Professional Documents

Culture Documents

Department of Mechanical and Design Engineering

Department of Mechanical and Design Engineering

Uploaded by

dantan187Copyright:

Available Formats

You might also like

- Plastic Processing Question Paper 2016Document27 pagesPlastic Processing Question Paper 2016Supreeth Premkumar100% (2)

- De Thi ISE - Work Design - Mar - 2013 - Midterm - Soln - ThaoDocument5 pagesDe Thi ISE - Work Design - Mar - 2013 - Midterm - Soln - ThaoMBSNo ratings yet

- Automatic Perform Shape Optimization For The Stretch Blow Molding ProcessDocument6 pagesAutomatic Perform Shape Optimization For The Stretch Blow Molding Processhed_panNo ratings yet

- Bottle Blow MoldingDocument3 pagesBottle Blow MoldingDANISHPREET SINGHNo ratings yet

- H or of Eng N Ical Engi R of Engin I I NG ES G: BAC EL I Eering in Mechan Neering Bachelo EER NG Anufacturi D I N Eng NEEDocument4 pagesH or of Eng N Ical Engi R of Engin I I NG ES G: BAC EL I Eering in Mechan Neering Bachelo EER NG Anufacturi D I N Eng NEEAlex LakeNo ratings yet

- "Bottle Blow Molding" by Milind H. Mahajan, Girish M. Lonare IRJET-V6I1217Document2 pages"Bottle Blow Molding" by Milind H. Mahajan, Girish M. Lonare IRJET-V6I1217MilindMahajanNo ratings yet

- Design Technology Paper 1 HLDocument23 pagesDesign Technology Paper 1 HLAallia BindraNo ratings yet

- ME51008Exam2012 13 BlackboardDocument3 pagesME51008Exam2012 13 BlackboardlisandroNo ratings yet

- Some Critical Issues 4 Injection MoldingDocument280 pagesSome Critical Issues 4 Injection MoldingMiralles Martínez JordiNo ratings yet

- ME51008Exam2011 12 BlackboardDocument3 pagesME51008Exam2011 12 BlackboardlisandroNo ratings yet

- Rap ToolDocument15 pagesRap Toolmedane_saad6707No ratings yet

- HT TP: //qpa Pe R.W But .Ac .In: 2012 Material Science and TechnologyDocument7 pagesHT TP: //qpa Pe R.W But .Ac .In: 2012 Material Science and TechnologyPuspendu Roy ChowdhuryNo ratings yet

- Composite Materials - QP UT-1 - M.EDocument1 pageComposite Materials - QP UT-1 - M.EGobivel KathirvelNo ratings yet

- 17 Experimental Determination of Freezethaw Resistance in Selfcompacting Concretes2019IOP Conference Series Materials Science and EngineeringDocument8 pages17 Experimental Determination of Freezethaw Resistance in Selfcompacting Concretes2019IOP Conference Series Materials Science and EngineeringВладиславNo ratings yet

- Technical Test HOP InfrastructuresDocument6 pagesTechnical Test HOP Infrastructuresnour mostafaNo ratings yet

- University Institute of Engineering & Technology Kurukshetra University, KurukshetraDocument3 pagesUniversity Institute of Engineering & Technology Kurukshetra University, KurukshetraagogNo ratings yet

- Pre PHD Question PapersDocument4 pagesPre PHD Question PapersIkoka RiderNo ratings yet

- Gujarat Technological University: InstructionsDocument2 pagesGujarat Technological University: InstructionsPratik DiyoraNo ratings yet

- CPE7012-B Coursework 2 Brief 2020-1Document6 pagesCPE7012-B Coursework 2 Brief 2020-1Prashant PrashantNo ratings yet

- Materials and Design: Babur Ozcelik, Ibrahim SonatDocument9 pagesMaterials and Design: Babur Ozcelik, Ibrahim SonatmubarakNo ratings yet

- Assignment Last SemDocument13 pagesAssignment Last SemLarry JamesNo ratings yet

- Midterm232 English 2 v2Document7 pagesMidterm232 English 2 v2Phúc TôNo ratings yet

- Designand Analysisof Injection Moldingof MineralDocument11 pagesDesignand Analysisof Injection Moldingof MineralSadam AlmaqtariNo ratings yet

- Injection Molding Parameters Calculations by Using Visual Basic (VB) ProgrammingDocument9 pagesInjection Molding Parameters Calculations by Using Visual Basic (VB) Programmingdjsiraj834No ratings yet

