Professional Documents

Culture Documents

8) Qap Itp For Gen Civil & RCC (10 Pages) PDF

8) Qap Itp For Gen Civil & RCC (10 Pages) PDF

Uploaded by

omda4wadyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

8) Qap Itp For Gen Civil & RCC (10 Pages) PDF

8) Qap Itp For Gen Civil & RCC (10 Pages) PDF

Uploaded by

omda4wadyCopyright:

Available Formats

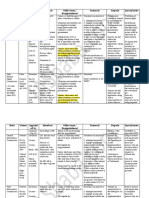

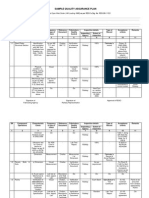

CONSTRUCTION OF BG RAILWAY SIDING AT KADAPA IRD

STANDARD INSPECTION & TEST PLAN (ITP) FOR CIVIL

WORKS :

1.0

GENERAL NOTES:

Inspection & Test Plan (ITP) given herein is indicative only.

Contractor shall prepare and submit ITP for all activities. The

provisions indicated herein for stage wise inspection are minimum

and the Engineer-in-charge may decide to increase the Hold

Point/Witness Point basis the work being carried out at site.

Contractor has to prepare ITPs for any of the activities not covered

herein, submit the same to HPCL and obtain their approval.

Contractor to prepare required reporting formats and job procedure

for each activity i.e. Setting out of work, levels at 5 m grid, prior to

excavation, submission of murrum samples meeting tender

specifications along with soil lab test report, concreting, etc., to

HPCL for approval well in advance prior to commencement of

activity. Any deviation to ITP shall be subjected to HPCL's written

approval. Contractor to carry out 100% examination; satisfy that the

specifications as per PO are complied & thereafter submit to HPCL

for witness/review as applicable.

2.0

LEGEND:

2.1

HP: HOLD POINT

A point which requires inspection/verification and acceptance by

HPCL before any further processing is permitted.

STANDARD INSPECTION & TEST PLAN

PAGE 1 OF 10

CONSTRUCTION OF BG RAILWAY SIDING AT KADAPA IRD

The Contractor shall not process the activity/item beyond the Hold

Point without written approval from Engineer-in-charge.

2.2

W: Witness Point

Any point which requires witness by HPCL when activity is

performed.

2.3

RW: review of contractors documentation

Contractors documentation to be reviewed by HPCL.

2.4

S: Surveillance inspection by HPCL

Monitoring of observations to verify whether or not

materials/items/services confirms to specified requirement.

Surveillance activities may include audit, inspection, witness of

testing, review of quality documentations and records, personnel

qualifications etc.

WC: 100% examination by contractor.

2.5

3.0

THE INDICATIVE INSPECTION AND TEST PLAN IS AS

BELOW,

STANDARD INSPECTION & TEST PLAN

PAGE 2 OF 10

CONSTRUCTION OF BG RAILWAY SIDING AT KADAPA IRD

S.NO

ACTIVITY

CONTRACT

OR

HPCL

LEAD LINE, R&D YARD AND UNLOADING SIDING

1.1

Fixing of Centre line & levels with respect to HPCL

coordinates & Bench Marks with Total Station. Setting out

of various control points & alignment, grid levels at every

3m c/c bothways before filling.

WC

HP

1.2

The readings will be taken after filling each layer

WC

HP

1.3

Submission of soil test reports confirming to PO

Specifications to HPCL for approval with all requisite

details like grain size analysis, atterberg limits, modified

proctor dry density with graph.

WC

HP

1.4

Submission of following documents to HPCL pertaining to

soil being brought for filling purposes.

WC

HP

a) Contractor to submit activities to be carried out

under this item for HPCLs review.

b) NOC from land owner or owner of borrow pit

c) 7/12 extract and village map indicating the location

of the plot/quarry.

d) Royalty payment slips

1.5

A) Rolling of each layer after filling & testing for specified WC

lab dry density achieved in case of soil only.

