Professional Documents

Culture Documents

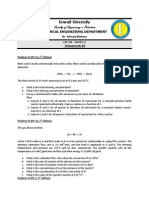

Chemical Reaction Engineering II Tutorial Sheet No. V

Uploaded by

Shashank_PardhikarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chemical Reaction Engineering II Tutorial Sheet No. V

Uploaded by

Shashank_PardhikarCopyright:

Available Formats

Chemical Reaction Engineering II

No. V

Tutorial Sheet

Qu 1. An irreversible first order reaction occurs on the interior pore surface of

catalyst particles in a fixed bed tubular reactor. Assume isothermal

operation and the dispersion model for the reaction mixture flowing

through the bed. The reactant concentration in the feed is C 0. Derive an

equation for the conversion in the reactor effluent. How is the equation

simplified if:

a.

Intraparticle diffusion resistance is unimportant?

b.

Fluid to particle (or external) mass transfer resistance is

unimportant?

c.

The global rate is controlled by the intrinsic reaction at the interior

site?

d.

Axial dispersion is unimportant ( Plug flow conditions)?

e.

Both conditions (c) and (d) apply?

Qu 2 Catalytic dehydrogenation of ethyl benzene to styrene is represented by

the following reaction

C6H5C2H5 C6H5CH=CH2 + H2 .

The global rate is given as rp = k(pE pspH/ K) where pE, pS and pH are

partial pressures of ethyl benzene, styrene and hydrogen, respectively.

The specific reaction rate and equilibrium constants are

Log k = -1.462 4770/ T where k is in kgmol/ s. kPa kg catalyst

T 0C

400

1.7 x 10-3

500

2.5 x 10-2

600

2.3 x 10-1

700

1.4

Estimate the amount of catalyst necessary to produce 13,620 kg of styrene a

day using a vertical tubes 1.22 m in diameter, packed with catalyst pellets.

Assume that there is no side reaction taking place and also there is no heat

exchange between the reactor and the surroundings. Assume that under

normal operation the exit conversion will be 45%. However, also prepare

graphs of conversion and temperature vs. Catalyst bed depth, up to

equilibrium conditions. He feed per reactor tube is 1.70 x 10 -3 kg mol/ s for

ethyl benzene and 34.0 x 10-3 kg mol/ s for steam. In addition,

Temperatue of mixed feed entering reactor

Bulk density of catalyst as packed

Average pressure in reactor tubes

Heat of reaction H

Surrounding temperature

898 K

1440 kg/ m3

121 kPa

1.39x 105 kJ/ kg mol

294 K

You might also like

- Sample - Solution Manual For Principles of Chemical Engineering Processes 1st Edition - Nayef Ghasem, Redhouane HendaDocument4 pagesSample - Solution Manual For Principles of Chemical Engineering Processes 1st Edition - Nayef Ghasem, Redhouane Hendaفراس الوافيNo ratings yet

- HW 4Document2 pagesHW 4kimyakimya89No ratings yet

- 2 CreDocument3 pages2 CreDamien MarleyNo ratings yet

- Batch Adiabatic ReactorDocument6 pagesBatch Adiabatic ReactorHarsh TekriwalNo ratings yet

- Adiabatic FBR DesignDocument10 pagesAdiabatic FBR DesignRana UzairNo ratings yet

- Assignment 2: (Subject: Ch.E. 401 Chemical Reactor Design) Related To CLO1Document4 pagesAssignment 2: (Subject: Ch.E. 401 Chemical Reactor Design) Related To CLO1imtiazNo ratings yet

- Chemical Reaction Engineering Ph. D. Qualifier Examination Open Book (Scott Fogler) ExamDocument3 pagesChemical Reaction Engineering Ph. D. Qualifier Examination Open Book (Scott Fogler) ExamNicole Anne BorromeoNo ratings yet

- Chemical Reactors: DC DT RDocument8 pagesChemical Reactors: DC DT ROsas Jessica UwoghirenNo ratings yet

- 2010 ChE 471 HW 8 FinalDocument4 pages2010 ChE 471 HW 8 FinalSiti HannaNo ratings yet

- 2010 ChE 471 HW 8 FinalDocument4 pages2010 ChE 471 HW 8 FinalpinhonceteNo ratings yet

- Intercompany Memorandum: Cal Chem Corporation To: Date: Fall Quarter File: CHE 435 FromDocument5 pagesIntercompany Memorandum: Cal Chem Corporation To: Date: Fall Quarter File: CHE 435 FromChong Ru YinNo ratings yet

- Models - Chem.round Jet BurnerDocument44 pagesModels - Chem.round Jet BurnerLe Nguyen Phuc ThienNo ratings yet

