Professional Documents

Culture Documents

Stainless Steel 420 PDF

Stainless Steel 420 PDF

Uploaded by

candratrikusumaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Stainless Steel 420 PDF

Stainless Steel 420 PDF

Uploaded by

candratrikusumaCopyright:

Available Formats

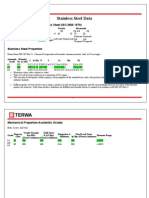

STAINLESS STEEL - 420

RELATED SPECIFICATIONS:

Germany

Great Britain

Japan

USA

W.Nr 1.4021 X20Cr13

BS970 Part 3 1991 420S37

JIS GR303 Sus 420J1

UNS 42000

SAE S1420 AISI 420

ASTM A276-420

DESCRIPTION:

420 is a martensitic stainless steel with 12% Chromium which is sufficient to give good corrosive

resistance properties. .Its best corrosive resistance is when hardened and surface is ground or

polished.It has good ductility in the annealed condition but can be hardened up to 500HB (highest of

the chromium grades). Martensitic Grades are known for high hardness and allowances must be

made for poor weldability and usually allowances for a final harden and temper treatment.

Steel is magnetic and welding is not recommended.

APPLICATIONS:

Knives, surgical instruments, fasteners, shaft sleeves, spindles, nozzles, shafts and plastic moulds.

CHEMICAL ANALYSIS:

Min.

Max.

C

%

0.15

Si

%

1.00

Mn

%

1.00

P

%

0.04

S

Cr

%

%

12.00

0.03 14.00

*Carbon Range can vary extensively from 420A (lowest carbon) increasing in carbon content to 420C.

TYPICAL MECHANICAL PROPERTIES:

Diameter

Condition

ALL

Up to

160m

ANNEALED

HARDENED

&

TEMPERED

Tensile

Strength MPa

Min.

Yield Strength

MPa min.

Elongation in

50mm % min.

Hardness

Brillnell Max.

850-1000

600

12

>230

>280

*Hardened and Tempered usually supplied in Condition R or Condition S.

SIZES AVAILABLE:

Available stock is normally supplied in 420C (highest carbon range) and hardened and tempered

Condition R to AS1444 standard.

Round bars supplied cold drawn to h9 condition up to 25.4mm, smooth turned and polished up to

127mm and peeled over 12.7mm

Size Range: 15.88mm 220mm

COLOUR CODE: ROSE PINK END

DISCLAIMER: This specification is for information purposes only. Global Metals takes no responsibility for the suitability of the steels referred to in this specification without prior

notification. Global Metals takes no responsibility for any errors1 or omissions, or for any consequences resulting from its use.

You might also like

- Oltc FundamentalDocument118 pagesOltc Fundamentalusefi100% (1)

- AISI 420 Data SheetDocument2 pagesAISI 420 Data SheetVicky GautamNo ratings yet

- 304L MTC Int PDFDocument1 page304L MTC Int PDFTanmoy DuttaNo ratings yet

- PSCAD Training 4Document47 pagesPSCAD Training 4usefi100% (1)

- 1 4301Document2 pages1 4301Nguyeentt TntNo ratings yet

- Aisi 4140 En8 En19Document1 pageAisi 4140 En8 En19Jose KurianNo ratings yet

- Application of Pscad-Emtp-Phase Shifter Modeling PDFDocument2 pagesApplication of Pscad-Emtp-Phase Shifter Modeling PDFusefi100% (1)

- Tap ChangerDocument10 pagesTap ChangerusefiNo ratings yet

- Homopolar GeneratorDocument29 pagesHomopolar GeneratorusefiNo ratings yet

- Transformer OilDocument48 pagesTransformer OilusefiNo ratings yet

- A4 80Document2 pagesA4 80alwezalokNo ratings yet

- Stainless Steel - 420: Related SpecificationsDocument1 pageStainless Steel - 420: Related SpecificationsSundar ASNo ratings yet

- High Tensile Alloy 4140Document1 pageHigh Tensile Alloy 4140browniezboyNo ratings yet

- AISI Alloy 4130 Steel Supply Range& 4140Document6 pagesAISI Alloy 4130 Steel Supply Range& 4140ap taNo ratings yet

- STAINLESS STEEL SS 416 / S41600 / 1.4005: Grade Uns No Old British Euronorm Swedish SS Japanese JIS BS en No NameDocument3 pagesSTAINLESS STEEL SS 416 / S41600 / 1.4005: Grade Uns No Old British Euronorm Swedish SS Japanese JIS BS en No NameksNo ratings yet

