Professional Documents

Culture Documents

Water Treatment

Uploaded by

Vipin KumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Water Treatment

Uploaded by

Vipin KumarCopyright:

Available Formats

WASTEWATER TREATMENT PLANT

MASTER PLAN

4. CAPACITY ANALYSES

This chapter summarizes the existing capacity for the Napa Sanitation District (District)

Wastewater Treatment Plant (WWTP). The capacity analysis objective was to determine the

existing WWTP capacity while considering how all of the processes interact. The conversion to

step-feed operation was included in the existing capacity. The capacity analysis did not consider

modifications involving significant construction, but the alternatives evaluation in Chapter 6 did

consider such changes. Unit process capacities were then compared to future projected flow and

loading conditions to determine the overall WWTP capacity and to identify future improvement

needs.

4.1

Basis of Capacity Analysis

The WWTP now has two seasonal operations modessummer reclamation mode and winter

river discharge mode. Figure 4-1 illustrates these basic modes. Refer to Figures E-1 and E-2 in

Appendix E for detailed typical summer and winter flow schematics. The discharge permit does

not allow discharge to the river during summer months (May through October) except under

emergency conditions. During summer months, some influent wastewater is treated for

reclamation while the facultative ponds treat and store the remainder. During the winter when

river discharge is allowed, staff gradually reduces the volume stored in the oxidation ponds by

treating and discharging flows in excess of daily influent flows.

The oxidation ponds provide a large wastewater storage volume at the WWTP, with wastewater

stored for months in some seasons. Such operation leads to a de-coupling between flow entering

and leaving the WWTP; therefore, WWTP capacity analyses falls into two distinct categories.

Influent capacity evaluates the capacity for wastewater to enter the WWTP. Influent capacity is

evaluated for the influent pump station (IPS), headworks, primary clarifiers, activated sludge

system, bypass piping, and oxidation ponds. Effluent capacity evaluates the capacity for

wastewater to leave the WWTP through reclamation or river discharge. Effluent capacity is

evaluated for the activated sludge system, Pond 4 pump station, flocculating clarifiers, filters and

disinfection.

Since both influent and effluent have different capacities during summer and winter, the analyses

presented address four capacity conditions (i.e., summer/influent, summer/effluent,

winter/influent and winter/effluent). The capacity analysis is based on projected influent flows

and loadings developed in Chapter 2. Capacities are compared to projected flows and loadings to

identify capacity shortfalls.

4-1

Use of contents on this sheet is subject to the limitations specified at the end of this document.

Chapter 4

Wastewater Treatment Plant Master Plan

Figure 4-1. Typical Flow Schematics

4-2

Use of contents on this sheet is subject to the limitations specified at the end of this document.

Chapter 4

4.2

Wastewater Treatment Plant Master Plan

Capacities Related to Trigger Conditions

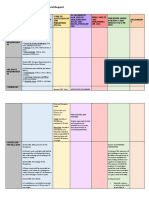

Table 4-1 summarizes the capacity of the existing WWTP. Appendix G contains technical memoranda that detail the capacity analysis

and includes unit process capacities, assumptions, modeling and results.

Table 4-1. Summary of Process Capacities and Triggers for Expansion

Process or Combination of Processes

Key Limitation

Trigger Requiring

Expansion1, 2

Approximate

Average Dry

Weather Flow

(ADWF), mgd2

Notes

Influent Peak Flow

Influent Pumping

25.0 mgd

PHWWF

25.0 mgd PHWWF

NA

Firm capacity with largest unit out of service and IPS

unflooded. Capacity with all units in service and IPS

flooded is 58.0 mgd.

Following the IPS, flow is split between the ponds and

the headworks/primary clarifiers.

Preliminary and Primary Treatment

Manhole 9 to Ponds

52.1 mgd

PHWWF

Headworks and Primary Clarifiers

15.1 mgd

PHWWF

Total Preliminary and Primary

Treatment

67.2 mgd

PHWWF

Hydraulic improvements can increase capacity to

20.0 mgd to match process capacity

67.2 mgd PHWWF

NA

18,500 lb/day AA

BOD Load

6.8

Influent Loading

Biochemical Oxygen Demand (BOD) Loading

Removed in primary clarifiers

8,000 lb/day

AWWMM BOD Load

Activated sludge

11,000 lb/day

AWWMM BOD Load

Facultative ponds

7,400 lb/day

AWWMM BOD Load

Total BOD Loading

26,400 lb/day

AWWMM BOD Load

4-3

Use of contents on this sheet is subject to the limitations specified at the end of this document.

Influent loading is limited by winter maximum month

loading conditions. Equivalent to approximately 38,500

equivalent dwelling units.