- Tutorial-3 CRE1 CLL122 PDFDocument4 pagesTutorial-3 CRE1 CLL122 PDFSunandita BorahNo ratings yet

- Homework 2 - 2020 - 01 - Sent (v4)Document4 pagesHomework 2 - 2020 - 01 - Sent (v4)DeividNo ratings yet

- Models - Chem.cstr StartupDocument16 pagesModels - Chem.cstr StartupBilal BELMEKKINo ratings yet

- Boon PinDocument13 pagesBoon PinjayaprinaNo ratings yet

- J. Appl. Chem. Biotechnol. 1974, 24, 759-768Document10 pagesJ. Appl. Chem. Biotechnol. 1974, 24, 759-768Robert L JonesNo ratings yet

- Optimal Cooling of A Tubular Reactor: Created in COMSOL Multiphysics 5.3aDocument24 pagesOptimal Cooling of A Tubular Reactor: Created in COMSOL Multiphysics 5.3akingsley peprahNo ratings yet

- RRRRRR Chido ReactHetExamenOrdinarioJunio2020aDocument4 pagesRRRRRR Chido ReactHetExamenOrdinarioJunio2020aDaniel Moreno CabreraNo ratings yet

- hw3 - Che324Document3 pageshw3 - Che324Ahmed Ali0% (1)

- Reactor Design IIDocument68 pagesReactor Design IIKORAMA KIEN0% (1)

- Chemical Recator Design: 6 Semester B.Sc. Chemical EngineeringDocument19 pagesChemical Recator Design: 6 Semester B.Sc. Chemical EngineeringzeeshanNo ratings yet

- CSTRDocument25 pagesCSTRAinul Mardhiah Abdul Rahim100% (1)

- Try This For Lab Report #5Document16 pagesTry This For Lab Report #5thuy duongNo ratings yet

- CHE 140B Problem Set No. 8: Fogler, 8-5Document2 pagesCHE 140B Problem Set No. 8: Fogler, 8-5Biniyam haileNo ratings yet

- Chemical Reactors - Problems of Reactor Association 47-60: (Exam Jan'09)Document6 pagesChemical Reactors - Problems of Reactor Association 47-60: (Exam Jan'09)Alfredo ZuñigaNo ratings yet

- Taller 3 - 2016Document2 pagesTaller 3 - 2016LifeswolfsNo ratings yet

- Experiment 1B - Tubular ReactorDocument14 pagesExperiment 1B - Tubular ReactorNajmul Puda PappadamNo ratings yet

- Reactor ModelDocument12 pagesReactor ModelTanuja ThanuNo ratings yet

- PracDocument2 pagesPracjamy862004No ratings yet

- Sample - Solution Manual For Principles of Chemical Engineering Processes 1st Edition - Nayef Ghasem, Redhouane HendaDocument4 pagesSample - Solution Manual For Principles of Chemical Engineering Processes 1st Edition - Nayef Ghasem, Redhouane Hendaفراس الوافيNo ratings yet

- 8Document4 pages8Hashem HomadyNo ratings yet

- CH353 Exercise Problem 5 Batch IIDocument3 pagesCH353 Exercise Problem 5 Batch IISagarNo ratings yet

- Entropy Notes PDFDocument69 pagesEntropy Notes PDFAsza ShahizaNo ratings yet

- Parallel Flow, A (m2) 2.624 Counter Flow, A (m2) 2.434 Shell and Tube HX, A (m2) 2.523Document4 pagesParallel Flow, A (m2) 2.624 Counter Flow, A (m2) 2.434 Shell and Tube HX, A (m2) 2.523Chinwuba Samuel EbukaNo ratings yet

- Introduction To Chemical Reactor Engineering - Problems PDFDocument75 pagesIntroduction To Chemical Reactor Engineering - Problems PDFJojie-Ann Alabarca100% (1)

- Indian Institute of Technology Madras Department of Chemical EngineeringDocument2 pagesIndian Institute of Technology Madras Department of Chemical Engineeringkarthickclean8827No ratings yet

- CHE 430 Fa21 - HW#3 (10-September-2021)Document2 pagesCHE 430 Fa21 - HW#3 (10-September-2021)Charity QuinnNo ratings yet

- CL324 - 2023 - Tutorial 02Document2 pagesCL324 - 2023 - Tutorial 02Prince KumarNo ratings yet

- TDCE Question Bank - 2018 Unit IDocument11 pagesTDCE Question Bank - 2018 Unit IvinodNo ratings yet

- Reactors Sizing: Transesterification ReactorsDocument20 pagesReactors Sizing: Transesterification ReactorsJobb Six-steps MatheusNo ratings yet

- Lecture 20: The Fixed Bed Catalytic Reactor: RXN RXNDocument10 pagesLecture 20: The Fixed Bed Catalytic Reactor: RXN RXNreddi ramuNo ratings yet