B) Each layer shall not exceed specified loose thickness

STANDARD INSPECTION & TEST PLAN

PAGE 3 OF 10

HP

CONSTRUCTION OF BG RAILWAY SIDING AT KADAPA IRD

S.NO

1.6

ACTIVITY

CONTRACT

OR

HPCL

A) Embankment formation :

Specified layer checking with templates/tools at various WC

coordinates & recording.

Watering the layer, checking the OMC through Moisture WC

tester & recording co-ordinate wise.

B) Compaction :

Rolling the OMC watered layer immediately till

WC

specified Modified Proctor lab dry density is achieved.

Testing for compaction to confirm its specified Modified

Proctor dry density achieved coordinate wise, recording WC

the levels co-ordinate wise. (Min. test as specified per

layer)

Offering tested layer to HPCL to inspect & witness to WC

W

HP

HP

give clearance for next layer.

1.7

Obtaining NOC from District Mining Officer/relevant WC

statutory authority as regard to royalty payment for

executed quantity basis HPCL letter before final bill.

STANDARD INSPECTION & TEST PLAN

PAGE 4 OF 10

HP

CONSTRUCTION OF BG RAILWAY SIDING AT KADAPA IRD

S.NO

1.8

ACTIVITY

Construction of side shoulders, watering and compaction

up to a thickness of compacted thickness and trimming

of inside edge to vertical.

CONTRACT

OR

WC

Laying of courses and rolling with Vibromax/10T roller

to specified thickness and checking with templates/ tools

WC

at various coordinates and recording layer wise.

Offering to HPCL layer wise to inspect & witness and to

give clearance for next layer.

STANDARD INSPECTION & TEST PLAN

PAGE 5 OF 10

WC

HPCL

W

W

HP

CONSTRUCTION OF BG RAILWAY SIDING AT KADAPA IRD

S.NO

ACTIVITY

CONTRACT

OR

HPCL

RCC,PCC & assoc. works

2.1

Laying of PCC beneath foundations Checking of layout

and materials, compaction of sub grade

Visual inspection, sieve analysis and carrying out all the WC

field tests of the sand and coarse aggregates as per

attached specifications.

WC

Verification of the test reports of all the tests of cement,

sand, water and coarse aggregates specified in tender

documents from govt. approved laboratory supplied by

the contractor with respect to the specifications

WC

HP

HP

Mix proportion

WC

HP

Check for shuttering , dewatering if any

WC

Concreting with proper compaction with plate vibrators

WC

W

HP

Checking of top level of PCC

WC

Curing

STANDARD INSPECTION & TEST PLAN

PAGE 6 OF 10

CONSTRUCTION OF BG RAILWAY SIDING AT KADAPA IRD

S.NO

2.2

ACTIVITY

CONTRACT

OR

HPCL

Bottom Raft, side walls & wingwalls:

Carrying out PCC as per drawings and specifications.

WC

hold point clearance for center points for side walls and WC

Rafts and center lines for haunch

HP

Submission of design calculations for

including shuttering and props.

formwork WC

HP

Approved quality shuttering to be provided. Inside

WC

dimensions to be marked.

HP

Reinforcement steel to be placed as per HPCL approved

bar

bending

schedule/drawings

with

cover WC

blocks/spacers.

Contractor

will

provide

the

gauge/template for measuring the diameter of

reinforcement bars. The sample piece will be taken out

from above supplied steel; the same will be tested at WC

designated laboratories as given in attached

specifications. Placement of concrete will be started only WC

after the receipt of test report of the steel testing.

Counting authorized laps and chairs.

Visual inspection, sieve analysis and carrying out of all

the field test of the sand and coarse aggregates as per

attached specifications.

STANDARD INSPECTION & TEST PLAN

PAGE 7 OF 10

HP

W

HP

CONSTRUCTION OF BG RAILWAY SIDING AT KADAPA IRD

S.NO

2.2

ACTIVITY

2.3

CONTRACT

OR

HPCL

Verification of the test reports of all the tests of cement, WC

water, sand and coarse aggregates specified in tender

documents from approved laboratory

HP

Mass batching of aggregates, sand and cement as per mix WC

designed & placing of concrete.

