Professional Documents

Culture Documents

Dspic30F Motor Control PWM: Digital Signal Controller

Dspic30F Motor Control PWM: Digital Signal Controller

Uploaded by

jcarolsilva8Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dspic30F Motor Control PWM: Digital Signal Controller

Dspic30F Motor Control PWM: Digital Signal Controller

Uploaded by

jcarolsilva8Copyright:

Available Formats

dsPIC30F Motor Control PWM Module

DS

Digital Signal Controller

dsPIC30F Motor Control PWM

Module

© 2005 Microchip Technology Incorporated. All Rights Reserved. dsPIC30F Motor Control PWM Module 1

Welcome to the dsPIC30F Motor Control PWM Module web seminar.

© Microchip Technology Inc. Page 1

dsPIC30F Motor Control PWM Module

Session Agenda

O MC Peripheral Overview

O PWM Time Base and Period Setting

O Duty Cycle Programming

O Dead Band Generators

O Output Override

O Fault pins

O A/D Converter Syncronization

O MC PWM in Power Safe Modes

© 2005 Microchip Technology Incorporated. All Rights Reserved. dsPIC30F Motor Control PWM Module 2

Here is the agenda for today’s seminar.

We will talk about the general structure of the peripheral and then we will have

some details on the period generator and the duty cycle generators. The

different drive capabilities of the output pins will be targeted and we will see

how dead bands help in preventing damages or even the destruction of the

external power stages. The fault pins can help us in this as well.

The A/D syncronization capability permits us to select the exact timing for

starting the conversion.

At the end we will see how the peripheral behaves in the idle and sleep modes,

that is in the power save modes.

© Microchip Technology Inc. Page 2

dsPIC30F Motor Control PWM Module

MCPWM Features

O Dedicated time base with TCY/2 edge resolution

O Complementary or independent outputs

O Hardware dead time generators

O Output pin polarity set with configuration bits

O Multiple output modes

O Manual override

O Fault pins

O Special event trigger for A/D conversion

© 2005 Microchip Technology Incorporated. All Rights Reserved. dsPIC30F Motor Control PWM Module 3

The peripheral uses a dedicated timer for the generation of the PWM

frequency. Its maximum input frequency is the instruction cycle frequency Fcy,

but the duty cycle edge resolution can be enhanced half an instruction cycle for

improved performances.

The peripheral pins can be coupled to give complementary outputs or used as

single ended pins. In both cases the polarity (active high or active low) can be

set as part of the configuration bits.

The implementation of external bridge power circuits requires that the

peripheral should be capable of adding dead times between the commutations

of the two complementary outputs in order to avoid short circuits through the

power transistors. An added safety feature are the fault pins that are capable of

disabling in a very short time the PWM outputs so that “fault” conditions in the

power section of the board are not destructive to the circuitry.

In many motor control applications, like BLDC motors, it is required that the

firmware be able to replace the PWM output with a constant low or high output

signal: the manual override function is what helps in these situations.

For sensorless control of BLDC motors, the necessity of synchronizing the

PWM output to the A/D converter arises. This allows the designer to select the

correct timing for sampling the back emf to determine the run-time position of

the rotor.

© Microchip Technology Inc. Page 3

dsPIC30F Motor Control PWM Module

MC PWM Block Diagram

16-bit Time-base

Duty Cycle PWM4H

Dead Time Unit

Generator #4

PWM4L

Duty Cycle PWM3H

Four PWM output

Dead Time Unit pairs with output

Generator #3

PWM Override PWM3L polarity control

Logic

Duty Cycle PWM2H

Dead Time Unit

Generator #2 PWM2L

Duty Cycle PWM1H

Dead Time Unit

Generator #1 PWM1L

Fault A Two fault pins w/

A/D Conversion programmable fault

Trigger states

Fault B

© 2005 Microchip Technology Incorporated. All Rights Reserved. dsPIC30F Motor Control PWM Module 4

The high level block diagram of the Motor Control PWM module is shown.

We can see the PWM period generator at the top left, the 16-bit Time Base.

