achieve required standards with regards to materials.

workmanship and final product,

2.0 SCOPE OF WORK

‘This method staternent describes the necessary construction activities for laying

quarry dust bitumen premix works. This document covers all the necessary

felevant procedures and processes in relation to the provision of all

responsibilities of personnel involved, supply, execution procedure, tool,

equipment, safety factors, document to be recorded, inspection and testing to

be carried out.

3.0 REFERENCE DRAWINGS/DOCUMENTS

3.1 Approved for Construction Drawing list for Foundation Layouts & Details as

following:-

a. Treated Water Tank (Unit 01) - MY1008-00UGA01-&CLC070-033151

REV.01-03

b, Treated Water Tank (Unit 02) - MY1008-00UGA02-&CLC070-033152

REV.01-03

cc, Demineralized Water Tank (Unit 01) - MY1008-00UGCO1-&CLCO70-

033251 REV.01-03

d. Demineralized Water Tank (Unit 02) - MY1008-00UGC02-&CLCO70-

033252 REV.01-03

e. Demineralized Water Tank (Unit 03) - MY1008-00UGC03-&CLC070-

033253 REV.01-03

f. Condensate Water Tank (Unit 01) - MY1008-30UGX01-&CLCO70-033951

REV.01-03

g. Condensate Water Tank (Unit 02) - MY1008-30UGX02-&CLC070-033952

REV.01-03

PENGERANG COGEN PLANT PROJECT

MMC ‘Owner Doc. No | PCP-MMC-@AC-MST-UG-010180

SIM tenNe SERVES SOHO Rev. 00/00

Doc No MY1008-UG-&ABG020-010180

METHOD STATEMENT FOR LAYING OF QUARRY DUST BITUMEN PREMIX ATTANK |. 4 org

FOUNDATION 7

REV.01-03

Condensate Water Tank (Unit 03) - MY1008-30UGX03-&CLC070-033953

i. Condensate Water Tank (Unit 04) - MY1008-30UGX04-&CLCO70-033954

REV.01-03.

3.1. Project Quality Plan

3.2 Project Specification

3.3 Material Approval Request

4.0 TOOLS AND EQUIPMENT

The tools equipment required for various stages of construction activities are as

listed below:-

Item Tool/Equipment Remarks

1 | Pump To spread the tack coat.

2 | 1 ton Roller ‘Compaction of premix.

3 | Plate Compactor ‘Compaction of premix.

4. | Backhoe Transport the premix to the top of

foundation.

Wheel Barrow, Hand premix

Transport/spread the premix (pulling

S| screed/Rake and spread to desired thickness).

6 | thermometer Record the premix temperature.

7 _ | Premix Hand Tamp and amp loose premix and scrape loose

Scraper debris prior to sealing.

5.0 WORKS PROCEDURE

5.1 Preparation Works.

§.1.1 Controlled points and

Temporary Bench Marks (IBM) shall be

established by the site survey and shall be reference checked with

the nearest control points.

5.1.2 A fleet truck is provided to ensure that the supply of quarry dust

bitumen premix is smooth and continuous.

MMC ‘Owner Doc. No | PCP-MMC-QAC-MST-UG-010180

PENGERANG COGEN PLANT PROJECT

ent sees Rev. 00/00

Doc No MY1008-UG-&ABG020-010180

METHOD STATEMENT FOR LAYING OF QUARRY DUST BITUMEN PREMIX AT TANK

FOUNDATION Page 5 of 6

5.2

5.3

5.1.3. The quarry dust bitumen premix temperature of each truck shall be

measured. Initial mixing temperature from the plant shall be at 120

to 170 degree.

6.1.4 Premix truck shall be covered with a canvas sheet to protect

materials against weather during transport to the site.

5.1.5 All surfaces receiving the premix shall be free from moisture,

cleaned and coated with bitumen emulsion/tack coat.

5.1.6 Level marking shall be done prior to receive the premix materials

Laying of premix.

5.2.1 Tack coat will be applied by means of a mechanical spreader to

all the surfaces receiving the premix.

§.2.2 Premix shall be spread over on top of tanks foundation with wheel

barrow and manual leveling shall be done to achieve the required

thickness and specified level

Compaction of premix.

§.3.1 Compaction shall be carried out by 1 ton roller/plate compactor.

5.3.2 Levels and surface accuracy of the laid premix will be checked

using string marking during the rolling. Displacement shall be

adjusted immediately by the use of rakes and addition of fresh hot

asphalt dust mix.

5.3.3 Rolling shall continue until the total compacted thickness asphalt

dust layer is achieved. The finished surface shall be smooth and

properly graded,

6.0 RECORDS

Asa minimum the forms listed below shall be used throughout the concreting

work process to ensure the required quality can be achieved and recorded,

61

6.2

63.

