Professional Documents

Culture Documents

Low-Cost Bidirectional Brushed DC Motor Control

Low-Cost Bidirectional Brushed DC Motor Control

Uploaded by

Devendra DwivdiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Low-Cost Bidirectional Brushed DC Motor Control

Low-Cost Bidirectional Brushed DC Motor Control

Uploaded by

Devendra DwivdiCopyright:

Available Formats

AN893

Low-Cost Bidirectional Brushed DC Motor Control

Using the PIC16F684

Author: Mike Rylee CALCULATING ECCP PWM

Microchip Technology Inc. PARAMETERS

When working with the ECCP in PWM mode, the PWM

INTRODUCTION frequency, duty cycle and resolution, there are three

useful pieces of information to be calculated.

This application note discusses how to use the

Enhanced, Capture, Compare, PWM (ECCP) on the

PIC16F684 for bidirectional, brushed DC (BDC) motor

Frequency

control. Low-cost brushed DC motor control can be Selecting a PWM frequency for the motor control

used in applications such as intelligent toys, small application will effect the sound of the motor and the

appliances and power tools. The PIC16F684 takes power transistor's switching speed. The human ear can

Microchip's Mid-Range Family of products to the next detect frequencies ranging from 20 Hz-20 kHz.

level with its new ECCP peripheral. The ECCP Generally, frequencies greater than 4 kHz are not

peripheral builds on the technology of the CCP module audible to the human ear. Choosing a PWM frequency

with added features such as four PWM channels for greater than 4 kHz helps reduce the humming sound

easy bidirectional motor control through the hardware. heard while the motor is running.

This application note focuses on using the ECCP in

The PWM period and frequency can be calculated

PWM mode using the full-bridge configuration. Using

using Equations 1 and 2 located in Appendix A.

the ECCP allows easy interfacing to a full-bridge

configuration for bidirectional BDC motor control.

Duty Cycle

This application note will discuss the following:

• Calculating ECCP PWM Parameters Changing the PWM duty cycle will change the average

voltage across the motor, which changes the motor's

• Initializing the ECCP in full-bridge PWM mode

speed. The PWM duty cycle is calculated by using

• Bidirectional BDC Motor Control Equation 3. The average voltage across the BDC

• Sensorless Motor Control Feedback motor is calculated by using Equation 4.

• Example Application

Note: All equations referenced in this application Resolution

note can be found in Appendix A. The PWM duty cycle resolution determines the amount

of precision with which the duty cycle can be changed.

For example, a 10-bit resolution allows 1024 possible

values for the duty cycle where an 8-bit resolution only

allows 256 values. The PWM frequency, PIC16F684

oscillator frequency and Timer2 prescaler all effect the

resolution value. The maximum resolution is 10 bits.

The PWM duty cycle resolution is calculated by using

Equation 5.

INITIALIZING THE ECCP IN

FULL-BRIDGE PWM MODE

When initializing the ECCP in full-bridge PWM mode,

four registers need to be initialized.

PR2

The PR2 register effects the PWM frequency/period.

The value to use for the PR2 register is calculated from

Equation 6.

2003 Microchip Technology Inc. DS00893A-page 1

AN893

CCPR1L:CCP1CON<5:4>

The PWM duty cycle has a full resolution of 10 bits.

Since all registers on the PIC16F684 are 8-bits wide,

the 10 bits are spread over two registers. CCPR1L

contains the upper 8 bits and CCP1CON<5:4>

contains the lower 2 bits. The 10-bit value for

CCPR1L:CCP1CON<5:4> is calculated by using

Equation 7.

CCP1CON

In addition to storing the lower 2 bits of the 10-bit PWM

duty cycle, CCP1CON is used to set up the ECCP in

PWM mode using bits CCP1CON<3:0> and can

change the motor direction using bits CCP1CON<7:6>.

When setting up the ECCP in PWM mode, there are

four possible configurations. These configurations

accommodate H-bridges with MOSFETS that are

active high, active low or a combination of both active

high and active low. Motor direction can be changed in

hardware by configuring bits CCP1CON<7:6> to be

‘01’ for forward or ‘11’ for reverse. The PIC16F684

ECCP hardware takes care of switching channels for

activating and modulating the appropriate MOSFET

drivers in the H-bridge.

