Professional Documents

Culture Documents

Pioneer Pd-z74t z570t

Uploaded by

arielizzo0 ratings0% found this document useful (0 votes)

1K views67 pagesdoble compactera cd player

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentdoble compactera cd player

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

1K views67 pagesPioneer Pd-z74t z570t

Uploaded by

arielizzodoble compactera cd player

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 67

YQ PIONEER’

The Art of Entertainment

ORDER NO.

ARP2131

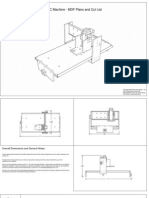

TWIN-TRAY COMPACT DISC PLAYER

D=-2Z74T

PD-Z570T

MODEL PD-Z74T AND PD-Z570T HAVE FOLLOWING VERSIONS:

|__ Applicable mode!

Type Power requirement Export destination

PD-z74T | PD-Z570T

‘AG220V, 240 (ewitchablo)® European continent

‘AC220V, 240 (switchable)* | Ewropesn continent

| Ac22ov, 240V (ewichabiey* | Unites kingdom

AC220V, 240V (switchable)* United kingdom |

ACI IOV, 120V-127V, 220V, 240 (switchable) | Kingdom of Saudi Arabia and general market

‘AC220V, 240V (ewitchable)* Australia

* Change the position of the jumper ofthe mother board assembly

@This manual is applicable to the PD-Z74T/HEM, HEMXJ, HB, HBXJ, SD, HPW,

PD-Z570T/HEM and SD types.

@ As to the PD-Z74T/HEMXJ, HB, HBXJ, SD, HPW and PD-Z570T/SD types, refer to

pages 73-79.

@PD-Z74T/HEMXJ and HBXJ types, manufactured in singapore, are identical with

PD-Z74T/HEM and HB types respectively.

For identification, “MADE IN SINGAPORE” is shown on the rear panel of the product.

@ As to the mechanism description, refer to PD-Z74T SERVICE GUIDE ARP2144.

@ Ce manuel pour le service comprend les explications de réglage en frangais.

@ Este manual de servicio trata del método ajuste escrito en espafiol.

PIONEER ELECTRONIC CORPORATION | 4-1, sieguio 1-Chome, Meguro-ku, Tokyo 183, Japan

PIONEER ELECTRONICS SERVICE INC. P.O. Box 1760, Long Be: fornia 90601 US A,

PIONEER ELECTRONICS OF CANADA, INC. 505 Cochrane Orive, Markham, Ontario L3R 8E3 Canada

PIONEER ELECTRONIC [EUROPE] NV. Keetbe 40 Beveren, B

PIONEER ELECTRONICS AUSTRALIA PTY. LTD. 178-184 Boundary Roao.

© PIONEER ELECTRONIC CORPORATION 1991

1oria 3185, Australia TEL: [03]

50 JAN. 1991 Printed in Japen

D-Z74T, PD-Z570T

CONTENTS)

‘SAFETY INFORMATION « 7. P.C.B's PARTS LIST

2. REMOVING AND MOUNTING OF EACH & ADJUSTMENTS:

BLOCK 3 8 REGLAGE

3. EXPLODED VIEWS, PACKING AND @ AJUSTE «

PARTS LIST- 5 @.IGINFORMATION (T9257)

4, LINE VOLTAGE SELECTION FOR HEM, 10. FOR PD-Z74T/HEMXJ, HB, HBXJ, SD, HPW

HEMXJ, HB, HPW AND HBX, TYPES, 12 ‘AND PD-Z570T/SD TYPES: 73

5. SCHEMATIC DIAGRAM: 16 11. PANEL FACILITIES: oe 77

6. P.C. BOARDS CONNECTION DIAGRAM «------21 12, SPECIFICATIONS « se 79

1. SAFETY INFORMATION

(FOR EUROPEAN MODEL ONLY)

|

— Additional Laser Caution

Ievaocke Mechanism

‘The ON/OFF (ON: low fvel/OFF: igh loved tutus

of the U (S501) and L (S603) switches for detecting

the dee lame ‘sate is detected by the syetom

‘erorcaao, sid the no Seve ae ose |

‘oan fn both switches U and are OFF Cogh

seve.

Thus, the itaock wil oo longer faneion if swine |

U"GS60%) and ($608) ae elbertly shorted.

Laser dete escavon wil continue pins 2 and 3

of CXATATIS QCI01) are connected to ground oF pin

20 is connected to hgh love! (OND oF the termeals

{of O1OT bre shorted to ach other (laut condtin).

LABEL CHECK (TWIN type)

2. Whan the cover is opened, close viewing of the |

cblectve ln with the rated eve wl cause exooaure |

te a Cass Tor higher laser eam,

HEM, HEMXJ, HB and

HEM and HEMX< types.

HBX types

— eA ULON

INVISIBLE LASER

RADIATION WHEN OPEN,

LASER PRODUCT AVOID. EXPOSURE

T0_BEAM Pawio18

HEM, HEMX¢, HB and HEM and HEMXs types, HB and HBXJ typos

HBX types

PD-Z74T, PD-Z57

2. REMOVING AND MOUNTING OF EACH BLOCK

REMOVAL OF TRAY | AND TRAY II @ MOUNTING OF TRAY!

Open the tray 1 1

Insert the flat blade screwdriver into the slit in the left of,

tray I, Pull out the tray I by pushing the screwdriver.

|. Set the disc II to the clamp position and open the tray I

2. Align the Ist tooth of tray T to ungrooved portion of geat I

and insert the tay |

¥,

1st tooth

Siit position of tray |

Fig. 2

* When remove the tray Il open it fist, insert the flat blade

Serevsiriver into the sit nthe right of ray i, and pulloutihe ——@ MOUNTING OF TRAY Il

Ce eae oe 1. Set the dise Ito the clamp position and open the tray TL

2. Align the Ist tooth of tray Il to [] marked position of gear

1, and insert the tray IL

‘Align horizontally © C mart.

Isttooth

Fig. 3

Fig. 1

PD-Z74T, PD-Z570T

(@ MOUNTING AND POSITIONING OF

MAIN CAM, FOLLOW GEAR, GEAR |

AND GEAR II

Set the following gears to the position as shown by arrows.

Protrusion

Follow gear \

Follow gear

Fig. 4

@ MOUNTING OF CLAMPER ASSEMBLY

Mount the clamper assembly by aligning the protrusion portion

as shown in the figure,

__— Protrusion

Fig. 5

et at t 2 ! 3 ' 4 t 5 q 6 EE

3. EXPLODED VIEWS, PACKING AND PARTS LIST

3.1 EXTERIOR

PD-Z74T, PD-Z570T

‘TWIN-TRAY MECHANISM

(Gee page 8) NOTES:

* Parts without part number cannot be supplied

* The dy mark found on some component parts indicates the impotance of the safety factor of the part. Therefore, when replacing, be sure

REAR BASE SECTION

i A SOuse parts of identical designation.

ae + Parts marked by *@" are not always kept in stock. Their delivery time may be longer than usual or they may be unavailable

Parts List

Mark No. Symbol & Description __Part No. Mark No. Symbol & Description __Part No.

1 SCREW BEZ30POGORMC 2% ANGLE

2 SCREW BBZS0P080FCC 27 FUNCTION PANEL ——-PNW1865

— - a 28 ‘TRAY NAME PLATE 1 PNW1666

4 SCREW BBZS0POGOF2K (For PD — 2147)

5 SCREW BBZ30P100FMC TRAY NAME PLATE 1 PNWIS74

(or PD ~2570T)

6 SCREW BBZ30P120FMC 29 TRAY NAME PLATE 2 PNW1867

A 7 STRAIN RELIEF cM 228 (For PD ~ 25707)

PD-2570T ONLY 8 SCREW 1BZ30P150F MC TRAY NAME PLATE 2 PNWI875

‘ 9 DISC BUTTON PACIS22, 30. PCB SPACER

(For PD ~ 2741)

8 DISC BUTTON PACISIS 31 INSTRUCTION MANUAL PRE1136

(For PD ~2570T) (For PD~Z74T)

10 POWER BUTTON PACIS23 INSTRUCTION MANUAL PREIS

(or PD ~274T) or PD -2570T)

POWER BUTTON PACIB6 4 82. POWER TRANSFOMER PTT1I25

(For PD ~2570T) © 83 MOTHER BOARD ASS'Y PwMI350

(For PD-Z74T)

11 PLAY BUTTON PACIS24 ® MOTHER BOARD ASS'Y PWM1345

or. PD — 2747) For PD 25707)

PLAY BUTTON PACI528 © 84 SUB BOARD ASSY = Pwx1142

- (For PD ~ 25701) @or PD Z747)

12 WINDOW PAMI450 © SUB BOARD ASS'Y — PWX1141

(or PD ~ 2747) @or PD ~ 25707)

WINDOW 35 FOOT ASS'Y PXAL201

(For PD 25707) PAMI4S1 (or PD-Z74T)

13, SOP F+F+C/0V PDDIO“®

14 CORD WITH MINI PLUG PDE ~319 36 INSULATOR ASSY —-PXAIB43

(or PD ~ 7747) (For PD- 2747)

18 CORD WITH PIN PLUG PDE1065 37 PIONEER BADGE

e or PD ~z741) 38 SHEET 723 - 022

39 FUNCTION PANEL PEAL29

16 CORD WITH PDEI067 ASSY (For PD- 25707)

CONNECTOR 40 severe

(For PD ~ 7741)

CORD WITH PDEILM 41 OPTICAL FIBER CABLE AKX1031

CONNECTOR or PD-2570T)

(For PD ~ 25707) 42. FL PLATE PAMMs2

17 AC POWER CORD PDG1008 (For PD- 25707)

18 SCREW PDZ30FO50FMC 43. STOPPER PNM1070

il a (For PD- 25707)

20 PROTECTOR F PHALII 44 INSULATOR PNWIS73

(For PD - 7747) or PD~2570T)

PROTECTOR F PHALIAS 45. INSULATOR PNW1574

(For PD ~2570T) (For PD 25707)

21 PROTECTOR R PHALM2 48 PANEL NAME PLATE PNW1876

For PD~z1a1) (For PD-2570T)

i PROTECTOR R PHAIAG 47 SUB PANEL PNWIB77

(For PD ~ 25707) (For PD Z570T)

co FOR PD-2570T 0 22 PACKING CASE PHGIS7B 48 TRACK BUTTON PACIS27

(For PD~Z747) (For PD- 25707)

PACKING CASE PHGIS7 49 SCREW 1B230P20FMC

(or PD ~ 75707)

23 BONNET CASE PyY1s

24 UNDER BASE

25 REAR BASE

43, NOTE : Use it seperately = P

4 1 2 1 3 1 a 1 5s 1 ae —

PD-Z74T, PD-Z570T

3.3. MECHANISM SECTION

7 vale

@ Servo Mechanism Assembly Section

© How to install the disc table

(1) Use nippers or other tool to cut the two sections

marked @ in figure [1]. Then remove the spacer.

[2] While supporting the spindle motor shaft with

the stopper, put spacer on top of the motor base

(angled so it doesn’t touch section ®), and stick

the disc table on top (takes about 9kg pressure).

