Professional Documents

Culture Documents

4910-w1 Engineering Guideline For Flexible Metal Hose

Uploaded by

LorenaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4910-w1 Engineering Guideline For Flexible Metal Hose

Uploaded by

LorenaCopyright:

Available Formats

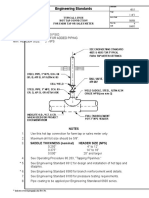

Engineering Standards

Standard

4910

Page

1 of 1

GUIDELINE FOR PURCHASE AND

USE OF FLEXIBLE METAL HOSE

Issue Date

Rev. No.

Date

06/86

1

06/91

1.

SCOPE

This standard establishes guidelines for the specification and use of flexible metal hose for natural gas applications

where flexibility is required in a small diameter connection. Such specifications are required for the purchase and

installation of flexible metal hose in DOT jurisdictional piping since no qualifying industry manufacturing

specifications are known.

2.

LIMITATIONS

2.1

Flexible metal hose should not be used in gas piping at compressor stations and process plants.

2.2

Flexible metal hose with a nominal diameter exceeding 2" nominal diameter should not be used.

3.

PURCHASE SPECIFICATIONS

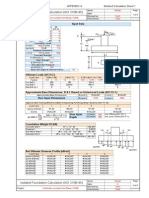

The following specifications are recommended for the purchase of flexible metal hose for natural gas service.

3.1

The rated burst pressure shall not be less than four (4) times the maximum allowable operating pressure

after correcting for service temperature. The maximum service temperature shall be 200F unless

specified otherwise.

3.2

Reinforcing braid is required on any hose with a maximum allowable operating pressure over 25 psig.

3.3

All end connectors shall be welded to the flexible metal hose and braid. The design of the welded joint

attaching the hose and braid to the end connector will not result in any part of the end connector or

connected component being covered by braid. The welds shall be done by the gas tungsten arc welding

(GTAW) process and be inspected by either magnetic particle or dye penetrant methods.

3.4

The corrugated steel and reinforcing braid, if required, shall be Type 304 or Type 316 stainless steel.

3.5

End connectors shall be carbon steel unless specified otherwise.

3.6

All flexible metal hoses shall be hydrostatically tested. The minimum test pressure shall be 1.5 times the

maximum allowable operating pressure and maintained for at least five (5) minutes.

3.7

The hose shall be permanently marked with the information as prescribed in MSS SP-25 on the hose or

end connectors. The test pressure shall be included in the markings. If the markings are die stamped, the

die must have blunt or rounded edges that will minimize stress concentrations.

3.8

Required Purchase Information

a.

b.

c.

d.

e.

f.

g.

Diameter

Overall length

Maximum allowable operating pressure (MAOP)

Service temperature if it exceeds 200F.

End connector type (e.g., male or female, screwed or socket welded)

End connector material (e.g., Type 316 stainless steel)

Minimum allowable rated burst pressure

* Indicates revised paragraph, this Rev. No.

You might also like

- Trusting JesusDocument1 pageTrusting JesusLorenaNo ratings yet

- Tower of BabelDocument5 pagesTower of BabelLorenaNo ratings yet

- Fire protection system philosophy for Collie Urea PlantDocument60 pagesFire protection system philosophy for Collie Urea PlantLorena Dávila100% (1)

- Good Cooling Tower PractiseDocument59 pagesGood Cooling Tower Practiseamahmoud3No ratings yet

- 4940-w3 Standard For Purchase of Valves For Critical Gas ServiceDocument8 pages4940-w3 Standard For Purchase of Valves For Critical Gas ServiceLorena DávilaNo ratings yet

- Demonstration of Hydrogen Air-Assisted FlaDocument18 pagesDemonstration of Hydrogen Air-Assisted Flahk168No ratings yet

- Fluidos Termicos y Circuitos de CalentamientoDocument38 pagesFluidos Termicos y Circuitos de CalentamientoClaudio Antonio Figueroa PulgarNo ratings yet

- What's New - CADWorx 2016Document5 pagesWhat's New - CADWorx 2016LorenaNo ratings yet

- 2813 HXGN Live 2813 MccombDocument19 pages2813 HXGN Live 2813 MccombLorenaNo ratings yet

- Report DesignerDocument255 pagesReport Designerdgrant775No ratings yet

- Series 1500 Cooling Tower SpecificationDocument9 pagesSeries 1500 Cooling Tower SpecificationLorenaNo ratings yet