T2CON

The T2CON register is used for setting up the Timer2

prescaler and turning on Timer2. The Timer2 prescaler

is contained in bits T2CON<1:0> and is used in

determining the PWM frequency, duty cycle and

resolution. Timer2 must be turned on by setting bit

T2CON<2> before the PWM signal will start. For an

algorithm that calculates the Timer2 prescaler and PR2

values given a known PWM frequency (see Figure B-1

in Appendix B).

DS00893A-page 2 2003 Microchip Technology Inc.

AN893

BIDIRECTIONAL BDC MOTOR

CONTROL

The ECCP makes changing motor direction easy by

configuring CCP1CON<7:6> to be ‘01’ for forward

(Figure 1) or ‘11’ for reverse (Figure 2).

FIGURE 1: FULL-BRIDGE FORWARD CURRENT FLOW DIAGRAM

V+

FET QA QC FET

PIC16F684 Driver Driver

Logic ‘1’

P1A

Logic ‘0’ BDC

P1B

FET I FET

Driver Driver

Logic ‘0’

P1C QD

QB

P1D

CCP1CON<3:0> = ‘1100’

CCP1CON<7:6> = ‘01’

FIGURE 2: FULL-BRIDGE REVERSE CURRENT FLOW DIAGRAM

V+

FET QA QC FET

PIC16F684 Driver Driver

Logic ‘0’

P1A

BDC

P1B

FET I FET

Driver Driver

Logic ‘1’

P1C QD

QB

Logic ‘0’

P1D

CCP1CON<3:0> = ‘1100’

CCP1CON<7:6> = ‘11’

2003 Microchip Technology Inc. DS00893A-page 3

AN893

LOW COST SENSORLESS MOTOR Sensorless Current Measurement

CONTROL FEEDBACK Low-cost current measurements can be performed by

using a current sensing resistor between the

Sensorless RPM Measurement MOSFETS and ground (see Figure 4). To select a

value appropriate for the resistance, consider the

Low-cost RPM measurement can be performed with a maximum amount of current allowed to flow through

BDC motor by measuring the back EMF voltage from the resistor and the maximum amount of power

the motor (see Figure 3). The BDC RPM is directly dissipation.

proportional to the back EMF voltage. Since a BDC

motor can be modeled as an inductive load, the voltage In this application, a 0.1 ohm, 1W current sensing

across the motor is equivalent to the inductance multi- resistor was used with a maximum current of 3A. When

plied by dI/dt. In this application, a 12V, 9600 max RPM 3A are flowing through the resistor, the ideal power

BDC motor was used. To measure the back EMF dissipated in the resistor is 0.9W (see Equation 9).

voltage, turn the modulated FET “off.” This will cause Also, when 3A are flowing through the resistor, the

the current to flow in the opposite direction. After voltage across the resistor is 0.3V (see Equation 10). In

initially shutting off the FET, dI/dt must stabilize before order to get the most resolution from the 10-bit A/D

taking the measurement. In order to use the PICmicro® converter, the voltage across the resistor at 3A must be

microcontroller A/D converter, the measured voltage amplified as close as possible to the PIC16F684 VDD,

must be between 0V and VDD. Since the back EMF which is 5V in this application. Using Microchip's

voltage can be between 0V-12V, a voltage divider MSP6S26 PGA, a gain of 16 will ideally give 4.8V, at

circuit is used to scale the back EMF voltage between the maximum 3A specified current (see Equation 11). A

0V and VDD. Using Microchip's MSP6S26 gain of 16 gives a 9.94 bit A/D resolution for measuring

Programmable Gain Amplifier (PGA), a gain of 1 is current (see Equations 12 and 13). The current through

used for buffering the scaled voltage that is being the resistor can then be computed using Equations 14,

measured by the PIC16F684 A/D channel (see 15 and 16.

Equation 8 for calculating RPM). Since a PWM signal is used to drive the BDC motor,

the H-bridge circuit only draws current during the

high pulse-width of the PWM period. To obtain a

current measurement, the voltage across the current

sensing resistor is sampled over a PWM period. A

sampling and averaging algorithm of taking

measurements over multiple PWM periods is shown

in Figure B-2 in Appendix B.