The dsPIC is capable of generating up to four output PWM signals, with the

same period but different duty cycles. There are four such units in devices with

64 or more pins.

The Duty cycle generators are followed by the dead time units. The outputs

from these units go through the PWM Override Logic and finally to the output

pins. The output pins are grouped in pairs, to facilitate driving the low side and

high side of a power half-bridge.

The safety fault feature is directly connected to the output stages of the

peripheral in order to have the smallest possible response time.

At the bottom left we can also find the A/D Conversion trigger block.

© Microchip Technology Inc. Page 4

dsPIC30F Motor Control PWM Module

MC-PWM Timebase

O Dedicated 15-bit time-base, period register

O Up count (edge align), up/down count (center align)

O PWM resolution : Tcy/2 For Example:

O At 20 MIPS: 19.5 KHz @ 11 bit

i.e. 11 bit resolution above audible frequencies

O PWM interrupt every 1-16 periods

O 1:1, 1:4, 1:16, or 1:64 prescaler options

PTCON Register

PTEN - PTSIDL - - - - -

bit15 14 13 12 11 10 9 bit8

PTOPS3 PTOPS2 PTOPS1 PTOPS0 PTCKPS1 PTCKPS0 PTMOD1 PTMOD0

bit7 6 5 4 3 2 1 bit0

© 2005 Microchip Technology Incorporated. All Rights Reserved. dsPIC30F Motor Control PWM Module 5

The time base is generated by a 15 bit timer called PTMR with a prescaler

which divides the timebase frequency by 1, 4, 16 or 64. Bit 15 of the PTMR

register indicates the count direction: 0 indicates an upward count and 1

indicates a downward count. This feature allows the unit to generate edge

aligned and center aligned PWM waveforms, as we will see shortly.

The timer content is continuosly compared with the value of the preset period

register. When a period match occurs, an interrupt to the CPU is generated.

The module can be configured to generate an interrupt after up to 16 period

match events. This feature reduces the CPU overhead, since in many

applications the duty cyle value need not be changed one every PWM cycle.

Though the clock to the time base timer is Tcy, the duty cycle resolution is

Tcy/2; this feature can be utlized to obtain finer PWM resolution at lower device

operating speeds, e.g., 11 bits of resolution at 19.5 Khz using a 20 MHz clock.

The PTCON register is used to switch the timer on and off, to halt it in IDLE

mode, to set the prescaler and postscaler value and to select one of the four

operating modes of the peripheral: free running mode, single event mode,

continuos up/down mode, countinuos up/down with double PWM update. We

will discuss these modes in the following foils.

© Microchip Technology Inc. Page 5

dsPIC30F Motor Control PWM Module

Edge Aligned PWM

DUTY CYCLE

UPDATE

PTPER

PDC1

PTMR COUNT

PDC2

Time

PWM1H

PWM2H

INTERRUPTS

PERIOD REGISTER

RELOAD

© 2005 Microchip Technology Incorporated. All Rights Reserved. dsPIC30F Motor Control PWM Module 6

The edge aligned PWM is generated when the time base is operating in Free

Running mode

At the beginning of each period the outputs are driven active (high in this

example). As soon as the timer value, while counting up, matches the value in

any duty cycle register (PDC1, PDC2, and so on), the output is driven inactive

(low here).

The duty cycle registers are updated when the timer register is reset to zero

and start counting up again. The application software can update the duty cycle

value at any time during the period.

Duty cycles from 0% to 100% are allowed.

An interrupt is generated, if enabled, when the timer resets, due to a match with

the PTPER register.

In order to avoid glitches the duty cycle registers are double buffered.

In the figure only two out of four duty cycle registers and outputs are shown.

© Microchip Technology Inc. Page 6

dsPIC30F Motor Control PWM Module

Single Event PWM

PTPER

PDC1

PDC2

Time

PWM1H

PWM2H

INTERRUPT

© 2005 Microchip Technology Incorporated. All Rights Reserved. dsPIC30F Motor Control PWM Module 7

The Single Event feature alllows to generate a single output pulse. Setting the

PTEN enable bit in the PTCON register the timer starts counting up; the bit will

be automatically reset when the timer resets and stops counting.

