Professional Documents

Culture Documents

1.2311 40crmnnimo8-6-4 MCM: Chemical Composition

Uploaded by

uksrajOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1.2311 40crmnnimo8-6-4 MCM: Chemical Composition

Uploaded by

uksrajCopyright:

Available Formats

Material No.

Code:

DE - Brand:

1.2311 40CrMnNiMo8-6-4

MCM

In the DIN EN ISO 4957 the grades 1.2311 (AISI P20), 1.2312

(AISI P20+S) and 1.2738 (AISI P20+Ni) covered by the above

mentioned code were amalgamated. The grade 1.2311 does not

contain additional quantities of Sulphur or Nickel

Chemical composition:

(Typical analysis in %)

Mn

Cr

Mo

0,40

1,50

1,90

0,20

Steel properties:

Plastic mould steel that is usually supplied in a quenched

and tempered condition. Good machinability, better

polishability, compared to 1.2312 (AISI P20+S). Similar

to AISI P20.

Applications:

Plastic moulds, frames for plastic pressure dies, hydroforming tools.

Condition of delivery:

Quenched and tempered, 950 - 1100 N/mm

Physical properties:

-6

Thermal expansion coefficient

Thermal conductivity

10 m

20-100C 20-200C

m K

12,1

12,7

20C

350C

m K

39,6

39,2

20-300C 20-400C

13,2

13,6

Heat treatment:

Soft annealing

Stress relief annealing

The recommendation 500 - 550C is valid for quenched

and tempered condition. In the soft annealed condition

stress relieving between 600 - 650C is possible.

Cooling

Hardness

710 - 740C

furnace

max. 235 HB

Temperature

Cooling

500 - 550C

furnace

Temperature

Cooling

Tempering

830 - 870C

oil or hot bath

180 - 220C

see tempering

diagram

04/05

Hardening

Temperature

Drrenberg Edelstahl GmbH Hammerweg 7 D-51766 Engelskirchen

A company of the

(1.2311) Thermal Cycle Diagram

600-650C

Tempering

hardening temperature

2nd preheating

step

min. / mm

~650C

Finish

machining

cooling slowly

in furnace

Hardening

Intermediate

machining

Rough

machining

Temperature

Stress relief annealing

cooling

oil

1st preheating

step

min. / mm

~400C

hot bath

~200C

tempering

1 h / 20 mm

at least 2 h

equalisation

1 h / 100 mm

Time

Continuous Cooling Transformation Diagram (CCT)

Austenitizing temperature: 850C

1200

Temperature [C]

1000

Ac3

800

F

1 5

600

400

200

Ac1b

50

50

A

Ms

80 95

M

580 575

0

0,1

10

10

93

455

3

10

Time [s]

10

435

215 HV

10

10

Tempering Diagram

70

65

Hardness [HRc]

60

55

50

45

40 Test specimen:

= 30 mm, h = 40 mm

35 quenched from 850C

in oil

30

0

100

200

300

400

500

Tempering temperature [C]

600

700

You might also like

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- 1.2311 40crmnnimo8-6-4 MCM: Chemical CompositionDocument2 pages1.2311 40crmnnimo8-6-4 MCM: Chemical CompositionDiaconu AndreeaNo ratings yet

- Plastic Mould SteelDocument20 pagesPlastic Mould SteeldocumentosvaltierraNo ratings yet

- Uporedna Tabela Za CelikeDocument6 pagesUporedna Tabela Za Celikesnuffit11No ratings yet

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeFrom EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNo ratings yet

- en 10222 5 PDFDocument23 pagesen 10222 5 PDFnegg 348100% (1)

- P20 Steel Plate Tool SteelDocument4 pagesP20 Steel Plate Tool SteelSama UmateNo ratings yet

- Feedstock Technology for Reactive Metal Injection Molding: Process, Design, and ApplicationFrom EverandFeedstock Technology for Reactive Metal Injection Molding: Process, Design, and ApplicationNo ratings yet

- Material Specification Sheet Saarstahl - 36crnimo4Document1 pageMaterial Specification Sheet Saarstahl - 36crnimo4Anonymous rYZyQQot55No ratings yet

- Cold Rolled 2010 DUNAFER HungriaDocument12 pagesCold Rolled 2010 DUNAFER HungriaBeatriz RizzoNo ratings yet

- 4340Document1 page4340ralishNo ratings yet

- Materialqualitaeten EDocument2 pagesMaterialqualitaeten EjvilamaiorNo ratings yet

- Mould SteelsDocument32 pagesMould SteelsAnonymous B3I6zYNhqdNo ratings yet

- 1.0425 P265GH BOILER HTTP WWW - Ccsteels.com Structural Steel 37 PDFDocument2 pages1.0425 P265GH BOILER HTTP WWW - Ccsteels.com Structural Steel 37 PDFVaibhav GuptaNo ratings yet

- 1.8550 - 34CRAlNi7sdfDocument2 pages1.8550 - 34CRAlNi7sdfAdrian FinichiuNo ratings yet