- Horizontal Injection MoldingDocument6 pagesHorizontal Injection MoldingFaisal IqbalNo ratings yet

- Sathyabama University: (Established Under Section 3 of UGC Act, 1956)Document2 pagesSathyabama University: (Established Under Section 3 of UGC Act, 1956)Mahendranath RamakrishnanNo ratings yet

- Fiber Reinforced Plastics VesselsDocument5 pagesFiber Reinforced Plastics VesselsandreshuelvaNo ratings yet

- International Refereed Journal of Engineering and Science (IRJES)Document3 pagesInternational Refereed Journal of Engineering and Science (IRJES)www.irjes.comNo ratings yet

- Gufran Project-1Document60 pagesGufran Project-1Gufran AhmadNo ratings yet

- Final Theory Exam-307 Dec11-FinalDocument14 pagesFinal Theory Exam-307 Dec11-FinalJagadeesh EllilNo ratings yet

- MP II - Nov 2011Document2 pagesMP II - Nov 2011abhay_15865099No ratings yet

- Design and Fabrication of Economical Plastic Injection Molding MachineDocument69 pagesDesign and Fabrication of Economical Plastic Injection Molding MachineGAURAV SHARMANo ratings yet

- POLYPROPYLENE I Thesis (Final)Document8 pagesPOLYPROPYLENE I Thesis (Final)falmubaddelNo ratings yet

- Some Effects of Multiple Injection Moulding On SelDocument8 pagesSome Effects of Multiple Injection Moulding On SelEdna Odette Melo UscangaNo ratings yet

- LABORATORY MANUAL DECLARATION FORM EdittedDocument46 pagesLABORATORY MANUAL DECLARATION FORM Edittedalipjack100% (1)

- Project Report Guide LinesDocument13 pagesProject Report Guide LinesNagabhushanaNo ratings yet

- Process Description and Potential MaterialsDocument10 pagesProcess Description and Potential MaterialsSaddy DipoNo ratings yet

- Evaluation of Material Modification Concrete Printing TechnologyDocument7 pagesEvaluation of Material Modification Concrete Printing TechnologyM.C.2024No ratings yet

- Forced 4Document15 pagesForced 4Gaurav KhantwalNo ratings yet

- NTU - Engineers and Society - Instrn & Proj 1 (17 Jan 11)Document5 pagesNTU - Engineers and Society - Instrn & Proj 1 (17 Jan 11)Jane TongNo ratings yet

- ABAF 2015 - Paper-Onderka, Dobrocký - RevisedDocument9 pagesABAF 2015 - Paper-Onderka, Dobrocký - RevisedDavid DobrockyNo ratings yet

- SCH4108201612 Chemical Enginnering Plant DesignDocument4 pagesSCH4108201612 Chemical Enginnering Plant DesignAnavheoba AbrahamNo ratings yet

- Crack Tip Opening Displacement (Ctod) in Single Edge Notched Bend (Sen (B) )Document328 pagesCrack Tip Opening Displacement (Ctod) in Single Edge Notched Bend (Sen (B) )Kingsly PrakashNo ratings yet

- Gujarat Technological University: InstructionsDocument1 pageGujarat Technological University: InstructionsPratik DiyoraNo ratings yet

- Ubmm1011 Fegt AmdDocument14 pagesUbmm1011 Fegt Amd阿雯MaxNo ratings yet

- PHD Thesis On PGPRDocument5 pagesPHD Thesis On PGPRgj84st7d100% (2)

- The Influence of Injection Molding Parameter On Properties of Thermally Conductive PlasticDocument10 pagesThe Influence of Injection Molding Parameter On Properties of Thermally Conductive PlasticRoly RamirezNo ratings yet

- L-4/T-l/MME - Date: 17/02/2018Document12 pagesL-4/T-l/MME - Date: 17/02/2018Utsho DasNo ratings yet

- Design and Automation of Plastic Injection Molding Machine: Under The Valuable Guidance ofDocument49 pagesDesign and Automation of Plastic Injection Molding Machine: Under The Valuable Guidance ofAniket ChavanNo ratings yet

- 136 Ijmperdfeb2018136Document10 pages136 Ijmperdfeb2018136TJPRC PublicationsNo ratings yet

- Assignment 6Document3 pagesAssignment 6Dhrumil VashiNo ratings yet

- Casting Simulation and Optimisation Benefits BottlDocument13 pagesCasting Simulation and Optimisation Benefits BottlA ChakourNo ratings yet