FIGURE 3: FULL-BRIDGE FORWARD CONFIGURATION WITH BACK EMF MEASUREMENT

V+

FET QA QC FET

PIC16F684 Driver Driver

Logic ‘1’

P1A

Logic ‘0’ VBACKEMF BDC

P1B

FET FET

Driver Driver

Logic ‘0’

P1C QD

QB

Logic ‘0’

P1D

CCP1CON<3:0> = ‘1100’

CCP1CON<7:6> = ‘01’

V = V+ - V

DS00893A-page 4 2003 Microchip Technology Inc.

AN893

FIGURE 4: FULL-BRIDGE FORWARD WITH CURRENT-SENSING RESISTOR

V+

FET QA QC FET

PIC16F684 Driver Driver

Logic ‘1’

P1A

Logic ‘0’ BDC

P1B

FET FET

Driver Driver

Logic ‘0’

P1C QD

QB

VACTUAL

0.1Ω current sensing

resistor

P1D

CCP1CON<3:0> = ‘1100’

CCP1CON<7:6> = ‘01’

EXAMPLE APPLICATION and duty cycle, change the PIC16F684 internal

oscillator frequency in real-time, and view RPM and

This example application demonstrates a low-cost current measurements. This application source code

BDC Motor Control system using the ECCP configured was written using the HI-TECH C Compiler, MPLAB®

in full-bridge PWM mode (see Figure 5). The user IDE, and the Microsoft Visual C++® 6.0 development

interface allows the user to easily configure a BDC platform.

motor with the PIC16F684, adjust the PWM frequency

FIGURE 5: MECHATRONICS BLOCK DIAGRAM

Windows GUI

PIC16F684

Sensorless

BDC RPM and

Motor Current

Measurements

Physical Process

2003 Microchip Technology Inc. DS00893A-page 5

AN893

Firmware Software

The example firmware is responsible for many The Windows® user interface provides the user a

operations. friendly environment for interfacing the BDC motor. The

• Initializing the PIC16F684 user interface allows the user to adjust the PWM

frequency, duty cycle, motor direction and internal

• Sending bit-banged SPI™ commands to the PGA

oscillator frequency. The user interface also displays

• Receiving commands from the PC the PWM frequency, duty cycle, resolution, RPM and

• Modifying the PWM frequency and duty cycle current. The PC software is the host and sends

• Changing the motors direction commands to the PIC16F684 using RS-232. The

• Changing the internal oscillator frequency Windows user interface source code can also be down-

loaded from www.microchip.com. The Windows user

• Taking A/D converter measurements for RPM and

interface example is shown in Figure 6.

current

The PIC16F684 firmware implements a bit-banged

RS-232 USART running at 9600 bps. See Appendix C

for the RS-232 serial protocol used in this application

note. The C source code can be downloaded from

www.microchip.com. See Figure B-3 in Appendix B for

the main program flow.

FIGURE 6: WINDOWS USER INTERFACE SCREEN

Hardware The measurement section consists of Microchip's

MSC6S26 multi-channel PGA and a voltage divider

The hardware used in this application note contains circuit for scaling the back EMF voltage, as discussed

three major sections; a power stage for motor control, in the ”Sensorless RPM Measurement” section.

communication for RS-232, and measurement for RPM

and current. The PIC16F684 communicates to the PGA via a 3-wire

bit-banged SPI interface. The CS pin is connected to

The power stage consists of a full H-bridge used for RA1. The SCK pin is connected to RA2. The SI pin is

bidirectional BDC motor control. The PIC16F684 uses connected to RC0. The VREF pin is connected to GND.

RC2-RC5 as the four ECCP pins that interface with the The RA0 pin is used as an analog input for measuring

full H-bridge circuit. RPM and current. The RA0 pin is connected to the

The communication section consists of a RS-232 serial VOUT pin on the PGA. Channel 0 on the PGA is used

communication configuration. The PIC16F684 uses for RPM measurements. Channel 1 on the PGA is used

RA5 for sending and receiving RS-232 data. for current measurements. See Figure D-1 in Appendix

D for the schematic diagram of the hardware.

DS00893A-page 6 2003 Microchip Technology Inc.

AN893

CONCLUSION

The PIC16F684 is well suited for low-cost bidirectional

BDC motor control. This application note demonstrates

how easy it is to calculate the necessary parameters for

using the ECCP in PWM mode, initialize the necessary

ECCP registers, use the ECCP for bidirectional BDC

motor control, and implement sensorless RPM and

current measurements. This application note

concludes by showing a full application implementation

using the PC Windows software, PIC16F684 firmware

and Motor Control hardware.

