Professional Documents

Culture Documents

185-170-5-300-M5-1010 RevE

Uploaded by

Vashish RamrechaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

185-170-5-300-M5-1010 RevE

Uploaded by

Vashish RamrechaCopyright:

Available Formats

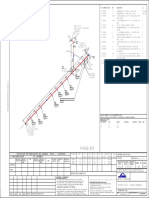

NOZZLE SCHEDULE

3500

N3

25 TYP

N8

350

585

N15

N7

465

N5

N13

700

550

N9

250

N1

250

350

200

NOTE EACH CONDENSATE

INLET NOZZLE TO HAVE

15NB 6000# THR'D-O-LET

WELDED AS SAMPLING

POINT C/W 1/2" BSP PLUG

N11 F/S

10PL

150 TYP

TORISPHERICAL

DISHED ENDS

EX.8 PLATE

MIN. 5mm THK.

AFTER ROLLING

ITEM NO.

N1

1

N2

1

N3

1

N4

1

N5

1

7

R1

0

LG

M1

600

N14

500

N/S

SERVICE

INLET - V1 COND. TANK

CONDENSATE OUTLET

FLASH TO V3

DRAIN

SAFETY RELIEF VALVE

150NB

80

N7

1

SPARE ( BLANKED )

N8

150NB

80

1

SPARE ( BLANKED )

N9

40NB

NPT 6000 LB LEVEL CONTROL

1

N10 1

15NB

NPT 6000 LB TEMPERATURE GAUGE

N11 5

15NB

6000#

THR'D-O-LET SAMPLING POINT

N12 1

25NB

NPT 6000 LB

N13 1

200NB

40

INLET - B3 EVAP

N14 1

15NB

NPT 6000 LB PRESSURE GAUGE

N15 1

200NB

40

INLET - A3 EVAP

150NB

HIGH LEVEL SWITCH

LS

1

450NB

MANHOLE

M1

1

300NB

SIGHT GLASS

SG 2

300NB

LG

1

LIGHT GLASS

NOZZLES DESIGNED GENERALLY IN ACCORDANCE WITH PD5500

500

LS

TYPE

300

260

500

R1700

W.T.

40

40

40

80

80

500

250

N10

MATERIAL SPECIFICATION

SHELLS

EN 10028-2 P265GH

ENDS

EN 10028-2 P265GH

TUBE PLATES

TUBES

TUBE PLATE STAYS

NOZZLES

ASTM A106 GR.B

FLANGES

EN 10028-2 P265GH

REINFORCING PADS

EN 10028-2 P265GH

BOLTS

CARBON STEEL GRADE 8,8

GASKETS

CNAF

STIFFENERS, RIBS AND GUSSETS EN 10028-2 P265GH

SUPPORT LEGS

EN 10025 S355JR

SADDLES

EN 10025 S355JR

BAFFLES

INTERNALS

CATLADDERS / PLATFORMS

INSULATION ( mm )

40mm THK. 80kg/m3 MINERAL WOOL

PAINTING

REFER TO PROJECT SPECIFICATION

GENERAL NOTES

1. MATERIAL: AS NOTED ABOVE

2. ALL WELDS U.O.N. SHALL COMPLY TO THE REQUIREMENTS

OF THE QUOTED DESIGN STANDARD OR TO AN APPROVED

WELD PROCEDURE.

3. ALL SHARP EDGES TO BE CHAMFERED OR ROUNDED

90

90

200 TYP

6PL

5. MACHINING TO BE DONE AFTER WELDING

6. ALL ITEMS TO BE HARD STAMPED WITH PART NUMBER

AND/OR EQUIPMENT NUMBER

7. FLANGES : SABS 1123 NP1000/3

8. BOLTS : BS4190

9. PAINTING:

- ALL PREPARATION AND PAINTING TO BE IN

ACCORDANCE WITH THE PROJECT SPECIFICATIONS

- ALL MACHINED SURFACES TO BE COATED WITH

ANTI-RUST PRESERVATIVE

10. INSULATION : REFER TO PROJECT SPECIFICATION FOR

FIXING AND CLADDING DETAILS.