- IOP ConferenceDocument9 pagesIOP ConferenceSayyid AbulkhairNo ratings yet

- MP Previous Qp-Me3393Document21 pagesMP Previous Qp-Me3393azhagan.mecNo ratings yet

- Ed 9271 Rapid Prototyping and ToolingDocument1 pageEd 9271 Rapid Prototyping and ToolingroscillaNo ratings yet

- A Review On Plastic Moulding Manufacturing Process and ParametersDocument9 pagesA Review On Plastic Moulding Manufacturing Process and ParametersIJAERS JOURNALNo ratings yet

- Accepted Manuscript: 10.1016/j.matdes.2017.11.027Document49 pagesAccepted Manuscript: 10.1016/j.matdes.2017.11.027Kenan MuhamedagićNo ratings yet

- Syllabus Be EDDocument24 pagesSyllabus Be EDAnup KumarNo ratings yet

- Tutorial 5 QuestionsDocument1 pageTutorial 5 QuestionsNick ChuoNo ratings yet

- From Additive Manufacturing to 3D/4D Printing 2: Current Techniques, Improvements and their LimitationsFrom EverandFrom Additive Manufacturing to 3D/4D Printing 2: Current Techniques, Improvements and their LimitationsNo ratings yet

Department of Mechanical and Design Engineering

Department of Mechanical and Design Engineering

Uploaded by

dantan187Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Department of Mechanical and Design Engineering

Department of Mechanical and Design Engineering

Uploaded by

dantan187Copyright:

Available Formats

Department of Mechanical and Design Engineering

UNIVERSITY OF PORTSMOUTH

Laboratory Activity (2010)

Unit: Materials and Manufacture 2 (U15585)

Student Number: Student Name:

Submission Date: Mark:

Title: Thermoplastics and Injection Moulding

This laboratory activity consists of six tasks. At the end of these tasks, the student

should be able to appreciate two thermoplastics (HDPE and PS) and their manufacturing

by injection moulding.

Learning Outcomes:

• To understand the basic processes involved in injection moulding.

• To identify the parts and their functions in an injection moulding machine and mould.

• To appreciate the common operations involved in an injection moulding process.

• To explore features and differences between amorphous and semi-crystalline

plastics.

Student Input:

Students are expected to actively participate in the lab activity, to complete six tasks

and to submit a report.

Submission:

The report should be prepared using Microsoft Word and must be submitted to the

Department Office (A1-12) before the deadline given by the lecturer at the lab session.

Assessment:

Assessment on this activity will be based on student’s performance during the

laboratory session and the quality of the report submitted. The marking criteria is listed

as follows:

70-100 Active participation and very good understanding of different aspects of

thermoplastics and injection moulding; High quality lab report in which all

tasks are satisfactorily dealt with.

60-69 Good understanding and good quality lab report in which all tasks are

reasonably dealt with.

50-59 Good efforts in understanding and presentation but has difficulties in some

tasks.

40-49 Attendance at laboratory session but unsatisfactory attempt to follow

laboratory procedure and record relevant results.

1-39 Attendance at laboratory session but poor participation and failing in

submitting an acceptable report.

You can have an electronic copy of this lab sheet at http://www.port.ac.uk/composites/Teaching or go to

L:\Technology\Student\MechEng\ZhangzY\Undergradute

Designed and updated by Dr Z Y Zhang and Mr M Hacon in January 2010. 1

Task 1: [10 Marks]

(a) Two thermoplastics will be injection moulded in this lab activity. They are High

Density Polyethylene (HDPE) and Polystyrene (PS), respectively. Write the

chemical reactions of synthesising HDPE and PS by addition polymerisation;

Addition polymerisation of HDPE

Addition polymerisation of PS

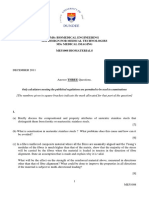

(b) The following thermoplastics are commonly used for injection moulding; Fill in the

table to show what they stand for and their structural features;

Morphology

Abbreviation Full Name

Amorphous Semi-crystalline

LDPE

HDPE

PP

PS Polystyrene

HIPS

ABS

PVC

PC

PA

PET

PBT

PMMA

PTFE

Designed and updated by Dr Z Y Zhang and Mr M Hacon in January 2010. 2

Task 2: [10 Marks]

Below is a drawing of an injection moulding machine. Identify each part (six in total) in

this injection moulding machine and briefly discuss its functions.

i.

ii.

iii.

Designed and updated by Dr Z Y Zhang and Mr M Hacon in January 2010. 3

.