Take off the spacer.

1 2

Spacer

chaps

ys. Aoressure of

"bout Ba)

Bn ise tae

. ae

‘Spacer seting

postion

Spindle“

PD-Z570T

Parts List of Mechanism Section

Mark No. Symbol & Description Part No. Mark No. Symbol & Description Part No.

1 Clamp spring PaH1103, 101 Yoke

2 Lever spring PBHI104 102 Magnet

3 Belt PEBI106 103 Clamper holder

4 Motor pulley PNW1634 104 Clamper S

5 Tray 1 PNW1839 105 Mechanism P.C.B assembly

6 Tray 2 PNW1840 108 Servo mechanism assembly

7 Sub tray PNWiIB41 107 Connector assembly (6P)

& Loading base PNw1B42 108 Mechanism chassis

9 Main cam PNW1843 109 Motor base

10 Follow gear PNW1644 110 Mechanism base

1 Gear 1 PNW1845, 111 Actuater cover

12 Gear 2 PNW1846 112 Sub plate

13° Idler gear PNWI847

14° Clamper arm U PNWI850

18 Clamper arm B PNWI851

16 Clamp cam PNW1852

17 Float base PNW1853

38 Lock lever PNW1854

19 Motor (LOADING) PXMI010

20 Floating rubber PEBIONM

21 Floating rubber PEBLIG2

22 Screw PBA1048

23 Screw IPZ30P080F MC

24 Screw TPZ20PO80FMC

25 Chip capacitor CKSYF 105216

26 Screw JFZ20P025F MC

27 Drive spring PBHI084

28 Plate spring PBK1057

29° Bett PEBIO72

20 Drive screw PLAIOG3

31 Guide bar PLAIOTL

82 Half nut PNW1605,

33 Disc table PNW1608

34 Pulley PNW1634

35 Earth spring PBE1009,

36 Push switch DsG1014

37 Spindle motor assembly PEA1028

Gwith oft)

38 Pick ~up assembly PEAIO3)

39° Screw ‘BPZ20PO80F2K

40 Screw PMZ20P030FMC

41 Motor (CARRIAGE) PXMIOI3.

42 Screw PBZ30P080FMC

43 Semi-fixed resistor PCP1008

44 Screw PMZ28P040FMC

45 Gear pulley PNWIB48,

48 Push spring PBHLI05

47 Screw IPZ30P200F MC

48 Pulley PNW1066

49 Screw 1B230P120FMC

4

PD-Z74T, PD-Z570T

4. LINE VOLTAGE SELECTION FOR HEM, HEMXu, HB,

HPW AND HBXJ TYPES

1. Disconnect the AC power con

2. Remove the bonnet

3. Change the position of the jumper ® as follows.

Voltage Jumper ® position

220v oO

240V @®

4. Stick the Line voltage label on the rear panel

Description | PartNo.

220V label | AAX-193

240V label | AAX-192

|

1!

7

Sasi

NZEZz6OL

5. SCHEMATIC DIAGRAM

5.1 WAVEFORMS

Note: The encircled numbers denote measuring points in the

schematic diagram,

"1 SOT-JUMP: After switching to the pause mode, press the

‘manual search key

+ 2FOCUS-IN: Press the key without loading a dis

a

oo0szaxo

TPI-Pin 1: PLAY MODE

) (RF)

500mVidiv_ S00nsecidiv

@

oon @ ‘soni

GViaiv_ somseciaiv

1Vidiv _200msecidiv

@ Be

- ono

|@

1C20-Pin 9: POWER SWITCH-ON

(RST)

2Vidiv_100msec/div

-Gno

~ TPI-Pin 1: TRACK SEARCH MODE

(Re)

BOOmVidiv 200xsecidiv

OA Ee

-aNnD

| >) 2201 Emitter: PLAY MODE 1C201-Pin 3: PLAY MODE

© Wen © xt

ee _tmseisy ‘hat 2sicv

= GND -cn|

ca eeiaies |

1C301-Pin 32: PLAY MODE (kHz)

(Cex:

2Vidiv 10xsec/div

1C20-Pin 9: POWER SWITCH-OFF

(RST)

2Vidiv_100msecidiv

GND

“TP!-Pin 6: PLAY MODE

3) (FOER)

100mVidiv_10mseciaiv

©

FR) 208 Emittr: PLAY MODE 1C201-Pin 3 TRACK SEARCH MODE!

© «ron (8) icaon

S00mVidiv_Tesecidiv 1 Nirdiv_ 200meecidiv

al

(ATA)

®

TRACK SEARCH MODE

Upper: 1P1-Pin IRF) “TWiaiv

USiver: C1 51-Pin 35 (MRR)

2Vidiv 200usec/aN

|

|

~GND GND - GND —GND

@® Trent @ Soni Wid Toaweca ® ee ® feo

A ANSE

BY MLL — cs

/

14

SZZELVXD

PD-Z74T, PD-Z570T

ee Pea at itd 2 ! 3 ! 4 ! 5 | 6 | 7 | 8 | °

5.2 SCHEMATIC DIAGRAM

Tie pemeaica sas "

- * R05. = & = “ + Tr PCB ” = Foucu ervo loop

| weary —-l Vege eel Tei, Eesueeene

i 1 peat0s0 - ool Te Tse ee PUA 346 weo-zsver-ao) | erst Sallis aa 1 Tracking servo loop

| SE Fe F Yo8 eee Meee rt ee peti ieee + Carriage servo loop

| 8] cov PWM1350 (o-z74T/ Hem He,new) | Loading motor route

elit ts i Spilaiecarterat cote

: eae > Measurement point

j adel e clots Cee ee

| eon i Lome ae “we

: : act csi | 4 a : 2 ee

1 anor foul 5 _ ar i veal dio 7” acl aaa Es aaa] '

: cmadl | dese F ait CXD2500Q a sini th Tiemgaan | | comm | |

| it Tove EE] |e: (ozcoveR) PPL Gy TB nae cagt i

: exon, EtEl Bl Lees ae aspire ae 1

ti bax i oa = F " Poke mt ceae i

8 i Y , nina xaaeed 8Sog2 Bx ot desouen, |

| pie sy sandy ate oa a |

| ae ie ca : ale : |

0 211 = on AS |

: : Qype as a 3) a |v rE he i

| | 4 Resale, | |

' i Sez01 a7) nee ie os

: | i ALAGs20 4

I certnoce onive,

1 C361

| BREET) Connect with ane

! : 1

: a ~ welll

iE ERR egg — Be

lid pa esa Soo :

a Fy leer. op pane

on 159 ee BO Bip Ree

irorct YU) col eon

echoes | Si og .

e G S res Ce eE I [vce | 28 10351

0 he wi 7 ass ne 2 ol 58s | P28

LOADING MTR aoe re- Psy]

ae: ccc ove T Te] barra fe

Liat] | sot 3s} | [os ae a Si d| &

steal aes | 2. | i =e. S Ee a

recon PORT LOGIC 3 = age O° are

TIhals 12 con ta wns

rele [els Neal he = S| Eee oe

See |S carina one YT hand Crete sto ue PD4309A

at : bi For po-z7aT/emxy “sag

Ae La eo ae paneactersloceissricas A iS PES

late a. 4 ae ate Singentiee! (aysrem covraa.)

ale wjeye ' ie __oaw > g aa

atte ‘ic201 , 4

Heel | eee pce

ele lt lala |»

sleti 1

Tite ia[«

1Lete |

An :

mle Ul | s |

tlelete le | jee, §

. eee SabSS SOO SO00O006

ea ee — — - = G9S599599 SOSOOOOOOOOOO

} 1

FL INDICATOR TUBE

_ 721] _s725]!_ s701| 5705] s709 v70) | Fa

we s

1 PHP Pon ' | ee | '

| Pete atari! all]! |

7 { T5375 at?) on™" |or8Z"4 ;

F | ede lated A SUB PCB ASS'Y r oP) | FOTIA AGL TPT 3B | Mae ea|

PWK1141 (ro-2570F sentes) ' feperetoepeey wa a

' Pantie toner sens) | ' : ME PD-Z74T SERIES: PD-Z74T/HEM, HB, HEMXJ,SD,HPW TYPES.

\execsimneeee L

ise PD-Z570T SERIES: PD-Z570T/HEM, SD TYPES.

1. RESISTORS:

Indicated in f, W, Ye. #5 tolerance unless otherwise noted KS

MeMa, (F) = 21%, (G) :=2%, IK) +10% (M); £205 tolerance

2. CAPACITORS:

Indicated in capacity (uF/voltage (V) unless otherwise noted p : oF

Indieation without voltage is SOV except slectrolytic capacitor

3. VOLTAGE, CURRENT:

0c woltage (VI at no input signal

4 OTHERS:

= Signal route,

© -Agjuring point

The mark found on some component parts incicates the im

portance of the safety factor of the part Theretore, wien replacing

be sure to use gers of identical designation.

“marked capacitors and resstors have parts numbers.

‘This isthe batic shematie dlagram, but the acwal ecu may vary

‘due to improvements in design.

8.S¥ITCK

MECHA PCD Asseably

‘601

s60z s

séoa

‘UB PCD Assewbly

sn7 +10 s701 0/0 01

s7is ovo S72 0/¢ 02

sn9 220 S702 1

si 5 S704 02

sm 9 5105 Deb (BI)

sm 8 S706 cORPU

sm 4 $707 pen

smu 3 sos 2%pin

2pin. <—> 28pin

38pin <—> 64pin

39pin =<—> pin

63pin <—> 25pin

64pin <—= 26pin

PD-Z74T, PD-Z570T

List of semiconductor terminal voltage

Note: Ail terminal voltages are measured in the PLAY.

mode.

‘The PD-Z2570T uses optical output, thus there is no.

Ie401 (TC8237N}, 1C404(op Amp), 0403-405,

ters

CxAt3728

Pin No] volts [Pin No] Vales

1

9

10

até

12

13

14

15

16

[a7 |

18

19

20 [0

21

22

23

24

e101

cXAMTIS.