- ST 12 - Echivalenta DC01Document12 pagesST 12 - Echivalenta DC01mariussinhoNo ratings yet

- 1.2344 X40Crmov5-1 Wp5V: Chemical CompositionDocument2 pages1.2344 X40Crmov5-1 Wp5V: Chemical CompositionsarossyattilaNo ratings yet

- BUTTING Duplex PipesDocument20 pagesBUTTING Duplex PipeswenigmaNo ratings yet

- X6CrNiTi18 10Document64 pagesX6CrNiTi18 10Amir GrbicNo ratings yet

- Charla Ing. Andreas Hunger - Nuevas Tendencias en El ProcesoDocument39 pagesCharla Ing. Andreas Hunger - Nuevas Tendencias en El ProcesoWalter-uniNo ratings yet

- Tool Steel: Uni Euronorm WNR Din Afnor Aisi/Sae Bs - 1.2311 40crmnmo7 40Cmd8 (P20)Document1 pageTool Steel: Uni Euronorm WNR Din Afnor Aisi/Sae Bs - 1.2311 40crmnmo7 40Cmd8 (P20)Adrian FinichiuNo ratings yet

- Février 2000: DIN EN 10222-5Document23 pagesFévrier 2000: DIN EN 10222-5Nicolas AguilarNo ratings yet

- 1.4112 X90Crmov18 R17X: Chemical CompositionDocument2 pages1.4112 X90Crmov18 R17X: Chemical CompositionirajfarjiNo ratings yet

- p355n NH Nl1 Nl2 TubesDocument4 pagesp355n NH Nl1 Nl2 TubesMiclea Dragos-CostinNo ratings yet

- Implant: Stainless SteelDocument2 pagesImplant: Stainless SteelSachin GhalmeNo ratings yet

- High Temp Resistant SteelDocument14 pagesHigh Temp Resistant SteelrajivashishNo ratings yet

- Din & IsoDocument94 pagesDin & IsoZeinHarisHasibuan100% (5)

- Thyssenkrupp Materials International: Material Data SheetDocument4 pagesThyssenkrupp Materials International: Material Data SheetjaseerkannothNo ratings yet

- Material Selection & Corrosion Resistance Alloys For Petroleum IndustryDocument4 pagesMaterial Selection & Corrosion Resistance Alloys For Petroleum Industryعزت عبد المنعمNo ratings yet

- 1.4922 SteelDocument2 pages1.4922 Steeldnageshm4n244No ratings yet

- 1.2379 X153Crmov12 Cppu: Chemical CompositionDocument2 pages1.2379 X153Crmov12 Cppu: Chemical CompositionAdrian Finichiu100% (1)

- 2312 DatasheetDocument1 page2312 Datasheetfuransu777No ratings yet

- 17Mn4 P295GHDocument1 page17Mn4 P295GHKarthikeyan ShanmugavelNo ratings yet

- Material Specification Sheet Saarstahl - 30Mnvs6 (27mnsivs6) - Saarform 900Document1 pageMaterial Specification Sheet Saarstahl - 30Mnvs6 (27mnsivs6) - Saarform 900RajaSekarsajja100% (1)

- Niedax KR 2009 IntDocument382 pagesNiedax KR 2009 IntCris_eu09No ratings yet

- UTOP Mo4 1.2345 - enDocument2 pagesUTOP Mo4 1.2345 - enGoran ErakovicNo ratings yet

- (ENG) Product Catalogue: Push-Fit Polypropylene Wastewater SystemDocument20 pages(ENG) Product Catalogue: Push-Fit Polypropylene Wastewater SystemyaseraleweNo ratings yet

- Hot-Rolled Flat Products For Cold Forming From Low-Pearlite Fine Grained SteelsDocument3 pagesHot-Rolled Flat Products For Cold Forming From Low-Pearlite Fine Grained SteelsBielXDNo ratings yet

- Aisi 52100 SpecificationsubyuyDocument1 pageAisi 52100 SpecificationsubyuyankitsarvaiyaNo ratings yet

- Duplex Stainless Steel For Storage TanksDocument8 pagesDuplex Stainless Steel For Storage TanksimtiazkianiNo ratings yet

- En 10222-5Document22 pagesEn 10222-5Paul DaasNo ratings yet

- Tipos de Acero InoxidableDocument4 pagesTipos de Acero Inoxidablechorch123No ratings yet

- Born From Fire, Made To Endure: Stainless SteelDocument12 pagesBorn From Fire, Made To Endure: Stainless Steelqnetomid55No ratings yet

- Mould+Steel+1 2316 (ESR)Document3 pagesMould+Steel+1 2316 (ESR)tnchsgNo ratings yet