An interrupt is generated, if enabled, when the timers resets.

When the PTEN bit is set, the I/O pins are driven to their active state: they will

be driven to the inactive state again when a match with a duty cycle register

occurs.

© Microchip Technology Inc. Page 7

dsPIC30F Motor Control PWM Module

Center Aligned PWM

DUTY CYCLE UPDATE

PTPER

PDC1

PDC2

Time

PWM1H

PWM2H

INTERRUPTS

PERIOD

REGISTER

RELOAD

© 2005 Microchip Technology Incorporated. All Rights Reserved. dsPIC30F Motor Control PWM Module 8

In the center aligned mode, the time base is an up-down counter: it starts from

zero, counts up to the value in the period register and then counts down to zero

and so on. Bit 15 in the timer register indicates the counting direction. In this

mode, the PWM period is twice the time base period.

The duty cycle buffers are updated when the timer is reset to zero; the interrupt

flag is set at the same time.

As you can see from the figure, the PWM waveform is centered around the

instant in time when the timer reaches its maximum value and start counting

back: from this the name “center aligned”.

Although the PWM frequency is half the edge aligned PWM, this mode is very

useful because it avoids the simultaneous switching of all the PWM outputs at

the same time. This is not a problem for the device itself, but since power

switches are connected to these outputs, the switching current can be quite

high and may require an oversized power supply.

© Microchip Technology Inc. Page 8

dsPIC30F Motor Control PWM Module

Center Aligned PWM with

Double Update

DUTY CYCLE

UPDATE

PTPER

PDC1

PDC2

Time

PWM1H

PWM2H

INTERRUPTS

PERIOD

REGISTER

RELOAD

© 2005 Microchip Technology Incorporated. All Rights Reserved. dsPIC30F Motor Control PWM Module 9

This mode is quite similar to the previous one. The time base operates in a

continuous up/down count mode.The main difference is that the duty cycle

buffer update is done twice per period: when the timer reaches zero and when it

counts to the upper limit.

The advantage is that the output PWM waveform is no more symmetrical.

Again the interrupt flags are set when the timer reaches zero.

© Microchip Technology Inc. Page 9

dsPIC30F Motor Control PWM Module

Dead Time Control

O Applies only to pin pairs in complementary mode

O Two programmable dead times

O One dead time per pair for multiple inverters OR

O Two dead times per pair for distortion optimization

O Tcy minimum resolution with four pre-scale options

Dead Time A Dead Time B

PWM1H

PWM1H

PWM1L

PWM1L

© 2005 Microchip Technology Incorporated. All Rights Reserved. dsPIC30F Motor Control PWM Module 10

The dead time unit immediately follows the duty cycle generators and applies

only in complementary mode. Since power switches in the high and low sides

usually have different on and off times, if both were operated at the same time it

is possible that the two transistors in a complementary pin-pair are switched on

simultaneously for a short duration: this causes a short circuit betweeen the

supply rails and a huge amount of current flows through the devices, potentially

causing damage to the system.

The solution is to delay the switching of the two transistors by adding a small

amount of time between the falling edge of one pin and the rising edge of the

other.

You can select one or two different dead times; the devices with 6 output pins

provide one dead time whereas those with 8 outputs have two. Having 2 dead

time units is useful in 2 ways. First, to compensate for the difference in the

switching times of the 2 transistors in the same complementary pair. Second, to

enable control of different motor drive circuits using different complementary

pin-pairs.

