Professional Documents

Culture Documents

Biodiesel Prod

Biodiesel Prod

Uploaded by

meeradavCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Biodiesel Prod

Biodiesel Prod

Uploaded by

meeradavCopyright:

Available Formats

BIODIESEL PRODUCTION

The production of biodiesel, or alkyl esters, is well known. There are three basic

routes to ester production from oils and fats:

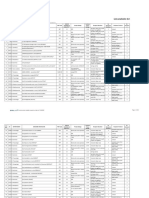

∗ Base catalyzed Process Input Levels = Process Output Levels

transesterification of the oil with

alcohol.

∗ Direct acid catalyzed

esterification of the oil with Alcohol 4%

methanol. Alcohol 12% Fertilizer 1%

Catalyst1% Glycerine 9%

∗ Conversion of the oil to fatty Oil 87% Methyl Ester86%

acids, and then to Alkyl esters

Nothing is wasted

with acid catalysis.

The majority of the alkyl esters produced today are done with the base

catalyzed reaction because it is the most economic for several reasons:

∗ Low temperature (150 F) and pressure (20 psi) processing.

∗ High conversion (98%) with minimal side reactions and reaction time.

∗ Direct conversion to methyl ester with no intermediate steps.

∗ Exotic materials of construction are not necessary.

The general process is depicted below. A fat or oil is reacted with an alcohol,

like methanol, in the presence of a catalyst to produce glycerine and methyl

esters or biodiesel. The methanol is charged in excess to assist in quick

conversion and recovered for reuse. The catalyst is usually sodium or potassium

hydroxide which has already been mixed with the methanol.

Alcohol

Alcohol

ò Recovery

~

Biodiesel

ò Reactor Settler Washing Purification Evaporation

ò

Vegetable ~~

Oil Glycerine

ò

Catalyst

Mineral Neutralization Settler Evaporation

Acid Distillation

Fatty Acids

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Classification TestsDocument12 pagesClassification Testsepsonme101No ratings yet

- Mathongo Question Alcohol Phenol and Ether Jee Main 2021 February chapterwiser9uHArGoIELFoWyM8g5M-1Document8 pagesMathongo Question Alcohol Phenol and Ether Jee Main 2021 February chapterwiser9uHArGoIELFoWyM8g5M-1malladisanjayNo ratings yet

- Resonance DPP 1Document6 pagesResonance DPP 1Subham YadavNo ratings yet

- Stereoisomerism - Mind Maps - (JEE Ultimate CC 2.0 2023)Document1 pageStereoisomerism - Mind Maps - (JEE Ultimate CC 2.0 2023)ShahzadNo ratings yet

- Important Chemical Reactions For Class 12 Chemistry With MechanismDocument9 pagesImportant Chemical Reactions For Class 12 Chemistry With MechanismSoma SahaNo ratings yet

- NorrisolidetDocument4 pagesNorrisolidetOscar Martin OrdoñezNo ratings yet

- Lab 04 A Kinetic Vs Thermodynamic Control ExperimentDocument11 pagesLab 04 A Kinetic Vs Thermodynamic Control ExperimentRobMate VA100% (1)

- Lista Noua Synlab 2022Document190 pagesLista Noua Synlab 2022Maria AmaliaNo ratings yet

- 5.03 Carboxylic Esters and Lactones: B. R. Buckley Loughborough University, Loughborough, UKDocument48 pages5.03 Carboxylic Esters and Lactones: B. R. Buckley Loughborough University, Loughborough, UKCeciNo ratings yet

- Chemistry SME Notes (Organic Chemmistry)Document14 pagesChemistry SME Notes (Organic Chemmistry)Sayeef MahdiNo ratings yet

- Final Merck Price Book 2018 Research Applied PartWiseDocument374 pagesFinal Merck Price Book 2018 Research Applied PartWiseGita ArinawanNo ratings yet

- Hot KMnO4Document4 pagesHot KMnO4Xiu JingNo ratings yet

- DVSDVSDVSDocument17 pagesDVSDVSDVSRicardo HernandezNo ratings yet

- Test 3 Extra Synthesis Practice-AnswersDocument6 pagesTest 3 Extra Synthesis Practice-AnswersVinh HoangNo ratings yet

- IUPAC NomenclatureDocument24 pagesIUPAC NomenclatureSougata DasNo ratings yet

- Solucionario de Wade-306-323 PDFDocument18 pagesSolucionario de Wade-306-323 PDFCésar PastranoNo ratings yet

- Three Catalysts Tango With Olefins: News & ViewsDocument3 pagesThree Catalysts Tango With Olefins: News & ViewsAnahí TessaNo ratings yet

- AITS Schedule 2023Document2 pagesAITS Schedule 2023NigamjeeNo ratings yet

- Protein BiokimiaDocument44 pagesProtein BiokimiaAdnindya JeehanNo ratings yet

- Solutions For Chapter6Document14 pagesSolutions For Chapter6kyyhnwyhc6No ratings yet

- Chapter - 9 Biomolecule DPP - 1 PDFDocument19 pagesChapter - 9 Biomolecule DPP - 1 PDFR.SaivigneshNo ratings yet

- Chemsheets A2 1025 Reactions of AromaticsDocument5 pagesChemsheets A2 1025 Reactions of AromaticsEbtihal AlharthiNo ratings yet

- 9701 Y25-27 Sy-PagesDocument4 pages9701 Y25-27 Sy-PagesanjuNo ratings yet

- Sample Paper Gr11Document3 pagesSample Paper Gr11Enoca AJNo ratings yet

- Poly OlsDocument104 pagesPoly OlsA Mahmood100% (2)

- Antiviral Diterpenes From Salvia OfficinalisDocument3 pagesAntiviral Diterpenes From Salvia OfficinalisGuaguanconNo ratings yet

- Fat & Essential Fatty Acid PDFDocument25 pagesFat & Essential Fatty Acid PDFYUSRINA PUTRI NUGRAHAENI WIBOWONo ratings yet

- SyllabusDocument4 pagesSyllabusAndrew MooreNo ratings yet

- Addition Reactions and Their MechanismsDocument47 pagesAddition Reactions and Their MechanismsttinbddinNo ratings yet

- CH 11 ExerciseDocument33 pagesCH 11 ExerciseTr Mazhar PunjabiNo ratings yet