HP

Vibrating, tamping and finishing smooth.

WC

Measurement of finished dimensions. It shall be the sole

responsibility of the contractor to ensure the members are WC

in a proper grade & levels as per the approved drawing.

Curing of the cast concrete.

WC

Slump cone test.

WC

HP

WC

HP

WC

HP

Cube test sample collection from the mix, curing and its

testing as per IS: 456, submission of following laboratory

reports ,

a) slump test - field

b) cube strength - lab/field

STANDARD INSPECTION & TEST PLAN

PAGE 8 OF 10

HP

CONSTRUCTION OF BG RAILWAY SIDING AT KADAPA IRD

S.NO

3.1

ACTIVITY

CONTRACT

OR

HPCL

Plastering :

Visual inspection, sieve analysis and carrying out of all WC

field tests of sand as per attached specifications

HP

Verification of the test reports of all the tests of cement WC

and sand specified in tender documents from approved

laboratory supplied by the contractor with respect to the

specifications

WC

Carrying out plastering of specified thickness with CM

as per specification.

WC

Final acceptance after checking thickness of plaster with

thickness gauge to be provided by the contractor at some

random places as decided by HPCL.

HP

STANDARD INSPECTION & TEST PLAN

PAGE 9 OF 10

W

HP

CONSTRUCTION OF BG RAILWAY SIDING AT KADAPA IRD

S.NO

4.0

ACTIVITY

CONTRACT

OR

HPCL

BACK FILLING:

Back filling in foundation trenches after construction of

foundation or wherever required as per the directions of

HPCL engineer in charge, using the serviceable earth

Offering the selected material from excavated earth for

WC

backfilling to HPCL to inspect and witness.

WC

Filling the material in layers of specified thicknesses

Watering the layer and compaction using plate vibrator

WC

Offering tested layer to HPCL to inspect & witness to WC

give clearance for next layer.

STANDARD INSPECTION & TEST PLAN

PAGE 10 OF 10

HP

HP

You might also like

- Meth Negotiation IIDocument14 pagesMeth Negotiation IIJustin RohrlichNo ratings yet

- Safe Erections WebDocument36 pagesSafe Erections Webuday64668No ratings yet

- MTS-Hard Landscaping & Road WorksDocument7 pagesMTS-Hard Landscaping & Road WorksAshimolowo BabatundeNo ratings yet

- Body Nature Appoint Ed by Members Office Term / Reappointment Removal Reports Special NotesDocument4 pagesBody Nature Appoint Ed by Members Office Term / Reappointment Removal Reports Special NotesPrynkaNo ratings yet

- Preliminary Quality Assurance/Quality Control Plan: Mohawk Solar ProjectDocument4 pagesPreliminary Quality Assurance/Quality Control Plan: Mohawk Solar Project无时差No ratings yet

- Original Due Declaration and Notice ofDocument6 pagesOriginal Due Declaration and Notice ofLucy Maysonet100% (3)

- ITP - Road MarkingDocument5 pagesITP - Road MarkingMARK PALEGNo ratings yet

- Saveto MTSDocument79 pagesSaveto MTSIB KNo ratings yet

- Method Statement For ScaffoldingDocument3 pagesMethod Statement For ScaffoldingDouglas JambaNo ratings yet

- Saudi Aramco Typical Inspection Plan: Soil Improvement (Vibro Replacement & Vibro Compaction) 30-Oct-17 CivilDocument10 pagesSaudi Aramco Typical Inspection Plan: Soil Improvement (Vibro Replacement & Vibro Compaction) 30-Oct-17 CivilJagdishNo ratings yet

- Civil Construction ProcedureDocument6 pagesCivil Construction Procedureคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Hollow Core Slab PDFDocument4 pagesHollow Core Slab PDFStraus WaseemNo ratings yet

- Site Investigation Land Survey Installation of BenchmarkDocument17 pagesSite Investigation Land Survey Installation of BenchmarkAnonymous ze9ag1No ratings yet