Iv.

v.

vi.

Task 3: [10 Marks]

Below is a drawing of an injection mould.

Designed and updated by Dr Z Y Zhang and Mr M Hacon in January 2010. 4

Label each part (seven in total) and briefly discuss its functions.

i.

ii.

iii.

iv.

v.

vi and vii.

Task 4: [10 Marks]

Temperature is an important controlling parameter to successfully manufacture parts by

injection moulding. Two temperature control schemes are implemented to illustrate the

effect of temperature on moulded parts;

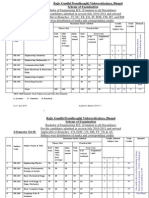

(a) Fill in the table below to illustrate the temperature scheme in setup A and set-up B

and weigh the moulded parts;

Designed and updated by Dr Z Y Zhang and Mr M Hacon in January 2010. 5

Setup Temperature (o C) Weight of injection

Zone 1 Zone 2 Zone 3 Zone 4 moulded parts (g)

Plunger Probe Barrel Screw

Setup A

Setup B

(b) Sketch the injection moulded parts manufactured by two different temperature set-

ups;

Setup A Setup B

(c) Briefly discuss the possible solutions to resolving the incomplete mould filling

problem.

Task 5: [10 Marks]

Dimension accuracy and consistency are important for injection moulded parts. The

mould cavity dimension is shown below. It is expected that the moulded parts should be

Designed and updated by Dr Z Y Zhang and Mr M Hacon in January 2010. 6

different from the cavity when the molten plastics are cooling down and consolidating in

the cavity.

(a) Measure the dimensions of an injection moulded HDPE part and a PS part and

compare them to the dimensions of the mould cavity;

Length L (mm) Width W (mm) Thickness

L1 L2 L3 W1 W2 W3 T (mm)

Cavity 50.20 22.70 15.20 30.20 22.20 16.20 10.05

HDPE

PS

(b) Briefly discuss what would cause the dimensional reduction of the moulded parts

compared to the cavity and why dimensional reductions in HDPE and PS parts are

different.

Designed and updated by Dr Z Y Zhang and Mr M Hacon in January 2010. 7

(c) Briefly discuss possible solutions to dealing with the shrinkage.

Task 6: [50 Marks]

Both HDPE and PS are manufactured by injection moulding in this laboratory activity;

(a) Briefly discuss the differences between HDPE and PS in the context of their

chemical structures, processing features, properties, attributes and applications;

(b) Briefly discuss why HDPE is semi-crystalline and PS is amorphous;

(c) Sketch the microstructures of PS and HDPE at ambient and their manufacturing

temperatures;

(d) Recycling plastics are becoming increasingly important. Briefly discuss

methodologies which can be employed to identify and differentiate HDPE and PS

so they can be separated and sorted for recycling purpose;

(e) The physical and mechanical performance of PS can be modified and enhanced by

co-polymerisation of styrene with other monomers. ABS is a copolymer of three

monomers, namely Acrylonitrile (A), Butadiene (B) and Styrene (S). Briefly discuss

general properties and characteristics of ABS resin and each monomer’s

contributions to these properties and characteristics of ABS resin.

Designed and updated by Dr Z Y Zhang and Mr M Hacon in January 2010. 8

Designed and updated by Dr Z Y Zhang and Mr M Hacon in January 2010. 9

You are welcome to make some recommendations and comments on this lab activity.

Designed and updated by Dr Z Y Zhang and Mr M Hacon in January 2010. 10

You might also like

- Plastic Processing Question Paper 2016Document27 pagesPlastic Processing Question Paper 2016Supreeth Premkumar100% (2)

- De Thi ISE - Work Design - Mar - 2013 - Midterm - Soln - ThaoDocument5 pagesDe Thi ISE - Work Design - Mar - 2013 - Midterm - Soln - ThaoMBSNo ratings yet

- Automatic Perform Shape Optimization For The Stretch Blow Molding ProcessDocument6 pagesAutomatic Perform Shape Optimization For The Stretch Blow Molding Processhed_panNo ratings yet

- Bottle Blow MoldingDocument3 pagesBottle Blow MoldingDANISHPREET SINGHNo ratings yet

- H or of Eng N Ical Engi R of Engin I I NG ES G: BAC EL I Eering in Mechan Neering Bachelo EER NG Anufacturi D I N Eng NEEDocument4 pagesH or of Eng N Ical Engi R of Engin I I NG ES G: BAC EL I Eering in Mechan Neering Bachelo EER NG Anufacturi D I N Eng NEEAlex LakeNo ratings yet