Chapter 4

Wastewater Treatment Plant Master Plan

Table 4-1. Summary of Process Capacities (continued)

Process or Combination of Processes

Key Limitation

Trigger Requiring

Expansion1, 2

Approximate

Average Dry

Weather Flow

(ADWF), mgd2

Notes

Winter River Discharge

Secondary Effluent

Activated Sludge

11.0 mgd

AWWMM Flow

Based on typical loadings during the maximum month

influent flow. Since wastewater is more dilute,

activated sludge can treat a higher flow.

Flocculating Clarifiers for Pond

Effluent

6.9 mgd

AWWMM Flow

Limited by hydraulic capacity which could be

increased by raising the flocculating clarifier weirs.

Flocculating clarifier effluent capacity is shown.

Flocculating clarifier sludge flow is 0.6 mgd.

Direct Filtration of Pond Effluent

2.8 mgd

AWWMM Flow

Filter effluent capacity is shown. Direct filtration reject

flow is 1.2 mgd

Total Secondary Effluent

20.7 mgd

AWWMM Flow

7.1 mgd ADWF

7.1

22.7 mgd

AWWMM Flow

7.7 mgd ADWF

7.7

Chlorine Contact for River Discharge

Reclamation

Secondary Effluent

Activated Sludge

2.4 mgd Peak Day Recycled

Water Feed to Filters3

Flocculating Clarifiers for Pond

Effluent

6.9 mgd Peak Day Recycled

Water Feed to Filters

Total Secondary Effluent (Feed to

Filter)

9.3 mgd Peak Day Recycled

Water Feed to Filters

Total Secondary Effluent

9.3 mgd Peak Day Recycled

Water Feed to Filters

8.1 mgd Peak Day

Recycled Water Produced

6.3 mgd Peak Day Feed to

Filters

5.1 mgd Peak Day

Recycled Water Produced

Tertiary Filtration with Blended Feed

Constant flow to filters required, so limited to

approximately the current night time minimum flow.

Assuming 1.2 mgd filter backwash.

NA

4-4

Use of contents on this sheet is subject to the limitations specified at the end of this document.

Assuming 1.2 mgd filter backwash. Filter could be

loaded at higher rate treating only activated sludge

effluent, but current WWTP can only produce 2.4 mgd

of activated sludge effluent at a constant flow.

Chapter 4

Wastewater Treatment Plant Master Plan

Table 4-1. Summary of Process Capacities (continued)

Process or Combination of Processes

Key Limitation

Trigger Requiring

Expansion1, 2

Approximate

Average Dry

Weather Flow

(ADWF), mgd2

Notes

Chlorine Contact for Reclamation

10.1 mgd Peak Day Flow

10.1 mgd Peak Day

Recycled Water Produced

NA

Recycled Water Pumping

16.4 mgd Peak Day Flow

16.4 mgd Peak Day

Recycled Water Produced

NA

Recycled Water Storage

6.5 MG storage

6.5 mgd Peak Month

Recycled Water Produced

NA

One day of storage at maximum month recycled water

flow.

DAFT

9,500 lb TS/day to process in

maximum month

Has capacity for activated

sludge system treating

approximately

14,500 lb/day AWWMM

BOD Load.4

NA

Polymer addition could increase capacity, no

redundancy.

TWAS Pumping

72,600 lb TS/day to process in

maximum month

Has capacity for activated

sludge system treating

approximately

100,000 lb/day AWWMM

BOD Load4

NA

Firm capacity with largest unit out of service.

Anaerobic Digestion

27,000 lb TS/day to process in

maximum month

21,000 lb/day AA TSS

Load

7.5

Minimum 16.5-day hydraulic retention time, no

redundancy.

Digested Sludge Storage

23,800 lb TS/day to process in

maximum month

33,300 lb/day AA TSS

Load

11.9

Assumes four days of storage.

BFP Feed Pumping

22,800 lb TS/day to process in

maximum month

32,000 lb/day AA TSS

Load

11.4

Firm capacity with largest unit out of service.

BFP Dewatering

18,400 lb TS/day to process in

maximum month

25,800 lb/day AA TSS

Load

9.2

Based on 42 hours of operation per week.

Solids Handling

Notes:

1

Expansion must be complete when this trigger is reached. Triggers to begin projects depend on project durations and are discussed in Chapter 7.

2

Conversions between average wet weather maximum flow (AWWMF), average annual (AA) and average dry weather flow (ADWF) are based on flow and loading projections shown in Table 2-13.

3

Based on night time minimum flow to ADWF ratio of 0.45.

4

Dissolved air flotation thickener (DAFT) and thickened waste activated sludge (TWAS) capacity are related to activated sludge loading. Since loading is divided between processes, DAFT and TWAS

pumping can not be directly related to any influent characteristic. Both have more than enough capacity for the existing activated sludge system.