© Microchip Technology Inc. Page 10

dsPIC30F Motor Control PWM Module

Dead Time Registers

O DTCON1 selects dead time value for A and B

DTBPS1 DTBPS0 DTB<5:0>

bit15 14 13 12 11 10 9 bit8

DTAPS1 DTAPS0 DTA<5:0>

bit7 6 5 4 3 2 1 bit0

O DTCON2 selects which dead time value is assigned

to the active(A) or inactive(I) edge of each generator

- - - - - - - -

bit15 14 13 12 11 10 9 bit8

DTS4A DTS4I DTS3A DTS3I DTS2A DTS2I DTS1A DTS1I

bit7 6 5 4 3 2 1 bit0

© 2005 Microchip Technology Incorporated. All Rights Reserved. dsPIC30F Motor Control PWM Module 11

Two registers are used to enable and program the dead band generator. It is

based on a 6 bit down counter with a maximum clock frequency of Fcy

optionally divided by a 1:2, 1:4 or 1:8 prescaler.

Register DTCON1 selects the period match value and the prescaler for both

dead time generators, called A and B.

Register DTCON2 allows selection of the dead time unit (A or B) for each

output pin (low and high) and for each edge (rising an falling). Thus, the

designer has full control over dead time insertion.

© Microchip Technology Inc. Page 11

dsPIC30F Motor Control PWM Module

Complementary Outputs

+V

3 Phase

BLDC or

1H 2H 3H ACIM

1L 2L 3L

© 2005 Microchip Technology Incorporated. All Rights Reserved. dsPIC30F Motor Control PWM Module 12

Each output pin pair can be programmed in the independent mode or in the

complementary mode.

In the independent mode the dead time generators are disabled and there is no

restriction in the state of the pins for any output pin pair.

The complementary mode is very useful in driving loads such as the inverter in

this figure, that could be used for any three phase load, for example: Brushless

DC Motors and Induction Motors. As we have seen, dead time insertion helps

preventing short circuits between the two rails through each couple of

transistors.

Through device configuration bits, the reset-state polarity of the output pins can

be selected.

The HPOL bits in the BOR/POR configuration register determines whether the

high-side output pins must have an active high or low output polarity. The LPOL

bits in the same register set the low-side active high or low polarity.

Moreover, at reset the peripheral output pins can be controlled by PORT

registers, that is, they are normal input-output pins initilized as inputs, or they

can be directly controlled by the Motor Control PWM module as output pins.

© Microchip Technology Inc. Page 12

dsPIC30F Motor Control PWM Module

Independent Outputs

O Independent mode is used for switched reluctance

motors

O Special inverter circuit to control current in SR motors

O Independent mode enables both devices to turn on

+V

PWM1H PWM2H PWM3H PWM4H

PWM1L PWM2L PWM3L PWM4L

© 2005 Microchip Technology Incorporated. All Rights Reserved. dsPIC30F Motor Control PWM Module 13

This is an example where all the four PWM outputs are used in independent

mode to drive a Switched Reluctance motor, where each pair of outputs drives

one phase of the stator.

© Microchip Technology Inc. Page 13

dsPIC30F Motor Control PWM Module

Output Override

O Used for motor commutation

O Drive PWM or Drive active or inactive

O POVD bits decide if I/O pin is controlled manually

O POUT bits set state of I/O pin under manual control

O Dead time requirements are always satisfied in

complementary mode

OVDCON Register

POVD4H POVD4L POVD3H POVD3L POVD2H POVD2L POVD1H POVD1L

bit15 14 13 12 11 10 9 bit8

POUT4H POUT4L POUT3H POUT3L POUT2H POUT2L POUT1H POUT1L

bit7 6 5 4 3 2 1 bit0

© 2005 Microchip Technology Incorporated. All Rights Reserved. dsPIC30F Motor Control PWM Module 14

The manual override control bits allow the user to implement motor

commutation. Through the control bits, a particular output pin may be

programmed to receive the PWM signal from the duty cycle generator, driven

active, or driven inactive. There is a POVD control bit for each PWM output

pin. If this bit is cleared, the pin will output a PWM signal. If the POVD bit is

set, the pin will be controlled manually. There is a POUT bit for each PWM pin

that sets the state of the pin when the output is manually controlled.

Restrictions for complementary outputs cannot be violated through manual

PWM control. When the module is operating in the complementary mode, the

signals on each high-side ouput pin will take priority and the proper dead time

will always be inserted.

