Professional Documents

Culture Documents

Scdisc Manual - Nismo Manual JAP Version

Scdisc Manual - Nismo Manual JAP Version

Uploaded by

Lehis Luguer De Queiros VOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Scdisc Manual - Nismo Manual JAP Version

Scdisc Manual - Nismo Manual JAP Version

Uploaded by

Lehis Luguer De Queiros VCopyright:

Available Formats

NISMO &

NISMO CLUTCH DISC & CLUTCH COVER

INSTALLATION MANUAL, INSTRUCTION MANUAL

/Manual No.

TY-301-01

Thank you for your purchase of this product. Please read this manual thoroughly before installation and use, to ensure proper operation

and handling.

After installation, please be sure to pass this manual on to the customer.

NISMO

As NISMO products are handled differently from Nissan genuine products, this product may not be covered under the vehicle repair warranty.

Copying or reprinting any part of this manual without permission is prohibited.

After opening the packing, check to see if any parts are missing and the product is in good condition and not damaged.

Characteristics of the product

The semimetal type clutch disc may produce a sound caused by heavy pieces of metal striking together and cause a judder when

starting your vehicle, but this does not effect performance.

You will see various symbols in this manual. They are used in the following ways:

/ WARNING

This is used to indicate the presence of a hazard that could cause death or serious personal injury.

To avoid or reduce the risk, the procedures must be followed precisely.

/CAUTION

This is used to indicate the presence of a hazard that could cause minor or moderate personal injury or damage to your vehicle.

To avoid or reduce the risk, the procedures must be followed carefully.

/ Before Installation (to the technician)

1.

This product should be installed in a service facility equipped with proper installation tools and should be inspected by a licensed

inspector.

2.

When replacing, be sure to observe the procedures stated in the service manual published by Nissan Motor Co., Ltd., and be sure to

install this product while observing all warnings and precautions stated in this manual.

Do not make any alteration or modification to this product. Serious injury may result.

Before installing this product, confirm application and part numbers match your vehicle.

If the product is installed on an improper vehicle, it may result in vehicle damage or an accident.

The specified torque shown in this manual must be used.

Tightening bolts below the specified torque may result in bolts loosening and causing an accident.

Do not touch the wedge collar in the center of the pull type clutch cover. A poor disengagement of the clutch or a judder may

result.

Do not drop or hit the product.

The product may be damaged, deformed or disabled while being installed and a poor disengagement of the clutch or a

judder may result.

If the related parts (e.g. release bearing) are deteriorated, replace them with new ones.

If a bearing sleeve is specified, use the specified one.

/ WARNING

/CAUTION

/NOTE

/ Before Using (to the customer)

/WARNING

/NOTE

Always observe rules, regulations and posted speed limits when operating any motor vehicle.

Not doing so may result in only damage to your vehicle or could cause serious personal injury.

If any abnormal noises are heard or abnormal vibrations are felt, immediately stop the vehicle in a safe place and check your vehicle.

Driving with an abnormal condition may result in an accident and serious personal injury.

Do not use the product for anything other than the purpose described in this manual.

Any accident or injury incurred by improper use of this product is the sole responsibility of the user.

200km

Soon after installation, test-drive the vehicle for about 120 miles (200 km). Avoid any quick maneuvers.

NISMO

When the NISMO clutch cover is installed, the reactive force of the clutch pedal is increased, therefore, try to get used to it.

/Installation and Removal of Transmission

When connecting the transmission to the engine, never tighten the bolts to do so.

A dowel pin is used to connect the parts between the transmission and the engine. As the dowel pin is made of hard material

and the connecting parts of the transmission are made of aluminum, you may tighten them too much, even if the dowel pin is

inserted diagonally.

Tightening as described above may cause the main drive shaft to become angled, this results in a poor disengagement of

the clutch, damage to the disc, abnormal noises, or abnormal vibrations.

/CAUTION

When removing and installing the transmission, support it with a

transmission jack. Doing so not only reduces your effort, but

also avoids the trouble described above.

When installing the transmission, do not shake it side to side or up

and down. To smoothly put in the transmission, turn the gear into

the high position and turn the output shaft right and left.

/

Mission jack

/Tightening Bolts of Each Part

6

45

4

5

/

Aligning bar

8

2

When tightening it, refer to the list of tightening torques (page 6).

Tighten them in a diagonal pattern in four or five steps. Also,

check that the aligning bar moves back and forth smoothly at

the same time.

