Professional Documents

Culture Documents

Lesson 6

Lesson 6

Uploaded by

kantscribdCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lesson 6

Lesson 6

Uploaded by

kantscribdCopyright:

Available Formats

(Six Sigma Process):

TQM 1

/

5

1) (Define) (Deployment Phase)

2) (Measurement)

3) (Analysis)

4) (Improvement)

5) (Controlling Process)

6 (SIX SIGMA)

165

1 : (Define:D)

(Sigma)

3 (Champion) (Black Belt)

(Green Belt)

(Champion)

(Leader)

(Project)

(Measure) 1

2

1 1

2 1 (Six Sigma)

(Black Belt)

(Black Belt)

(Project)

(Cross-functional team members) (Project)

(Full-time project leader) 1 50

1 100

2

1 1 (Project)

2 3 ( Project )

( Project )

6 (SIX SIGMA)

166

( Green Belt )

( Project )

( Green Belt )

( Project )

( Part - time project ) 1 20

2

1 5

2 1

( Project )

2 : (Measurement:M)

3 : (Analysis:A)

4 : (Improvement:I) ( Design

of Experiments : DOE)

5 : (Controlling process:C)

6 (SIX SIGMA)

167

(Normal Distribution)

( Normal Distribution )

0 1(X ~ N(0,1))

100% X 6.1

....(6.1)

5 . 5 Z

6.1 Z

1.000

0.9973 1 - 0.9973 = 0.00270

0.00270 2 = 0.00135 Z

3 99.73% 3 6.2

3

6 (SIX SIGMA)

168

0.00135

0.00135

-3.0

2

1 0.9973

+3.02

6.2

5 . 5

Z

Z = 3

/

/

99.73 / 0.27

Z = 6

/ /

99.9999998

Z = 3 Z = 6 ( Harry 1978 ) 6.1

6.1

Z = 3 3

- 20,000

- 15

- 5,000

-

2

- 200,000

- 7

Z = 6 6

- 7

- 1 7

- 1.7

-

1 5

- 68

1 34

6.1 Z = 6

Z = 3

6 (SIX SIGMA)

169

LSL

USL

0.00000000098

7

0.00000000098

7

6 5 4 3 2 2 3 4 5 6

6.3 Z = 1 Z = 6

6.3 Z

(Defect) (Part per million : ppm)

(Sigma: )

6.2

6.2

( Spec. Limit)

(%)

(part per million : ppm)

68.27

317300

95.45

45500

99.73

2700

99.9937

63

99.999943

0.57

99.9999998

0.002

6.3 6.2 Z

/

6 (SIX SIGMA)

170

/

() 6.4 6.3

(Normal distribution)

Shifted 1.5

-1.5 +1.5

LSL

USL

6 5 4 3 2 2 3 4 5 6

6.4

1.5

6.3

6.3 (defect)

()

( Spec. Limit)

(%)

30.23

69.13

93.32

99.3790

99.97670

99.999660

(ppm.)

697700

308700

66810

6210

233

3.4

6 (SIX SIGMA)

171

6.3 ()

6

3.4 ( 3.4 parts per million: ppm)

66,810

( 66,810 parts per million: ppm)

6.5

6.5 3

10

4 30

5 5

70

6

6 (SIX SIGMA)

172

( Y Key Process Output Variable : KPOV)

(Dependent)

( KPIV )

Y =

( KPOV )

Y (KPOV)

(Dependent)

(Output)

(Effect)

(Symptom)

(Monitor)

F (X)

KPIV : Key Process Input Variable

KPOV : Key Process Output Variable

X1,X2,,Xn(KPIV)

(Independent)

(Input)

(Cause)

(Problem)

(Control)

X X

( Key Process Input Variable : KPIV )

6.1

(Hard Disk Drive)

( Hole Bushing )

5

6 (SIX SIGMA)

173

(Hard Disk Drive)

(SWG hole bushing )

6.6 (Hard Disk Drive)

1 (Define) :

(Problem Statement )

(Project Objective)

1. 1.

(Silicate bush)

2.

2. 3.

( 4.

)

(Design of Experimental:DOE) 7

3.

(7QCTools)

(Porprotion Test) ( ttest)(F-test)

6 (SIX SIGMA)

174

(Goal of Production)

1. 30 %( 2,000,000

1,700,000

2. ( 200 PCs

251 PCs )

(Project Period)

-

2 (Measurement) :

(burr) 3

200 pcs

210 pcs

220 pcs

230 pcs

260 pcs

250 pcs

(Burr)

240 pcs

(Burr)

(Burr)

6.7 (Burr)

6 (SIX SIGMA)

175

3 (Analysis) : KPIV (Key Process Input

Variable) KPOV(Key Process Output Variable)

KPIV (Key Process Input Variable) (Silicate

brush feature: X1) (Operator: X2)

(Tool life of main machine : X3) (Part

condition: X4)

(Tooling condition: X5)

KPOV (Key Process Output Variable)

(Swage hole burr condition)

(Swage hole scratch)

6.8

(Method)

(Machine)

(Run out)

( Man)

(Material)