6.4

Field Quality Plan FQP).

Notification of Inspection (NO).

Inspection Checklist

Test Report.

PENGERANG COGEN PLANT PROJECT

‘Owner Doc. No | PCP-MMC-QAC-MST-UG-010180

MMC. " Rev. 00/00

Doc No MY1008-UG-&ABGO20-010180

METHOD STATEMENT FOR LAYING OF QUARRY DUST BITUMEN PREMIX AT TANK

Page 6 of 6

FOUNDATION

7.0

8.0

SUPERVISION AND LABOUR

To achieve the highest quality or works, all stages of the work shall be

thoroughly checked by the supervisors, inspectors and confirmed by the

Project Engineer prior to final inspection, The Quality Department shall raise a

“Notification of Inspection” fo issue to the Owner to request a final inspection

prior to laying/commence the works. Skilled workers shall be utilised to

execute the works.

INSPECTION AND TESTING

To determine the highest quality of quarry dust bitumen premix laying, testing

will be carried out by appointed tester as per below tests:

8.1 Marshall's density test.

8.2. Marshall's hardened/stabilty test.

MMIC ENGINEERING SERVICES SDN BHD.

| Ammc._ re

oa te

or

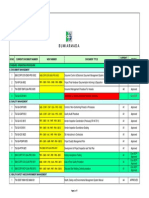

oe DESCRITION OF CHECK come Aaa comments

1 [purasanon wows

1 fleetoe atgmer

> [ores

© fesmvo orrmeux

2 frow cootmatunen seo ontop astoce

2 penoved roteaioroten me

@ Preniierpaoise > 120

§ fawterd reirenteedon NC emre

& |werconpoctedondsrootnsvoe

7 [oren

esas aenian oH ee ena ear cmenemd

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Material Over Short and Damage ReportDocument1 pageMaterial Over Short and Damage ReportamirrulasyrafNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Sop MDRDocument7 pagesSop MDRamirrulasyrafNo ratings yet

- Code and Standards List - 2014Document42 pagesCode and Standards List - 2014amirrulasyraf100% (2)

- Code and Standards List - 2014Document42 pagesCode and Standards List - 2014amirrulasyraf100% (2)

- Question and Answer For RTDocument81 pagesQuestion and Answer For RTamirrulasyrafNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Curriculum Vitae: ULL AMEDocument13 pagesCurriculum Vitae: ULL AMEamirrulasyrafNo ratings yet

- NDT Ut QDocument113 pagesNDT Ut QamirrulasyrafNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- BSP Project Quality Awareness Trainings (New)Document22 pagesBSP Project Quality Awareness Trainings (New)amirrulasyrafNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Employment Application FormDocument3 pagesEmployment Application FormamirrulasyrafNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- 2017 Sirah AyahDocument11 pages2017 Sirah AyahamirrulasyrafNo ratings yet

- Set 4 Sirah Kertas 1Document6 pagesSet 4 Sirah Kertas 1amirrulasyrafNo ratings yet

- Question and Answer For RTDocument70 pagesQuestion and Answer For RTamirrulasyrafNo ratings yet

- DCQ Assessment Questionnaire Subjective Question Position: NDT InspectorDocument5 pagesDCQ Assessment Questionnaire Subjective Question Position: NDT InspectoramirrulasyrafNo ratings yet

- DCQ Assessment Questionnaire Subjective Question Position: NDT InspectorDocument7 pagesDCQ Assessment Questionnaire Subjective Question Position: NDT InspectoramirrulasyrafNo ratings yet

- Eddy Current Testing Level I (20 Questions)Document13 pagesEddy Current Testing Level I (20 Questions)amirrulasyrafNo ratings yet

- MY1008 GS Pre-Fab AGENDA Drums and Flashtank Rev01Document2 pagesMY1008 GS Pre-Fab AGENDA Drums and Flashtank Rev01amirrulasyrafNo ratings yet

- Pan Malaysia Transportation & Installation of Offshore FacilitiesDocument2 pagesPan Malaysia Transportation & Installation of Offshore FacilitiesamirrulasyrafNo ratings yet

- HR - Medical Leave Form, DentalDocument1 pageHR - Medical Leave Form, DentalamirrulasyrafNo ratings yet

- Additional Risk On QAQCDocument4 pagesAdditional Risk On QAQCamirrulasyrafNo ratings yet

- HRA 003 - Travel Authorisation Request Form OctDocument1 pageHRA 003 - Travel Authorisation Request Form OctamirrulasyrafNo ratings yet

- Jadual Tazkirah Iftar: & Imam Terawih Ramadan 1435HDocument1 pageJadual Tazkirah Iftar: & Imam Terawih Ramadan 1435HamirrulasyrafNo ratings yet