When connecting the transmission, similarly tighten the bolts in a

diagonal pattern in four or five steps, while checking that it is

tightened evenly.

/

Viewed from vehicle front

3

7

2

/ Tightening order exsample

/Handling the Disc

Use new gloves or gloves which have been washed and do not have any oil or grease on them.

Before working with your bare hands, remove any oil or grease that is on your hands.

Do not drop the discs. Doing so may deform them. Also, do not pile them up when storing them.

/Applying Grease

Different parts need different grease. Use the appropriate

grease, according to the description below. Also, be sure to

wipe off excessive grease.

1KR106-00010

1: NISSAN Clutch Grease (KR106-00010)

Clutch disc serration

Main drive shaft serration

2 KR116-00010

2: NISSAN Clutch Sleeve Grease (KR116-00010)

Sleeve sliding part

Withdrawal lever parts

Inside of release bearing

/ Dust cover

/ Retainer spring

2

2

/

Release sleeve

/

Release bearing

1

2

/

Holder spring

2

1

2

/

/

/

Release bearing Withdrawal lever Main drive shaft

/Application of Oil and Grease and Using Degreasing Agents

Application of oil and grease to the clutch disc, the cover and the flywheel causes slip, and may result in a

poor disengagement of the clutch and abnormal vibration. If oil and grease are on them, clean and degrease

them.

Although degreasing agents such as brake cleaner are available to remove excessive grease, if too much

agent is sprayed it may get into the serration and grease may leak out. To avoid this, do not directly spray the

degreasing agent on the part, put it on a clean cloth and wipe it on.

/Bleeding Air from Clutch Oil Line

/ Front

In vehicles equipped a the clutch damper or branch pipe in the

oil line between the clutch master cylinder and the operating

cylinder, lift only the front tires with a jack before bleeding air.

/

Jack-up only front wheel

/Possible Problems

NISMO

3

Installing a NISMO reinforced clutch results in some differences from the genuine clutch. The three points

below are typical examples.

1) The reactive force of the clutch pedal is increased.

In the reinforced clutch, most of the diaphragm springs of the clutch cover are reinforced to transmit engine power to

the drive shaft without losing power. Therefore, the reactive force of the clutch pedal is increased.

2

2) Scraping sound is heard when the clutch is engaged.

When the metal clutch disc is installed, sound may be produced when clutch is engaged. This sound is produced

when metal surfaces of the clutch disc, the cover and the flywheel rub each other. This is not a malfunction or failure.

3

2,000rpm

3) Rattling sound is heard while increasing the speed when the engine is idling or the engine speed is low.

As the sport clutch disc and lightweight flywheel are designed to improve the clutch response and the output, a resonant

sound (rattling sound) produced in the transmission and the bearing may be more likely than with NISSAN genuine parts.

Especially, a gear chattering sound may be heard when increasing the speed while the engine is idling or the engine

speed is around 2,000 rpm. This is not a malfunction or failure.

/Parts List

5

14

13

11

6

12

2

7

12

10

/Part Name

1. /Side Plate

8. /Cushioning Plate Rivet

2. /Torsion Spring

9. /Facing

3. /Disc-hub (Serration)

10. /Facing Rivet

4. /Facing Rivet

11. /Stop Pin

5. /Facing

12. /Friction Washer

6. /Driving Plate

13. /Friction Plate

7. /Cushioning Plate

14. /Friction Spring

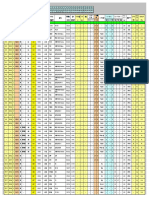

/List of Tightening Torques for Clutch Cover (including flywheel)

Dimensions Clutch Classification Parts Number

160

/Single

30210-RS260

180

215

225

/Single

/Single

/Single

/Single

240

/

Super Coppermix

250

/Single

Spec I

/Twin

8.5/ Spec II

/Twin

8.5 inch.

G-MAX

Spec III

/

Triple & Four

COMPETITION-model

Super Coppermix Twin

(including COMPETITION-model)

30210-RS100

30210-RS261

30210-RS187

30210-RS130

30210-RS360

30210-RS600

30210-RS550

30210-RS526

30210-RS540

30210-RS420

30210-RS560

30210-RS245

30210-RS240-G1

30210-RS242-G1

30210-RS255

30210-RSZ30

30210-RS582

30210-RSR40

3021A-RS050

3021B-RS060

3021B-RS061

3021A-RS055

3021B-RS065

3021B-RS066

3021A-RS070

3021B-RS080

3021B-RS081

3021A-RSC01

3021A-RSC50

3021B-RSC01

3021B-RSC11

3021A-RSC50

3021A-RSC60

/Specified Torque N-m (kgf-m/ ft-lbf)

/Clutch Cover

/Flywheel

2229(2.23.0/16.221.4

The tightening torque of the flywheel is set

according to the engine model.