- 420 Data SheetDocument2 pages420 Data SheetSaransiri WongsiriNo ratings yet

- Grade Data Sheet: Heat ResistanceDocument2 pagesGrade Data Sheet: Heat Resistanceapurv bhartiNo ratings yet

- Stainless Steel Bar 431 Atlas 431: Colour Code: Signal RedDocument3 pagesStainless Steel Bar 431 Atlas 431: Colour Code: Signal RedNitin AggarwalNo ratings yet

- Mild Steel SpecificationDocument1 pageMild Steel SpecificationSteinol SolutionsNo ratings yet

- Euro 410 Ni MoDocument1 pageEuro 410 Ni MoMustafa OğuzhanNo ratings yet

- 1.4306 enDocument2 pages1.4306 enRoberto_PrrNo ratings yet

- Stainless Steel ASTM A815 S31803: Specifications Alloy DesignationsDocument2 pagesStainless Steel ASTM A815 S31803: Specifications Alloy Designationsallouche_abdNo ratings yet

- Stainless Steel 316Document1 pageStainless Steel 316Bungsu ZamzamNo ratings yet

- MaterialDocument4 pagesMaterialAmit PandeyNo ratings yet

- High Tensile Alloy 4340Document1 pageHigh Tensile Alloy 4340Qureis HabibNo ratings yet

- Aalco Metals LTD Stainless Steel 14021 Bar 311Document2 pagesAalco Metals LTD Stainless Steel 14021 Bar 311joseocsilvaNo ratings yet

- Steel SpecificationsDocument4 pagesSteel Specificationsgaurav tiwariNo ratings yet

- Stainless Steel Grade 410Document5 pagesStainless Steel Grade 410Rajesh N Priya Gopinathan100% (1)

- Aalco Metals LTD Stainless Steel ASTM A815 S31803 261Document2 pagesAalco Metals LTD Stainless Steel ASTM A815 S31803 261Irvin PajueloNo ratings yet

- Chemical Formula Topics Covered: Table 1. Composition Ranges For 410 Grade Stainless SteelDocument4 pagesChemical Formula Topics Covered: Table 1. Composition Ranges For 410 Grade Stainless Steelaryanscrews2329No ratings yet

- Macsteel VRN VRN 200 DatasheetDocument1 pageMacsteel VRN VRN 200 DatasheetIgor NhamanoNo ratings yet

- Datenblatt 4105 UKDocument2 pagesDatenblatt 4105 UKVahid SarfarazNo ratings yet

- Section 2.0 Alloy SteelsDocument10 pagesSection 2.0 Alloy SteelsAloísio NascimentoNo ratings yet

- Nirosta 4104: Krupp EdelstahlprofileDocument2 pagesNirosta 4104: Krupp EdelstahlprofileLuis MayorgaNo ratings yet

- Material - (1 4462)Document2 pagesMaterial - (1 4462)Ashutosh PathakNo ratings yet

- SS 6mo - 1.4547Document1 pageSS 6mo - 1.4547f_riseNo ratings yet

- SS DataDocument2 pagesSS Datarobertino00No ratings yet

- X65Cr13 C 0.58 - 0.70 CR 12.50 - 14.50 S Max. 0.015Document2 pagesX65Cr13 C 0.58 - 0.70 CR 12.50 - 14.50 S Max. 0.015Jim SmithNo ratings yet

- Technical Datasheet: Engineering SteelDocument1 pageTechnical Datasheet: Engineering SteelKarimulla ShaikNo ratings yet

- Stainless Steel 420 Material Chemical CompositionDocument3 pagesStainless Steel 420 Material Chemical Compositionr arumugamNo ratings yet

- Product Manual: BarrettDocument52 pagesProduct Manual: Barrettbrajendra1020No ratings yet

- ASTM A320: GradesDocument1 pageASTM A320: Gradesmaryam KAHRIZINo ratings yet

- UNS R30006 Steel GradesDocument3 pagesUNS R30006 Steel GradesRatnakar PatilNo ratings yet

- Difference Between y Block and Other Xmas TreeDocument6 pagesDifference Between y Block and Other Xmas TreeMOHAMED FAISALKHANNo ratings yet

- 316l Austenitic Stainless Steel BarDocument3 pages316l Austenitic Stainless Steel Barதமிழன் இராமசாமிNo ratings yet

