Professional Documents

Culture Documents

Certificate in Process Plant Layout & Piping Design - Engineering Institute

Uploaded by

murthykeshavaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Certificate in Process Plant Layout & Piping Design - Engineering Institute

Uploaded by

murthykeshavaCopyright:

Available Formats

Certificate in Process Plant Layout & Piping Design | Engineering Institute of Technology

Certificate in Fundamentals of Process Plant Layout and Piping Design

WHAT YOU WILL LEARN

Plant layout fundamentals and work flow procedures

Terminology and symbols used in plant layout

Plot plans, elevations and 3-D models

Fundamental principles of chemical process technology

Process flow diagrams (PFDs)

Equipment used in process plants

Instrument symbols and abbreviations

Piping and instrumentation diagrams (P&IDs)

Piping design and engineering principles

Terminology, symbols and abbreviations used in piping design

Piping materials

Piping specifications and piping codes

Components of piping systems - fittings, flanges and valves

Piping isometrics and bill of materials

Course Overview

Process plants, such as refineries and petrochemical plants, are complex facilities consisting of equipment, piping systems, instruments, electrical systems, electronics,

computers, and control systems. The design, engineering and construction of process plants involves a multidisciplinary team effort. Plant layout and design of piping

systems constitutes a major part of the design and engineering effort. The goal is to design safe and dependable processing facilities in a cost effective manner. The

fact is that there are very few formal training programs that focus on design and engineering of process plants and piping systems. Therefore, most of the required

skills are acquired while on the job, reducing productivity and efficiency.

The objective of this course is to provide the delegates the basic knowledge and skills in this discipline to facilitate faster learning curves while on the job. This course

will cover the fundamental principles and concepts used in process plant layout and piping design. Upon completion of this course the delegates will have a clear

understanding of the design and engineering principles used in plant layout and piping design.

COURSE OUTLINE

UNIT 1: Introduction to Process Plant Layout and Piping Design

Plant layout fundamentals

Procedures and workflow

Physical quantities and units

UNIT 2: Introduction to Chemical Processing Methods

Unit operations and unit processes

Process flow diagrams (PFDs)

Heating and cooling utilities used in process plants

Typical equipment specifications

UNIT 3: Equipment Used in Process Plants - I

Process equipment

Reactors - Towers

Exchangers - Furnaces

Vessels

Mechanical equipment

Pumps - Compressors

Turbines

Equipment foundations and supports

UNIT 4: Equipment Used in Process Plants - II (Documents)

http://www.eit.edu.au/certificate-process-plant-layout-piping-design[10/17/2010 8:20:51 AM]

Certificate in Process Plant Layout & Piping Design | Engineering Institute of Technology

Equipment data sheets

Equipment sketches

Equipment drawings

Equipment nozzle specifications

Equipment foundation drawings

UNIT 5: Plant Layout and Plot Plans

Plant layout specifications

Codes and safety considerations

Development of plot plans

Plot plan use by disciplines

Sample plot plans and equipment arrangement drawings

Layout case studies

UNIT 6: Piping Materials and Material Specifications

Material properties

Classification of materials

Material specifications (ASTM)

Common piping materials

Piping specifications

Material selection

Material testing, inspection and QA

UNIT 7: Piping and Instrumentation Diagrams (P&IDs) - I

P&ID basics

Use of P&IDs by different disciplines

Information contained in P&IDs

Instruments and instrument symbols

UNIT 8: Piping and Instrumentation Diagrams (P&IDs) - II

Local control, DCS and PLC

Discussion of a sample P&ID

Control valve manifolds

Meter runs

UNIT 9: Plant Layout and Piping Design Documentation and Tools - I

Piping codes

Piping specifications

Equipment lists

Piping line lists

UNIT 10: Plant Layout and Piping Design Documentation and Tools - II

Stress isometrics

Piping isometrics and Bill of Materials

PFDs, plot plans, and P&IDs

3D models

UNIT 11: Fundamentals of Pipe and Pipe Fittings

Pipe dimensions and pipe representation

Use of pipe data tables

Pipe joining methods

Pipe fittings

- Elbows

- Tees

- Reducers

- End caps

http://www.eit.edu.au/certificate-process-plant-layout-piping-design[10/17/2010 8:20:51 AM]