REFERENCES

[1] DS41202A, 14-Pin Flash-Based, 8-Bit CMOS

data sheet (PIC16F684) - www.microchip.com.

[2] DS21117A, Single-Ended, Rail-to-Rail I/O, Low

Gain PGA, MCP6S21/2/6/8 data sheet -

www.microchip.com

[3] HI-TECH C - www.htsoft.com

[4] MPLAB® IDE - www.microchip.com

2003 Microchip Technology Inc. DS00893A-page 7

AN893

APPENDIX A: EQUATIONS

EQUATION 1: PWM FREQUENCY (HZ)

1

Frequency = ------------------

Period

EQUATION 2: PWM PERIOD (SECONDS)

Period = [ ( PR2 + 1 ) ] × 4 × T OSC × TMR2Prescaler

EQUATION 3: DUTY CYCLE (SECONDS)

DC = CCPR1L:CCP1CON<5:4> × T OSC × TMR2Prescaler

EQUATION 4: VOLTAGE ACROSS BDC MOTOR (VOLTS)

V BDC = V DD × ------------------

DC

Period

EQUATION 5: RESOLUTION (BITS)

log ------------------------------------------------------------------------

F OSC

( FPWM × TMR2Prescaler )

Resolution = --------------------------------------------------------------------------------------

log ( 2 )

EQUATION 6: PR2

PR2 = ----------------------------------------------------------------------- – 1

Period

4 × T OSC × TMR2Prescaler

DS00893A-page 8 2003 Microchip Technology Inc.

AN893

EQUATION 7: CCPR1L:CCP1CON<5:4>

DC

CCPR1L:CCP1CON<5:4> = -------------------------------------------------------------

-

T OSC × TMR2Prescaler

EQUATION 8: RPM

RPM = 1 – ------------------------------------------------ × RPM MAX

ADRESH:ADRESL

1024

EQUATION 9: POWER (W)

2 2

P = I MAX × R = 3 × 0.1 = 0.9 W

EQUATION 10: MAXIMUM VOLTAGE ACROSS RESISTOR (VOLTS)

V NOMINALMAX = I MAX × R = 3 × 0.1 = 0.3V

EQUATION 11: MAXIMUM VOLTAGE AFTER AMPLIFICATION (VOLTS)

V GAINMAX = V NOMINALMAX × Gain = 0.3 × 16 = 4.8V

EQUATION 12: BITS OF RESOLUTION

V GAINMAX

2 = --------------------------- × 1024 , where X is bits of resolution

X

V DD

EQUATION 13: BITS OF RESOLUTION SOLVED FOR X

V GAINMAX

- × 1024

-------------------------- log ------- × 1024

4.8

V DD 5.0

X = log --------------------------------------------------- = --------------------------------------- = 9.94 bits

log ( 2 ) log ( 2 )

2003 Microchip Technology Inc. DS00893A-page 9

AN893

EQUATION 14: GAIN VOLTAGE MEASURED (VOLTS)

V GAIN = -----------------------------------------------

ADRESH:ADRESL-

X

× V GAINMAX

2

EQUATION 15: ACTUAL VOLTAGE ACROSS RESISTOR (VOLTS)

V GAIN

V ACTUAL = ----------------

Gain

EQUATION 16: CURRENT THROUGH RESISTOR (VOLTS)

V ACTUAL

I = -----------------------

R

DS00893A-page 10 2003 Microchip Technology Inc.

AN893

APPENDIX B: FLOW CHARTS

FIGURE B-1: CALCULATING TIMER2 PRESCALER AND PR2 ALGORITHM GIVEN A PWM

FREQUENCY

Start

i=0

PR2 = 1000

Prescaler = 1

No

Is PR2 > 255? Done

Yes

No

Is Prescaler > 16? Prescaler = 2i

Yes

Yes Calculate PR2

Is Prescaler ≤ 16?

Equation 6

No

i=i+2

PR2 = unsigned int.

Prescaler = unsigned char.

i = unsigned char.