50x50x3 ANGLE

SUPPORT ON ALL

INTERNAL PIPING

NAMEPLATE

F/S

1167

550

40

40

FIXED

40

B

1167

N4

1166

3000 CENTERS

750

40

A

SLIDE

ENLARGED DETAIL B

E

D

C

04

B

A

03

02

01

2

REV.

SCALE 1 : 5

250

850

N2

LG

6PL

1900

SG

F/S

N5

40x40x5 L

x 1260 LG

N11

F/S

LG

N/S

LS

N/S

ELEVATION

SCALE 1 : 10

1010

N11

72

STATUTORY NOTE:

THE CLIENT IS RESPONSIBLE FOR ENSURING COMPLIANCE TO ANY

LOCAL HEALTH AND SAFETY LAWS AND REGULATIONS

RT

I FI

260

400

LS

500

605

THIS DRAWING WAS PREPARED USING A CERTIFIED QUALITY

MANAGEMENT SYSTEM TO ISO 9001:2008

9001 :

08

SG

MANHOLE SAFETY RELIEF MECHANISM

STANDARD LEVEL SWITCH BRANCH CONNECTION DETAILS

450NB MANHOLE FOR PRESSURE VESSELS

STANDARD LIGHT AND SIGHT GLASS FOR PRESSURE VESSELS

NAMEPLATE AND BRACKET DETAILS

VIII FLASH VESSEL DETAILS

REFERENCE DRAWING

N15 N13

16/07/2015

02/07/2015

12/06/2015

22/05/2015

18/05/2015

08/05/2015

06/05/2015

22/04/2015

02/04/2015

05/03/2015

DATE

APPR'D

20

1010

N1

500

TEST PRESSURE UPDATED

TITLE BLOCK UPDATED

DRAWING UPDATED

ISSUED FOR A.I.A. APPROVAL

CLIENT CHANGES UPDATED

APPROVED FOR CONSTRUCTION

UPDATED AFTER DESIGN CHECK

ISSUED FOR CLIENT APPROVAL

ISSUED FOR DESIGN CHECK

PROCESS PARAMETERS CHANGED, RESIZED

DESCRIPTION

SD-0012

SD-0005

SD-0002

SD-0001

ME-0133

ME-0131

DRG. No.

N15

N13 N1

P.S.

P.S.

K-L.K.

P.S.

P.S.

N. DU P.

B.M.

N. DU P.

N. DU P.

N. DU P.

BY

ED

100 TYP

F/S

DESIGN CODE : PD5500 CATEGORY 2 / 3

INTERNAL

EXTERNAL

DESIGN PRESSURE kPa ( g )

-100 TO 100

0

150

35

OPERATING PRESURE kPa ( g )

16

ATMOSPHERE

104

35

SHOP TEST PRESSURE kPa ( g )

165

FIELD TEST PRESSURE kPa ( g )

125

9

RADIOGRAPHY

10%

CORROSION ALLOWANCE ( mm ) 1,5 DISHED END / 3 SHELL

MEDIUM

V2 CONDENSATE / V3 VAPOUR

MASS FULL WITH WATER ( kg )

10990

MASS EMPTY ( kg )

2195

I SO

F/S

REFER TO DRG.NO. SD-0005

REFER TO DRG.NO. SD-0002

REFER TO DRG.NO. SD-0001

REFER TO DRG.NO. SD-0001

SIZE

200NB

200NB

200NB

100NB

80NB

DESIGN DATA

OPERATING LVL.