Certificate in Process Plant Layout & Piping Design | Engineering Institute of Technology

Fitting dimensions and tables

UNIT 12: Piping System Components

Basics of flanges

Flange ratings and flange types

Flange data tables and their use

Different types of valves and their applications

Valve data tables

Piping restraints

Supports, anchors and guides

http://www.eit.edu.au/certificate-process-plant-layout-piping-design[10/17/2010 8:20:51 AM]

You might also like

- Engineering Fee Estimate TemplateDocument1 pageEngineering Fee Estimate TemplateJoey RazoNo ratings yet

- SOP Compressed GasesDocument13 pagesSOP Compressed GasesShamsol AriffinNo ratings yet

- Piping & Instrumentation DiagramDocument15 pagesPiping & Instrumentation Diagramplanet123No ratings yet

- Moors Sovereign Dollarium 500 Gold Backed Dollarium PicautoDocument2 pagesMoors Sovereign Dollarium 500 Gold Backed Dollarium Picautoakil kemnebi easley elNo ratings yet

- Piping EngineeringDocument15 pagesPiping EngineeringRANJITHNo ratings yet

- PROJECT STANDARDS and SPECIFICATIONS Instrumentation Project Engineering Rev01Document20 pagesPROJECT STANDARDS and SPECIFICATIONS Instrumentation Project Engineering Rev01Laurence Malanum50% (2)

- Piping DesignDocument4 pagesPiping DesignTerry YongNo ratings yet

- Well Testing Project Management: Onshore and Offshore OperationsFrom EverandWell Testing Project Management: Onshore and Offshore OperationsNo ratings yet

- 1 Aerodynamics Lecture - Viscous FlowDocument70 pages1 Aerodynamics Lecture - Viscous Flowccoyure100% (2)

- 07 101 Production Jack UpsDocument4 pages07 101 Production Jack UpsShamsol Ariffin100% (1)

- Pistep Act ModDocument13 pagesPistep Act ModkamlNo ratings yet

- Process Plant Eng Activity ModelDocument43 pagesProcess Plant Eng Activity Modelمحمد يازيد هوساينNo ratings yet

- PG PipingMainDocument7 pagesPG PipingMainAnh Vân Trần100% (1)

- Piping Study Material - RoltaDocument49 pagesPiping Study Material - Roltahummingbird4u92% (12)

- Sibp Gep Design PlanningDocument8 pagesSibp Gep Design PlanningEnrique PomalesNo ratings yet

- Automatic Instruments and Measuring Systems: Jones' Instrument TechnologyFrom EverandAutomatic Instruments and Measuring Systems: Jones' Instrument TechnologyRating: 5 out of 5 stars5/5 (1)

- Product Manufacturing and Cost Estimating using CAD/CAE: The Computer Aided Engineering Design SeriesFrom EverandProduct Manufacturing and Cost Estimating using CAD/CAE: The Computer Aided Engineering Design SeriesRating: 4 out of 5 stars4/5 (4)

- Mary Szybist On Visual Poetry Compressed PDFDocument5 pagesMary Szybist On Visual Poetry Compressed PDFcarlos.enrique.fonseca1440No ratings yet

- Kitchen Window Herb GardenDocument2 pagesKitchen Window Herb GardenNevin SmithNo ratings yet

- ISO 8861 Blower Engine RoomDocument28 pagesISO 8861 Blower Engine Roommohammad choirul huda100% (1)

- Project Engineering in Oil & Gas Industry SharedDocument24 pagesProject Engineering in Oil & Gas Industry SharedKojiro Hadate100% (3)