2003 Microchip Technology Inc. DS00893A-page 11

AN893

FIGURE B-2: PWM SAMPLING AND FIGURE B-3: MAIN ROUTINE

AVERAGING ALGORITHM

Start

Start

Initialize

PIC16F684

Measure PWM

Period

Is command No

received?

All samples Yes Average

taken? samples

Yes

No

Is command No

Done

Synchronize on valid?

PWM high edge

Yes

Process

Delay command

Start A/D Send response

Conversion

Is A/D

Conversion No

complete?

Yes

Log sample

Increment Delay

DS00893A-page 12 2003 Microchip Technology Inc.

AN893

APPENDIX C: RS-232 SERIAL C.2 Example Application Command

COMMUNICATIONS Set

PROTOCOL PR2 Command: Loads data into the PR2 register.

Since one-wire communication is being implemented, PC Command: (aAF)

the command sent from the PC to the PIC16F684 will PIC16F684 Response: [A]

be echoed back. An example of this can be seen on the

firmware version box in the Windows GUI. The CCPR1L Command: Loads data into the CCPR1L

firmware version box contains (f)[F1.0]. The PC register.

command sent is (f). The PIC16F684 firmware PC Command: (b1F)

response is [F1.0]. The general form of the command

and response are described below as well as the PIC16F684 Response: [B]

commands implemented in the example application.

CCP1CON<5:4> Command: Loads data into

CCP1CON<5:4>.

C.1 General Form

PC Command: (c3)

PC Command: PIC16F684 Response: [C]

<command start><command><data> <command end>

Timer2 Prescaler Command: Loads data into

Ex: (f).

T2CON<1:0>.

PIC16F684 Response: PC Command: (d0)

<response start><response><data><response end> PIC16F684 Response: [D]

Ex: [F1.0] Fosc Command: Loads data into OSCCON<6:4>.

PC Command: (e6)

Note 1: The <command> is lower case. PIC16F684 Response: [E]

2: The <response> is the upper case of the

FW Command: Requests the PIC16F684 firmware

<command>.

version.

3: If there is no <data> to be sent, the

PC Command: (f)

<command end> can be the next

character sent. PIC16F684 Response: [F1.0]

4: All <data> is sent in Hex format. Motor Control Command: Loads data into

5: All <data> is sent Most Significant Byte CCP1CON<7:6>.

first. PC Command: (g3)

6: Invalid commands are ignored and PIC16F684 Response: [G]

responded with a [?].

7: Invalid <command start> is ignored RPM Measurement Command: Requests a RPM

and not responded to. measurement.

8: Commands and responses are currently PC Command: (h)

set to 10 characters each, this can be PIC16F684 Response: [H3FF]

adjusted in the source code on both the

Windows software and PIC16F684 Current Measurement Command: Requests a

firmware. Current measurement.

PC Command: (i)

PIC16F684 Response: [I2BC]

2003 Microchip Technology Inc. DS00893A-page 13

AN893

APPENDIX D: APPENDIX D - SCHEMATICS

FIGURE D-1: HARDWARE SCHEMATIC

PIC16F684

DS00893A-page 14 2003 Microchip Technology Inc.

AN893

FIGURE D-2: BDC MOTOR CONTROL SCHEMATIC

2003 Microchip Technology Inc. DS00893A-page 15

AN893

NOTES:

DS00893A-page 16 2003 Microchip Technology Inc.

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip's Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device Trademarks

applications and the like is intended through suggestion only

The Microchip name and logo, the Microchip logo, Accuron,

and may be superseded by updates. It is your responsibility to

dsPIC, KEELOQ, MPLAB, PIC, PICmicro, PICSTART,

ensure that your application meets with your specifications.

PRO MATE and PowerSmart are registered trademarks of

No representation or warranty is given and no liability is

Microchip Technology Incorporated in the U.S.A. and other

assumed by Microchip Technology Incorporated with respect

countries.

to the accuracy or use of such information, or infringement of

patents or other intellectual property rights arising from such AmpLab, FilterLab, microID, MXDEV, MXLAB, PICMASTER,

use or otherwise. Use of Microchip’s products as critical com- SEEVAL, SmartShunt and The Embedded Control Solutions

ponents in life support systems is not authorized except with Company are registered trademarks of Microchip Technology

express written approval by Microchip. No licenses are con- Incorporated in the U.S.A.

veyed, implicitly or otherwise, under any intellectual property Application Maestro, dsPICDEM, dsPICDEM.net,

rights. dsPICworks, ECAN, ECONOMONITOR, FanSense,

FlexROM, fuzzyLAB, In-Circuit Serial Programming, ICSP,

ICEPIC, microPort, Migratable Memory, MPASM, MPLIB,

MPLINK, MPSIM, PICkit, PICDEM, PICDEM.net, PICtail,

PowerCal, PowerInfo, PowerMate, PowerTool, rfLAB, rfPIC,

Select Mode, SmartSensor, SmartTel and Total Endurance

are trademarks of Microchip Technology Incorporated in the

U.S.A. and other countries.