Refer to the following list.

CR12DE

3444(3.54.5/25.132.5)

1215(1.21.5/8.911)

(M6 9)

3444(3.54.5/25.132.5)

M89/

M8 Hexagon Bolt (9 bolts)

22.633.3(2.33.4/16.724.6)

3/Cap Bolt (3 bolts)

8.813.7(0.91.4/6.510)

M86/

M8 Hexagon Bolt (6 bolts)

22.633.3(2.33.4/16.724.6)

M89/

M8 Hexagon Bolt (9 bolts)

22.633.3(2.33.4/16.724.6)

3/Cap Bolt (3 bolts)

8.813.7(0.91.4/6.510)

93.1102.9

(9.510.5/6976)

SR20DE

SR20DET

(RNN14/ 83.493.2

Except RNN14) 8.59.5/6269

VG30DET

VQ35DE

SR20DET

(RNN14)

127.4137.2

1314/94101

RB26DETT

RB25DET

RB20DET

142.2152.0

14.515.5/105112

/List of Thickness Limit of Clutch Disc

/

Size/Series

160

180

215

225

240

250

/Type

3C /Semimetal C

B /Semimetal B

B /Semimetal B

C /Semimetal C

/Asbestos free

C /Semimetal C

/Asbestos free

/Asbestos free

/Asbestos free

/Coppermix

A /Semimetal A

B /Semimetal B

/Coppermix

/Super Coppermix

/Asbestos free

/Asbestos free

/Asbestos free

/Solid metal

A /Semimetal A

B /Semimetal B

C /Semimetal C

C /Semimetal C

/Coppermix

/Asbestos free

/Asbestos free

B /Semimetal B

C /Semimetal B

/Twin

G-MAX

/Triple

/Super Coppermix Twin

Parts Number

30100-RS260

30100-RS200

30100-RR187

30100-RS261

30100-RN215

30100-RS360

30100-RN225

30100-RS227

30100-RN525

30100-RS225

30100-RS550

30100-RS500

30100-RS240

30100-RS240

30100-RS243

30100-RN580

30100-RN583

30100-RS245

30100-RS650

30100-RS612

30100-RS236

30100-RS581

30100-RS252

30100-RS254

30100-RN255

30100-RSR40

30100-RS582

3010C-RS040

3010C-RS045

3010D-RS070

3010D-RR080

30100-RSC01

/

Thickness Limit (t) mm(in)

2.60.3 (0.10.012)

5.00.3 (0.20.012)

5.80.3 (0.230.012)

2.60.3 (0.10.012)

6.00.3 (0.240.012)

2.60.3 (0.10.012)

6.00.3 (0.240.012)

5.80.3 (0.230.012)

6.00.3 (0.240.012)

2.60.3 (0.10.012)

6.00.3 (0.240.012)

2.60.3 (0.10.012)

2.70.1 (0.10.004)

2.90.1 (0.110.004)

7.10.3 (0.280.012)

/

Measured part for thickness limit

/

Facing

/

Driving plate

/Common Problems (damage to rivets)

140kgfm

As the rivet of the copper mix disc has been produced to resist torque of140 kgfm (all sizes) in the bench test, there

is no problem on the strength of the rivet.

/CAUTION

, ,

If assembled as described 1, 2 and 3 below, the rivet or the cushioning plate may be damaged even if they are used for a

short period.

/ Disc-hub (normally installed)

When assembling the transmission forcibly while centering of the

disc is incomplete.

When the cushioning plate of the disc is deformed by shaking

the transmission when putting in the input shaft.

/

Disc-hub (installed in 1 - 3 methods)

When installing the transmission with the center misaligned or at

an improper angle against the engine.

* If the rivet or the cushioning plate are damaged after driving a

comparatively short distance after the clutch has been installed, most

of the cases are caused by an improper installation like the above.

* It is recommended to ask a reliable service shop to do the installation.

NISMO

NISMO performed the bench test described below to reproduce the symptoms

of damage caused by an improper installation.

/Experimental method (reference)

1.