4-5

Use of contents on this sheet is subject to the limitations specified at the end of this document.

Chapter 4

Wastewater Treatment Plant Master Plan

As summarized in Table 4-1, capacities determined for most conditions can be related back to

Average dry weather flow (ADWF) using the flow and loading projections. Figure 4-2 shows the

ADWF capacity. These conversions are only valid if the wastewater strength and peaking factors

remain constant. For example, if the wastewater strength increases, then the rated ADWF will be

too high since the limiting loading will be reached before the calculated ADWF.

Summer effluent capacity (emergency discharge or recycled water) cannot be related to ADWF

entering the WWTP because water can be stored for months.

Figure 4-2. Estimated ADWF Capacity Current

4.3

Unit Process Limitations

This section summarizes limitations for each unit process under conditions likely to be

encountered at the WWTP. Subsequent sections will combine and relate these unit process

limitations to determine overall WWTP capacity.

Table 4-2 presents the limitations of each liquid treatment process at the WWTP. Appendix G

includes details on the assumptions and modeling used to determine unit process limitations.

4-6

Use of contents on this sheet is subject to the limitations specified at the end of this document.

Chapter 4

Wastewater Treatment Plant Master Plan

Table 4-2. Summary of Liquid Unit Process Limitations

Process

Limiting Capacity

Under the Condition

Condition

Notes

Influent Pumping

PHWWF

25.0 mgd

Firm capacity with largest unit out of service and IPS unflooded. Capacity with all units

in service and IPS flooded is 58.0 mgd.

Diversion pipeline to ponds

PHWWF

52.1 mgd

Hydraulic capacity from Manhole 9 to ponds.

Headworks

PHWWF

15.1 mgd

Raising primary diversion structure weir would increase capacity to 20.0 mgd to match

capacity of downstream processes.

Primary Clarifiers

PHWWF

15.6 mgd

Raising primary diversion structure weir and potentially modifying the aeration tank feed

piping would increase capacity to 20.0 mgd to match primary clarifier process capacity.

Activated Sludge

ADWMM Loading to Activated

Sludge, constant flow to one train

6,400 lb BOD/day and

1,200 lb NH3-N/day

Limitation with one train operating at constant flow. In the dry season, low nighttime

flows are not sufficient to operate two trains and produce a constant flow for downstream

processes. This mode is currently used to provide constant flow to the filters. Assumes

step-feed operation, which would operate best with the addition of mixers to

Compartment 5.

ADWMM Loading to Activated

Sludge, diurnal flow to both trains

11,600 lb BOD/day and

2,200 lb NH3-N/day

Limitation for two trains treating diurnal summer flows. Assumes step-feed operation,

would operate best with the addition of mixers to Compartment 5.

AWWMM Loading to Activated

Sludge

11,300 lb BOD/day and

1,500 lb NH3-N/day

Limitation assumes two trains in operation. Assumes step-feed operation, which would

operate best with the addition of mixers to Compartment 5.

ADWMM Loading to Ponds

8,900 lb BOD/day

Includes existing pond aerators during the worst summer conditions (lowest solar energy

month in summer).

AWWMM Loading to Ponds

7,400 lb BOD/day

Includes existing pond aerators during the worst winter conditions (lowest solar energy

month).

Pond 4 Pump Station

Peak flow

12.6 mgd

Firm capacity with largest unit out of service

Flocculating Clarifiers

Peak flow

7.5 mgd

Limiting flow could be increased by raising the flocculating clarifier weirs. Flocculating

clarifier feed flow is shown. Flocculating clarifier sludge flow is 0.6 mgd.

Secondary Effluent Pumping

Peak flow

20.0 mgd

Firm capacity with largest unit out of service.

Facultative Ponds

4-7

Use of contents on this sheet is subject to the limitations specified at the end of this document.

Chapter 4

Wastewater Treatment Plant Master Plan

Table 4-2. Summary of Liquid Unit Process Limitations (continued)

Process

Filtration

Limiting Capacity

Under the Condition

Condition

Notes

Blended Feed (activated sludge

and flocculating clarifier effluent)

for reclamation

6.3 mgd

Filter feed capacity assuming 1.2 mgd filter reject. Based on filter loading rate of

2.2 gpm/sf.

Activated Sludge Effluent for

reclamation

12.1 mgd

Filter feed capacity assuming 1.2 mgd filter reject. Based on filter loading rate of

4.2 gpm/sf.

Direct Filtration (pond effluent)

for river discharge

4.0 mgd

Filter feed capacity assuming 1.2 mgd filter reject. Based on filter loading rate of

1.4 gpm/sf.