6.8

6 (SIX SIGMA)

176

4 (Improvement) :

(Rework)

(Analysis of variance)

5 (Controlling Process) :

1 4

(Process)

6.1

(Process Capability Index) (Process Cycle Time)

/(Defects per Opportunity-DPO /

Defects per Million Opportunities-DPMO) /( Yield / Rolled

Though out Yield-RTY)

5

(Process Cycle Time)

6 (SIX SIGMA)

177

1

1

(Defects per Opportunity-DPO)

3

500 3

5

DPO 1.0 %

(Defects per

Opportunity-DPO / Defects per Million Opportunities-DPMO) DPMO

// ()

DPO DPMO

4

1

1 = 1 Unit

1 = 1 Opportunity

1 = 4

O (Opportunities for a defect)

6 (SIX SIGMA)

178

D (Defect) /

U (Unit)

DPU (Defect per Unit)

D

(6.2)

DPU

U

DPO

.(6.3)

DPU

D

O

UO

.(6.4)

DPMO DPO 10 6

(Defect) DPU DPO

D

DPU 1

U

DPO

DPU 1

0 .25

O

4

D

DPU 2

U

DPO

DPU 2

0 .50

O

4

6.2

6 A B C D E F

(Defect) (Unit)

(opportunity per unit)

6.4 D U O DPU DPO DPMO

DPU

DPO

DPMO

A (Type A)

B (Type B)

C (Type C)

D (Type D)

E (Type E)

F (Type F)

21

10

8

68

74

20

327

350

37

743

80

928

92

85

43

50

60

28

0.064

0.029

0.216

0.092

0.925

0.022

0.0007

0.0003

0.0050

0.0018

0.0154

0.0008

698

336

5,028

1,830

15,417

770

0.0016

1,554

Total

201

6 (SIX SIGMA)

179

(DPU)

(DPO)

1,000,000 (DPMO) A

21

D

A:

0.064

DPU

U

327

DPU

0.064

0.0007

DPO

O

92

DPMO DPO 10 6 0.0007 10 6 698

1,000,000 (DPMO) X

Y

1,000,000 (DPMO)

P a r e to C h a r t o f ty p e

25000

100

80

15000

60

10000

40

5000

20

0

ty p e

Count

Pe rce nt

Cum %

T ype E

15417

6 4 .0

6 4 .0

T ype C

5028

2 0 .9

8 4 .9

T ype D

1830

7 .6

9 2 .5

T ype F

770

3 .2

9 5 .7

O th e r

1034

4 .3

1 0 0 .0

Pe r c e n t

DPM O

20000

6.6

6 (SIX SIGMA)

180

Input

Output

(Poisson Distribution)

x 0

e x

e

x

e D/U e DPU

Y (Throughput Yield)

X

(Poisson)

TP ( Throughput yield)

TP e DPU

RT (Rolled Throughput yield)

1 m m

RT

i 1

TPi

; i= 1,2,,m

2 (First - time yield)

(Final Yield) (First - time yield)

(rework)

(First - time yield)

6 (SIX SIGMA)

181

(Throughput yield)

(Rolled throughput yield) (rework)

6.3 5 467

(Unit) (DPU) 0.01071 (5/467)

x 0 e DPU

e 0.01071

0 . 98935

6.4 5

(Input)

(rework) (Scrap)

6.5

(Input)

1

2

3

4

5

1,000

960

874

804

732

(rework)

920

754

633

519

493

40

120

171

213

221

765

Throughput

(Scrap)

Yield

40

86

70

72

18

286

960

874

804

732

714

0.92

0.82

0.84

0.82

0.95

RT

=0.4936

6.5

6.7 1 1,000

920 40 40

6 (SIX SIGMA)

182

1 960

(Throughput yield : TP ) 0.92 (920/1,000 = 0.92)

1,000

Y1 = 0.92

Rework ( 4%)

960

Y2 = 0.82

Scrap ( 9%)

Rework ( 9%)

754

Y3 = 0.84

Scrap ( 8%)

Rework ( 8%)

633

Y4 = 0.82

Scrap ( 9%)

Rework ( 9%)

519

Y5 = 0.95

493

Scrap ( 4%)

Scrap ( 2.5%)

Rework ( 2.5%)

40

960

86

874

70

804

72

732

18

714

YI Throughput Yield

6.7 5

2 960

754 120 86

2 874

(Throughput yield : TP ) 0.82 ( 724 / 920 = 0.82 )

3 874

633 171 70

6 (SIX SIGMA)

183

3 804

(Throughput yield : TP ) 0.84 ( 633 / 754 = 0.84 )

4 804

519 213 72

4 732

(Throughput yield : TP ) 0.82 ( 519 / 633 = 0.82 )

5 732

493 221 18

5 714

(Throughput yield : TP ) 0.95 ( 493 / 519 = 0.95 )

(First - time

yield) (Throughput yield)

960

1 (First - time yield)

=

0.96

1000

920

(Throughpout yield) =

0.92

1000

(First - time yield) 1

0.96 100 96

1 (Throughput yield)