- "Bottle Blow Molding" by Milind H. Mahajan, Girish M. Lonare IRJET-V6I1217Document2 pages"Bottle Blow Molding" by Milind H. Mahajan, Girish M. Lonare IRJET-V6I1217MilindMahajanNo ratings yet

- Design Technology Paper 1 HLDocument23 pagesDesign Technology Paper 1 HLAallia BindraNo ratings yet

- ME51008Exam2012 13 BlackboardDocument3 pagesME51008Exam2012 13 BlackboardlisandroNo ratings yet

- Some Critical Issues 4 Injection MoldingDocument280 pagesSome Critical Issues 4 Injection MoldingMiralles Martínez JordiNo ratings yet

- ME51008Exam2011 12 BlackboardDocument3 pagesME51008Exam2011 12 BlackboardlisandroNo ratings yet

- Rap ToolDocument15 pagesRap Toolmedane_saad6707No ratings yet

- HT TP: //qpa Pe R.W But .Ac .In: 2012 Material Science and TechnologyDocument7 pagesHT TP: //qpa Pe R.W But .Ac .In: 2012 Material Science and TechnologyPuspendu Roy ChowdhuryNo ratings yet

- Composite Materials - QP UT-1 - M.EDocument1 pageComposite Materials - QP UT-1 - M.EGobivel KathirvelNo ratings yet

- 17 Experimental Determination of Freezethaw Resistance in Selfcompacting Concretes2019IOP Conference Series Materials Science and EngineeringDocument8 pages17 Experimental Determination of Freezethaw Resistance in Selfcompacting Concretes2019IOP Conference Series Materials Science and EngineeringВладиславNo ratings yet

- Technical Test HOP InfrastructuresDocument6 pagesTechnical Test HOP Infrastructuresnour mostafaNo ratings yet

- University Institute of Engineering & Technology Kurukshetra University, KurukshetraDocument3 pagesUniversity Institute of Engineering & Technology Kurukshetra University, KurukshetraagogNo ratings yet

- Pre PHD Question PapersDocument4 pagesPre PHD Question PapersIkoka RiderNo ratings yet

- Gujarat Technological University: InstructionsDocument2 pagesGujarat Technological University: InstructionsPratik DiyoraNo ratings yet

- CPE7012-B Coursework 2 Brief 2020-1Document6 pagesCPE7012-B Coursework 2 Brief 2020-1Prashant PrashantNo ratings yet

- Materials and Design: Babur Ozcelik, Ibrahim SonatDocument9 pagesMaterials and Design: Babur Ozcelik, Ibrahim SonatmubarakNo ratings yet

- Assignment Last SemDocument13 pagesAssignment Last SemLarry JamesNo ratings yet

- Midterm232 English 2 v2Document7 pagesMidterm232 English 2 v2Phúc TôNo ratings yet

- Designand Analysisof Injection Moldingof MineralDocument11 pagesDesignand Analysisof Injection Moldingof MineralSadam AlmaqtariNo ratings yet

- Injection Molding Parameters Calculations by Using Visual Basic (VB) ProgrammingDocument9 pagesInjection Molding Parameters Calculations by Using Visual Basic (VB) Programmingdjsiraj834No ratings yet

- Horizontal Injection MoldingDocument6 pagesHorizontal Injection MoldingFaisal IqbalNo ratings yet

- Sathyabama University: (Established Under Section 3 of UGC Act, 1956)Document2 pagesSathyabama University: (Established Under Section 3 of UGC Act, 1956)Mahendranath RamakrishnanNo ratings yet

- Fiber Reinforced Plastics VesselsDocument5 pagesFiber Reinforced Plastics VesselsandreshuelvaNo ratings yet

- International Refereed Journal of Engineering and Science (IRJES)Document3 pagesInternational Refereed Journal of Engineering and Science (IRJES)www.irjes.comNo ratings yet

- Gufran Project-1Document60 pagesGufran Project-1Gufran AhmadNo ratings yet

- Final Theory Exam-307 Dec11-FinalDocument14 pagesFinal Theory Exam-307 Dec11-FinalJagadeesh EllilNo ratings yet

- MP II - Nov 2011Document2 pagesMP II - Nov 2011abhay_15865099No ratings yet

- Design and Fabrication of Economical Plastic Injection Molding MachineDocument69 pagesDesign and Fabrication of Economical Plastic Injection Molding MachineGAURAV SHARMANo ratings yet