- Process Piping Design & Engineering Per ASME B 31.3Document13 pagesProcess Piping Design & Engineering Per ASME B 31.3Gaurav PanjwaniNo ratings yet

- Mission-Critical and Safety-Critical Systems Handbook: Design and Development for Embedded ApplicationsFrom EverandMission-Critical and Safety-Critical Systems Handbook: Design and Development for Embedded ApplicationsRating: 5 out of 5 stars5/5 (1)

- Fundamentals of Process Plant Layout and Piping DesignDocument2 pagesFundamentals of Process Plant Layout and Piping DesignSamer Houzayn67% (3)

- Process P ID Training 1705304683Document130 pagesProcess P ID Training 1705304683rajesh_sgNo ratings yet

- Introduction To Process Plant Layout and Piping DesignDocument39 pagesIntroduction To Process Plant Layout and Piping DesignJohn Jhay Canlas100% (2)

- Chemical and Process Plant Commissioning Handbook: A Practical Guide to Plant System and Equipment Installation and CommissioningFrom EverandChemical and Process Plant Commissioning Handbook: A Practical Guide to Plant System and Equipment Installation and CommissioningNo ratings yet

- Ingenieria Basica y Detalle ISADocument50 pagesIngenieria Basica y Detalle ISAdalver17100% (1)

- Pump and CompressorDocument26 pagesPump and CompressorShamsol AriffinNo ratings yet

- Chapter 1Document40 pagesChapter 1Hadeer AlbalushiNo ratings yet

- The Engineer's Guide to Plant Layout and Piping Design for the Oil and Gas IndustriesFrom EverandThe Engineer's Guide to Plant Layout and Piping Design for the Oil and Gas IndustriesRating: 4 out of 5 stars4/5 (16)

- Magnus Process Design EquipmentDocument5 pagesMagnus Process Design EquipmentAditya DharanipragadaNo ratings yet

- Process Design Course-PD01Document4 pagesProcess Design Course-PD01Junaid ParkerNo ratings yet

- Thermal Power Plant: Pre-Operational ActivitiesFrom EverandThermal Power Plant: Pre-Operational ActivitiesRating: 4 out of 5 stars4/5 (4)

- 6engineer ActivityDocument43 pages6engineer ActivitymkrasanNo ratings yet

- Welding Dissimilar MetalsDocument6 pagesWelding Dissimilar MetalsNitintak100% (1)

- Process Piping DraftingDocument3 pagesProcess Piping DraftingtsplinstNo ratings yet

- Eng MGT Training 2015 IFPTDocument95 pagesEng MGT Training 2015 IFPTihllhm100% (1)

- Project Standards and Specifications Process Control Package Rev01Document10 pagesProject Standards and Specifications Process Control Package Rev01Ahmad EmamNo ratings yet

- Process Piping Design & EngineeringDocument4 pagesProcess Piping Design & Engineeringtibi1000No ratings yet

- Iec 60812-2006Document11 pagesIec 60812-2006Refibrian Dwiki100% (1)

- Process Plant Layout and Piping Design: Fundamentals ofDocument4 pagesProcess Plant Layout and Piping Design: Fundamentals ofSolakhudin Al Ayubi100% (1)

- Engineering Applications: A Project Resource BookFrom EverandEngineering Applications: A Project Resource BookRating: 2.5 out of 5 stars2.5/5 (1)

- PG Diploma in Piping Design and Autocad Training CourseDocument4 pagesPG Diploma in Piping Design and Autocad Training CourseWin LinnNo ratings yet

- Understanding Blow Molding: Norman C. LeeDocument11 pagesUnderstanding Blow Molding: Norman C. LeeKiran ModakNo ratings yet

- Practical Process Plant Layout and Piping DesignDocument136 pagesPractical Process Plant Layout and Piping Designgonvic7411No ratings yet

- Test Engleza Clasa A5a Modul 3Document3 pagesTest Engleza Clasa A5a Modul 3Adelina HasasNo ratings yet