Reclamation

10.1 mgd

Limited by hydraulics. Process capacity is 13.2 mgd with 120 minutes contact time.

River Discharge

22.7 mgd

Based on all chlorine contact tanks in service. Limited by hydraulics in chlorine contact

tanks.

Outfall

River Discharge

Greater than 25.1 mgd

Outfall hydraulics do not limit river discharge

Recycled Water Pumping

Peak flow

16.4 mgd

Firm capacity with largest unit out of service.

Recycled Water Storage

Peak month flow

6.5 mgd

One day of storage at maximum month recycled water flow. Storage capacity is 6.5 MG.

Chlorine Contact

4-8

Use of contents on this sheet is subject to the limitations specified at the end of this document.

Chapter 4

Wastewater Treatment Plant Master Plan

The activated sludge analysis determined that conversion to step-feed operation would make best

use of the existing tanks. This conversion would operate best with mixers in each tanks

Compartment 5, and would increase capacity by about 35 percent over the current plug flow

operational mode. The capacities shown above are for step-feed operation.

Tertiary filtration operates best at a constant loading rate. Filtration is difficult to control with a

varying blend of flocculating clarifier effluent and activated sludge effluent, so the blend of

waters must remain at a nearly constant ratio and flow throughout the day for proper filter

performance. The current WWTP does not have the capability to equalize activated sludge

effluent (or primary effluent), so to produce a constant flow for the filters, the activated sludge

process is operated to produce a constant flow approximately equal to the minimum nighttime

flow. Alternatively, the activated sludge process could treat diurnally varying flows, and effluent

flows greater than the nighttime minimum flow could be routed to the ponds and later retreated

to remove algae, thus wasting energy. During summer reclamation, therefore, the District

operates only one activated sludge train to produce a constant flow for filtration. This flow is

supplemented by a constant flow from the flocculating clarifiers. This limitation will exist for the

duration of the planning period since nighttime influent flows are not predicted to increase

significantly (from approximately 3.0 mgd now to 3.8 mgd in 2030); therefore, the capacity for

one activated sludge train treating a constant influent flow was determined.

The capacity of both activated sludge trains treating varying diurnal flows was also determined.

The WWTP currently operates in this mode when river discharge season begins and influent

flows are still low. The District typically operates through the winter discharge season using two

activated sludge process trains online. Depending on WWTP improvements (e.g., secondary

effluent equalization), this mode may be used in the future for reclamation.

Table 4-3 presents the limiting capacity of each solids handling process at the WWTP.

Appendix G includes details on the assumptions and modeling used to determine unit process

capacities.

Table 4-3. Summary of Solids Treatment Process Limitations

Item

DAFT

Maximum Month

Solids Capacity,

lb/day Total

Solids

9,500

Notes

Polymer addition could increase capacity.

TWAS Pumping

72,600

Firm capacity with largest unit out of service.

Anaerobic Digestion

27,000

Minimum 16.5-day hydraulic retention time.

Digested Sludge Storage

23,800

Assumes four days of storage.

BFP Feed Pumping

22,800

Firm capacity with largest unit out of service.

BFP Dewatering

18,400

Based on 42 hours of operation per week.

4-9

Use of contents on this sheet is subject to the limitations specified at the end of this document.

Chapter 4

4.4

Wastewater Treatment Plant Master Plan

Existing WWTP Influent Capacity

Influent capacity evaluates the capacity for wastewater conveyance into and through secondary

treatment. Influent capacity is evaluated for the IPS, headworks, primary clarifiers, activated

sludge system, bypass piping, and allowable loadings to the oxidation ponds. This section

compares the existing unit process capacities to the projected influent flows and loadings.

4.4.1

Peak Hour Flow

The WWTP must handle the peak hour wet weather flow (PHWWF). The IPS pumps all flows

entering the WWTP to either the headworks or directly to the oxidation ponds for subsequent

storage and treatment. As shown in Figure 4-3, the IPS lacks capacity to handle projected

PHWWF. The current IPS firm capacity is much less than projected build-out PHWWF.

As shown on the flow schematic in Figure 4-1, downstream of the IPS, the flow is either treated

in the headworks or diverted directly to the ponds at Manhole 9. The combined capacity of the

headworks and the diversion pipeline to the oxidation ponds is sufficient for projected PHWWF.

All flow treated in the headworks is routed to the primary clarifiers. Existing primary clarifier

hydraulic capacity exceeds headworks capacity. Projects to eliminate hydraulic bottlenecks and

restore headworks and primary clarifier capacities to the design value of 20 mgd should be

considered to maximize the flow receiving primary treatment.