- POLYPROPYLENE I Thesis (Final)Document8 pagesPOLYPROPYLENE I Thesis (Final)falmubaddelNo ratings yet

- Some Effects of Multiple Injection Moulding On SelDocument8 pagesSome Effects of Multiple Injection Moulding On SelEdna Odette Melo UscangaNo ratings yet

- LABORATORY MANUAL DECLARATION FORM EdittedDocument46 pagesLABORATORY MANUAL DECLARATION FORM Edittedalipjack100% (1)

- Project Report Guide LinesDocument13 pagesProject Report Guide LinesNagabhushanaNo ratings yet

- Process Description and Potential MaterialsDocument10 pagesProcess Description and Potential MaterialsSaddy DipoNo ratings yet

- Evaluation of Material Modification Concrete Printing TechnologyDocument7 pagesEvaluation of Material Modification Concrete Printing TechnologyM.C.2024No ratings yet

- Forced 4Document15 pagesForced 4Gaurav KhantwalNo ratings yet

- NTU - Engineers and Society - Instrn & Proj 1 (17 Jan 11)Document5 pagesNTU - Engineers and Society - Instrn & Proj 1 (17 Jan 11)Jane TongNo ratings yet

- ABAF 2015 - Paper-Onderka, Dobrocký - RevisedDocument9 pagesABAF 2015 - Paper-Onderka, Dobrocký - RevisedDavid DobrockyNo ratings yet

- SCH4108201612 Chemical Enginnering Plant DesignDocument4 pagesSCH4108201612 Chemical Enginnering Plant DesignAnavheoba AbrahamNo ratings yet

- Crack Tip Opening Displacement (Ctod) in Single Edge Notched Bend (Sen (B) )Document328 pagesCrack Tip Opening Displacement (Ctod) in Single Edge Notched Bend (Sen (B) )Kingsly PrakashNo ratings yet

- Gujarat Technological University: InstructionsDocument1 pageGujarat Technological University: InstructionsPratik DiyoraNo ratings yet

- Ubmm1011 Fegt AmdDocument14 pagesUbmm1011 Fegt Amd阿雯MaxNo ratings yet

- PHD Thesis On PGPRDocument5 pagesPHD Thesis On PGPRgj84st7d100% (2)

- The Influence of Injection Molding Parameter On Properties of Thermally Conductive PlasticDocument10 pagesThe Influence of Injection Molding Parameter On Properties of Thermally Conductive PlasticRoly RamirezNo ratings yet

- L-4/T-l/MME - Date: 17/02/2018Document12 pagesL-4/T-l/MME - Date: 17/02/2018Utsho DasNo ratings yet

- Design and Automation of Plastic Injection Molding Machine: Under The Valuable Guidance ofDocument49 pagesDesign and Automation of Plastic Injection Molding Machine: Under The Valuable Guidance ofAniket ChavanNo ratings yet

- 136 Ijmperdfeb2018136Document10 pages136 Ijmperdfeb2018136TJPRC PublicationsNo ratings yet

- Assignment 6Document3 pagesAssignment 6Dhrumil VashiNo ratings yet

- Casting Simulation and Optimisation Benefits BottlDocument13 pagesCasting Simulation and Optimisation Benefits BottlA ChakourNo ratings yet

- IOP ConferenceDocument9 pagesIOP ConferenceSayyid AbulkhairNo ratings yet

- MP Previous Qp-Me3393Document21 pagesMP Previous Qp-Me3393azhagan.mecNo ratings yet

- Ed 9271 Rapid Prototyping and ToolingDocument1 pageEd 9271 Rapid Prototyping and ToolingroscillaNo ratings yet

- A Review On Plastic Moulding Manufacturing Process and ParametersDocument9 pagesA Review On Plastic Moulding Manufacturing Process and ParametersIJAERS JOURNALNo ratings yet

- Accepted Manuscript: 10.1016/j.matdes.2017.11.027Document49 pagesAccepted Manuscript: 10.1016/j.matdes.2017.11.027Kenan MuhamedagićNo ratings yet

- Syllabus Be EDDocument24 pagesSyllabus Be EDAnup KumarNo ratings yet

- Tutorial 5 QuestionsDocument1 pageTutorial 5 QuestionsNick ChuoNo ratings yet

- From Additive Manufacturing to 3D/4D Printing 2: Current Techniques, Improvements and their LimitationsFrom EverandFrom Additive Manufacturing to 3D/4D Printing 2: Current Techniques, Improvements and their LimitationsNo ratings yet