M1

TEL: +27 (0)31 535 6000

FAX: +27 (0)31 535 6010

e-mail: mail@boschprojects.co.za

website: www.boschprojects.co.za

400

1 HOLWOOD PARK

5 CANEGATE ROAD

LA LUCIA RIDGE OFFICE ESTATE

DURBAN, SOUTH AFRICA, 4320

COPYRIGHT AND USE OF THIS DRAWING IS RESERVED BY BOSCH PROJECTS

G.P. BARTHOLOMEW

656

DESIGNED

15NB BALL VALVE

SOCKET WELDED ENDS

TO BS5159 PN10

SG

1100

N12

25NB BALL VALVE

SOCKET WELDED ENDS

TO BS5159 PN10

SAFETY RELIEF MECHANISM

FOR VESSEL ENTRY

N2

VIEW C - C ON N1,N13 & N15 SAMPLE POINTS

SCALE 1 : 10

CHECKED

CIVIL

ENGINEER

INSTRUMENT

ENGINEER

MECHANICAL

ENGINEER

N/A

A. GODFREY

B. WELCH

APPROVED

VIEW A - A

SCALE 1 : 10

500

N4

1150

N. WENTZEL

K. NEL

PROJECT MANAGER

DRAWING OFFICE MANAGER

VIII FLASH VESSEL

GENERAL ARRANGEMENT

425

500

PROCESS

A. RAGHUNANDAN

ENGINEER

STRUCTURAL

N/A

ENGINEER

ELECTRICAL

N/A

ENGINEER

CO-ORDINATION

N. DU PLESSIS

ENGINEER

ZAMBIA SUGAR PLC

NAKAMBALA PRODUCT ALIGNMENT

AND REFINERY PROJECT

EQUIPMENT SUPPLY

840 TO CL.

425

B. MOTHILALL

DRAWN

SADDLE

DOUBLER PAD = 250x8PL

BASE PLATE = 1150x160x16PL

RIB/WEB THICKNESS = 8PL

SCALE

185-170-5-300-M5-1010 RevE

AS SHOWN

DATE

REVISION

DRAWING NUMBER

1 REQUIRED

185-171-5-100-ME-0130

02/03/2015

A1

You might also like

- Detail B: Page 1 of 2Document5 pagesDetail B: Page 1 of 2namasralNo ratings yet

- RFQ For Investment Casting PartsDocument2 pagesRFQ For Investment Casting PartsHarshanand KalgeNo ratings yet

- SVSW 004110 G16 0001 Rev.a Datasheet For PumpDocument6 pagesSVSW 004110 G16 0001 Rev.a Datasheet For Pumpnguyenquoc1988No ratings yet

- JCI Cataloge 2014Document60 pagesJCI Cataloge 2014KAZIMALI25No ratings yet

- TCO RCM Cell Flotation Rev7Document210 pagesTCO RCM Cell Flotation Rev7ositorxNo ratings yet

- MPVN BrochureDocument32 pagesMPVN Brochurefernando_naciamentNo ratings yet

- 2-01201-N-T-019 R05 Diseño de TuberiasDocument55 pages2-01201-N-T-019 R05 Diseño de TuberiasnarufredNo ratings yet

- Catalogos BombasDocument12 pagesCatalogos BombasJose NavarreteNo ratings yet

- Ge Make BrekaersDocument16 pagesGe Make Brekaerssuji100% (1)

- Ev DG05Document14 pagesEv DG05mtbecerrapNo ratings yet

- Seccion: 3300-15R-612 0T 240K-C2-1:50Document1 pageSeccion: 3300-15R-612 0T 240K-C2-1:50Leo Unocc YauriNo ratings yet

- Evaporator Data Sheet - SKO0501049 Rev0Document10 pagesEvaporator Data Sheet - SKO0501049 Rev0chublackNo ratings yet

- TFP950 10 2010Document6 pagesTFP950 10 2010elpelaracingNo ratings yet

- Ta38107 1 PDFDocument20 pagesTa38107 1 PDFVyasaraj KumarNo ratings yet

- Brooks-Mite Purgemeter: Data SheetDocument4 pagesBrooks-Mite Purgemeter: Data SheetraulNo ratings yet

- Modular Dual Line SystemDocument6 pagesModular Dual Line Systemangela_draguNo ratings yet

- Min1244a12 - Tag 130-Pu-029Document7 pagesMin1244a12 - Tag 130-Pu-029Monty MathewsNo ratings yet

- IsometricsDocument4 pagesIsometricsMuhammedHafisNo ratings yet

- Ivar Aasen Field Development Project - PDQ: Dn02-S09011-E-Xk-3436-00 01EDocument3 pagesIvar Aasen Field Development Project - PDQ: Dn02-S09011-E-Xk-3436-00 01EayemyothantNo ratings yet