Serialized Quick Turn Programming (SQTP) is a service mark

of Microchip Technology Incorporated in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2003, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received ISO/TS-16949:2002 quality system certification for

its worldwide headquarters, design and wafer fabrication facilities in

Chandler and Tempe, Arizona and Mountain View, California in October

2003 . The Company’s quality system processes and procedures are

for its PICmicro® 8-bit MCUs, KEELOQ® code hopping devices, Serial

EEPROMs, microperipherals, non-volatile memory and analog

products. In addition, Microchip’s quality system for the design and

manufacture of development systems is ISO 9001:2000 certified.

2003 Microchip Technology Inc. DS00893A-page 17

WORLDWIDE SALES AND SERVICE

AMERICAS ASIA/PACIFIC Korea

168-1, Youngbo Bldg. 3 Floor

Corporate Office Australia

Samsung-Dong, Kangnam-Ku

2355 West Chandler Blvd. Suite 22, 41 Rawson Street

Seoul, Korea 135-882

Chandler, AZ 85224-6199 Epping 2121, NSW

Tel: 82-2-554-7200 Fax: 82-2-558-5932 or

Tel: 480-792-7200 Australia

82-2-558-5934

Fax: 480-792-7277 Tel: 61-2-9868-6733

Technical Support: 480-792-7627 Fax: 61-2-9868-6755 Singapore

Web Address: http://www.microchip.com 200 Middle Road

China - Beijing

#07-02 Prime Centre

Atlanta Unit 706B

Singapore, 188980

3780 Mansell Road, Suite 130 Wan Tai Bei Hai Bldg.

Tel: 65-6334-8870 Fax: 65-6334-8850

Alpharetta, GA 30022 No. 6 Chaoyangmen Bei Str.