- Complex First-Order Reactions in Fluidized ReactorsDocument40 pagesComplex First-Order Reactions in Fluidized ReactorsingemarquinteroNo ratings yet

- Catalytic Dehydrogenation of Z-Butanol With Zno and CuoDocument4 pagesCatalytic Dehydrogenation of Z-Butanol With Zno and CuoRosy Vargas CaroNo ratings yet

- Chapter 8 - Steadystate Non-Isothermal ReactorDocument49 pagesChapter 8 - Steadystate Non-Isothermal ReactorAbdul Majid IaNo ratings yet

- Tutorial CREDocument1 pageTutorial CREShashank_PardhikarNo ratings yet

- Experiment CSTR 40LDocument18 pagesExperiment CSTR 40LSaber Minato Azrul100% (2)

- Tutorial 7 (Lecture 7, Chapter 7) Engineering Mechanics DepartmentDocument3 pagesTutorial 7 (Lecture 7, Chapter 7) Engineering Mechanics DepartmentAhmedSeragNo ratings yet

- ChE426 Final Exam 2005Document2 pagesChE426 Final Exam 2005احمد الدلالNo ratings yet

- Cre Ii - 33 - 34Document37 pagesCre Ii - 33 - 34Mehul VarshneyNo ratings yet

- FinalDocument4 pagesFinalMohammed AliraqiNo ratings yet

- Department of Chemical Engineering, Iit Delhi Reactor Sizing Problems Assignment-2Document2 pagesDepartment of Chemical Engineering, Iit Delhi Reactor Sizing Problems Assignment-2ShubhamGuptaNo ratings yet

- JAB-TALLER 3er PARCIAL IRQ-2020-1Document5 pagesJAB-TALLER 3er PARCIAL IRQ-2020-1JESSICA PAOLA TORO VASCONo ratings yet

- Isothermal Reactor Design Part 1: Mole Balances in Terms of ConversionDocument10 pagesIsothermal Reactor Design Part 1: Mole Balances in Terms of ConversionIqbal Al FuadyNo ratings yet

- Physical Chemistry Reference 2Document33 pagesPhysical Chemistry Reference 2Kuo SarongNo ratings yet

- A Modern Course in Statistical PhysicsFrom EverandA Modern Course in Statistical PhysicsRating: 3.5 out of 5 stars3.5/5 (2)

- 14 Coastal Economic Zones Being Developed Under Sagarmala: Ministry of ShippingDocument3 pages14 Coastal Economic Zones Being Developed Under Sagarmala: Ministry of ShippingShashank_PardhikarNo ratings yet

- ShortlistDocument9 pagesShortlistShashank_PardhikarNo ratings yet

- Telephone Directory 2015-16Document3 pagesTelephone Directory 2015-16Shashank_PardhikarNo ratings yet

- Aroma Extraction by PervaporationDocument9 pagesAroma Extraction by PervaporationShashank_PardhikarNo ratings yet

- Problem StatementDocument6 pagesProblem StatementShashank_PardhikarNo ratings yet

- Platform EngineerDocument2 pagesPlatform EngineerShashank_PardhikarNo ratings yet

- Future First Seating PlanDocument26 pagesFuture First Seating PlanShashank_PardhikarNo ratings yet

- Six Comparison Operations (Equal, Not Equal Etc) Conjunction - andDocument1 pageSix Comparison Operations (Equal, Not Equal Etc) Conjunction - andShashank_PardhikarNo ratings yet

- Rules and Procedures of Branch ChangeDocument3 pagesRules and Procedures of Branch ChangeShashank_PardhikarNo ratings yet

- Internet: by Rakesh Ranjan Kumar Mandeep HarodeDocument21 pagesInternet: by Rakesh Ranjan Kumar Mandeep HarodeShashank_PardhikarNo ratings yet

- Creative Practice (Subject-Wise) PDFDocument33 pagesCreative Practice (Subject-Wise) PDFShashank_PardhikarNo ratings yet

- Tutorial CREDocument1 pageTutorial CREShashank_PardhikarNo ratings yet

- All About Inflation: Club of Economics and Finance IIT (BHU), VaranasiDocument16 pagesAll About Inflation: Club of Economics and Finance IIT (BHU), VaranasiShashank_PardhikarNo ratings yet

- Mass Transfer TutorialDocument4 pagesMass Transfer TutorialShashank_PardhikarNo ratings yet

- Chemical Reaction Engg TutorialDocument1 pageChemical Reaction Engg TutorialShashank_PardhikarNo ratings yet

- Cre TutorialDocument1 pageCre TutorialShashank_PardhikarNo ratings yet