- Pipe Flange and Gaskets BasicsDocument3 pagesPipe Flange and Gaskets BasicsEhab AbowardaNo ratings yet

- Professional Certificate of Competency in The Fundamentals of Process Plant LayoutDocument28 pagesProfessional Certificate of Competency in The Fundamentals of Process Plant LayoutNellis BlancoNo ratings yet

- Competency in Process Plant Layout and Piping Design - 2Document3 pagesCompetency in Process Plant Layout and Piping Design - 2Bonzibit ZibitNo ratings yet

- 312013145817piping Design Engineering With PDMS Training CourseDocument4 pages312013145817piping Design Engineering With PDMS Training CourseAsan IbrahimNo ratings yet

- Process Plant Layout and Piping Design: Lesson 1 - PrelimsDocument17 pagesProcess Plant Layout and Piping Design: Lesson 1 - PrelimsRaia SeoNo ratings yet

- Piping EngineeringDocument2 pagesPiping EngineeringSuvidya Institute of TechnologyNo ratings yet

- Diploma in Piping Engineering - Couse On Piping Engineering in Mumbai - Professional Training Couse in Piping EngineeringDocument2 pagesDiploma in Piping Engineering - Couse On Piping Engineering in Mumbai - Professional Training Couse in Piping EngineeringSuvidya Institute of Technology50% (2)

- Ee 1C Lesson 5 Instrumentation DocumentationDocument10 pagesEe 1C Lesson 5 Instrumentation DocumentationJohnNo ratings yet

- 1 General MOOCDocument49 pages1 General MOOCMahathir Che Ap100% (1)

- PT-E - Fundamentals of Process Plant Layout and Piping DesignDocument14 pagesPT-E - Fundamentals of Process Plant Layout and Piping DesignNofrizal HasanNo ratings yet

- Fundamentals of Process Plant Layout and Piping Design: 12 Modules Over 3 MonthsDocument3 pagesFundamentals of Process Plant Layout and Piping Design: 12 Modules Over 3 MonthsAnkitaSharmaNo ratings yet

- Suvidya Institute of TechnologyDocument1 pageSuvidya Institute of Technologygandhisagar76No ratings yet

- Mechanical Design of Process EquipmentsDocument2 pagesMechanical Design of Process EquipmentsSuvidya Institute of TechnologyNo ratings yet

- Depps - Abu DhabiDocument10 pagesDepps - Abu Dhabiamli22No ratings yet

- Product Performance Evaluation using CAD/CAE: The Computer Aided Engineering Design SeriesFrom EverandProduct Performance Evaluation using CAD/CAE: The Computer Aided Engineering Design SeriesNo ratings yet

- Configuring Catalyst SwitchDocument22 pagesConfiguring Catalyst SwitchShamsol AriffinNo ratings yet

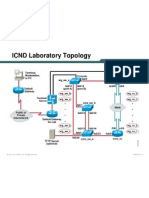

- ICND Laboratory Topology: © 2004 Cisco Systems, Inc. All Rights ReservedDocument3 pagesICND Laboratory Topology: © 2004 Cisco Systems, Inc. All Rights ReservedShamsol AriffinNo ratings yet

- ICND Laboratory Topology: © 2004 Cisco Systems, Inc. All Rights ReservedDocument15 pagesICND Laboratory Topology: © 2004 Cisco Systems, Inc. All Rights ReservedShamsol AriffinNo ratings yet

- CCNA INTRO1.0a Knet HiResDocument822 pagesCCNA INTRO1.0a Knet HiResShamsol AriffinNo ratings yet

- CCNA INTRO1.0a Knet HiResDocument822 pagesCCNA INTRO1.0a Knet HiResShamsol AriffinNo ratings yet