Beijing, 100027, China Taiwan

Tel: 770-640-0034

Tel: 86-10-85282100 Kaohsiung Branch

Fax: 770-640-0307

Fax: 86-10-85282104 30F - 1 No. 8

Boston Min Chuan 2nd Road

China - Chengdu

2 Lan Drive, Suite 120 Kaohsiung 806, Taiwan

Westford, MA 01886 Rm. 2401-2402, 24th Floor, Tel: 886-7-536-4818

Tel: 978-692-3848 Ming Xing Financial Tower Fax: 886-7-536-4803

Fax: 978-692-3821 No. 88 TIDU Street

Chengdu 610016, China Taiwan

Chicago Tel: 86-28-86766200 Taiwan Branch

333 Pierce Road, Suite 180 Fax: 86-28-86766599 11F-3, No. 207

Itasca, IL 60143 Tung Hua North Road

China - Fuzhou Taipei, 105, Taiwan

Tel: 630-285-0071

Unit 28F, World Trade Plaza Tel: 886-2-2717-7175 Fax: 886-2-2545-0139

Fax: 630-285-0075

No. 71 Wusi Road

Dallas Fuzhou 350001, China EUROPE

4570 Westgrove Drive, Suite 160 Tel: 86-591-7503506

Austria

Addison, TX 75001 Fax: 86-591-7503521

Tel: 972-818-7423 Durisolstrasse 2

China - Hong Kong SAR A-4600 Wels

Fax: 972-818-2924 Unit 901-6, Tower 2, Metroplaza Austria

Detroit 223 Hing Fong Road Tel: 43-7242-2244-399

Tri-Atria Office Building Kwai Fong, N.T., Hong Kong Fax: 43-7242-2244-393

32255 Northwestern Highway, Suite 190 Tel: 852-2401-1200 Denmark

Farmington Hills, MI 48334 Fax: 852-2401-3431 Regus Business Centre

Tel: 248-538-2250 China - Shanghai Lautrup hoj 1-3

Fax: 248-538-2260 Room 701, Bldg. B Ballerup DK-2750 Denmark

Kokomo Far East International Plaza Tel: 45-4420-9895 Fax: 45-4420-9910

2767 S. Albright Road No. 317 Xian Xia Road France

Kokomo, IN 46902 Shanghai, 200051 Parc d’Activite du Moulin de Massy

Tel: 765-864-8360 Tel: 86-21-6275-5700 43 Rue du Saule Trapu

Fax: 765-864-8387 Fax: 86-21-6275-5060 Batiment A - ler Etage

China - Shenzhen 91300 Massy, France

Los Angeles

Rm. 1812, 18/F, Building A, United Plaza Tel: 33-1-69-53-63-20

18201 Von Karman, Suite 1090 No. 5022 Binhe Road, Futian District Fax: 33-1-69-30-90-79

Irvine, CA 92612 Shenzhen 518033, China

Tel: 949-263-1888 Germany

Tel: 86-755-82901380 Steinheilstrasse 10

Fax: 949-263-1338 Fax: 86-755-8295-1393 D-85737 Ismaning, Germany

Phoenix China - Shunde Tel: 49-89-627-144-0

2355 West Chandler Blvd. Room 401, Hongjian Building Fax: 49-89-627-144-44

Chandler, AZ 85224-6199 No. 2 Fengxiangnan Road, Ronggui Town Italy

Tel: 480-792-7966 Shunde City, Guangdong 528303, China Via Quasimodo, 12

Fax: 480-792-4338 Tel: 86-765-8395507 Fax: 86-765-8395571 20025 Legnano (MI)

San Jose China - Qingdao Milan, Italy

1300 Terra Bella Avenue Rm. B505A, Fullhope Plaza, Tel: 39-0331-742611

Mountain View, CA 94043 No. 12 Hong Kong Central Rd. Fax: 39-0331-466781

Tel: 650-215-1444 Qingdao 266071, China Netherlands

Tel: 86-532-5027355 Fax: 86-532-5027205 P. A. De Biesbosch 14

Toronto

India NL-5152 SC Drunen, Netherlands

6285 Northam Drive, Suite 108

Divyasree Chambers Tel: 31-416-690399

Mississauga, Ontario L4V 1X5, Canada

1 Floor, Wing A (A3/A4) Fax: 31-416-690340

Tel: 905-673-0699

Fax: 905-673-6509 No. 11, O’Shaugnessey Road United Kingdom

Bangalore, 560 025, India 505 Eskdale Road

Tel: 91-80-2290061 Fax: 91-80-2290062 Winnersh Triangle

Japan Wokingham

Benex S-1 6F Berkshire, England RG41 5TU

3-18-20, Shinyokohama Tel: 44-118-921-5869

Kohoku-Ku, Yokohama-shi Fax: 44-118-921-5820

Kanagawa, 222-0033, Japan

Tel: 81-45-471- 6166 Fax: 81-45-471-6122 11/24/03

DS00893A-page 18 2003 Microchip Technology Inc.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- HYVA-Crane-2013 High Res AttachmentDocument53 pagesHYVA-Crane-2013 High Res AttachmentBalaji RathinavelNo ratings yet

- How To - Open A Specific Port in CyberoamDocument3 pagesHow To - Open A Specific Port in CyberoamdenisNo ratings yet

- Power Project BoardDocument1 pagePower Project BoardHitesh MehtaNo ratings yet

- Instrument Mechanic 146180122Document50 pagesInstrument Mechanic 146180122Hitesh MehtaNo ratings yet

- Three Phase Measurement SystemDocument2 pagesThree Phase Measurement SystemHitesh MehtaNo ratings yet

- AlstomDocument34 pagesAlstomHitesh MehtaNo ratings yet

- Kulliyyah of EngineeringDocument11 pagesKulliyyah of EngineeringHitesh MehtaNo ratings yet

- Vickers Servo ValveDocument28 pagesVickers Servo ValveHitesh MehtaNo ratings yet

- Control Valave TrainerDocument5 pagesControl Valave TrainerHitesh MehtaNo ratings yet

- Class e Resonant InverterDocument6 pagesClass e Resonant InverterHitesh MehtaNo ratings yet