When installing the transmission, a washer is put between the engine and the

transmission and the transmission is forcibly installed diagonally.

2. (10kgfm)(6,500rpm)

The engine is started and a load with the specified torque (10 kgfm) and the

specified speed (6,500 rpm) are applied.

/Result

The rivet (rivet and cushioning plate) is damaged.

140-85632 -10 -67 0120-846-423

8

You might also like

- Aspira Suku Cadang Mobil & Motor - 2Document914 pagesAspira Suku Cadang Mobil & Motor - 2Natal TambunanNo ratings yet

- Mitsubishi Mini-Cab Truck Owner's ManualDocument214 pagesMitsubishi Mini-Cab Truck Owner's Manualronald ramiro mariaca diazNo ratings yet

- Din en 1560 e 2009 07Document18 pagesDin en 1560 e 2009 07melisse16No ratings yet

- JPN Isuzu 200708Document15 pagesJPN Isuzu 200708Jhonny Vasquez100% (1)

- Toyota Voxy Owners ManualDocument452 pagesToyota Voxy Owners ManualMark Anthony FletcherNo ratings yet

- ISUZUDocument21 pagesISUZUTeera AkkharaaphiphokheeNo ratings yet

- ZX140W-3 Isuzu 4JJ1 Engine Parts CatalogDocument156 pagesZX140W-3 Isuzu 4JJ1 Engine Parts Catalogderekpalang1003No ratings yet

- JimnyDocument21 pagesJimnyjuli fitriyantoNo ratings yet

- Aode 4R70WDocument2 pagesAode 4R70WDanyNo ratings yet

- SUZUKI-Application ChartDocument8 pagesSUZUKI-Application ChartMuhammad YaseenNo ratings yet

- Subaru XV Crosstrek 2012 2017 Workshop ManualDocument4,493 pagesSubaru XV Crosstrek 2012 2017 Workshop ManualTheVojislavbbNo ratings yet

- ZF 16S-151 - 1315 051 201 - 2009 PDFDocument51 pagesZF 16S-151 - 1315 051 201 - 2009 PDFnamduong368No ratings yet

- Gd-Ha12v Gf-Ha12s Gf-Ha22sDocument983 pagesGd-Ha12v Gf-Ha12s Gf-Ha22sはせがわまだお100% (1)

- ISUZU F Series ManualsDocument2 pagesISUZU F Series Manualshumphrey.mark01scrib100% (1)

- NKK IndexDocument224 pagesNKK IndexLuis Arturo Arevalo LeonNo ratings yet

- Nachi PVD-1B-32P-11G5 - Mini Excavator Hydraulic Pump PDFDocument3 pagesNachi PVD-1B-32P-11G5 - Mini Excavator Hydraulic Pump PDFMichael BochoridisNo ratings yet

- Manual Yammar 4TNV 30597Document215 pagesManual Yammar 4TNV 30597Tonytec Manutenção100% (1)

- ZF6HP26 ADocument0 pagesZF6HP26 ADaniel Favuzzi GaribaldiNo ratings yet

- Bobcat 453 Skid Steer Workshop Manual Bobcat 453Document288 pagesBobcat 453 Skid Steer Workshop Manual Bobcat 453lukasz_b7No ratings yet

- Yamaha Tricker (XG250) 2010 Owner Manual (Japanese) 20105XTADocument58 pagesYamaha Tricker (XG250) 2010 Owner Manual (Japanese) 20105XTAT. FANCYNo ratings yet

- Customize Parts Catalog ForesterDocument30 pagesCustomize Parts Catalog ForesterSOtgonbor100% (1)

- Honda Motorcycle DataDocument38 pagesHonda Motorcycle Datanao kurNo ratings yet

- Alloffuelpump (2015)Document105 pagesAlloffuelpump (2015)Eleazar PavonNo ratings yet

- Smashmotosierrasmash 4600Document6 pagesSmashmotosierrasmash 4600Guillermo carralNo ratings yet

- Thermo Catalog ToyotaDocument84 pagesThermo Catalog ToyotaAlberth Jacob Miranda FelicesNo ratings yet

- pds70 90s 5b1Document59 pagespds70 90s 5b1Сергей Банников100% (1)

- Thermostat Pictures 20170328Document19 pagesThermostat Pictures 20170328Yi Chen100% (1)

- Mitoyo PDFDocument13 pagesMitoyo PDFJohn AzimovNo ratings yet

- 2014 k33 SBP Manual Cbr300 HRCDocument36 pages2014 k33 SBP Manual Cbr300 HRCRed AhmadNo ratings yet