© Microchip Technology Inc. Page 14

dsPIC30F Motor Control PWM Module

Output Override

O Using PWM for 6-step modulation

O Energize BLDC motor coils based on

measured rotor position

O PWM override register used to control active

transistors -- duty cycle sets current

1 2 3 4 5 6

PWM1H

+V

3 Phase PWM1L

1H 2H 3H BLDC

PWM2H

PWM2L

1L 2L 3L

PWM3H

PWM3L

© 2005 Microchip Technology Incorporated. All Rights Reserved. dsPIC30F Motor Control PWM Module 15

This is a typical application of the override capability. In order to be able to

control the rotor speed, the PWM is output on the high side transistors: its duty

cycle will determine the medium voltage applied to the motor and hence its

speed. The required software overhead is really minimum.

© Microchip Technology Inc. Page 15

dsPIC30F Motor Control PWM Module

Fault Pins

O Two programmable fault pins: Fault A, Fault B

O Fault pins can be assigned to each output pair

O Fault pin asynchronously over-rides PWM output

O Fault state for each output is programmable

O Automatic or latched fault protection

O Interrupt vector for each fault input

FLTACON Register

FAOV4H FAOV4L FAOV3H FAOV3L FAOV2H FAOV2L FAOV1H FAOV1L

bit15 14 13 12 11 10 9 bit8

FLTAM - - - FAEN4 FAEN3 FAEN2 FAEN1

bit7 6 5 4 3 2 1 bit0

© 2005 Microchip Technology Incorporated. All Rights Reserved. dsPIC30F Motor Control PWM Module 16

The fault pins are safety features: if asserted, they will drive the PWM I/O pins

to a defined state. The action takes place without software intervention, thus

allowing fast and safe response to system failures.

In the smallest devices you can find one fault pin (FLTA), the bigger ones have

them all (FLTA and FLTB). They are active low inputs so that you can easily

wire-OR many different sources.

The FAEN bits allows you to select if any output pin-pair will be controlled by

the fault pins when a fault occurs.

If the functionality is enabled, as soon any fault pin is asserted, the PWM output

pins will go active or inactive according to the content of the upper part of the

FLTACON (or FLTBCON) register.

Each fault pin has its own interrupt vector, flag and interrupt priority register.

There are two different operating modes. In the latched mode as soon as the

fault pin is asserted, the PWM output will get the value defined in the FLTxCON

register. The outputs will remain in this state until the fault pin is deasserted and

the corresponding interrupt flag is cleared.

In the automatic mode, the outputs will keep the fault value as long as the fault

pin is asserted. When released, at the beginning of the following PWM period,

the output will return to normal PWM operation.

© Microchip Technology Inc. Page 16

dsPIC30F Motor Control PWM Module

A/D Synchonization

O SEVTCMP register sets A/D

conversion start time

O SEVTDIR bit sets direction of

PTMR

O Ensure A/D properly captures

shunt current

To A/D

O Minimize control loop update

delay

© 2005 Microchip Technology Incorporated. All Rights Reserved. dsPIC30F Motor Control PWM Module 17

The PWM module has a special trigger that allows the A/D converter to be

synchronized to the PWM time base. This trigger will start the conversion phase

of the A/D block, in order to minimize the delay between getting the A/D

conversion result and updating the duty cycle value.

The Special Event Compare Register is loaded with a number which is

compared to the content of the time base timer, while this one is counting up or

down. The counting direction is set by the Special Event Direction bit. As soon

as there is a match between the two registers, the trigger is generated and the

A/D conversion is started.

This feature is very useful for synchronizing with the phase drive signals the

reading of the shunt currents or the reading of the back emf in a sensorless

BLDC motor control.

© Microchip Technology Inc. Page 17

dsPIC30F Motor Control PWM Module

MC PWM in Power Save Modes

O In SLEEP mode all PWM output pins are frozen to

the value prior to entering sleep

O Fault pins are active

O Fault event wakes the device from sleep

O In IDLE mode the PWM can optionally continue to

operate

O Time base interupt wakes the devise from IDLE

© 2005 Microchip Technology Incorporated. All Rights Reserved. dsPIC30F Motor Control PWM Module 18

Finally, let us study the oepration of the peripheral in device power save modes.