- CV-0013-005 - Method Statement For Concrete Work (Revised)Document13 pagesCV-0013-005 - Method Statement For Concrete Work (Revised)한상호No ratings yet

- 08-02 ManholeTestingDocument3 pages08-02 ManholeTestingelcivilengNo ratings yet

- Samson v. AguirreDocument2 pagesSamson v. AguirreNoreenesse SantosNo ratings yet

- QM Plan ProcedureDocument13 pagesQM Plan ProcedureHans JonesNo ratings yet

- 16 0105 Construction Method StatementDocument3 pages16 0105 Construction Method StatementChun KedNo ratings yet

- Method Statement For Retaining Wall: 1.1 List of Proposed Manpower and MachineriesDocument2 pagesMethod Statement For Retaining Wall: 1.1 List of Proposed Manpower and MachineriesSerkam PEDNo ratings yet

- MOS For Epoxy PaintingDocument3 pagesMOS For Epoxy PaintingHussam WaleedNo ratings yet

- Method Statement For Sign Board InstallationDocument45 pagesMethod Statement For Sign Board InstallationEngr Primus ChinonyeNo ratings yet

- Standard Inspection Test Plan Itp For Civil WorksDocument10 pagesStandard Inspection Test Plan Itp For Civil WorksDushyantKhatanaNo ratings yet

- MS For Deep ExcavationDocument8 pagesMS For Deep ExcavationBilalNo ratings yet

- Forex Managed Account AgreementDocument8 pagesForex Managed Account AgreementBetan NorthNo ratings yet

- Compacted Earth FillDocument8 pagesCompacted Earth FillTwin Wayne100% (1)

- Checklist For Wall Panels InstallationDocument2 pagesChecklist For Wall Panels InstallationChristos LoutrakisNo ratings yet

- Method Statement - Concreting WorkDocument4 pagesMethod Statement - Concreting WorkArnold Roy ManaloNo ratings yet

- Training Design of The Mandatory Training For Sangguninang Kabataan Treasurer Secretary and KagawadDocument3 pagesTraining Design of The Mandatory Training For Sangguninang Kabataan Treasurer Secretary and KagawadDeanne Mitzi Somollo100% (1)

- Lps 01 Hti MST Me 007 GRP Water TankDocument12 pagesLps 01 Hti MST Me 007 GRP Water TankJomy JohnyNo ratings yet

- 11 - Method of Statement For Stub Angle InstallationDocument10 pages11 - Method of Statement For Stub Angle InstallationiloveumakkahNo ratings yet

- Advanced Financial Accounting & Reporting Part 2Document18 pagesAdvanced Financial Accounting & Reporting Part 2Ezio PaulinoNo ratings yet

- Rev Description Prepared by Approved by Date Method Statement For Cold Water Services PJSBDocument5 pagesRev Description Prepared by Approved by Date Method Statement For Cold Water Services PJSBToyEn MEgatNo ratings yet

- Method Statement of Installing I-BeamDocument1 pageMethod Statement of Installing I-BeamfaizbukhariNo ratings yet

- The Future of The Euro PDFDocument369 pagesThe Future of The Euro PDFodradek4No ratings yet

- Method Statement: Soil Replacement Under FoundationsDocument1 pageMethod Statement: Soil Replacement Under FoundationsMohamed SalahNo ratings yet

- Method Statement Installation of Air Handling UntDocument6 pagesMethod Statement Installation of Air Handling UntkouarNo ratings yet

- Method Statement For Linen ChuteDocument8 pagesMethod Statement For Linen ChuteGary LoNo ratings yet

- Methodology For Water Proofing WorkDocument9 pagesMethodology For Water Proofing WorkJITHESH K G GVRNo ratings yet

- Quality Assurance and Quality Control PlanDocument6 pagesQuality Assurance and Quality Control PlanTia KurniawatiNo ratings yet