- YZF-R1 R1 Manual2018 PDFDocument82 pagesYZF-R1 R1 Manual2018 PDFMariano GimenezNo ratings yet

- VNX - Su Pajero 2001 Workshop Manual Electrical Wiring PDFDocument934 pagesVNX - Su Pajero 2001 Workshop Manual Electrical Wiring PDFmtbscinbox100% (1)

- Каталог NISSAN ATLAS F24 (1.15-2t)Document12 pagesКаталог NISSAN ATLAS F24 (1.15-2t)scr1988No ratings yet

- Docuro Product ListDocument96 pagesDocuro Product ListWayne McmeekanNo ratings yet

- Airman Engine Generator Part Catalog Sdg45s-3a8 and Sdg45s-7a8Document48 pagesAirman Engine Generator Part Catalog Sdg45s-3a8 and Sdg45s-7a8Estika SulistiyantoNo ratings yet

- 2015 M-Slaz 150Document349 pages2015 M-Slaz 150Nathawat0% (1)

- RX 8Document15 pagesRX 8MonyasNo ratings yet

- ZF6HP26, 6R60 PDFDocument2 pagesZF6HP26, 6R60 PDFDavidoff RedNo ratings yet

- Thermostat Catalog HKTDocument252 pagesThermostat Catalog HKTIsuru DeshanNo ratings yet

- Sakai GW750-2 - 3498-17281-6 (20509 - )Document132 pagesSakai GW750-2 - 3498-17281-6 (20509 - )Paola SolanoNo ratings yet

- GolfIV GW Bora Accessories PDFDocument32 pagesGolfIV GW Bora Accessories PDFNakanishi ToruNo ratings yet

- Furukawa Auto Wiring AllDocument13 pagesFurukawa Auto Wiring AlljigmasterNo ratings yet

- Kubota - Motor - D722 E2B EU Y2 SchäfferDocument58 pagesKubota - Motor - D722 E2B EU Y2 SchäfferMMM-MMM100% (1)

- Alp Kauçuk E-CatalogueDocument368 pagesAlp Kauçuk E-CatalogueKudanthai SenthilkumarNo ratings yet

- FLAMMA CROSS REFERENCE 20211011Document2 pagesFLAMMA CROSS REFERENCE 20211011Akachat ToufikNo ratings yet

- Xenia November 2017Document571 pagesXenia November 2017myvidentNo ratings yet

- Parts Catalog 2017: MD 30B2 40B2 50B2Document146 pagesParts Catalog 2017: MD 30B2 40B2 50B2Bogdan SurgheNo ratings yet

- ZF Ecomid 9S1115-TD - 1324 - 032 - 007 - Hino FM260Document69 pagesZF Ecomid 9S1115-TD - 1324 - 032 - 007 - Hino FM260atorres611No ratings yet

- RSK FrezuDocument47 pagesRSK FrezuАндрій КарасьNo ratings yet

- EE80000MGSA11 HowtoDocument2 pagesEE80000MGSA11 HowtoそすんNo ratings yet

- MS303 47003Document4 pagesMS303 47003Mirage KitNo ratings yet

- ミドルウェイトアウターローターキットDocument8 pagesミドルウェイトアウターローターキットpapa.x0727No ratings yet

- 6196 Ext 01 0Document43 pages6196 Ext 01 0Jayden BarnesNo ratings yet

- Core 143Document6 pagesCore 143Mirage KitNo ratings yet

- 2021.6.2 ARV-015MX 日本語取扱説明書Document24 pages2021.6.2 ARV-015MX 日本語取扱説明書Francisco SanchezNo ratings yet

- HM 4002jeDocument4 pagesHM 4002jeTrần Thành ĐạtNo ratings yet

- Am002Document10 pagesAm002pan10f1No ratings yet

- NC750X 30MKL810 0Document136 pagesNC750X 30MKL810 0aliceNo ratings yet

- OM1009074JE03 YA-1AH011Tseries YA-1AH011T0Y 10 PDFDocument20 pagesOM1009074JE03 YA-1AH011Tseries YA-1AH011T0Y 10 PDFVander StrapazzonNo ratings yet

- Erks Shimpo NidecDocument12 pagesErks Shimpo NidecManuel RangelNo ratings yet

- Core 155Document6 pagesCore 155Mirage KitNo ratings yet