Pin No] vans [Pin No] volts

1 [Nc [a6

2.9 [47

Eat [18

a9

20

24

22

19

PD-Z74T, PD-Z570T

1c20

Msz08P

[Pin No] vor Vorts

1 fs. 2

2[Nc

a fs

4[o

5 8.2

6 c

7 [asc

8 ¢

an

12

aE)

14

15

16

e|~|efeolalolfz|efz|z/ 2a

cao e101

NJMe5#80-D resz3N

Pin No] Volts Pin No] Volts

1 Fo. 2 ifs

i 2[0

1 a]s

Es Ee be

1 S205

3 6 [2.5

Fo 7/0

5 8 [0

9 | 2.5

io [2.5

ai [s

1z [0

13 [Ne

14 [0

1s [0

16 | 1.0

i [ane

1s | 5

19 | 2

20] 0

2ifo

22] 0

23 | 0

24|5

25 | 2,5

26] 2.5

27]2.5

ze

20

east

POss6A

Pin No] volte [Pim No] Vole [Pin No] voke [Pin No] vole

ast So eae 49-22

213. 3 18 | 0 34 | 5 so | 0

afs.s[19|5 a5 | 0 si [5

4-10. S| 20[ 0.5] 36] 0 520

[2 [asa as 8, 37 [0 53 [0

“6 | 4.8 | 22/0 3a [o 54 26

7 [4s [23/0 55 [26

a[sa.s|24fo 56-26

o|23)]25]5 57 [5

10] o 26] 5 sao

ceva 27|s 5.0 | a

12) |, 2. au feeoe| 0. eo] 5

13 [5 29|5 ei 2. 6

14 |5 30 | 2.5 62 [2

1s | 5 a1 [2.5 63-2. 5

as [o 32 [oe eas

car

cxozs000

Pin No[ volts [Pin No] volts [Pin No.

ifs si [wc | en

2[nic|s2|2.5 | 62

3a[s 33 [5 63

4|2.6|34|2.5| 64

s [wc] 3s] 2.5] 65

6 | 5 a6 |N.c| 66

T[ aw cpar[ Nc] 67

a|[x.c|38|n.c| 6a

e|o 39 [N.c | 69

io [0 40 [N.c | 70

a [ee}a1[ Ne] 7a

12 [0 az [5 72

13[Nc]as[N.c|ts

a4 [uic|aa[nic| te

as[Nclas [Nc [75

1s [Nc] 46 | 4.4| 76

a7|0 a7 [0 77

1s [25 |e l|o 78

19 | 2.4] 49 loos | 79

zo [24|[so0|[nc| eo

21 [0 si [Nc

22 [2.5] 52] 0

235 33) 2.5

ad Eases, [40 | Nc,

2s [n.c|s5 | 0

26] 0 se N.C

27]25[s7|Nc

280 58 [Nc

29 [w.c|s9 | 0

azofo |eo|nec

al u ' 2 ' 3 ' 4 ! 5 ! 6 ! 7 I 8

6. P.C. BOARDS CONNECTION DIAGRAM

MOTHER PCB ASSEMBLY

(PWM1345 :PD-Z570T/ HEM)

(PWM1347 ‘PD-Z570T/SD) proton nt tesee ee 7

(PWM1348:PD-Z74T/SD)

eee é f i

r :PO- !

i Powec/siptlyi section torleaaeed f OU aS | (PWM 1350: PD-274T/HEM,HB,HPW) | ; A

AS |e Pee | ie A\ 4c power coro mmm PRIMARY

Slam = os .

| ——Seet NM | wns cet oes : 3 osee

ce = t (HEM, P0G1008)

FS [ara cS eee | thew; Poster) oss

ES on 0 wom | | rf

= joe) | eee) | oro:

cal Eo) Bach capacec | ! A Ac} 4

a. *

a | a ee ee

= eS al Ee

+ | e- = eo es ie | 8

8 as : ees) |

CG |e D ic101 404

fal ae

S Y ae ! s7OT TYPE ONLY 0 Y ee

Le Bes || ot4yes| eee 1 {

ae | = ! 747 TYPE ONLY ( 190 088 Iea04

Ea 5 eo lesen ee 1 vei02| 1c20 0405 =

[ie = eS I E west) cae

: i vvmios)zzos ozo

—- - +--+ eee ees vRise| e201 ic4or

See ease

5 c

SUB PCB ASSEMBLY WN ge : vert e301

(PWX 1141 | PD-Z570T SERIES)

(PWX1142 | PD-Z74T SERIES) :

ws MH 8 j) N]

— ‘ hae i

8 a c : : i 3

lbonial 1c351

“a

| ossi

o

d (ey

oma (ete,

=a :

5) a =

23

TOYES-G4 .TAYS-49 e | ; ! ° ! 2 | . ' e ! s ' ' [=

MAADAIC UOITOSUNOD 2@GAAOS 0.9 8

This P.C.B. connection diagram is viewed from the foil side.

YIGM32eA 8 oa ASHTOM

prongeseonsenoe

A i i | i

YRANTAS , anos nawos oa AY 2 | can eae Pe :

. vores SHES |] 1. roronuse soaraoy 1

on aia £ : sHODNOe g ‘ i soorees \

eeee 3 ' '

C0 Bl: ! |

a reco lo ray Hy 1 1 i

oe : i c ey Y4aMa22A 899 A3HTOM 1

1

|

i as

i : eet rstosnott y

} i ' Vorsvoss

i! ' waxes |

a Baie 3 1 J

sore roro} 4 !

zoo v Yano 38YT Toves-a9 : |

seal i ma 1

‘BORO! YINO 39YT TAY: 1 It

\

_ 20no 0801 orm f ! \ E

remy \ |

soto ' !

toso cose] eornv|

ro891 rose [serv

'

9 is

toes} terol P Yijamaeea 899 gue

(egiage TOveS-a9: 1 Arr xWa)

| °

Pre, YIaM32@2A 899 AHO3M

S

7 Zs : e

~——

roso1 : :

reeo! ait : He r re i |

tee0 . ae

a

4

ea

— e 1 8 1 = 1 a 1 2 1 » I e I

PD-Z74T, PD-Z570T

7. P.C.B’s PARTS LIST

NOTES:

+ Parts without part number cannot be supplied

+ Parts marked by “@" are not always kept in stock. Their delivery time may be longer than usual or they may be unavailable.

+ The (A, mark found on some component parts indicates the importance ofthe safety factor of the part. Therefore, when replacing, be sure

to use pars of identical designation

# When ordering resistor, first convert resistance values into code form as shown inthe following examples

x1 When there are 2 effective digits (any digit apart from 0), such as 560 ohm and 47k ohm (tolerance is shown by J=5%, and K=10%)

5609. — $6 x 10° S61 * RDI/APS;

47k Q + 47 x 10° 473 «++ RDIPS (4

SQ —+0RS RN2H [OJRIIS]K

1Q 010 +++ * + RSIP[O)LIJIO]K

Et ii seers civ gis (oct sna pre ce ln sao)

$.62k Q—-562 x 10° 5621 ++ . = RNU/ASR| iF

Mark No. Symbol & Description Part No. Mark No. Symbol & Description Part No.

@ MOTHER BOARD ASSEMBLY (C60 ELECTR, CAPACITOR CEASOLONSO

(PWM1350)(For PD-Z74T/HEM) C101 ELECTR. CAPACITOR CEASATIMERS.

(€102 ELECTR, CAPACITOR ceasiowm0

SEMICONDUCTORS (C103 CERAMIC CAPACITOR coccHig0ys0

Ay 1C20 REGULATOR 1C ws208P

ds 1C30 IC PROTECTOR IcP-N10 (C104 ELECTR, CAPACITOR ceasioumo

TCLOL PRE ANP IC cars C110 CERAMIC CAPACITOR cRCYFIO3z50

151 SERVO IC cxALST25, (C153 ELECTR. CAPACITOR cBASIOWMIO

Ay IC2OL POWER OP-AMP, IC 1a8520 (C155 MYLOR FILM CAPACITOR ‘OQwAa82J50

(C156 MYLOR FILM CAPACITOR CMASSSKSO

C301 EFM DEMODULATION IC cxp25000

1C351. MICROCOMPUTER PD43058 (C157 MYLOR FILM CAPACITOR ‘CMA 03x50

1C40L TC9237K (C158, 159 MYLOR FILM CAPACITOR —CQMAI04K50

ICAO OPAMP. TC JNASS8D-D (C160 ELECTR, CAPACITOR CEASARTISO

(962 TRANSISTOR 23017405 C161 MYLOR FILM CAPACITOR COMALO4KSO

(€162 ELECTR. CAPACITOR CEASO1ON50

Q1O1 TRANSISTOR 2SAR5 4S

Q201 TRANSISTOR 2308581 (€163 MYLOR FILM CAPACITOR oMa04s0

(Q202 TRANSISTOR 2841399 (C164 MYLOR FILM CAPACITOR ‘waosKso

(Q203 TRANSISTOR 2803581 (C167 CERAMIC CAPACITOR cxcYF103250

(Q204 TRANSISTOR 2541399 (C168 MYLOR FILM CAPACITOR cMAssSKSO

(€169 MYLOR FILM CAPACITOR ‘owa03K50

Q381, 382 TRANSISTOR 2sc1740S

(0403, 404 TRANSISTOR 2S21445 C170 MYLOR FILM CAPACITOR OMA3s2I50

(Q405. TRANSISTOR DICI24ES CATA MYLOR FILM CAPACITOR comaaT2J50

A D1L-14 DIODE NES2 (C172 MYLOR FILM CAPACITOR coma 2s0

AN (DS2 DIODE NES? (€202 CERAMIC CAPACITOR cCYF1O3250

(C212 MYLOR FILM CAPACITOR cmAn0sKs0

54 ZENNER DIODE warzi168

D211. ZENNER DIODE W126, 28 (C216, 217 ELECTR. CAPACITOR CEASSSONLG

1381-385 DIODE 1SS254 (C301 MYLOR FILM CAPACITOR CqMAo4Kso

(€306 CERAMIC CAPACITOR cKCYBISZK50

COILS/TRANSFORMERS C307 MYLOR FILM CAPACITOR comA473/50

1381 AXTAL INDUCTOR Lavoiok (C308 MYLOR FILM CAPACITOR cMAn03KsO

LAOL AXIAL COIL LauR22x

11402, 403 AXTAL INDUCTOR Lavoiok (C309 ELECTR CAPACITOR CeaSRATISO

(C351 ELECTR. CAPACITOR CEASATIMERS.

CAPACITORS: (C353 CERAMIC CAPACITOR ‘cxcYFi03z50

C1I-14 CERAMIC CAPACITOR ‘cxcyF103z50 (C855 CERAMIC CAPACITOR ‘CKCYE103250

(C25 BLACTR, CAPACITOR ‘CEASSB2N16 (C361 CERAMIC CAPACITOR ckCHF103z50

(C26 ELECTR, CAPACITOR ‘CEAS222016

(C27 ELECTR. CAPACITOR CCEASATIMGRS (C383, 384 CERAMIC CAPACITOR cKCYP103250

(C28 ELECTR. CAPACITOR ceAsiOIM10 (CAOL CERAMIC CAPACITOR ‘cKCYE103250

(C403, 404 CERAMIC CAPACITOR ‘COCCHATONSO

(C52 ELECTR, CAPACITOR CEASLOINSS (C410, 411 CERAMIC CAPACITOR CCCSLS60550

27

PD-Z74T, PD-Z570T

Mark No. Symbol & Description __Part No. Mark No. Symbol & Description __Part No.