In sleep mode the PWM output pins will retain the value that they had when entering sleep. It is

your responsability to put the output pins in a known state before entering power save: this can

be very important for some kind of loads.

During sleep the fault pins, if enabled, will continue to control the outputs, so that if any fault

input is asserted the output PWM pins will be driven to the state programmed into the Fault

Control register. If the fault interrupt enable pin is set, the device will be waken up from sleep

when the fault pin is asserted. If the interrupt priority is higher than the current CPU priority the

ISR will be served, otherwise the code execution will continue from the next instruction following

the PWRSAV instruction.

In IDLE mode the PWM peripheral can be completely functional, according to the value of the

PWM Time Base Stop in IDLE Mode Bit. If reset, the unit will operate normally. The time base

interrupt, if enabled, will wake the unit. Code execution will continue with the ISR if the priority is

higher than the CPU priority or with the next instruction after the PWRSAV instruction.

A last feature is worth mentioning, which is extremely useful during code debugging. The PWM

pins can be optionally tri-stated when the emulator or the debugger is halted. You should install

pull-up or pull-down resistor in order to ensure that the PWM outputs are diven to the correct

state so that external hardware is not damaged.

© Microchip Technology Inc. Page 18

dsPIC30F Motor Control PWM Module

Key Support Documents

Device Selection Reference Document #

General Purpose and Sensor Family Data Sheet DS70083

Motor Control and Power Conv. Data Sheet DS70082

dsPIC30F Family Overview DS70043

Base Design Reference Document #

dsPIC30F Family Reference Manual DS70046

dsPIC30F Programmer’s Reference Manual DS70030

MPLAB MPLAB® C30 C Compiler User User’s Guide DS51284

MPLAB ASM30, LINK30 & Utilities User DS51317

dsPIC® Language Tools Libraries DS51456

© 2005 Microchip Technology Incorporated. All Rights Reserved. dsPIC30F Motor Control PWM Module 19

For more information, here are references to some important documents that

contain a lot of information about the dsPIC30F family of devices.

The Family Reference Manual contains detailed information about the

architecture and peripherals, whereas the Programmer’s Reference Manual

contains a thorough description of the instruction set.

© Microchip Technology Inc. Page 19

dsPIC30F Motor Control PWM Module

Key Support Documents

Device Specific Reference Document #

O dsPIC30F2010 Data Sheet DS70118

O dsPIC30F3010/3011 Data Sheet DS70141

O dsPIC30F4011/4012 Data Sheet DS70135

O dsPIC30F6010 Data Sheet DS70119

Microchip Web Site: www.microchip.com

© 2005 Microchip Technology Incorporated. All Rights Reserved. dsPIC30F Motor Control PWM Module 20

For device-specific information such as pinout diagrams, packaging and

electrical characteristics, the device datasheets listed here are the best

source of information.

© Microchip Technology Inc. Page 20

dsPIC30F Motor Control PWM Module

Related Material

O Apps Notes on Motor Control

AN901 Using the dsPIC30F for Sensorless BLDC Control

AN908 Using the dsPIC30F for Vector Control of an ACIM

AN957 Sensored BLDC Motor Control Using dsPIC30F2010

© 2005 Microchip Technology Incorporated. All Rights Reserved. dsPIC30F Motor Control PWM Module 21

We also have some application notes on motor control, in which the peripheral

is extensively used.

All these documents can be obtained from the Microchip web site, by clicking

on the “dsPIC® Digital Signal Controllers” or “Technical Documentation” link.

This wraps up the seminar on dsPIC30F Motor Control Peripheral. Thank you

for your interest in the dsPIC30F Family of Digital Signal Controllers.