- Kaiser Aluminum Shapes Soft Alloy PDFDocument18 pagesKaiser Aluminum Shapes Soft Alloy PDFgerrzen64No ratings yet

- SINOXX 4116 Steel: Designation by StandardsDocument2 pagesSINOXX 4116 Steel: Designation by StandardsSamirNo ratings yet

- Spring MaterialsDocument4 pagesSpring MaterialssohamkoliNo ratings yet

- 25CR20NIDocument2 pages25CR20NIShariq KhanNo ratings yet

- 316 LSDocument5 pages316 LSRouse ToxquiNo ratings yet

- Aalco Metals LTD Stainless Steel 14571 Bar 40Document3 pagesAalco Metals LTD Stainless Steel 14571 Bar 40raduonoNo ratings yet

- SS 410Document2 pagesSS 410saikarthik103212No ratings yet

- Atlas Grade Datasheet 410 Rev May 2008Document2 pagesAtlas Grade Datasheet 410 Rev May 2008Satendra ThakurNo ratings yet

- 1Document4 pages1Anonymous 6MI1wMNo ratings yet

- Manufacturers & Suppliers of Forged Flanges: Corporate OfficeDocument4 pagesManufacturers & Suppliers of Forged Flanges: Corporate Officeabhishek_negi_41No ratings yet

- Grade 430 Stainless Steel Technical DataDocument3 pagesGrade 430 Stainless Steel Technical DataMahmood KhanNo ratings yet

- Carpenter Stainless Type 430: IdentificationDocument4 pagesCarpenter Stainless Type 430: Identificationumesh sengarNo ratings yet

- 420 Martensitic Stainless Steel BarDocument4 pages420 Martensitic Stainless Steel BarAHMED FATHINo ratings yet

- Din 1652-3 Grade 16Mncr5 Treated To Ferritic-Pearlite Structure and Cold-DrawnDocument3 pagesDin 1652-3 Grade 16Mncr5 Treated To Ferritic-Pearlite Structure and Cold-DrawnairkadNo ratings yet

- En 8Document1 pageEn 8Devendera TripathiNo ratings yet

- Astm A582 Round Bar, Flat Bar & Astm A582 Material Suppliers IndiaDocument6 pagesAstm A582 Round Bar, Flat Bar & Astm A582 Material Suppliers IndiaAVINASHRAJNo ratings yet

- Aspac Royalloy enDocument7 pagesAspac Royalloy enNugroho Faris SudrajatNo ratings yet

- Easergy P3 - REL52034Document6 pagesEasergy P3 - REL52034usefiNo ratings yet

- WEG Brushless Excitation System Series Diode Redundancy Usa10023 Brochure English PDFDocument2 pagesWEG Brushless Excitation System Series Diode Redundancy Usa10023 Brochure English PDFusefiNo ratings yet

- Design of Antiwindup AVR For Synchronous Generator Using Matlab SimulationDocument9 pagesDesign of Antiwindup AVR For Synchronous Generator Using Matlab SimulationusefiNo ratings yet

- PDS Nytro Libra enDocument2 pagesPDS Nytro Libra enValeriano SilvestriNo ratings yet

- Nytro 10XN: Designed For Heavy Duty Product DescriptionDocument2 pagesNytro 10XN: Designed For Heavy Duty Product DescriptionusefiNo ratings yet

- PDS Nytro Bear ASTM EN PDFDocument2 pagesPDS Nytro Bear ASTM EN PDFP_sanchezNo ratings yet

- Transformer OilDocument10 pagesTransformer OilusefiNo ratings yet

- Nyhib 10: Property Unit Test Method Specification Limits Typical Data MIN MAXDocument1 pageNyhib 10: Property Unit Test Method Specification Limits Typical Data MIN MAXusefiNo ratings yet

- Nynas 10 GBNDocument1 pageNynas 10 GBNMoinuddin MohammedNo ratings yet

- Nytro 10XN: Designed For Heavy Duty Product DescriptionDocument2 pagesNytro 10XN: Designed For Heavy Duty Product DescriptionusefiNo ratings yet

- Nynas OilDocument2 pagesNynas OilusefiNo ratings yet

- Nedic Tech Rep 2002Document17 pagesNedic Tech Rep 2002Samee UllahNo ratings yet

- LECTURE 28 (Ch. 11) Ac Voltage Controllers: ECE 452 Power ElectronicsDocument18 pagesLECTURE 28 (Ch. 11) Ac Voltage Controllers: ECE 452 Power ElectronicsNishant ParikhNo ratings yet