CAL2-415 CERAMIC CAPACITOR ——_cocc390N50 @ MOTHER BOARD ASSEMBKLY

(PWM1348)(For PD-2570T/HEM)

420 ELECTR CAPACITOR ceasaconns

C421 CERAMIC CAPACITOR cxcyei7s250 ‘SEMICONDUCTORS

C22 CERAMIC CAPACITOR cxcvr103730 AL Tc20 REGULATOR IC 208

6428, 430 ELECTR. CAPACITOR ceaszeaues 1630 1¢ proTECTOR 1cP-¥10

(C431 482 MYLOR FILM CAPACITOR COHALOARSO C101 PRE AMP 1c alanis

TCS] SERVO IC x32

3, 434 WYLOR FTLM CAPACITOR cRMALOKSD ds 1C201 POWER OP-aw, 1¢ Lass20

(C438 CHRUUIC CAPACITOR cxevr10szs0

(C44, 442 WYLOR FTLM CAPACITOR CRMALS2IS0 C301 BEM DEMCDULATION IC cxo2s00a

1381 MICROCOMPUTER Poes038

RESISTORS 52 TeaRSISTOR 25017408

51-53 CARBONFILM RESISTOR ——_ROI/@PMCIOXD 101 TRANSISTOR 2548545

RL, 62 CARBONPILM RESISTOR RDI/BPMIOIY 201 TRANSISTOR 2503581

101-110 CARBONPILM RESISTOR RDI/GPMIOO!

158-158 CARBONPLLM RESISTOR RDI/@MCIOO 202 TRANSISTOR 2541399

160 CARGONFTLA RESISTOR ro1/6MO0) 203 TRANSISTOR 2303581

204 TRANSISTOR 2541388,

201-208 CARBONFILM RESISTOR 881, 382 TRANSISTOR 25017408

20S, 208 CARBONPILM RESISTOR DII-14 DIODE un6s2

208-212 CARBONEILM RESISTOR

221-224 CARBONFILM RESISTOR A ps2 Dione Ese

RSOI-S12 CARBONFILM RESISTOR 54 ZENER DIODE wr2s188

bait zexmER D100e N26. 28

352,359 CARBONPILM RESISTOR OI/@PACION. 381-385 DIODE 158254

356-360 CARDONFILM RESISTOR RDI/6PMIOO.

356-369 CARBONPILM RESISTOR RD1/6PMIOCU COILS/TRANSFORMERS

381-396 CARBONPILM RESISTOR RD1/6PMCOU. 1381 AXIAL INDUCTOR Lavook

401-413 CARDONFILM RESISTOR RDI/SPMOOU

CAPACITORS

RA43, 444 CARDONPTLM RESISTOR ROI/@PMCIOO C1I-14 CERAMIC CAPACITOR cxcvereszso

AGT, (48 CARBONPILM RESISTOR ROI/6PMOIOCU (25 ELECTR CAPACITOR ceASS32N16

495-488 CARBONFILM RESISTOR RD1/SPMCIOO! 25 ELECTR CAPACITOR cessozaN6

Yai02 ¥R RCPIOG CET ELECTR. CAPACITOR easaTINGR

vRi03 VR RcPio4d C28 ELECTR. CAPACITOR ceastouno

VRIS1, 152 ¥R RCPIONS 82 ELECTR, CAPACITOR ceastounss

(80. ELECTR. CAPACITOR CEASOIONSO

OTHERS CiOL ELECTR. CAPACITOR (CEASATINGR

‘cu101 cowectoe 2045-1610 hoz ELECTR, CAPACITOR cessioMMlo

(CAB51. CONNECTOR LEWBOS-1 (108 CERAMIC CAPACITOR coceut80150

(2381 CONNECTOR AP) a)

JA381 JACK/12V owl004 hos ELECTR, CAPACITOR ceasioumio

SAMO} JAK 81008 CL10 CERAMIC CAPACITOR ‘cir i03zs0

(153 ELECTR, CAPACITOR ceASIOINIO

351. CERAMIC RESONATOR Wssi014 385 LOR FILM CAPACITOR cous2350

401 XTAL RES (05C) 551006 256 WVLOR FILM CAPACITOR 09333450

x57 sLoR FILM CAPACITOR ccquan0aes0

158,159 WYLOR PLLA CAPACITOR —_GEMALOAKSO

180 ELECTR, CAPACITOR CEASRTHSO

CBI MYLOR FILM CAPACITOR couat0sks0

h82 ELECTR. CAPACITOR ‘CEASOL0N50

188 LOR FILM CAPACITOR ‘counsoses0

384 LOR FILM CAPACITOR ‘cua0se50

(187 CERAMIC CAPACITOR ‘ckcv108250

188 LOR FILM caPaCrToR cuss33850

(89 MiLOR FILM CAPACITOR oMa05K50

co srLoR FILE caPacrToR ‘couns32J50

ATL LOR FILM CaPACrToR cuatr2150

172 WLOR FILM CaPACrTOR cowaa72xs0

(C202 CERAMIC CAPACITOR cacy 108250

28

PD-Z74T, PD-Z570T

Mark No. Symbol & Description __Part No. Mark No. Symbol & Description _Part No.

(C212 MYLOR FILM CAPACITOR ‘CQMALOSKSO @ SUB BOARD ASSEMBLY.

(PWX1142)(For PD-Z74T/HEM)

(C216, 217 ELECTR. CAPACITOR ceasszom6

C301" MFLOR FILM CAPACITOR ‘Cuaio4Kso ‘SEMICONDUCTORS

(C304, 305 CERAMIC CAPACITOR ‘eccca150350 DTO1-T04 DIODE 1sses4

C306" CERANIC CAPACITOR ccYBISeKsO

(GOT MFLOR FILM CAPACITOR (Cawaa3i50 ‘SWITCHES

‘ST01-116 SHITCH 361006

(C308 MILOR FILM CAPACITOR ‘cquaroseso 801 SFITCH Psci00?

(C309 ELECTR, CAPACITOR ‘CEASRATNSO

321 CERAMIC CAPACITOR cxciF103250 OTHERS

323 CERAMIC CAPACITOR cxcrPi03zs0 ‘ovT01_cowecror HLeMsoR-1

(351 ELECTR, CAPACITOR CEASATINGRS V7O1 FL. INDICATOR TUBE PELIOS

C353. CERAMIC CAPACITOR ‘cxc¥P103250 @ SUB BOARD ASSEMBLY

(355 CERAMIC CAPACITOR cxcirioszs0 (PWX1141)(For PD-Z570T/HEM)

361 CERAMIC CAPACITOR cxciri03zs0

C401 CERAMIC CAPACITOR. cxcrri03250 SEMICONDUCTORS,

C422 CERAMIC CAPACITOR cxcrearszs0 DIO1-107 DIODE 1ss2sa

RESISTORS SWITCHES

51-53 CARBONFILM RESISTOR RoW/eRMIOO 101-128 SITCH 7561006

261, 62 CARBONPILM RESISTOR ro1/eAO 801 SWITCH F9G1007

RIOL-110 CARBONPILM RESISTOR RDL/6MIOD

253-158 CARBORFILM RESISTOR ROL/6AMCIOCS OTHERS

160 CARBONPILM RESISTOR 01/603 (Ov7O1 CONNECTOR HLEWaOR-=1

VOL FL INDICATOR TUBE PELI043

201-208 CARBONEILM RESISTOR /e0

205, 206 CARBONFILM RESISTOR D1/6MCIOIO MECHANISM P.C.B ASSEMBLY

208-212 CARBONFTLM RESISTOR RD1/6PMOIO

221-204 CARBONFTLM RESISTOR © RD1/6PMQIO ‘SWITCHES

301-309 CARBONPILM RESISTOR —RDI/6PMIOO ‘601-608 PUSH SWITCH sg1017

321 CARBONPILM RESISTOR ro1/eNtO003

R352 CARBONPTLM RESISTOR FO1/6AOQO3

356-360 CARBONPILM RESISTOR RD1/6PMIOIO

366-369 CARBONFTLM RESISTOR —ROI/6PMOOO

381-385 CARBONPILM RESISTOR RD1/6PMCIO

aioe ve ROPLOAS

vaio3 ¥z RCPION

YRISI, 152 VR Reri046

OTHERS

(Cu1O1 coNvECTOR 52045-1610

©4351. CONNECTOR LBV30S-1

(381. CONECTORC4P) wed

44301 OPTICAL OUTPUT J4oK x18

3301 XTAL RES (OSC) 51008

1351 CERAMIC RESONATOR yssi014

eg

PD-Z74T, PD-Z570T

8. ADJUSTMENTS

1. Adjustment Methods

Ifa dise player is adjusted incorrectly or inadequately, it may malfunction or not work at all even though there is nothing at all wrong with

the pickup or the circuitry. Adjust correctly following the adjustment procedure.

1-1 Adjustment items/verification items and order

sp tem Testpo Tajesnect tection

a Tipe Fos. ena) | Vivoo FOS OFS)

| Gee ears TPH.Png (RK ERA) | Grathg anon oi

2 | Tictng over blane adusent [TPH Pin? (TC ERR) | VRNoe TAK BAD

Fay ta , Fadl edjsinet sere, Tengen

+ | tangential direction tt adjustment TAP | tit adjustment sorow

5 RF level adjustment ‘TP1, Pin 1 (RF) | var (RF level)

«| rocusonoteorgainadueinant | ERBMEIFCS.IN, | rasa rcs. caN)

1 | racking sevoteopgainscusment | EN PmSTRCW) | vues cr GAN)

Cs Tipe (ros.enm | ——

@ Abbreviation table

FCS. ERR: Focus Error

FCS. OFS: Focus Offset

TRK. ERR : Tracking Error

TRK. BAL: Tracking Balance

FCS.IN _: Focus In

TRK. IN: Tracking Ia

1-2. Measuring instruments and tools

Dual trace oscilloscope (10:1 probe)

Low-frequency oscillator

Test dise (YEDS-7)

12-cm disc (with at least about 70 minutes of recording)

Low-pass filter (39 Q +0.001 uF)

6. Resistor (100 k® )

Hexagonal wrench (M3 mm)

‘Standard tools

30

PD-Z74T, PD-Z570T

1-3. Test point and adjustment variable resistor positions

Test mode

Jumper wires:

Figure 1 Adjustment Locations

1-4 Notes

1 Use a 10:1 probe for the oscilloscope.

2, All the knob positions (settings) forthe oscilloscope in the adjustment procedures are for when a 10:1 probe is used,

1-5 Test mode

These models have a test mode so that the adjustments and checks required for service can be carried out easily, When these models are in

test mode, the keys on the front panel work differently from normal. Adjustments and checks can be carried out by operating these keys

with the correct procedure. For these models, all adjustments are carried out in test mode.

{Setting these models to test mode]

How to set this model into test mode

1. Tum off the power switch

2. Short the test mode jumper wires. (See Figure 1.)

Tum on the power switch.

When the test made is set correctly, the display is different from what it usually is when the power is tumed on. If the display is still the

same as usual, test mode has not been set correctly, so repeat Steps 1-3

aa

PD-Z74T, PD-Z570T

[Release from test mode]

Here is the procedure for releasing the test mode:

1. Press the STOP key and stop all operations.

2. Tur off the power switch on the front panel.

in test mode]

Code | Keyname | Function in test mode Explanation

Pom Focus servo close If Dise Tray 11s closed, Disk Tray 1 is moved to the play position. Then the laser

(PROGRAM) dlode is lt up and the focus actuator is lowered, then raised slowly and the focus

sero is closed atthe point where the objective lens is focused on the disc.

With the player inthis stato, if you ightly rotate the stopped disc by hand, you can

| hear the sound the focus servo.

you can hear this sound, the focus servo is operating correctly. I you press this

ey with no disc mounted, the laser diode lights up, the focus actuator is pullod

down, then the actuator is raised and lowered twice and returned to its original

position.