Figure 4-3. PHWWF Influent Capacity

IPS capacity is firm capacity. IPS capacity with all

units in service and a nearly flooded wet well is 58.0 mgd.

4-10

Use of contents on this sheet is subject to the limitations specified at the end of this document.

Chapter 4

4.4.2

Wastewater Treatment Plant Master Plan

Summer Loading Capacity

Figure 4-4 summarizes the summer maximum month loading capacity. Existing summer pond

capacity is shown, but additional aerators could increase capacity significantly. The influent

biochemical oxygen demand (BOD) loading removed by the primary clarifiers increases with

time, since the primary clarifiers have capacity to treat all of the increased dry weather flow and

loadings. Activated sludge operating capacity assumes step-feed. Activated sludge capacity is

shown for both one activated sludge train and for two trains treating diurnal flows (shown as the

increased capacity over one activated sludge train). The existing filtration system cannot treat

varying activated sludge flows as discussed previously, so although more loading could be

accommodated using both activated sludge trains, much of that water would then have to be

routed through temporary pumps back to the ponds and eventually treated in the flocculating

clarifiers.

The existing processes capacity with one activated sludge train in operation is slightly below

the 2030 projected conditions for summer maximum month loadings. With both trains in

operation, capacity exceeds 2030 projected conditions, assuming downstream issues are

resolved. The alternatives evaluation will consider equalizing primary effluent or activated

sludge effluent so both activated sludge trains can operate during the summer, which would

provide sufficient summer loading capacity. With one activated sludge train in operation, the

plant could add an additional 3,000 lb/day of winery waste to the ponds during summer.

Figure 4-4. Influent Loading Capacity for ADWMM BOD Loading

4-11

Use of contents on this sheet is subject to the limitations specified at the end of this document.

Chapter 4

4.4.3

Wastewater Treatment Plant Master Plan

Winter Loading Capacity

Figure 4-5 summarizes the maximum month loading capacity, including storm flows. Activated

sludge operating capacity assumes step-feed to two activated sludge trains operated at a constant

flow, since historic storm flows during the maximum month loading period exceeded the

capacity of two activated sludge trains. Existing pond capacity is shown, but additional aerators

could increase capacity significantly. The existing processes are not sufficient for the 2020

projected conditions at the maximum month loading condition.

Figure 4-5. Influent Loading Capacity for AWWMM BOD Loading

4.5

Existing WWTP Effluent Capacity

Effluent capacity is evaluated based on the capacity for wastewater to leave the WWTP through

reclamation or river discharge. Effluent capacity is evaluated for the Pond 4 Pump Station,

flocculating clarifiers, activated sludge system, secondary effluent pumping, filters and

disinfection. Because of the long-term storage in the facultative ponds, effluent capacity is not

directly related to influent capacity; however, any flow through activated sludge does flow

directly to WWTP effluent (reclamation or river discharge).This section compares the existing

unit process capacities to the projected effluent flows.

4.5.1

Summer Reclamation

Chapter 2 presents a discussion of recycled water demands, including results of the water

balance. Based on the water balance, peak recycled water demands with current ADWF into the

WWTP are 6.2 mgd to maximize supply with the ponds empty on May 1 (2,300 acre-feet [AF]

supplied in median year), and 11.0 mgd to maximize supply with the ponds nearly full on May 1

(3,700 AF supplied in median year). To maximize supply with 2030 ADWF (4,500 AF supplied

4-12

Use of contents on this sheet is subject to the limitations specified at the end of this document.

Chapter 4

Wastewater Treatment Plant Master Plan

in median year), peak recycled water demand is 13.8 mgd. As shown in Figure 4-6, additional

filter capacity is required to meet these demands.

Because the WWTP has no equalization for activated sludge effluent, to ensure a relatively

constant flow to the filters, the activated sludge flow feeding the filters is limited to

approximately the night time minimum flow, as discussed above. The activated sludge process

could produce more water, but the diurnal variations in flow rate can not be accommodated by

the filters. The alternatives evaluation will consider secondary effluent equalization to increase

the constant flow of activated sludge effluent available for filtration, which would increase the

capacity of available secondary effluent.

Filtration capacity is shown for a blend of activated sludge and flocculating clarifier effluents.

Filtering only activated sludge effluent could increase filtration capacity if equalization is

available; however, some pond water must be filtered, since future projected ADWF are less than

peak reclamation demands. The alternatives evaluation will consider dedicated, separate filters

for activated sludge effluent and for pond effluent.

Recycled water storage capacity is based on providing one day of storage. Evaluating additional

storage in the recycled water distribution system is beyond the scope of the Plan.

Figure 4-6. Summer Effluent Capacity

Filters require a constant flow and blend of flocculating clarifier and activated sludge effluents.