- SD25Document20 pagesSD25Mauricio Ariel H. OrellanaNo ratings yet

- Ac PDFDocument95 pagesAc PDFCarlos TorresNo ratings yet

- P-681 Classic 300D PerkinsDocument28 pagesP-681 Classic 300D PerkinsGeorge CalderonNo ratings yet

- Milnor ElectricalDocument37 pagesMilnor ElectricalSantiago JacoboNo ratings yet

- MepDocument44 pagesMepdush_qs_883176404No ratings yet

- Mixer XylemDocument2 pagesMixer XylemCoţac Oana CristinaNo ratings yet

- Repair Manual Canon Pixma IP5000Document37 pagesRepair Manual Canon Pixma IP5000jcoblesNo ratings yet

- 185-170-5-300-M44-0058 RevDDocument1 page185-170-5-300-M44-0058 RevDVashish RamrechaNo ratings yet

- Pioneer dv-383-s (ET)Document12 pagesPioneer dv-383-s (ET)azulazulNo ratings yet

- 00-GRC-EDA-100038-33 (Technical Submittal For Instruments) Rev02Document11 pages00-GRC-EDA-100038-33 (Technical Submittal For Instruments) Rev02Alaa RamadanNo ratings yet

- Model 770 Ordering GuideDocument2 pagesModel 770 Ordering GuideSkiFy AlexNo ratings yet

- AWACASTpartsDocument3 pagesAWACASTpartsMario Alfonso Maldonado BahamondeNo ratings yet

- Aiwa TP Vs500Document9 pagesAiwa TP Vs500Manuel PradoNo ratings yet

- TBE Inlet Separator V 2100 FLNG2Document6 pagesTBE Inlet Separator V 2100 FLNG2halipzramlyzNo ratings yet

- Brother PT-2500pc Parts ManualDocument16 pagesBrother PT-2500pc Parts ManualDuplessisNo ratings yet

- NOVA Servo CatalogueDocument7 pagesNOVA Servo CatalogueDip Narayan BiswasNo ratings yet

- Odular YPE A F S AF: IR Ilter EriesDocument9 pagesOdular YPE A F S AF: IR Ilter ErieshadeNo ratings yet

- Tad BT Tool s150361 - BDocument1 pageTad BT Tool s150361 - BHumayun NawazNo ratings yet

- Pu - Manual Pe-Cp150 - 09Document19 pagesPu - Manual Pe-Cp150 - 09samanhgsNo ratings yet

- Sds 150 eDocument16 pagesSds 150 ejbsb1No ratings yet

- Manual Valvula PentairDocument6 pagesManual Valvula PentairPaco BaGaNo ratings yet

- Fabrication Bill of MaterialDocument8 pagesFabrication Bill of MaterialHashemAliHashemNo ratings yet

- Parts CatalogueDocument109 pagesParts CatalogueSwarup Ranjan MohapatraNo ratings yet

- Service Parts List: Transmission C9602-14 4265430Document38 pagesService Parts List: Transmission C9602-14 4265430Chester Dalitso Mwanza100% (3)

- CL-kompl EDocument6 pagesCL-kompl EPetrisor IonelNo ratings yet

- Model 770: Incremental EncoderDocument2 pagesModel 770: Incremental EncoderwintermacNo ratings yet

- Fisa Tehnica Pompe MultifreeDocument10 pagesFisa Tehnica Pompe MultifreeOčtáv VátčoNo ratings yet

- P6 Limit SwitchDocument3 pagesP6 Limit SwitchABCdude1No ratings yet

- SD 25 eDocument20 pagesSD 25 eseaqu3stNo ratings yet

- 1Document2 pages1sachinrmishraNo ratings yet

- Pumps+Valves4 MudGateValves 081129Document6 pagesPumps+Valves4 MudGateValves 081129isamelgqNo ratings yet

- A09Document1 pageA09liviu_dovaNo ratings yet

- Ea 682808 001 R05Document7 pagesEa 682808 001 R05anbarasusivaprakasam100% (1)