> PLAY Spindle servo ON Stars the spindle motor in the clockwise direction and when the disc rotation

ches the prescribed speed (about 500 rpm al the inner periphery), sts the

spindle servo in a closed loop.

| Be carelul. Pressing this key when there is no disc mounted makes the spindle

| ‘motor un at the maximum speed.

| It the focus servo doos not go correctly into closed loop or the laser light shines

‘on the mirror section at the outermost periphery ofthe disc, the same symptom is

occurred.

| PAUSE Tracking sero Pressing this key when the focus servo and spindle servo are operating correctly

closelopen in closed loops puts the wracking servo into a closed loop, displays the track

number being played back and the elapsed time on the front panel, and outputs

the playback signal

It the elapsed time is not displayed or not counted correctly or the audio is not

played back correctly, it may be that the laser is shining on the section with no

‘sound recorded at tha outer edge ofthe disc, that something is out of adjustment,

‘or thal there is some other problem

‘This key is a toggle key and opan(close the racking servo alternately

This key has no effect f no disc is mounted,

fay | TRACK) Carriage reverse ‘Moves the pickup positon toward the inner periphery ofthe dis.

éq | MANUAL (owards) When this key is pressed with the tracking servo in a closed loop, the tracking

‘SEARCH REV servo automatically goes into an open loop. Since the pickup does not

‘automatically stop at the mechanical end point in test mode, be careful wth this

operation

pe) | TRACK! Carriage forward Moves the pickup postion toward the outer periphery of the dis.

bei | MANUAL (outwards) When this key is pressed with the tracking servo in a closed loop, the tracking

SEARCH FWD ‘servo automaticaly goes into an open loop. Since the pickup does not

‘automatically stop at the mechanical end point in test mode, be caroful with this

‘operation

m | stor Stop ‘Switches off all the servos and initializes.

‘The pickup remains where was when this Key was pressed.

& | OPEN/CLOSE | Disctray openiciose | Opensicloses the disc tray.

bisc 1 This key is a toggle key and openiclose tray alternately,

32

PD-Z74T, PD-Z570T

In test mode, since the servos operate independently, playing back a disc requires that you operate the keys in the correct order to close the

Here is the key operation sequence for playing back a disc in test mode,

[How to play back a disc in test mode}

PGM Lights up the laser diode and closes the focus serve.

[ pay oe Starts the spindle motor and closes the spindle servo.

[PAUSE Closes the tracking servo.

Wait at least 2-3 seconds between cach of these operations

aa

PD-Z74T, PD-Z570T

1. Focus offset adjustment

© Objective ‘Sets the DC offset forthe focus error amp.

@ Symptom when outof | The player does not focus in and the RF signal is dirty.

adjustment

@ Measurement instrument | Connect the osciloscope to TP1, Pin | @ Playerstate ‘Test mode, stopped

‘connections 6 (FCS ERR), (just the Power switch on)

[Settings] 5 mVidivision © Adjustment location _| vRt03 (FCS OFS)

10 ms/division

DC mode

© Disc None needed

[Procedure]

Adjust VR103 (FCS OFS) so that the DC voltage at TP1, Pin 8 (FCS ERA) is 50 + 50 mV.

PD-Z74T, PD-Z570T

2. Grating adjustment

© Objective ‘To align the tracking error generation laser beam spots to the optimum angle on the track

© Symptom when out of | Play does not stat, track search is impossible, tracks are skipped.

adjustment

© Measurement instrument | Connect the osciloscope to TP'., Pin | @ Playerstate Test mode, focus and spindle

connections 2 (TRK ERR) via low pass iter ‘servos closed and tracking servo

(See Figure 2) open

[Settings] 50 mv/division © Adjustment ocation —_| Pickup grating adjustment sit

'5 msidvision

Dc mode

| @ Disc 120m disc.

(YEDS-7 can not bo used.)

[Procedure] |

1. Move the pickup to the outer edge of the disc with the TRACKIMANUAL SEARCH FWD B® / Bib or Kal /<éal koy so that the grating

adjustment slit is atthe outer edge of the disc where itcan be adjusted

2. Press the PGM key, then the PLAY P> key in that order to close the focus servo then the spindle servo.

3. Insert an ordinary screwdriver into the grating adjustment sit and adjust the grating to find the null point. For more details, see the next

age.

4 If-you slowly tur the screwdriver counterclockwise from the null point, the amplitude of the wave gradually increases, then if you

Continue turing the sorewdriver, the amplitude of the wave becomes smaller again. Turn the screwdriver counterclockwise from the null

point and set the grating to the first point where the wave amplitude reaches its maximum.

Reference: Figure 3 shows the relation between the angle ofthe racking beam with the track and the wave form.

Note: The amplitude of the tracking error signal is about 3 Vp-p (when a 39 KO + 0.001 uF low pass filer is used). If this

amplitude is extremoly small (2 Vp-p or los), the objective lens may be diy or the pickup malfunctioning. If the diference

between the amplitude of the error signal atthe innermost edge and outermost edge of the disc is more than 10%, the

{fating isnot adjusted to the optimum point, so adjust it again.

'5. Rotur the pickup to more or loss midway across the dise with the TRACK/MANUAL SEARCH REV Med

Adjustment Locations

3s

PD-Z74T, PD-Z570T

[How to find the null point}

‘When you insert the regular screwdriver into the sit forthe grating adjustment and change the grating angle, the amplitude of the tracking

‘rror signal at TP1 Pin 2 changes. Within the range for the grating, there are five or six locations where the amplitude ol the wave reaches

‘@ minimum. OF these five or six locations, there is only one at which the envelope of the wave form is smooth. This location is where the

three laser beams divided by the grating are all ight above the same track. (See Figure 3.)

Ths points called the null point. When adjusting the grating, this nul point is found and used as the reference position

‘Turning the grating counter-clockwi se nny) the grating clockwise

Wave form of TP1 .Pin2 HNN |» he LW te

,

2

Grating adjustment position Nl oe,

Figure 3

=| | i A "NAVA

Nllo point waveform Maximum amplitude Waveform other than

waveform the null point

36

3. Tracking error balance adjustment

PD-Z74T, PD-Z570T

© Objective

@ symptom when out of

adjustment

@ Measurement instrument

‘Connect the oscilloscope to TP1, Pin

| To correct fr the variation in the sensitivity of the tracking photodiode

Play does not start or track search is impossible

‘Test mode, focus and spindle

‘servos closed and tracking servo

© Player state

1. Move the pickup to midway across the disc (

3. Line up the bright line (ground) at

‘same (in other words, so that there is no DC component)

commons 2 (TRK ERR) Te connoston may

| bevia tow pester, open

[Settings] 50 mV/division @ Adjustment location \VR102 (TRK BAL)

Domode

© ise

Procedure]

15 mm) with the TRACKIMANUAL SEARCH FWD Pi / PH or Mt hoy.

2. Press the PGM key, then the PLAY Be key n that order to close the focus servo then the spindle servo,

18 center ofthe oscilloscope screen and put the oscilloscope into DC mode.

4. Adjust VR102 (TRK BAL) so that positive amplitude and negative amplitude ofthe tracking error signal at TP! Pin 2 (TRK ERR) are the

bebe

+

<9 a

on

When thera is a DC

‘component

When there is no DC

‘component

a7

PD-Z74T, PD-Z570T

4. Pickup radial/tangential tilt adjustment

© Objective To adjust the angle ofthe pickup relative tothe disc so thatthe laser beams are shone straight down into

the disc for the best read out of the RF signals,

{@ Symptom when outot | Sound broken: some discs can be played but not others,

adjustment

© Moasurement instrument | Connect the osciloscope to TP1, Pin | @ Player sta | Test mode, play

connections 1 (RF) |

[Setings] 20 mv/vision © Adjustment ication | Pickup radial tit adjustment screw

1200 nsivision and tangential tit adjustment

AC mode screw

© Disc 12 om disc.

(YEDS-7 can not be used.)

(Procedure)

1. Move the pickup to the outer edge of the dise with the TRACKIMANUAL SEARCH FWD Die / i or Me <4 key 20 that the:

radialtangential it screws can be adjusted.

Press the PGM key. the PLAY De key, then the PAUSE,

player into play mode,

key in that order to close the focus servo then the spindle servo and put the

2. First, adjust the radial tit adjustment screw with an M3 mm hexagonal wrench so that the eye pattern (the diamond shape al the center

ofthe RF signal) can be seen the most clearly

3. Next, adjust the tangential tit adjustment screw with an M3 mm hexagonal wrench so that

Center of the AF signal) can be seen the most clearly (Figure 5)

‘eye patter (the diamond shape at the

4. Adjust the radial tit adjustment screw and the tangential tit adjustment screw again go that the eye pattern can be seen the most

Clearly, As necessary, atjust the two screws alternately so that the eye pattern can be seen the most clearly

Note: Radial and tangential mean the directions relative tothe disc showm in Figure 4

Radial direction

Radial drecion

| ‘Tangential direction

| yy Z il = 3

H

S80 g ( | +f

[Vz + Ul Fi

| (a=) weal

Die WEE

Figure 4 = Ss=

fA I>

‘Adjustment Locations

3a

Out of adjustment Optimum adjustment Out of adjustment

a

Out of adjustment Outof adjustment

Optimum adjustment

Figure 5 Eye Pattern

as

PD-Z74T, PD-Z570T

5. RF level adjustment

© Objective To optimize the playback RF signal amplitude

{© Symptom when outof | No play or no search

adjustment

@ Measurement instrument | Connect he osciloscope to TP1, Pin | @ Player state | Test mode, play

connections 1 (RF)

[Sotings] 50 mVidvision © Adjustment location —_| VR (laser power)

10 msidivision

AC mode

@ Disc Yeos-7

[Procedure]

1. Move the pickup to midway across the dise (R = 35 mm) with the TRACK/MANUAL SEARCH FWD bb / bb or tel key in that order to close the respective servos and put the player inte play mode,

2. Adjust VAI (laser power) so that the RF signal amplitude is 1.2 Vp-p + o.1V.

a0

PD-Z74T, PD-Z570T

6. Focus servo loop gain adjustment

© Objective ‘To optimize the focus servo loop gain

© Symptom when outof | Playback does not start or focus actuator noisy

agjustment

© Moasurementinstrument | See Figure 6. @ Player state Test mode, play

connections |

[Settings] © Adjustment location | R152 (FCS GAN)

| cH cue @ Disc YEDS-7

20 mVidivision 5 mVidivision

X-Y mode

(Procedure)

1. Sot the AF generator output to 1.2 KHz and 1 Vp.

2. Pross the TRACK/MANUAL SEARCH FWD Be / BH or Ke <#@ koy to move the pickup to halfway across the disc (R = 95 mm), then

press the PGM key, the PLAYP> key, then the PAUSEIII key in that order to close the corresponding servos and put the player into play

mode,

3. Adjust VR152 (FCS GAN) s0 that the Lissajous wave form is symmetrical about the X axis and the Y axie,

SPIN

(Fes IN)

4PIN

(GND)

6 PIN

(FCS ERR)