Since currently there is no equalization for activated sludge effluent or influent, activated sludge

flow feeding filters is limited to approximately the minimum night time influent flow. Pond flow

represents flocculating clarifier effluent capacity, accounting for 0.6 mgd of algae sludge. Filter

flow represents filter effluent capacity, accounting for 1.2 mgd of filter reject. Secondary effluent

pumping and recycled water pumping are firm capacities.

4-13

Use of contents on this sheet is subject to the limitations specified at the end of this document.

Chapter 4

4.5.2

Wastewater Treatment Plant Master Plan

Winter River Discharge

To reduce the water stored in the ponds, the WWTP typically starts river discharge at full

capacity in November, with both activated sludge trains in operation. The winter effluent

capacity required for future demand was assumed to equal the maximum month flow during the

wettest month, so even in the wettest month, pond levels would not increase. The water balance

confirmed that this flow was sufficient to prevent pond overflow.

Based on the schematic in Figure 4-1, all flow to river discharge must either be treated in the

flocculating clarifiers, activated sludge system, or direct filtration. The Pond 4 pump station

pumps to the flocculating clarifiers and direct filtration. Activated sludge effluent and

flocculating clarifier effluent are pumped by the secondary effluent pump station, while direct

filtration effluent flows by gravity, so all river discharge flow must pass through either the

secondary effluent pump station or direct filtration. All flow then flows through the chlorine

contact tanks.

As shown in Figure 4-7, the WWTP needs additional capacity to meet the projected demands for

both 2020 and 2030.

Figure 4-7. Winter Effluent Capacity

Assumes two activated sludge trains in step-feed mode under high flow conditions with average

influent loadings, so activated sludge capacity is 11.0 mgd. Filter reject assumed to be 1.2 mgd.

Flocculating clarifier sludge assumed to be 0.6 mgd.

Secondary effluent pumping is firm capacity.

4-14

Use of contents on this sheet is subject to the limitations specified at the end of this document.

Chapter 4

4.5.3

Wastewater Treatment Plant Master Plan

Impact of Potential Ammonia Limits

A range of potential ammonia limits were identified for evaluation, as discussed in Section 2.2.5.

The winter river discharge capacity shown in Figure 4-7 is for the potential high

ammonia-nitrogen limits (45 mg/L monthly average).

Figure 4-8 illustrates the maximum percentage of river discharge flow that can be pond water for

the various proposed limits as a function of pond effluent ammonia concentration. The WWTP

could reduce pond effluent flows so that the combined effluent meets limits.

Figure 4-8. Maximum Percentage of Pond Water for Discharge to

Meet Proposed Ammonia-Nitrogen Monthly Average Permit Limits

Assumes a monthly average activated sludge effluent ammonia-nitrogen concentration of 1 mg/L.

Historical maximum month pond effluent concentration was 23 mg/L, so discharge must be

less than 40 percent pond effluent to meet the winter limit of 10 mg/L and less than 90 percent

to meet a limit of 21 mg/L.

To meet the 2011 discharge permit ammonia-nitrogen limit (21 mg/L), the river discharge

capacity is not limited by ammonia considerations. Assuming the historical maximum month

pond effluent ammonia concentration (23 mg/L), pond effluent must be less than 90 percent of

the total river discharge flow, which is always the case.

To meet a potential lower winter ammonia-nitrogen limit (10 mg/L), the river discharge capacity

would be limited. Assuming the historical maximum month pond effluent ammonia

concentration (23 mg/L), pond effluent would need to be less than 40 percent of the total river

discharge flow, which limits the total peak discharge flow to 18 mgd assuming a peak activated

sludge flow of 11.0 mgd when wastewater is dilute. Early in the discharge season, and with

careful monitoring of ammonia concentrations, the District could discharge a higher percentage

of pond water.

4-15

Use of contents on this sheet is subject to the limitations specified at the end of this document.

Chapter 4

Wastewater Treatment Plant Master Plan

Belt filter press (BFP) filtrate adds a significant ammonia loading to the oxidation ponds. The

alternatives evaluation will consider separate filtrate treatment or routing filtrate to the activated

sludge system to reduce pond effluent ammonia-nitrogen concentrations and increase flows that

can be discharged with lower ammonia limits.

4.6

Solids Handling and Treatment Capacity

Solids handling and treatment capacities are based on peak month solids loadings. Maximum

primary solids loadings occur under maximum month loadings when all influent flow is treated

by the primary clarifiers. Maximum waste activated sludge (WAS) loadings occur with two

activated sludge trains operated in step-feed mode. Since the two activated sludge trains are

assumed to operate at maximum loading, WAS quantities do not increase over time; however,

liquid treatment alternatives that increase the activated sludge capacity would increase the WAS

quantity beyond these values. Digested sludge quantities were estimated based on historical

digester feed volatile solids to total solids ratio (81 percent) and historical digester volatile solids

reduction (55 percent).