- Water RecDocument9 pagesWater RecToyEn MEgatNo ratings yet

- ACROPOLIS Method Statement For Domestic Water Piping Installation UG & AGDocument14 pagesACROPOLIS Method Statement For Domestic Water Piping Installation UG & AGVontrex EngrNo ratings yet

- MS For Core Walls Dowels Location Repair (Towers)Document5 pagesMS For Core Walls Dowels Location Repair (Towers)rayNo ratings yet

- 2 Tamayo vs. GsellDocument2 pages2 Tamayo vs. GsellGelo Macaranas100% (1)

- Method of StatementDocument8 pagesMethod of StatementHisham BerrasaliNo ratings yet

- Qa QCDocument10 pagesQa QCBrain Dee Tech LtdNo ratings yet

- Method Statement For Coring WorkDocument6 pagesMethod Statement For Coring Workadeniyi abiolaNo ratings yet

- MS - Raft PouringDocument14 pagesMS - Raft PouringAby ThykkodathuNo ratings yet

- Cases From Mem AIds ObligationDocument10 pagesCases From Mem AIds ObligationDARLENENo ratings yet

- Method Statement For Fire TankDocument2 pagesMethod Statement For Fire TankJoyanta DebNo ratings yet

- Backfilling PDFDocument4 pagesBackfilling PDFAdjei BaldanNo ratings yet

- Method Statement For DI Pipe InstallationDocument7 pagesMethod Statement For DI Pipe InstallationJeffrey WeyNo ratings yet

- Ms Block WorksDocument3 pagesMs Block WorksjaladeepNo ratings yet

- Method Statement For GI Conduit-CDocument4 pagesMethod Statement For GI Conduit-CJaneNo ratings yet

- Checklist For Epdm Water ProofingDocument1 pageChecklist For Epdm Water ProofingVikas Singh ChandelNo ratings yet

- Method Statement of Steel Structures (TS TRUSS SDN BHD)Document21 pagesMethod Statement of Steel Structures (TS TRUSS SDN BHD)Calvin OhNo ratings yet

- Method Statement For Vertical StructureDocument7 pagesMethod Statement For Vertical StructureAdel SaqqaNo ratings yet

- Water Proofing SpecificationDocument1 pageWater Proofing Specificationprabhu81No ratings yet

- Pulley 1Document4 pagesPulley 1Vijayakumar SamyNo ratings yet

- Method Statement For Installation of DI Pipes at HETDocument9 pagesMethod Statement For Installation of DI Pipes at HETJahangir AlamNo ratings yet

- Method Statement For Water Proofing SubstructureDocument6 pagesMethod Statement For Water Proofing SubstructureRaja NasirNo ratings yet

- Method Statement FOR Embedded Conduits, Boxes and Fittings InstallationDocument6 pagesMethod Statement FOR Embedded Conduits, Boxes and Fittings InstallationWalidNo ratings yet

- Cem Tec White PuDocument2 pagesCem Tec White Pupravi3434No ratings yet

- QES PEVC-ENG237 - Checklist For PSS Fencing DetailsDocument2 pagesQES PEVC-ENG237 - Checklist For PSS Fencing DetailsRupesh Khandekar100% (1)

- Method Statement "Quickplast 399" Skim CoatDocument3 pagesMethod Statement "Quickplast 399" Skim CoatAdam TangNo ratings yet

- Rev 00 - Method Statement - Roof& Ceiling VentilatorDocument11 pagesRev 00 - Method Statement - Roof& Ceiling VentilatorJuwe PkdoNo ratings yet

- Hume Pipe Method StatementDocument2 pagesHume Pipe Method StatementDurgawati Mishra67% (3)

- Installation, Testing & Flushing of Firefighting Piping System - Method Statement HQDocument20 pagesInstallation, Testing & Flushing of Firefighting Piping System - Method Statement HQvishwas salunkhe100% (1)

- TADA Claim Form (New)Document2 pagesTADA Claim Form (New)MonuNo ratings yet

- 1 - Method StatementDocument29 pages1 - Method StatementsyedtalhamehmoodNo ratings yet