- Oxigen Gen Container CMM 35-21-14Document151 pagesOxigen Gen Container CMM 35-21-14herrisutrisna100% (2)

- Brother PT-9600 Parts ManualDocument18 pagesBrother PT-9600 Parts ManualDuplessisNo ratings yet

- 80valve Data SheetsDocument82 pages80valve Data SheetsOscarin1978No ratings yet

- NV OsiguraciDocument22 pagesNV OsiguracidukassNo ratings yet

- Williams 6-2009Document2 pagesWilliams 6-2009Vicente Elías Venegas LunaNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Max Allowable Pressure of Pipes and Pipellines CER 04022013 1 (V. S. Kumar Unprotected)Document106 pagesMax Allowable Pressure of Pipes and Pipellines CER 04022013 1 (V. S. Kumar Unprotected)Vashish Ramrecha100% (1)

- Piping FormulaeDocument9 pagesPiping FormulaeVashish RamrechaNo ratings yet

- ISA SymbolsDocument1 pageISA SymbolsmustafasandikciNo ratings yet

- Steel Beam BS 5950Document17 pagesSteel Beam BS 5950Vashish RamrechaNo ratings yet

- CH-4 Shells Under External PressureDocument64 pagesCH-4 Shells Under External PressureVashish RamrechaNo ratings yet

- Roll 2015Document26 pagesRoll 2015Vashish RamrechaNo ratings yet

- Legacy ECSA ProfEng Appform TESDocument1 pageLegacy ECSA ProfEng Appform TESVashish RamrechaNo ratings yet

- Gantt ChartDocument6 pagesGantt ChartVashish RamrechaNo ratings yet

- Steel Cals SimpleDocument53 pagesSteel Cals SimpleVashish RamrechaNo ratings yet

- In-Text: (Nickerson and Buist, 2008) Bibliography: Nickerson, D. and Buist, M. (2008) - Practical Application of Cellml 1.1: The IntegrationDocument1 pageIn-Text: (Nickerson and Buist, 2008) Bibliography: Nickerson, D. and Buist, M. (2008) - Practical Application of Cellml 1.1: The IntegrationVashish RamrechaNo ratings yet

- The Gurney Flap: A Case Study: 1.1 Issues in Wing DesignDocument9 pagesThe Gurney Flap: A Case Study: 1.1 Issues in Wing DesignVashish RamrechaNo ratings yet

- Development of A SemiDocument4 pagesDevelopment of A SemiVashish RamrechaNo ratings yet

- E C S A: DeclarationDocument1 pageE C S A: DeclarationVashish RamrechaNo ratings yet

- 4.2d - 4.6bDocument21 pages4.2d - 4.6bVashish RamrechaNo ratings yet

- Pressure-Volume Loops: Feasible For The Evaluation of Right Ventricular Function in An Experimental Model of Acute Pulmonary Regurgitation?Document6 pagesPressure-Volume Loops: Feasible For The Evaluation of Right Ventricular Function in An Experimental Model of Acute Pulmonary Regurgitation?Vashish RamrechaNo ratings yet

- Nations Cup TimetableDocument60 pagesNations Cup TimetableVashish RamrechaNo ratings yet

- Formula Sheet 2007Document3 pagesFormula Sheet 2007Vashish RamrechaNo ratings yet

- SRS Flowchart of ProcessDocument1 pageSRS Flowchart of ProcessVashish RamrechaNo ratings yet

- Cameron U2 BOP, Data SheetDocument4 pagesCameron U2 BOP, Data SheetIhonghong HongNo ratings yet

- Friction Losses in Pipes Consisting of Bends and ElbowsDocument11 pagesFriction Losses in Pipes Consisting of Bends and Elbowswhoelse_i86% (28)

- RKB Fuso BLM AdaDocument9 pagesRKB Fuso BLM AdaRachmad Budi WNo ratings yet

- Art of The Pid-Aiche-Rbt11-15-19Document94 pagesArt of The Pid-Aiche-Rbt11-15-19Yacine MokhtariNo ratings yet