Figure 6

Focus Gain Adjustment

Higher gain Optimum gain Lower gain

PD-Z74T, PD-Z570T

7. Tracking servo loop gain adjustment

© Objective ‘To optimize the tracking servo loop gain

© symptom when out of | Playback does not sta. during searches the actualor is noisy, or tracks are skipped

adjustment

@ Measurement instrument | See Figure 7 © Player stato “Test mode, play

connections

[Settings] © Adjustment location | VRI81 (TRK GAN)

cH one © disc YeDS.7

50 mVidvision 50 mViivsion

X:¥ moda

{Procedure}

1. Sot the AF generator output to 1.2 kHz and 2 Vp-p.

2, Pross the TRACK/MANUAL SEARCH FWD Pi /Dibl or Me / key to move the pickup to hallway across the dise (R = 35 mm), then

press the PGM key, the PLAY key, then the PAUSE kay in that order to close the corresponding servos and put the player into play

mode,

3. Adjust VA151 (TRK GAN) so that the Lissajous wave form is symmetrical about he X axis and the Y axis.

3PIN

(TRK IN)

4PIN

(GND)

2PIN

(TRK ERA)

Figure 7

‘Tracking Gain Adjustment

Higher gain Optimum gain Lower gain

PD-Z74T, PD-Z570T

8. Focus error signal (focus S curve) verification

© Objective To judge whather the pickup is ok or not by observing the focus error signal. The pickup is judged from the

‘amplitude of the tracking error signal (as discussed in the section on adjusting the tracking error balance)

‘and the wave form for the focus error signal

© Symptom when out of

adjustment

@ Measurementinstrument | Connect the osciloscope to TP1, Pin | @ Playorstate ‘Test mode, stop

‘connections 6 (FCS ERR).

[Sottings) 100 mVidvision @ Adjustment ocation | None

'5 msidvision

Dc mode

@ Disc YeDs-7

[Procedure]

1. Connect TPI Pin 5 to ground,

2. Mount the disc

‘3. While watching the oscilloscope screen, press the PGM key and observe the wave form in Figure 8 for a moment. Vert that the

amplitude is atleast 2.5 Vp-p and that the positive and negative amplitude are about equal. Since the wave form is only output fora |

moment wien the PGM key is pressed, press this key over and over until you have checked the wave form.

A

A=B

AsB225Vpp

o

Figure 8

[Judging the pickup}

Do not judge the pickup unti all the adjustments have been made correctly. In the following cases, there may be something wrong with the

| pickup.

1. The tracking error signal amplitude is extromely sm

(loss than 2 Vp-p)

2. The focus error signal amplitude is extremely small (less than 2.5 Vp-p).

3. The postive and negative amplitudes ofthe focus error signal are extremely asymmetrical (2:1 ratio or more)

4. The RF signal is too sme

standard level

(less than 0.8 Vp-p) and even if VA1 is adjusted (laser power), the RF signal can not be brought up to the

43

PD-Z74T, PD

rahe

8. REGLAGE

1. Méthodes de réglage

Si le lecteur CD est mal réglé, il risque de ne plus fonctionner normalement, voice ne plus fonctionner du tout, méme si le capteur et la

cireuiterie en présentent aucune anomalie. Par conséquent, ajuster le lecteur correctement en suivant les démarches de réglage

1-1 Points de réglage/Point et ordre de verification

Eape Pane Point feos con gee

1 [ Rége au aiclnge dota riw au pore | TPH Broce 0 FOS. ERA) | VRvea Fos. oF

2 Foge du reens de actor | TF Broche# (FRC ERR) | Farina iguge an reaoeudeavsion

2 | Rigas tiauirape torr TPrBrose2 (7K ERR) | VRIOE (TK BAL)

Réglage dinclinaison radialenangentille Vis de réglage d'incinaison radial,

P31, Broche 1 (RF)

5 Réglage du niveau RF ‘TP1, Broche 1 (RF) VAI (niveauRF)

«| Beorspganeetmcemnnon [rrr soom 2 c8 | vm 08 aay

7 | Flgnegeensetecemmeneon [er pos cre, | ws con

au point |

+ erreur de mite au point

décalage de mise au point

TRK. ERR : erreur d’alignement

‘TRK. BAL ; équilibrage d’erreur d’alignement

FCS. IN: mise au point correcte

TRK.IN_ : alignement correct

1-2 Intruments de mesure et outils

Oscilloscope cathodique & deux faisceaux (sonde 10:1)

Oscillateur de basse fréquence

Disque d’essai (YEDS-7)

Disque de 12.cm (avec au moins 70 minutes d’enregistrement)

Filtre passe-bas (39 K + 0,001 F)

Résistance (100 k& )

Clé hexagonale (M3 mm)

Outils conventionnels

4a

PD-Z74T, PD-Z570T

1-3. Point d’essal et positions de réglage de la résistance variable

Fils de liaison du

mode d'essai

Figure 1 Emplacement des Réglages

1-4 Remarques

1. Usiliser une sonde 10:1 pour loscilloscope.

2, Toutes les positions (réglages) des boutons de I'oscilloscope, dans les démarches de réglage, sont congues pour I'usage d'une sonde

10:1

1-5 Mode d’essai

Ces modéles sont munis d'un mode d’essai, de fagon que les réglages requis & la réparation puissent étre effectués aisément. Quand ces

modéles sont en mode d’essai, les touches du panneau avant ne fonctionnent pas comme & I'ordinaire. Les réglages et les vérifications

Peuvent s'effectuer par I'enclenchement de ces touches, & conditions de suivre les démarches requites. Dans le eas de ces modeles, tous les

réglages sont réalisés en mode d'essai

[Mise en mode d’essai]

Voici la manigre de mettre le modéle en mode dessa

1. Commuter I'intecrupteur d’ alimentation sur arr.

2. Court-cireuiter les fils de liaison du mode dessa. (voir Figure 1.)

3. Commuter I'interrupteur d’alimentation sur marche.

‘Quand le mode d’essai est correctement réglé, 'affichage est différent de celui qui apparait généralement 3 la mise sous tension. Si

affichage reste le méme, le mode d’essai n'a pas 61é réglé correctement. Dans ce eas, répéter les étapes 1 43,

4s

PD-Z74T, PD-Z570T

[Pour sortir du mode dessai]

Voici la procédure pour sortir du mode d’es

1. Appuyer surla touche STOP pour arréter toutes les opérations.

2, Sur le panneau avant, commuter l'interrupteurd’alimentation sur arcét

[Fonctionnement des touches en mode d’essai]

Nomdela | Fonetion en mode

seul touche d'ossal

Explications

Pom Fermeture du circuit | Sile plateau n° 1 est fermé, ilse place en made de lecture. Ensuite la diode laser

(PROGRAMME) | asservide la mise au | sallume et factuateur de la mise au point s/abaiase, puis se reléve lentement et

point le circuit servo de la mise au point se ferme au point ol la lentil de object se

focalse sur le disque.

Quand apparel est dans cot état, si fon fait bgBrement tourner a la main le

disque arété, le bruit produit parle circuit servo de la mise au point sera audible,

Si ce brut est pergu, le circuit servo de la mise au point fonctionne correctement.

| Si cette touche est enclenchée et qu’aucun disque n'est installé, la diode laser

Sallume, factuateur de la miso au point s'abaisse, se reléve, puis s'abaisse une

deuxiéme fois ot enfin, ravient sa position de départ

> | Pay ‘Asservissementde | Démarre le moteur de rotation dans le sens des aiglles dune montre, quand la

rotation en service | rotation du disque attint fa vitesse prescrite (environ 500 toursimin a la

Circonlérence interne) et place le ccuit servo de retaion dans une boucle

fermée

| tention, Si cate touche est enfoncée et quiun disque n'est pas instalé, le

motour do rotation va tourer & la vile maximum,

Site cuit sev de la mise au point ne passe pas comme prévu dans une

boucle fermée ou que la diode laser bile dans la mircr a la périphére exteme

du disque, le méme sympibme se produit.

mM | Pause Ouverture/Fermeture | Le fait d'appuyer sur cette touche quand le circuit servo de la mise au point et de

du circuit servo de | la rotation fonctionnent correctement en boucles fermées, place le circuit servo

"alignement de Taignement dans une boucle fermée, fait apparaite, sur le panneau avant, le

numéro de la piste en cours de lecture et la durée écoulée, puis sort le signal de

lecture,

Sila durée 6coulée n'est pas alfichée ou n'est pas correctement calculée, ou sila

reproduction sonore est anormale, il se peut que la diode laser s‘active dans la

section dépourvue de signaux enregistrés, a bord externe du disque, qu'un

ajustement quolconque soit déréglé, ou qu'un autre probléme se manifests.

Cotte touche est de type a bascule et ouvraiferme alternativement le circuit servo

de Falignement. Cette touche est inopérante si un disque n'est pas instal

wey | TRACK) Inversion du chariot | Déplace le captour vers la périphérie interne du disque.

sé | manuat (vers Fintérieur) uand cette touche est encienchée et que le circuit servo de Talignement

‘SEARCH REV vaille en boucle fermée, celu-ci change automatquement dans une boucle

were.

Comme le captour ne s'arréte pas automatiquement au point de fin mécanique

du mode d'essal,etlectuer cote démarche avec précaution,

pe) | TRACK) Inversion du chariot | Déplace le captour vers la périphérie externe du disque.

pei | MANUAL (ors Fextériour) uand cette touche est enclonchée et que le circuit serve de Falignement

‘SEARCH FWO travaille en boucle fermée, celu-ci change automatiquement dans une boucle

ouverte,

Comme lo capteur ne s'arréte pas automatiquement au point de fin mécanique

du mode d'essai,etfectuer cotte démarche avec précaution,

m | stor Art Mot tous les circuits servo hors service et les intalise.

‘Le captour reste lod il était quand cette touche a été onclonchéo,

& | OPENICLOSE | OwverturerFermeture | Cotte touche est de type A bascule et ouvrejferme allernativement le plateau. Le

Disc 1 fait c'enfoncer cette touche quand le plateau est ouvert le ferme et vice versa.

as

PD-Z74T, PD-Z570T

[Lecture de disque en mode d’essai]

En mode 'essai, comme les circuits servo fonctionnent de manitre indépendante, la lecture d’un disque exige que les touches soient

enclenchées dans l'ordre prescrt, afin de fermer les circuits servo.

Voici I’ordre d’enclenchement des touches pour reproduire un disque en mode dessa

PGM Allume la diode laser et ferme le circuit servo de la mise a point.

U

PLAY Démarre le moteur de rotation et ferme le circuit servo dela rotation.

["rause Ferme le circuit servo de Valignement

Attendre 2 8 3 secondes entre chaque opération.

a7

PD-Z74T, PD-Z570T

1. Réglage du décalage de la mise au point

@ ober Rigi le décalage 6 de fampicatour rovour do miso au poi

(© symptime quand dérégls | Le leteurneprocie pus Ala mis au pont ete signal Fret pas cl.