As shown in Figure 4-9, a small amount of additional digester capacity is required to meet

projected solids loadings. Although other solids handling processes have sufficient capacity, both

the DAFT and the anaerobic digestion lack redundancy. Redundancy for these processes will be

addressed in the alternatives analysis.

Figure 4-9. Solids Handling Capacity

Firm capacities are shown for TWAS pumping, BFP feed pumping and BFP dewatering. DAFT

thickening and anaerobic digester lack redundancy.

4-16

Use of contents on this sheet is subject to the limitations specified at the end of this document.

Chapter 4

4.7

Wastewater Treatment Plant Master Plan

Future Capacity Needs

Table 4-3 summarizes the future capacity needs.

Table 4-3. Future Capacity Needs

Item

Notes

IPS

PHWWF capacity needed

Headworks and primary clarifiers

Hydraulic improvements to increase capacity to 20 mgd

Influent BOD removal

Additional capacity needed in activated sludge, ponds, or a new process

Ammonia removal

Additional capacity needed to meet lower limits

River discharge

Additional capacity needed in flocculating clarifiers, activated sludge, direct filtration,

or a new process

Secondary effluent for reclamation

Additional capacity needed in flocculating clarifiers, activated sludge, activated sludge

effluent equalization, or a new process to provide sufficient water for Scenario 3.

Filtration

Additional capacity needed for reclamation

Chlorine Contact

Additional volume needed for maximum future reclamation demands. Hydraulic

improvements or additional volume needed for river discharge.

Anaerobic digester

Additional capacity and redundancy needed

DAFT

Redundancy or other backup needed

4-17

Use of contents on this sheet is subject to the limitations specified at the end of this document.

THIS PAGE INTENTIONALLY LEFT BLANK

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- 9 Science Exemplar Chapter 6 AnswerDocument6 pages9 Science Exemplar Chapter 6 AnswerVipin KumarNo ratings yet

- IDBI Bank Limited Attestation Form: WarningDocument5 pagesIDBI Bank Limited Attestation Form: WarningVipin KumarNo ratings yet

- Lecture Me. ReallyDocument6 pagesLecture Me. ReallyVipin KumarNo ratings yet

- Contract LawDocument11 pagesContract LawVipin KumarNo ratings yet

- 9 Science Exemplar Chapter 5 AnswerDocument3 pages9 Science Exemplar Chapter 5 AnswerVipin KumarNo ratings yet

- 9 Science Exemplar Chapter 3 AnswerDocument10 pages9 Science Exemplar Chapter 3 AnswerVipin KumarNo ratings yet

- Mid Sem Marks - PBT (Uploaded)Document2 pagesMid Sem Marks - PBT (Uploaded)Vipin KumarNo ratings yet

- Idioms and PhrasesDocument29 pagesIdioms and Phrasessandeep_sihag07100% (1)

- 9 Science Exemplar Chapter 4 AnswerDocument4 pages9 Science Exemplar Chapter 4 AnswerVipin KumarNo ratings yet

- Xanthomonas Campestris: Oxygen Supply Without Gas-Liquid Film Resistance To CultivationDocument10 pagesXanthomonas Campestris: Oxygen Supply Without Gas-Liquid Film Resistance To CultivationVipin KumarNo ratings yet

- Edible Oils Oil RefiningDocument5 pagesEdible Oils Oil RefiningVipin KumarNo ratings yet

- 9 Science NcertDocument5 pages9 Science NcertVipin KumarNo ratings yet

- Effluent Treatment Plant Operation @awl MundraDocument8 pagesEffluent Treatment Plant Operation @awl MundraVipin KumarNo ratings yet

- Aol PDFDocument1 pageAol PDFVipin KumarNo ratings yet

- Zinc Fingers: Presented by Vipin Kumar 2014h129007pDocument24 pagesZinc Fingers: Presented by Vipin Kumar 2014h129007pVipin KumarNo ratings yet

- Zinc Fingers: Presented by Vipin Kumar 2014h129007pDocument24 pagesZinc Fingers: Presented by Vipin Kumar 2014h129007pVipin KumarNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Step-by-Step: The Higg FEM Verification Trail: Section 5: WastewaterDocument35 pagesStep-by-Step: The Higg FEM Verification Trail: Section 5: WastewaterJakaria100% (1)

- الكود المصرى لاستخدام مياه الصرف الصحى المعالجة فى الزراعةDocument87 pagesالكود المصرى لاستخدام مياه الصرف الصحى المعالجة فى الزراعةAHMED100% (8)