- Installation Instructions For Cable Gland Type A2F: Certificate References: Sira 06 Atex 1097X Iecex Sir 06.0039XDocument9 pagesInstallation Instructions For Cable Gland Type A2F: Certificate References: Sira 06 Atex 1097X Iecex Sir 06.0039XShamsol AriffinNo ratings yet

- Lab 9.1.5b Trunking With 802.1q: ObjectiveDocument8 pagesLab 9.1.5b Trunking With 802.1q: ObjectiveShamsol AriffinNo ratings yet

- Hydrogen Codes and Standards Workshop: Naser ChowdhuryDocument24 pagesHydrogen Codes and Standards Workshop: Naser ChowdhuryDiana DhominicNo ratings yet

- CSCI101 - Lab08 - Functions Zewail CityDocument4 pagesCSCI101 - Lab08 - Functions Zewail CityMahmoud Ahmed 202201238No ratings yet

- In-Lab Sharp-Edged Orifice Meter ReportDocument9 pagesIn-Lab Sharp-Edged Orifice Meter ReportLiliane AlameddineNo ratings yet

- Poisson, Poisson-Gamma and Zero-Inflated Regression ModelsDocument43 pagesPoisson, Poisson-Gamma and Zero-Inflated Regression ModelszohrehNo ratings yet

- Product Presentation SphereOX - ChromiteDocument9 pagesProduct Presentation SphereOX - ChromiteÖzgür ÇalışkanNo ratings yet

- Farm Size Factor Productivity and Returns To ScaleDocument8 pagesFarm Size Factor Productivity and Returns To ScaleAkshay YadavNo ratings yet

- Ste FannyDocument17 pagesSte FannyElmer DE LA CruzNo ratings yet

- Spring Diameter of Spring Coil/cm Elastic Limit/n Spring Constant/nm-1 MaterialDocument4 pagesSpring Diameter of Spring Coil/cm Elastic Limit/n Spring Constant/nm-1 MaterialZahari Bin BakriNo ratings yet

- Loving Vincent: by Dorota KobielaDocument45 pagesLoving Vincent: by Dorota KobielaFairut CharrisNo ratings yet

- Mcbe2798 e 10 1Document42 pagesMcbe2798 e 10 1Manh DuyNo ratings yet

- Piping - Fitings HandbookDocument240 pagesPiping - Fitings HandbookzohirNo ratings yet

- Vandex Plug: Rapid-Setting, Crystalline Hydraulic CementDocument2 pagesVandex Plug: Rapid-Setting, Crystalline Hydraulic CementQuerubin EboliNo ratings yet

- LUXEON Altilon SMDDocument25 pagesLUXEON Altilon SMDBertram PredikNo ratings yet

- Business, Government & Society: Pawan Kumar N K 12301005Document8 pagesBusiness, Government & Society: Pawan Kumar N K 12301005Pawan NkNo ratings yet

- Lecture-I Introduction To Concrete TechnologyDocument102 pagesLecture-I Introduction To Concrete Technologyjs kalyana rama100% (4)

- Apple Computer Inc. v. Burst - Com, Inc. - Document No. 146Document39 pagesApple Computer Inc. v. Burst - Com, Inc. - Document No. 146Justia.comNo ratings yet

- ETP Combined Spec - R0Document60 pagesETP Combined Spec - R0Pravash Chandra Senapaty100% (1)

- Unit 2 SignalsDocument3 pagesUnit 2 SignalsDigitallogicdlNo ratings yet

- January 2005 6677 Mechanics M1: Mark SchemeDocument7 pagesJanuary 2005 6677 Mechanics M1: Mark SchemeWael TareqNo ratings yet

- Case How Innovation Drives Research and DevelopmentDocument4 pagesCase How Innovation Drives Research and DevelopmentMohit KumarNo ratings yet

- Montague Street Cable Car, Wall Street FerryDocument23 pagesMontague Street Cable Car, Wall Street FerryBob DiamondNo ratings yet

- Group 3 Aia ReportDocument26 pagesGroup 3 Aia ReportNAVAS E VNo ratings yet