- Liquidacion Stock HerramientasDocument3 pagesLiquidacion Stock HerramientasMateo PorrasNo ratings yet

- Sds-Model EngDocument21 pagesSds-Model EngMAZENNo ratings yet

- Gas Train Equipment 2016Document91 pagesGas Train Equipment 2016Ivan BeljinNo ratings yet

- Parker High Pressure Hyd FlangesDocument96 pagesParker High Pressure Hyd Flangesgoranm-mnflexNo ratings yet

- Rotar BSC R-Evo 10-15-20Document78 pagesRotar BSC R-Evo 10-15-20benjaminNo ratings yet

- Sistema Hidraulico d6NDocument14 pagesSistema Hidraulico d6Ngalvis1020100% (1)

- Slug Catcher-Finger Type DesignDocument5 pagesSlug Catcher-Finger Type Designdndudc86% (7)

- FullBulletinReport - Service Bulletin - 07012022 - 031515Document6 pagesFullBulletinReport - Service Bulletin - 07012022 - 031515Alphard DarmawanNo ratings yet

- Radial-Inflow Turbines: Vavra, M. HDocument65 pagesRadial-Inflow Turbines: Vavra, M. HSiraj MohammedNo ratings yet

- BookDocument65 pagesBookAntonio Regis MedeirosNo ratings yet

- Osama DawoudDocument33 pagesOsama DawoudEyob AdNo ratings yet

- Spillway Calc 412007Document111 pagesSpillway Calc 412007abhishek5810No ratings yet

- Boiler Feed Pump ManualDocument42 pagesBoiler Feed Pump ManualДмитрий ЗинченкоNo ratings yet

- Hmi Dcs Main Steam & Reheat SteamDocument7 pagesHmi Dcs Main Steam & Reheat SteamAziz SaputraNo ratings yet

- 1995 Sarawak Water Supply RegulationDocument69 pages1995 Sarawak Water Supply RegulationCheng Siaw HueiNo ratings yet

- Mixing Mixing: ENVE 301 Environmental Engineering Unit OperationsDocument47 pagesMixing Mixing: ENVE 301 Environmental Engineering Unit OperationsTaha ZiaNo ratings yet

- Test Procedure For Testing of Cryogenic Valves Based On BS 6364, API 598Document8 pagesTest Procedure For Testing of Cryogenic Valves Based On BS 6364, API 598vikram100% (1)

- HP Bypass Warm Up Lines Re Engineering To Prevent Condensate Accumulation, 97-98Document4 pagesHP Bypass Warm Up Lines Re Engineering To Prevent Condensate Accumulation, 97-98Charu Chhabra0% (1)

- Gas Turbine SlideDocument212 pagesGas Turbine SlideMuhd RizzuwanNo ratings yet

- 24-Flow Meters and Flow SensorsDocument4 pages24-Flow Meters and Flow SensorsSigfrido Bader GNo ratings yet

- Recommendation of Inspection/replacement of Hot Parts in Axial TurbochargerDocument2 pagesRecommendation of Inspection/replacement of Hot Parts in Axial Turbochargerronny ArdiansyahNo ratings yet

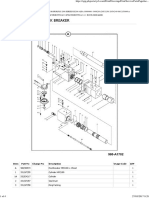

- 9812 - 5090 A3-4-1 Rock BreakerDocument4 pages9812 - 5090 A3-4-1 Rock BreakerAhmad JailaniNo ratings yet

- PPEC Pressure Powered Pump Selection and Sizing: Capacity LB/HDocument2 pagesPPEC Pressure Powered Pump Selection and Sizing: Capacity LB/Ht0r1t0 br4v0No ratings yet

- Piping Material Specification: Client: Emirates Aluminium Company LimitedDocument81 pagesPiping Material Specification: Client: Emirates Aluminium Company LimitedMohamed MansoorNo ratings yet

- BG Degassing Centrifugal Pump: Applications 50 HZDocument2 pagesBG Degassing Centrifugal Pump: Applications 50 HZJose Luis Vivanco MontenegroNo ratings yet