(© Raccordoment des Raccorderfoscilocope A TPI, | @ Eat du ecteur Mode dessa adie

Ihevomerte domosure | broche (FOS ERR)

(uste interrupteur dalimentation

‘commuté sur marche)

| (Reglages] 5 mVidivision (© Emplacement du réglage | VRt08 (FCS OFS)

10 msidvision |

mode CC |

© Disque ‘Aueun requis

[Marche a suivro}

Ajuster VR103 (FCS OFS) de facon que la tension & TPt broche 6 (FCS ERR) soit-50 + 50 mV,

48

PD-Z74T, PD-Z570T

2. Réglage du réseau de diffraction

© Object | Pour aligner les points du rayon laser producteur c'erreur dalignement sur rangle optimum dela piste

|

© Symptéme quand dérégié_| La locture ne commence pas, la recherche de piste est impossible, les pistes sont sautées.

@ Raccordement des | Raccorder osciloscope aTP1, | @ Etatdu lecteur Mode d'essai, circuits servo de la

instruments de mesure | broche 2 (TRK ERR) via un fire ‘mise au point at da la rotation

passe-bas. (Voir Figure 2) formés, circuit serve de

| alignement ouvert

[Réglages) 50 mVidivision © Emplacement du réglage | Fonto do réglage du réseau de

‘5 msidvision difraction du capteur

mode CC

@ Disque Disque de 12 cm.

{lest impossible d employer le

dieque YEDS-7)

(Marche & suivre]

1. Déplacer le capteur sur le bord exteme du disque par la touche TRACK! MANUAL SEARCH FWD BB /Bbou la touche Ke /bB4 ou Mt / te

Ensuite, appuyer sur la touche PGM puis sur la touche PLAY Be , dans cet ordre, pour fermer les circuits servo respects et mettre le

lecteur en mode de lecteur.

2. Ajuster VAI (alimentation du laser) de fagon que fampitude du signal RF atteigne 1,2 Vee + 0.1V.

54

PD-Z74T, PD-Z570T

6. Réglage de gain de boucle asservie de la mise au point

© Object | Pour optimaiser io gain de la bousie Casservissement dela mise au pont

© symptime quand déréglé_| La lecture ne commence pas ou actuateur de la mise au pont est paras

(© Raccordement des | VoirFigure ¢ ] (@ Etat du lecteur Mode dessa, lecture

inetruments da mesure

[Réglages) | @ Emplacement du réglage | VR152 (FCS GAN)

cant cata, | @ Dag veos.7

| 20 mVidvision 5 mVidivision

| Mode x-¥

[Marche a suivre]

1, Régler Ia sortie du générateur AF sur 1,2 KHz et 1 Ve-.

2. Appuyer sur la touche TRACK) MANUAL SEARCH FWD Di / Pb ou la touche Kee / #44 pour placer le capleur & mi-chemin sur le

disque (R = 35 mm). Ensuite, appuyer sur la touche PGM, la touche PLAY Pe, puis sur la touche PAUSE MIF. dans cet ordre, pour

former les circuits servo respects et placer le lecteur en mode de lecture,

3. Ajustar VRI52 (FSC GAN) de fagon que la forme d'onde de Lissajous soit symeétique aux alentours de axe X et axe Y.

cc (io)

5 Broche

(Fos IN)

4 Broche

(GND)

6 Broche

(FCS ERR)

(tos)

Figure 6

Adjustment de gain de mise au point

Gain supérieur Gain optimum Gain inférieur

ss

PD-Z74T, PD-Z570T

7. Réglage de gain de boucle asservie de l’alignement

© Object Pour optimatiser le gain de la boucle d'asservissement de lalignement,

© Symptéme quand dérégié_| La lecture ne commence pas, actuateur est parasité pendant la recherche, ou dee pistes sont sautées,

@ Raccordement dos | Voir Figure 7 @ Etat du lecteur Mode d'essai, lecture

instruments de mesure | |

[Réglages} | @ Emplacoment du régiage | VRI51 (TRK GAN)

CAN. 1 CAN.2 @ Disque YeDs-7

50 mVidivision 50 mVidivision

Mode X-¥

[Marche & suivre}

1. Régler la sortie du génératour AF sur 1,2 kHe et 1 Ve-

2, Appuyer sur la touche TRACK/ MANUAL SEARCH FWD Dee / Bib ou la touche Kl / fe pour placer le capleur & mi-cherin sur le

disque (R = 35 mm). Ensuite, appuyer sur la touche PGM, la touche PLAY be, puis eur la touche PAUSE I, dans cet ordre, pour

fermer les circuits servo respectfs et placer le lecteur en mode de lecture,

3. Ajuster VR1S1 (TRK GAN) de facon que la forme donde de Lissajous soit symétrique aux alentours de axe X et 'axe Y.

1 (10:1)

3 Broche

(RK IN)

4 Broche

(GND)

2 Broche

(TRK ERR)

Filtre passe-bas

Figure 7

Adjustment de gain d'alignement

Gain supérieur Gain optimum Gain inférieur

56

PD-Z74T, PD-Z57

8. Véri

ation du signal d’erreur de la mise au point

© Odjectit Pour juger silo captour est bon ou pas, en observant le signal derreur de la mise au point. L'état du

‘captour s'évalue & partir de Tampitude du signal dorrour dalignement (comme déerit dans lo

paragraphe reli a 'équilbrage d erreur d'aignement), ainsi u'a partir de la forme donde du signal

erreur de mize au point

© Symptime quand dérégis |

@ Raccordement des: | Raccorder loscilloscope & TPI, @ Etat du lecteur Mode de test, arrét

Inovorertdomesue | broch 6 (FOS ERR).

| tméciages) 100 mvidwlon | @ Emplacement du gage | Aucun

| Simavlon

| mode CC

© Disque veos7

Li ee

[Marche a suivre}

1, Raccorder TPI, broche 5 a la masse.

2. Installer le disque.

3. Tout en regardant 'écran de oscilloscope, appuyer sur la touche PGM ot observer la forme donde de la Figure &, pendant quelques

instants. Verifier que amplitude atteint au moins 2.5 Ve-c et que les ampliudes positive et négatives solent égales. Comme la forme ne

Sort que pour un moment, quand la touche PGM est enclenchée, appuyer sur & plusieurs reprises sur cette touche, jusqu’a ce que la

forme d'onde ait 6 vériiée,

$F ezssves

8

Figure 8

[Evaluation du capteur]

Ne pas tenter d'évaluer état du capteur tant que tous les réglages ne sont pas corrects. Les cas suivants témoignent de Vanomalio du

capteur.

1. Lampltude du signal 'erreur d'alignement est extrbmement petite (inférieure & 2 Ve).

2. Lampltude du signal d’ereur de mise au point est extrémomant petite (inférioure & 2.5 Vero)

8. Les amplitudes positive et négative du signal derreur de mise au point sont extrdmement asymétriques (taux 2:1 ou plus).

4. Le signal RF est trop pei inférieur & 0,8 Vc-c) et méme si VR1 (alimentation du laser) est ajustée, |

niveau standars,

Signal RF ne peut étre Slevé au

s7

PD-Z74T. PD-Z570T

8. AJUSTE

1. Métodos de ajuste

Si un reproductor de discos compactos se ajusta incorrecta o inadecuadamente, puede funci

nar mal o no trabajar incluso aunque no exi

ningén problema en el captor ni en los cizeuitos. juste correctamentesiguiendo el procedimiento de ajuste

1-1. ftemes de ajuste/verificacién y orden

item Punto de prueba Lugar de ajuste ]

1 | Ajvste del descentramionto de enfoque | TPY, Pala (FCS. ERR) | VAI03 FCS. OFS)

2 | Ajuste de retiula Pi, Pallla2 (TRK. ERA) | Ranura de ajuste de retcula |

3 ao ‘TP1, Patilla2 (TRK. ERR) | VR102 (TRK. BAL)

‘Aiuste de a inctinaciin en sentido | “Tomilo de ajuste de ia inctinacién racial

ad radialtangencial del captor eer Tomillo de ajuste de la inclinacién tangencial

5 | Austo del nivel de RF 1P', Patila 1 (RF) VAI (Nive de RF) |

‘Ajuste de a ganancia del ble del serve de. | TP, Patila 5 (FCS. IN)

© | entoque | TP1, Patita 6 (FCS. ERR) | VRIS2 (FCS. GAN)

‘Aluste de a ganancia del cle del vovo de | TP, Patila9 (TR. IN)

: ‘seguimiento. ‘PI, Patila2 (TRK. ERR) | VIS! (TRI GAN)

8 Veriticacién de la sefal de error de enfoque | TP1, Patilla 6 (FCS. ERR) a

@ Tabla de abreviaturas

FCS. ERR: Error de enfoque

FCS. OFS: Descentramiento de enfoque

TTRK. ERR : Error de seguimiento

‘TTRK. BAL : Equilibrio de seguimiento

FCS. IN: Entrada de enfoque

TTRK. IN : Entrada de seguimiento

1-2. Instrumentos y herramientas de medicion

Osciloscopio de doble traza (Sonda de 10:1)

(Oscilador de baja frecuencia

Disco de prueba (YEDS-7)

Disco de 12 em (con 70 minutos de grabacién por lo menos)

Para el tipo de reproduccién miltiple de disco compacto, emplee solamente el disco de prueba YEDS-7.

Filtro de paso bajo (39 k®2 + 0,001 uF)

Resistor (100 k& )

Lave hexagonal (M3 mm)

Herramientas estindar

so

PD-Z74T, PD-Z570T

1-3. Ubicacién de los puntos de prueba y los resistores variables de ajuste

vai

cnz01

1)

i vrtsi pa

ee =

6 8,

a

Hilos de puenteado det

mode de prueba

Figura 1 Lugares de Ajuste

1-4 Notas

Emplee una sonda de 10:1 para el osciloscopio,

2, Todas las posiciones de los mandos (ajustes) para el osciloscopio de los procedimientos de ajuste son para cuando se emplee la sonda

de 10:1

1-5 Modo de prueba

Estos modelos poseen un modo de prueba que permite realizar fécilmente los ajustes y las comprobaciones requeridos para el servicio.

Cuando estos modelos estén en el modo de prueba, las teclas del panel frontal trabajarin de forma diferente a la normal. Los ajustes y las

‘comprobaciones podrén realizarse accionando estas teclas de acuerdo con el procedimiento correcto. Para estos modelos, todos los ajustes

se realizarén en el modo de prueba.

[Puesta de estos modelos en el modo de prueba]

‘A continuacién se indica eémo poner estos modelos en el modo de prueba.

1, Ponga en OFF el interruptor de alimentacisn,

2. Cortocircuite los hilos de puenteado de modo de prueba. (Consulte la figura 1.)

3. Ponga en ON el interruptor de alimentacién.

Cuando haya ajustado correctamente el modo de prueba, la visualizacién seré diferente a la obtenida normalmente al conectar la

alimentacién. Si la visualizaci6n sigue siendo la normal, el modo de prueba no se habré ajustado normalmente, por lo que tendré que

repetir los pasos 1 a3,

59

PD-Z74T, PD-Z570T

[Desactivacién del modo de prueba]

A continuacién se indica el procedimiento para desactivar el modo de prueba

1, Presione la tecla STOP y cese todas las operaciones.