- Good Cooling Tower PractiseDocument59 pagesGood Cooling Tower Practiseamahmoud3No ratings yet

- Flare System PDFDocument41 pagesFlare System PDFAzar Deen100% (1)

- Onshore and Offshore: Echnical PresentationDocument66 pagesOnshore and Offshore: Echnical PresentationAnonymous 4MwmDaNbNo ratings yet

- 4895-w2 Standard For Purchase of Forged Flanges and FittingsDocument3 pages4895-w2 Standard For Purchase of Forged Flanges and FittingsLorenaNo ratings yet

- 4907-w0 Standard For Purchase of Line Pipe For Low Temperature Service (Supplement To ASTM A333)Document3 pages4907-w0 Standard For Purchase of Line Pipe For Low Temperature Service (Supplement To ASTM A333)LorenaNo ratings yet

- 4890 Guide Bar Installation For Weld TeesDocument2 pages4890 Guide Bar Installation For Weld TeesLorena DávilaNo ratings yet

- 4910-w1 Engineering Guideline For Flexible Metal HoseDocument1 page4910-w1 Engineering Guideline For Flexible Metal HoseLorenaNo ratings yet

- 4815 Typical 1 Hot Tap Connection For Farm Tap or Sales MeterDocument1 page4815 Typical 1 Hot Tap Connection For Farm Tap or Sales MeterLorenaNo ratings yet

- 4802-w2 Concrete Anchor Block - Installation DetailsDocument2 pages4802-w2 Concrete Anchor Block - Installation DetailsLorenaNo ratings yet

- 4763-w2 Yard Applied Concrete Pipe CoatingDocument7 pages4763-w2 Yard Applied Concrete Pipe CoatingLorena DávilaNo ratings yet

- Selecting and Designing Branch ConnectionsDocument8 pagesSelecting and Designing Branch ConnectionsLorenaNo ratings yet

- 4758-w0 Restoration of TerracesDocument1 page4758-w0 Restoration of TerracesLorenaNo ratings yet

- 4764-n1 Typical Pipeline Bolt On Type Concrete Weight For 42 O.D. PipelineDocument1 page4764-n1 Typical Pipeline Bolt On Type Concrete Weight For 42 O.D. PipelineLorenaNo ratings yet

- 4762-w0 Typical Canal Undercrossing, Lined or UnlinedDocument1 page4762-w0 Typical Canal Undercrossing, Lined or UnlinedLorenaNo ratings yet

- 4747-w2 Typical Natural Gas Pipeline and Pipeline Insulator Installation For Cased Highway UndercrossingDocument1 page4747-w2 Typical Natural Gas Pipeline and Pipeline Insulator Installation For Cased Highway UndercrossingLorenaNo ratings yet

- Enron Gas Pipeline Engineering Standards for Concrete Pipeline WeightsDocument2 pagesEnron Gas Pipeline Engineering Standards for Concrete Pipeline WeightsLorenaNo ratings yet

- 4760-w0 Typical Stream or Ditch Pipeline UndercrossingDocument1 page4760-w0 Typical Stream or Ditch Pipeline UndercrossingLorena100% (1)

- 4752-w2 Typical Natural Gas Pipeline and Pipeline Insulator Installation For Railroad UndercrossingDocument1 page4752-w2 Typical Natural Gas Pipeline and Pipeline Insulator Installation For Railroad UndercrossingLorenaNo ratings yet

- 4748-w0 Typical Pipeline and Casing Support at Cased UndercrossingsDocument1 page4748-w0 Typical Pipeline and Casing Support at Cased UndercrossingsLorenaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Effectiveness of Cassava (Manihot Esculenta) Starch in Creating Biodegradable PlasticDocument3 pagesThe Effectiveness of Cassava (Manihot Esculenta) Starch in Creating Biodegradable PlasticKimi Annika VillarealNo ratings yet

- Characterization of Minerals, Metals and MaterialsDocument723 pagesCharacterization of Minerals, Metals and Materialslfvorster99No ratings yet

- Claus ProcessDocument6 pagesClaus ProcessRafi AlgawiNo ratings yet

- Mechanical Design-Material PropertiesDocument61 pagesMechanical Design-Material Propertiesgaza001No ratings yet

- ME206 Lecture 3 - Key concepts in metal casting flowDocument28 pagesME206 Lecture 3 - Key concepts in metal casting flowHarsh ShahNo ratings yet