- Method Statement For Installation of Aluminium Curtain Wall Glass and Cladding at Main Terminal (Air Side)Document2 pagesMethod Statement For Installation of Aluminium Curtain Wall Glass and Cladding at Main Terminal (Air Side)md_rehan_2No ratings yet

- Part A-Standard Inspection Procedures For RoadworksDocument5 pagesPart A-Standard Inspection Procedures For RoadworksAnonymous Xb3zHioNo ratings yet

- AA Class Contractor As On 01.03.2016Document46 pagesAA Class Contractor As On 01.03.2016uday64668No ratings yet

- Sample QAP of Steel Bridge GirderDocument5 pagesSample QAP of Steel Bridge Girderuday64668No ratings yet

- List of Machines: S.No Description Specifications Unit CostDocument1 pageList of Machines: S.No Description Specifications Unit Costuday64668No ratings yet

- Qa Manual and QC May01Document70 pagesQa Manual and QC May01coli15No ratings yet

- Quality Plan and Inspection & Test Plan: Records Type To FrequencyDocument1 pageQuality Plan and Inspection & Test Plan: Records Type To Frequencyuday64668No ratings yet

- JCEPMS13002 Hyunjoo KimDocument9 pagesJCEPMS13002 Hyunjoo Kimuday64668No ratings yet

- Section1 - Instructions To TendererDocument16 pagesSection1 - Instructions To TendererParvez Syed RafiNo ratings yet

- Ethics For It Workers and It UsersDocument54 pagesEthics For It Workers and It UsersAshley MendozaNo ratings yet

- CU 22-09 Order Requiring Amendment Final Woodward High SchoolDocument3 pagesCU 22-09 Order Requiring Amendment Final Woodward High SchoolParents' Coalition of Montgomery County, MarylandNo ratings yet

- Enable RootDocument2 pagesEnable RootMuhammadZainulIkhsanNo ratings yet

- Municipal Form No. 97 Revised 2016: What You Need To KnowDocument6 pagesMunicipal Form No. 97 Revised 2016: What You Need To KnowDeanne QuintanaNo ratings yet

- Bkash Pricing StrategiesDocument15 pagesBkash Pricing StrategiesZuhayir MustafaNo ratings yet

- Karnataka HC Adoption 1 448484Document19 pagesKarnataka HC Adoption 1 448484Winston MenezesNo ratings yet

- 1007 Issue of The Daily JournalDocument28 pages1007 Issue of The Daily JournalSan Mateo Daily JournalNo ratings yet

- The Golden Rules of AccountingDocument1 pageThe Golden Rules of AccountingRamesh ManiNo ratings yet

- Origin and Development of World Trade Organisation (WTO) : By: Dr. Piyush ChaubeyDocument8 pagesOrigin and Development of World Trade Organisation (WTO) : By: Dr. Piyush ChaubeyVirendraNo ratings yet

- Trailers Division - Management ReviewDocument2 pagesTrailers Division - Management ReviewvinothNo ratings yet

- Ind AS 109 PDFDocument3 pagesInd AS 109 PDFChandraNo ratings yet

- Soliman v. Tuazon, 209 SCRA 47Document3 pagesSoliman v. Tuazon, 209 SCRA 47Vincent BernardoNo ratings yet

- de Neef Ha Cut Af En-GbDocument6 pagesde Neef Ha Cut Af En-GbZeeshanAliNo ratings yet

- Mu - Jftot 230 Mark IIIDocument265 pagesMu - Jftot 230 Mark IIIWilliams Medina100% (2)

- Department of Labor: 04 141Document2 pagesDepartment of Labor: 04 141USA_DepartmentOfLaborNo ratings yet

- Tutorial 4 Bt20403Document5 pagesTutorial 4 Bt20403Radzman Bin AliNo ratings yet

- Readme Hyph LVDocument3 pagesReadme Hyph LVRosa Martin HuelvesNo ratings yet

- BBA 6 Sem HRMDocument9 pagesBBA 6 Sem HRMUniversity Placement CellNo ratings yet

- PortDocument1 pagePortDinh Tan TranNo ratings yet