0.92 100 92

874

0.91

960

754

(Throughput yield) = 0.82

920

(First - time yield) 2

0.91 100 91

2 (Throughput yield)

0.82 100 82

2

(First - time yield)

(First - time

yield)

6 (SIX SIGMA)

184

(Rework)

(Throughput yield)

(Rework)

(Rolled Throughput yield)

(Rework)

714

Final Yield

=

0.714

1000

Rolled throughput yield:

RT

= TPi

i1

= (0.92 0.82 0.84 0.82 0.95)

= 0.4936

Final yield 0.714 100

72 ()

(Rolled throughput yield) 0.4936 100

( Rework ) 50

6.5 10 (step)

(throughput yield)

Y1 = 0.92

Y2 = 0.82

Y3 = 0.95

Y4 = 0.82

Y5 = 0.93

Y6 = 0.93

Y7 = 0.92

Y8 = 0.91

Y9 = 0.83

Y10 = 0.85

6.8 10

(Rolled throughput yield)

RT

m

TPi

i 1

= ( 0.92 0.82 0.85 ) = 0.27

6 (SIX SIGMA)

185

100 27

6.6 10

(Defect)

(Unit)

DPU = D/U

Rolled throughput yield

1

2

3

4

5

6

7

8

9

10

5

75

18

72

6

28

82

70

35

88

1495

1420

1402

1330

1324

1296

1214

1144

1109

1021

0.00334

0.05282

0.01284

0.05414

0.00453

0.02160

0.06755

0.06119

0.03156

0.08619

0.99666

0.94855

0.98724

0.94730

0.99548

0.97863

0.93469

0.94065

0.96893

0.91742

497

RT =

0.67317

(Rolled throughput

yield)

RT

= TP

i 1

= 0.99049 0.91564 .. 0.929

= 0.67317

100 67

(Sigma)

(Schmidt and Launsby (1997) ) (Sigma quality level)

= 0.8406 29.37 2.221 ln ppm

6 (SIX SIGMA)

186

6.6 800

142

(Sigma)

142

D

DPU =

0.1775

U

800

0.177510 = 177,500 ppm

0.8406 29.37 2.221 ln ppm

0.8406 29.37 2.221 ln177,500

2.43

2.43 (Sigma)

1.5

Z DPU 0.1775

1 0.1775 = 0.8225 Z = 0.9256

= Z + 1.5

= 0.9256 + 1.5

= 2.4256

2.4256 2.43

7

(Improvement and

Development) (Design of Experiments :DOE)

(Measurement System Analysis :MSA)

4 (S4)

6 (SIX SIGMA)

187

1.

2.

3.

4.

(4 Sigma)

(6 Sigma)

1. (6 ) (Six

Sigma)

2. (Six Sigma)

3.

0.001

(Sigma)

4. (Six Sigma)

You might also like

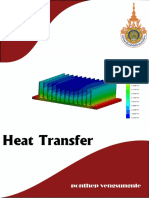

- Heat Transfer - - การถ่ายโอนความร้อนDocument94 pagesHeat Transfer - - การถ่ายโอนความร้อนkantscribd56% (9)

- ไฟไนต์เอลิเมนต์สำหรับวิศวกรรมDocument207 pagesไฟไนต์เอลิเมนต์สำหรับวิศวกรรมkantscribdNo ratings yet

- การใช้งานโซล่าเซลล์เบื้องต้นDocument39 pagesการใช้งานโซล่าเซลล์เบื้องต้นkantscribdNo ratings yet

- คำสั่งแต่งตั้งเจ้าหน้าที่ควบคุมเอกสาร (DC) PDFDocument4 pagesคำสั่งแต่งตั้งเจ้าหน้าที่ควบคุมเอกสาร (DC) PDFkantscribdNo ratings yet

- การควบคุมมอเตอร์ไฟฟ้า 3 เฟส PDFDocument265 pagesการควบคุมมอเตอร์ไฟฟ้า 3 เฟส PDFkantscribdNo ratings yet

- ระเบียบการใช้อุปกรณ์ชุดฝึกระบบนิวแมติก ยี่ห้อ FestoDocument1 pageระเบียบการใช้อุปกรณ์ชุดฝึกระบบนิวแมติก ยี่ห้อ FestokantscribdNo ratings yet

- ขั้นตอนการส่งบทความ estacon2016 PDFDocument5 pagesขั้นตอนการส่งบทความ estacon2016 PDFkantscribdNo ratings yet

- การบริหารคุณภาพด้วยSixSigmaDocument4 pagesการบริหารคุณภาพด้วยSixSigmakantscribdNo ratings yet

- QC - Lesson 3Document49 pagesQC - Lesson 3kantscribdNo ratings yet

- Course Specification of StaticDocument7 pagesCourse Specification of StatickantscribdNo ratings yet

- คู่มือการติดตั้งผลิตภัณฑ์ไม้คอนวูดDocument32 pagesคู่มือการติดตั้งผลิตภัณฑ์ไม้คอนวูดkantscribd0% (1)

- Matlab BookDocument314 pagesMatlab BookMr. Kaison Nasawat100% (2)