- Astm A106 Ts EnglDocument4 pagesAstm A106 Ts EnglxaviereduardoNo ratings yet

- 1.6580, DIN 30CrNiMo8, AISI 4340 Round Bar,1.6580, DIN 30CrNiMo8, AISI 4340 Forging,1.6580, DIN 30CrNiMo8, AISI 4340 Sheet,1.6580, DIN 30CrNiMo8, AISI 4340 Coil,1.6580, DIN 30CrNiMo8, AISI 4340 Flat Bar,1.6580, DIN 30CrNiMo8, AISI 4340 Pipe,LrregularDocument3 pages1.6580, DIN 30CrNiMo8, AISI 4340 Round Bar,1.6580, DIN 30CrNiMo8, AISI 4340 Forging,1.6580, DIN 30CrNiMo8, AISI 4340 Sheet,1.6580, DIN 30CrNiMo8, AISI 4340 Coil,1.6580, DIN 30CrNiMo8, AISI 4340 Flat Bar,1.6580, DIN 30CrNiMo8, AISI 4340 Pipe,Lrregularroberto_perraciniNo ratings yet

- Impact: Wear Resistant SteelDocument6 pagesImpact: Wear Resistant SteelmazuckNo ratings yet

- AluminumDocument7 pagesAluminumjagadish.kvNo ratings yet

- EldaDocument28 pagesEldaEldayadi Nefty Rizky ArismawanNo ratings yet

- 3 SpringDocument66 pages3 Springall_meca_allNo ratings yet

- En 10222-5Document23 pagesEn 10222-5Sakshi Agrawal100% (1)

- Cold Rolled Steel StripDocument40 pagesCold Rolled Steel StripshelarsanjayNo ratings yet

- Suspension Spring Quality CertificateDocument1 pageSuspension Spring Quality CertificateAlstom2020No ratings yet

- O RingsDocument211 pagesO Ringsberylqz100% (2)

- Cutting Materials, Tools and CoolantsDocument63 pagesCutting Materials, Tools and CoolantsLeonardo BarabasNo ratings yet

- TDBL - Polystone P Grey Homopolymer - GBDocument1 pageTDBL - Polystone P Grey Homopolymer - GBreinpolyNo ratings yet

- P91 MaterialDocument15 pagesP91 MaterialelrajilNo ratings yet

- Detailed SoP - Birsa Sinchai Koop SanvardhanDocument62 pagesDetailed SoP - Birsa Sinchai Koop Sanvardhanuksraj0% (1)

- Solved 2017 SSC CGL 17 Aug Shift-1 Paper With SolutionsDocument40 pagesSolved 2017 SSC CGL 17 Aug Shift-1 Paper With SolutionsuksrajNo ratings yet

- ASCI - Agriculture Skill Council of India QPDocument6 pagesASCI - Agriculture Skill Council of India QPuksrajNo ratings yet

- 3Document1 page3uksrajNo ratings yet

- MUDRA - Loan ApplicationDocument5 pagesMUDRA - Loan ApplicationuksrajNo ratings yet

- Drip Irrigation Pipe: Profile No.: 33 NIC Code: 24311Document8 pagesDrip Irrigation Pipe: Profile No.: 33 NIC Code: 24311uksrajNo ratings yet

- 5201 Designer SketcherDocument20 pages5201 Designer SketcheruksrajNo ratings yet

- Item Mat GRP Quantity Unit Last PO / Rate Vendor Consumption (Last 6 Months) Current StockDocument6 pagesItem Mat GRP Quantity Unit Last PO / Rate Vendor Consumption (Last 6 Months) Current StockuksrajNo ratings yet

- Busan To Kolkata: Vessel Name VOY Doc C/Time Cgo C/TimeDocument1 pageBusan To Kolkata: Vessel Name VOY Doc C/Time Cgo C/TimeuksrajNo ratings yet

- Forging Members DirectoryDocument11 pagesForging Members Directoryuksraj33% (3)

- JEE 2009 Paper I: (A) (B) (C) (D)Document19 pagesJEE 2009 Paper I: (A) (B) (C) (D)uksrajNo ratings yet

- 5001 Yarn OpenerDocument19 pages5001 Yarn OpeneruksrajNo ratings yet

- Sugar CaneMill V5.1Document7 pagesSugar CaneMill V5.1uksraj100% (1)

- AtoZ Alloys Pvt. LTDDocument1 pageAtoZ Alloys Pvt. LTDuksrajNo ratings yet

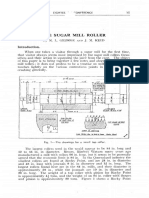

- The Sugar Mill Roller: BV R. I,. Geokge MDocument9 pagesThe Sugar Mill Roller: BV R. I,. Geokge MuksrajNo ratings yet

- Answer: CDocument24 pagesAnswer: CuksrajNo ratings yet

- 2010 Paper 2Document22 pages2010 Paper 2uksrajNo ratings yet

- Welcome To India in BusinessDocument6 pagesWelcome To India in BusinessuksrajNo ratings yet

- 614 Furnace Oil Burner DesignDocument4 pages614 Furnace Oil Burner DesignuksrajNo ratings yet

- Energy Efficiency in ForgingDocument42 pagesEnergy Efficiency in ForginguksrajNo ratings yet