© Microchip Technology Inc. Page 21

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Materials Science and Engineering Notes 091110Document12 pagesMaterials Science and Engineering Notes 091110Mete MetelanNo ratings yet

- Sparet Parts V3F80Document44 pagesSparet Parts V3F80Edgar Flores100% (2)

- Sad Raf Shari 2016Document9 pagesSad Raf Shari 2016mhmedNo ratings yet

- HoodsDocument56 pagesHoodscivodulNo ratings yet

- Indirect Matrix Converter Based On Investigations of Field-Oriented Control For Induction MotorDocument1 pageIndirect Matrix Converter Based On Investigations of Field-Oriented Control For Induction MotorSanhith ChowdaryNo ratings yet

- Filters and Tuned Amplifiers: Passive LC Filters Inductorless Filters Active-RC Filters Switched CapacitorsDocument31 pagesFilters and Tuned Amplifiers: Passive LC Filters Inductorless Filters Active-RC Filters Switched Capacitorspardeep184No ratings yet

- RectifiersDocument32 pagesRectifiersdilla11230% (1)

- Semikron SKKT 330Document5 pagesSemikron SKKT 330shubham kulshreshthaNo ratings yet

- 330W PERC Half-Cell Module: JAM60S03 310-330/PRDocument2 pages330W PERC Half-Cell Module: JAM60S03 310-330/PRSérgio CerdeiraNo ratings yet

- Philips AZ 1837 Service Manual PhilipsDocument38 pagesPhilips AZ 1837 Service Manual PhilipsAnom Manela100% (2)

- FormulatingDocument123 pagesFormulatingRaju100% (2)

- Best Deals 2012Document18 pagesBest Deals 2012mshopowNo ratings yet

- (Top View) : Input Output Adj/Gnd 1 2 3Document19 pages(Top View) : Input Output Adj/Gnd 1 2 3Bhadreshkumar SharmaNo ratings yet

- Capacitor LifeDocument17 pagesCapacitor Lifelimkokchiang809No ratings yet

- Optical Emission From SemiconductorsDocument36 pagesOptical Emission From SemiconductorsvardhanNo ratings yet

- Moulded - Case - Circuit BreakerDocument84 pagesMoulded - Case - Circuit BreakerSanatan JhaNo ratings yet

- Balun Application Notes MACONDocument4 pagesBalun Application Notes MACONMOISES DOS SANTOSNo ratings yet

- Flow Measurement and ControlDocument43 pagesFlow Measurement and ControlCao AnhNo ratings yet

- Your Best Chance For: International OffersDocument9 pagesYour Best Chance For: International Offersumesh kumarNo ratings yet

- Module 3 (Atomic Structure in Solids)Document25 pagesModule 3 (Atomic Structure in Solids)Ralph Andrew SilverioNo ratings yet

- Semiconductor KIA78R05PI KIA78R15PI: Technical DataDocument8 pagesSemiconductor KIA78R05PI KIA78R15PI: Technical DataMihai AlexandruNo ratings yet

- Technical Explanation: Skiip 3 V3Document49 pagesTechnical Explanation: Skiip 3 V3marco_christoforidisNo ratings yet

- LIC FLEXI Lab Manual Second Experiment Student Copy-3Document5 pagesLIC FLEXI Lab Manual Second Experiment Student Copy-3Vignesh RamakrishnanNo ratings yet

- PI734G - Winding 312: Technical Data SheetDocument9 pagesPI734G - Winding 312: Technical Data SheetLukiNo ratings yet

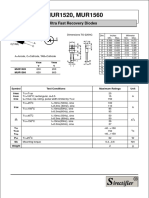

- Mur 1560Document3 pagesMur 1560cesarNo ratings yet

- PSC, NepalDocument4 pagesPSC, NepalNiraj BoharaNo ratings yet

- TDS Silica Fume For ConstructionDocument1 pageTDS Silica Fume For Constructionlpumsun1No ratings yet

- Datasheet PDFDocument4 pagesDatasheet PDFAndrés Olympus 593No ratings yet

- C7950 SERIES: FeaturesDocument2 pagesC7950 SERIES: Features박만진No ratings yet

- Free ScaleDocument39 pagesFree ScaleRavi VarmaNo ratings yet