- AD9852 DDS ModuleDocument10 pagesAD9852 DDS ModuleHitesh MehtaNo ratings yet

- Hall BookDocument126 pagesHall BookbanguyenbkNo ratings yet

- A Technical Guide To Smps AdaptersDocument28 pagesA Technical Guide To Smps AdaptersHitesh MehtaNo ratings yet

- JT 121 PP PDFDocument2 pagesJT 121 PP PDFRāĦul LuĦārNo ratings yet

- Friction and Lubrication in Medieval Europe The Emergence of Olive Oil As A Superior AgentDocument23 pagesFriction and Lubrication in Medieval Europe The Emergence of Olive Oil As A Superior AgentstankevichijusNo ratings yet

- شرح المحول الكهربيDocument88 pagesشرح المحول الكهربيAffify Afify100% (1)

- Math 3 Quarter 4 Preliminary Pages PDFDocument6 pagesMath 3 Quarter 4 Preliminary Pages PDFMhar Colipat ChavNo ratings yet

- SGS Conformity Enquiry Form (Application Form)Document3 pagesSGS Conformity Enquiry Form (Application Form)Hakeym LarhNo ratings yet

- Master RFI Register - NeoDocument41 pagesMaster RFI Register - NeoRajeev KumarNo ratings yet

- 694Document13 pages694Naresh MudaniNo ratings yet

- Motorola Accessoires PDFDocument4 pagesMotorola Accessoires PDFPopovici AdrianNo ratings yet

- Marketing NotesDocument5 pagesMarketing NotesfaisalNo ratings yet

- Department of Education: CI Team Accomplishment ReportDocument2 pagesDepartment of Education: CI Team Accomplishment ReportRhea Diaz-BadonNo ratings yet

- Lincoln - General Lubrication ProductsDocument103 pagesLincoln - General Lubrication ProductsRebecca Hartman100% (1)

- AA - IPB - Spare PartsDocument28 pagesAA - IPB - Spare PartsKaha ChogovadzeNo ratings yet

- Topic 5c - Cable Ampacity & SizingDocument19 pagesTopic 5c - Cable Ampacity & SizingAlla Naveen KumarNo ratings yet

- Antenna ServoDocument3 pagesAntenna ServoamarnathavulaNo ratings yet

- Ds181 Artix 7 Data SheetDocument63 pagesDs181 Artix 7 Data Sheetabhi_jNo ratings yet

- Fault Analysis of Three Phase Alternator Sequence Impedance: Apparatus RequiredDocument9 pagesFault Analysis of Three Phase Alternator Sequence Impedance: Apparatus RequiredMohan KrishnaNo ratings yet

- 6 DMDocument3 pages6 DMOlivier ORMANNo ratings yet

- Inventory Management Technique in ConstructionDocument6 pagesInventory Management Technique in ConstructionMohamed Wayrah0% (1)

- BS 1600 (1991)Document13 pagesBS 1600 (1991)victor_altamirano_28No ratings yet

- Digital Control of Dynamic Systems (1998)Document8 pagesDigital Control of Dynamic Systems (1998)NgọcBảoNo ratings yet

- Pionjar 120 Manual de OperacionDocument76 pagesPionjar 120 Manual de OperacionMi MoniNo ratings yet

- Introduction To EME - AB INITIODocument32 pagesIntroduction To EME - AB INITIONamrata Mukherjee0% (1)

- Isolated Footing Design PDFDocument45 pagesIsolated Footing Design PDFChau Suktana Enling0% (1)

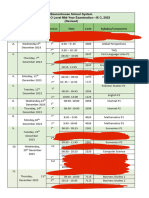

- Grade IX Mid Term Examination Datesheet 2023 RevisedDocument2 pagesGrade IX Mid Term Examination Datesheet 2023 Revisedraamir2010No ratings yet

- The Milan News-Leader Front PageDocument1 pageThe Milan News-Leader Front PageMichelle RogersNo ratings yet

- CAIRO Probs and SolutionsDocument2 pagesCAIRO Probs and Solutions3alliumcourt100% (1)

- Modo de Uso Centrifuga UniversalDocument2 pagesModo de Uso Centrifuga UniversalJocelyn GallardoNo ratings yet

- ApspscDocument1 pageApspscMadhu MadhavaNo ratings yet