- 49 Water UtilitiesDocument24 pages49 Water Utilitiesashry09No ratings yet

- MBR lý thuyếtDocument56 pagesMBR lý thuyếtTcnghe TuấnNo ratings yet

- IGBCDocument84 pagesIGBC04-AR-17-28 PRASAD SALONI PRAVEEN SUCHITANo ratings yet

- 2020-21 Briefing Book Digital Single Page ViewDocument60 pages2020-21 Briefing Book Digital Single Page ViewbexuxubeNo ratings yet

- November 2013Document68 pagesNovember 2013Treatment Plant Operator MagazineNo ratings yet

- RO/Water/Wastewater Treatment Supervisor/OperatorDocument3 pagesRO/Water/Wastewater Treatment Supervisor/Operatorapi-72678201No ratings yet

- Part 1 (Page 2281 2360)Document80 pagesPart 1 (Page 2281 2360)Nasim AhmedNo ratings yet

- AquaFit4Use - Methodology Water Quality ControlDocument33 pagesAquaFit4Use - Methodology Water Quality ControlIbou DiopNo ratings yet

- Chief Cost Estimator or Chief Estimator or Senior EstimatorDocument3 pagesChief Cost Estimator or Chief Estimator or Senior Estimatorapi-77412892No ratings yet

- E Cient and Safe Regulation Mechanism of Rural Domestic Sewage Reclaimed Irrigation of Paddy Eld in Southern ChinaDocument16 pagesE Cient and Safe Regulation Mechanism of Rural Domestic Sewage Reclaimed Irrigation of Paddy Eld in Southern ChinaShwetha JayakumarNo ratings yet

- Yudha Panji A - Integrated Wastewater Management Applicability in Developing CountriesDocument4 pagesYudha Panji A - Integrated Wastewater Management Applicability in Developing CountriesPanji Arya Yudha'sNo ratings yet

- On-Site Wastewater Treatment and Reuses in Japan: L. S. GaulkeDocument7 pagesOn-Site Wastewater Treatment and Reuses in Japan: L. S. GaulkeJuliansyah HarahapNo ratings yet

- Plappally and Lienhard 2012Document31 pagesPlappally and Lienhard 2012Umair KhanNo ratings yet

- Pure Water Project Feasibility Study Request For ProposalsDocument106 pagesPure Water Project Feasibility Study Request For ProposalsDaniel AgiruNo ratings yet

- Development of A Knowledge Base On Desalination Concentrate and Salt ManagementDocument280 pagesDevelopment of A Knowledge Base On Desalination Concentrate and Salt ManagementAnonymous owMJ21JRzCNo ratings yet

- Water Efficiency in Green Building Assessment ToolsDocument60 pagesWater Efficiency in Green Building Assessment ToolsZiad Awad100% (1)

- 2009 UPC PresentationDocument81 pages2009 UPC PresentationFarhsa Dhom Eemihahs DhomNo ratings yet

- Wastewater Reclamation and Reuse in China: Opportunities and ChallengesDocument11 pagesWastewater Reclamation and Reuse in China: Opportunities and ChallengesLaura Ximena Huertas RodriguezNo ratings yet

- Aspec FinalsDocument60 pagesAspec FinalsAujhen FuntelarNo ratings yet

- Guide For Sustainable Design of NEOM CityDocument76 pagesGuide For Sustainable Design of NEOM Cityxiaowei tuNo ratings yet

- DesalinationDocument4 pagesDesalinationkaseproNo ratings yet

- Code StudyDocument14 pagesCode StudyDainty Loren BarramedaNo ratings yet

- Water Treatment Plant Evaluation and Selection ProcessDocument86 pagesWater Treatment Plant Evaluation and Selection ProcessVuong BuiNo ratings yet

- Sustainability Assessment of Wastewater Reuse Alternati - 2018 - Journal of CleaDocument27 pagesSustainability Assessment of Wastewater Reuse Alternati - 2018 - Journal of CleaChris BryanNo ratings yet

- Wastewater Turning Problem To SolutionDocument128 pagesWastewater Turning Problem To Solutiondevanshi sharmaNo ratings yet

- BFC32703 Sustainable Construction ManagementDocument31 pagesBFC32703 Sustainable Construction ManagementFirdaus RidzuanNo ratings yet

- RainBird NonPotableDesignGuideDocument40 pagesRainBird NonPotableDesignGuidemohamed KotpNo ratings yet

- Newmont Goldcorp's Coffee Gold Modified Statement of Scope of ProjectDocument9 pagesNewmont Goldcorp's Coffee Gold Modified Statement of Scope of ProjectThe Narwhal100% (1)