- Technical Design Information for Latrine ConstructionDocument24 pagesTechnical Design Information for Latrine Constructionchris mwauraNo ratings yet

- Astm A560 A560m - 12Document3 pagesAstm A560 A560m - 12Leandro Dilkin ConsulNo ratings yet

- Mechanical Engineering-Steam Boilers, Engines, Nozzles and Turbines Important MCQ PDFDocument28 pagesMechanical Engineering-Steam Boilers, Engines, Nozzles and Turbines Important MCQ PDFRobert Michael CorpusNo ratings yet

- FME-2021-0403 Proof HiDocument41 pagesFME-2021-0403 Proof HiAsif EqubalNo ratings yet

- Slurry Shield AdditivesDocument8 pagesSlurry Shield AdditivesfabiodbdbNo ratings yet

- Method For Curing TyreDocument5 pagesMethod For Curing TyreNivantNo ratings yet

- Foundry Engineering MSE-316 Course OverviewDocument25 pagesFoundry Engineering MSE-316 Course OverviewMuhammad AsimNo ratings yet

- PQT First Aplication Banyu Urip Painting PrimerDocument19 pagesPQT First Aplication Banyu Urip Painting PrimerHeri FebriyantoNo ratings yet

- Pds Tial m80Document2 pagesPds Tial m80Yan FerizalNo ratings yet

- STANDARD SPECIFICATIONS FOR CONSTRUCTION OF ROADS AND BRIDGES ON FEDERAL HIGHWAY PROJECTS - fp14 PDFDocument762 pagesSTANDARD SPECIFICATIONS FOR CONSTRUCTION OF ROADS AND BRIDGES ON FEDERAL HIGHWAY PROJECTS - fp14 PDFAhmad Dzikri Fauzan100% (1)

- Dextra Prestressing Bar Rev 11 Oct 2016Document14 pagesDextra Prestressing Bar Rev 11 Oct 2016Natthawut CheencharoenNo ratings yet

- Manual For ConcretingDocument43 pagesManual For Concretinglwin_oo2435No ratings yet

- Automatic Wall Painting MachineDocument9 pagesAutomatic Wall Painting MachineaalekhNo ratings yet

- Pushover Analyses of TwoDocument6 pagesPushover Analyses of TwogazmirNo ratings yet

- Chapter 14 Electric Current and Its Effects Class 7 Extra Questions ScienceDocument6 pagesChapter 14 Electric Current and Its Effects Class 7 Extra Questions ScienceShaurya Maniktala50% (2)

- Weldment Deffect and Rejected by StationDocument28 pagesWeldment Deffect and Rejected by StationHadi azfar channelNo ratings yet

- Introduction To Mass TransferDocument44 pagesIntroduction To Mass TransferGhazanferAliNo ratings yet

- Simplified Plumbing Design NPC Philippines PDFDocument168 pagesSimplified Plumbing Design NPC Philippines PDFClimaco EdwinNo ratings yet

- 3rd Summative TestDocument8 pages3rd Summative TestAngelica ValdezNo ratings yet

- 04 Nowy-Styl-Group Price-List Office-Furniture EXP-CZ-SK en BNOS-RG E06 2018Document420 pages04 Nowy-Styl-Group Price-List Office-Furniture EXP-CZ-SK en BNOS-RG E06 2018Marin IonutNo ratings yet

- ACI 215R - Consideration For Design of Concrete Structures Subjected To Fatigue LoadingDocument24 pagesACI 215R - Consideration For Design of Concrete Structures Subjected To Fatigue LoadingAlbertoNo ratings yet

- Laboratory 9 - Soil Classification Accdg To AASHTO and USCSDocument3 pagesLaboratory 9 - Soil Classification Accdg To AASHTO and USCSVincent GuiaNo ratings yet

- Isolated Foundation Calculation (ACI 318M-95) : Input DataDocument5 pagesIsolated Foundation Calculation (ACI 318M-95) : Input DataJuan CarlosNo ratings yet

- HYDRAZINEDocument19 pagesHYDRAZINEDamla Taykoz100% (2)

- Kingspan Logstor Handling and Installation Manual User Installation Guide en EurDocument290 pagesKingspan Logstor Handling and Installation Manual User Installation Guide en Eurvalentin.gomez-valadesNo ratings yet