2. Ponga en OFF el interruptor de alimentacién del panel frontal.

[Operaciones de teclas en el modo de prueba)

Nombre dela | Funcién en el modo

ae tecle de prueba

Explicacion

Pam Cierre del servo de | Si la bandoja de disco 1 esti corrada, ésta se movers hasta la posicién de

(PROGRAMA) | enfoque teproduccin, Después el diodo Meer e@ encenderd y el actuador de enfoque

descenderd, después se elevaré lentamente, y el servo de enfoque se cerraré en

. ¢l punto en ol que e! objetivo se enfoque sobre ol disco.

Gon el reproductor en este estado, si gira ligeramente con la mano el disco

pparado podrd o'r el sonido del servo de enfoque.

Si puede ofr este sonido, e! servo de enfoque estar funcionando correctamente,

Si presiona esta tecla sin disco montado, el diode léser se encenderd,

actuador de enfoque se veré empujado hacia abajo, y después se levantard y

descenderd dos veces, y volveré a su posicién original

> | Pay ‘Activacion del servo | Pondra en marcha el moto del eje haciéndolo giar hacia la derecha y después

| deleje la rotacién del disco alcanzaré la velocidad prescria (unas 500 rpm en la

perileria interior), y pondré el sarvo del eje en un bucle cerrado. |

‘Tonga culdado. Si presiona esta tecla cuando no haya disco montads, el motor

dol eje giraré ala velocidad maxima,

SSi el servo de enfoque no pasa correctamente a un bucle corrado, o si el haz |

sérico incide en la seccién del espejo en el la perileria del disco, ocuriré el

mismo sintoma.

MW | Pause ‘Aperuralciere de! | Si presiona esta tecla cuando el servo de enfoque y el servo del eje estén

servo de seguimiento | funcionando correctamente on bucles cerrados, el servo de sequimiento se

ondra en bucle cerrado, en el panel frontal se visualizarén el ndmero de

cancién que esté reproduciéndose y el tiempo transcurrido, y se producira la

salida de la sefal de raproduccién,

Si el tiempo transcurride no se visualiza 0 no se cuenta correctamente, 0 si el

sonido no se reproduce correctamente, es posible que el rayo lasérico esté

incidiendo en la seccién sin sonido grabado en el borde exterior del disco, 0 que

exista algin otro problema.

Esta tecla es basculante (de accién altemativa) y abrelcierra el servo de

seguimiento alterativamente, Esta tocla no funcionara cuando no haya disco

rmontado,

kee) | TRACK) Retroceso del carro | Movera la posicién del captor hacia el didmetro interior de! disco.

| MANUAL (hacia adentro) Si presiona esta tecla con el servo de seguimionto en bucle corrado, dicho bucle

‘SEARCH REV ppasaré aulomdticamente a bucle abierto. Como ol captor no se para

fautomaticamente en el punto final mocdnico en el modo de prueba, tenga

Cuidado cuando realice esta operacion.

bm) TRACK! ‘Avance del carro ‘Moverd la posicién del captor hacia la pariferia del disco.

Pei MANUAL (hacia afuere) Si presiona esta tecla con el servo de soguimionto en bucle cerrado, dicho bucle

SEARCH FWD pasar autométicamente a bucia ablerto, Como el caplor no se para

lautométicamente en el punto final mecénico en el modo de prueba. tenga

‘evidado cuando realice esta operacin,

m | stop Parada Desactivara todos los servos @ inicializaré la unida.

El captor permanecera donde estaba cuando se presioné esta tecla

4 | OPENICLOSE | Aperturalciore de la | Abrirécorraré la bandoja del disco. Esta tecla os basculante (de accién

pisc1 bbandeja del disco | altomativa) y abro(ciera la bandoja alternativamente,

60

PD-Z74T, PD-Z570T

[Cmo reproducir un disco en el modo de prueba]

En el modo de prueba, como los servos funcionan independientemente, la reprodueccién de un disco requiere el que usted emplee las teclas

en el orden correeto para cerrar los servos.

AA continuacién se indica la secuencia de operacién de teclas para reproducir un disco en el modo de prueba

POM Lal Hard que se encienda el diodo lisery cerrard el servo de enfoque

Y

[pay | Pondré en marcha el motor del eje y hard que se cierre el servo del eje

U

PAUSE Cerraré el servo de seguimiento,

Espere de 2 a 3 segundos por lo menos entre cada una de estas operaciones.

PD-Z74T, PD-Z570T

1. Ajuste del descentramiento del enfoque

© Objetivo ‘Auste de ia ensién de OC pera el ampiiicador de error de enfogue

© Sintomas en caso do Elreproductor no enfoca y la sefal de RF contene perturbaciones,

dosajuste

© Conerién de los Conocte el osciloscopic a PY, patita | @ Estado del Modo de prueba, parado

instrumentos de medicén | 6, (FCS ERR) reproductor {con el interuptor de aimentacién

enon)

| tAjustes} 5 mvicvisién © Lugar de auste vrtes (Fs OFS)

10 meldvisién

modo de CC |

© Disco | Nos necesario.

| 1Procedimiento}

Aluste VR103 (FCS OFS) de forma que la tonsién de CC de TP1, patila 6, (FCS ERR) sea de ~50 + 50 mv.

se

PD-Z74T, PD-Z570T

2. Ajuste de reticula

© Odjetivo ‘Alineacién de los puntos del haz lasérico de generacién de error de seguimiento al Angulo éplimo en la

pista

@ Sintomas en caso de _| La reproduccién no se nica, la bsqueda de canciones es imposible, las pistas se saltan

desajuste

© Conexién de los | Conecte el osciloscopio a TP1, patila | @ Estado de! Modo de prueba, servos de

instrumentos de medicién | 2, (TRK ERR) a través de un fitro de | reproductor ‘enfoque y del eje cerrados, y servo

‘paso bajo, (Consuite la figura 2) de seguimiento abierto

[Alustes) 50 mViavieion @ Lugar de ajuste Ranura de ajuste de reticula del

| ‘5 msidivision ‘captor

modo de CC

@ Disco Disco de 12 em,

{Eldisco YEDS-7 no podra

| emploarse,)

[Procedimionto}

1. Mueva el captor hasta el borde exterior del disco con la tecla TRACKIMANUAL SEARCH FWD Bi /DBibio He do forma que la

nura de aluste de la reticula quede en el borde exterior del disco, donde puede ajustarse.

2, Presione la tecla PGM, y después la tecla PLAY B>, por este orden, a tin de cerrar el servo de enfoque y después el servo del

3. Inserte un destorillador normal en la ranura de ajuste de la reticulay ajuste la reticula hasta encontrar el punto nulo.

Para més detalles, consuls la pagina siguiente,

4, Sigira lentamente el destornillador hacia la izquierda desde el punto nulo, la amplitud de la onda aumentaré gradualmente. Después, si

Continda girando el destorillador, la amplitud de la onda se volveré otra vez més pequefia. Gire el destorillador hacia la aquierda,

desde el punto nulo ajuste la reticula al primer punto en el que la amplitud de la onda aleance su valor maximo.

Referencia: En a figura 3 se muestra la relacion entre el Angulo del haz de seguimiento con la pista la forma do onda.

Nota: La amplitud de la sefial de error de seguimiento ser de aproximadamente 3 Vp-p (cuando ee emplee un fitro de paso

bajo de 38 KO , 0,001 uF). Si esta ampliud es extremadamente pequetia (2 Vp-p o menos), es posible que el objetivo esté

‘sucio 0 que el captor est funcionando mal. Sila diferencia entre la ampltud de la sefal de error en el borde interior y

‘exterior del disco es superior al 10%, la reticula no estard sjustada al punto éptimo, por lo que tendré que volver &

alustarla.

5. Devuolva ol captor hasta la mitad més © menos del disco con la tocla TRACK/MANUAL SEARCH REV Kt / <#, prosione la tecla

PAUSE II, y vuelva a comprobar si en el panel frontal se vieuaizan el nimero de cancién y el tiempo transcurrido. Si no se visualizan

festa ver, 0 6 ol lempo transcuride cambia iregularmente, vuelva a comprobar el punto nulo ajuste otra vez la rtioula,

TP

2Patila

TAK ERA) |O]

4Patila

(exo) (2

Figura 2

Lugares de Ajuste

6s

D-Z74T, PD-Z570T

[Céme encontrar el punto nulo}

Cuando inserte el destornillador normal en la ranura para el ajuste de la reticula y cambie el angulo de la misma. La ampiitud de la sonal

e error de seguimiento de TP', patila 2, cambiar4. Dentro del margen para la reticula existen cinco 0 seis lugares en los que la amplitud

alcanza el valor minimo. Do estos cinco o seis lugares, solamente hay uno en el que la enwvalvante de la forma de onda es uniforme. Esto

lugar es donde los tres haces laséricos divididos por la roticula se encuentran exactamente sobre la misma pista. (Consult la figura 3)

Este punto se denomina punto nulo. Cuando ajuste la retcula, este punto se encontrara y empleard como posicién de referencia,

Giro de la rticula hacia la izquierda | Giro dela relicula hacia la derecha

amano | ih) i i Aes

iM i i

Forma de onda del Forma de onda de Forma de onda que no

unto nulo amplitud maxima es el punto nulo

64

PD-Z74T, PD-Z570

3. Ajuste del equilibrio de error de seguimiento

@ objetivo Corraccién de la variacién de la sensibilidad del folodiodo de seguimiento

@ Sintomas en caso de La reproduccisn no $e inicia ola bsqueda de canciones es imposible.

desajuste

© Estado del Modo de prueba, servos de

reproductor enfoque y del eje corrados, y sorvo

de sequimiento abierto

© Conexidn de los Conecte ol osciloscopio a TPI, patlla

instrumentos de medicién | 2, (TRK ERR). Esta conexién puede

realizarse a través de un filtro de paso

bajo,

[justes} 50 mvydhisién @ Lugar de ajuste \VRt02 (TRK BAL)

5 msidivision

modo de CC

(Procedimiento}

1, Mueva el captor hasta la mitad del disco (R = 35 mm) con a tecla TRACK/MANUAL SEARCH FWD DBE /DB1o Kt te

2. Presione latecla PGM, y después a tela PLAY be, por este orden, a fin de cerear el servo de enfoque y después el servo del ej

3. Haga coincitira linea brilant (masa) del contro de ta pantalla del osciloscopio y ponga éste en el modo de CC.

4, Ajuste VR102 (TRK BAL) de forma que la amplitud positva y la negativa de la sefal de error de seguimiento de TP1, patila 2, (TRK

ERR) sean iguales (en otras palabras, de forma que no haya componente de CC).

‘ oom f ec i

: f

‘Cuando hay componente ‘Cuando no hay componente

de CC de Cc

es

PD-Z74T, PD-Z570T

4. Ajuste de la inclinacién en sentido radial/tangencial del captor

© objetivo ‘Ajustar al Angulo del captor en relacién con el disco de forma que los haces laséricos incidan

perpendicularmente sobre el mismo a fin de poder leer con la mayor exacttud las seflales de RF.

@ Sintomas en caso de ‘Sonido quebrado, algunos discos pueden reproducirse pero otros no.

desajuste